A Guide to Accumulation Tables and Low-Pressure Conveyors

Discussing the Importance of Efficient Material Handling

Accumulation tables and low-pressure conveyors are both complementary pieces of equipment to production lines that play a role in optimizing material handling and maintaining a seamless production flow. In this overview, we’ll discuss what each piece of equipment does, its benefits, the industries they are used in, and more.

We will go over the following in this guide.

- What Is a Rotary Accumulation Table?

- What Is a Low-Pressure Accumulation Conveyor?

- Where to Find in a Production Line?

- Additional Equipment

- Popular Manufacturers

- Industries Used In

- Questions to Consider Before Buying or Selling

What Is a Rotary Accumulation Table?

Accumulation tables are designed to temporarily hold and accumulate products or items in a controlled manner. They are often used in situations where there is a mismatch in the pace of production and downstream processes. Accumulation tables allow products to accumulate without causing jams or disruptions in the production flow. They ensure a smooth transition between different stages of the production line, preventing bottlenecks and minimizing the risk of damage to products.

During operation, the accumulation table gathers products before releasing them onto another conveyor. Sometimes, instead of releasing the product, the rotary accumulation machine fills up with product at the end of a line.

What Is a Low-Pressure Accumulation Conveyor?

[Source: Kaman Distribution]

These units are also referred to as minimum-pressure conveyors. These conveyors are most often used to move and accumulate boxes or cartons so they are efficiently queued and ready to be fed into a sorting, wrapping, strapping, or other process.

This type of accumulator allows products to lightly touch as they are being conveyed. The conveyor stops the package but the contact pressure is kept to a minimum to eliminate package damage.

These units are not to be confused with a zero-pressure accumulation conveyor. Zero-pressure conveyors are designed for products not to touch.

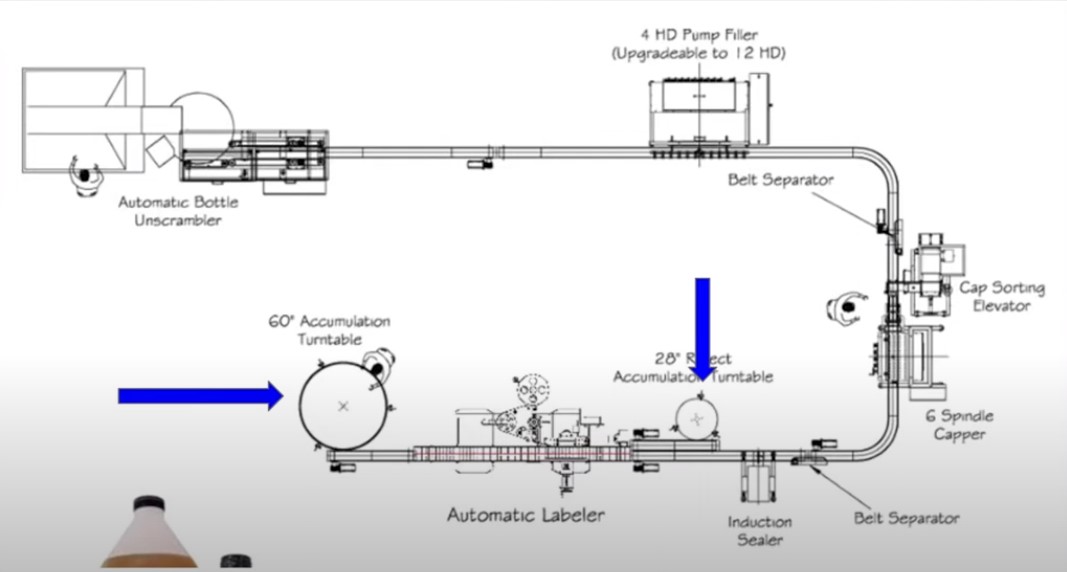

Where to Find an Accumulation Table in a Production Line?

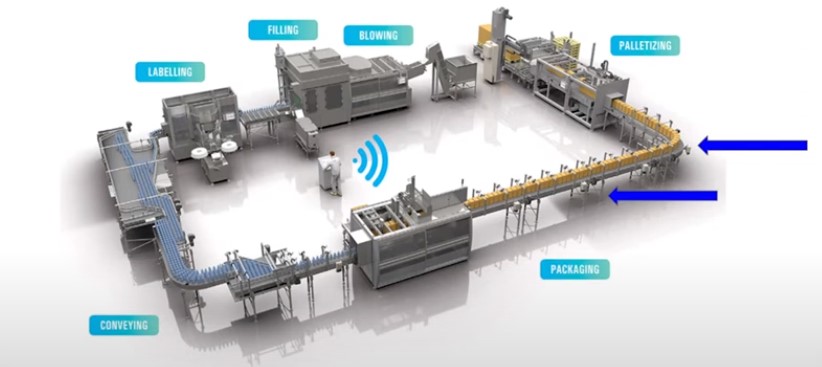

Where to Find a Low-Pressure Accumulation Conveyor in a Production Line?

Additional Equipment

If you are considering purchasing an accumulation table and low-pressure conveyor, you may also require certain upstream and downstream equipment to ensure a smooth production line. It's worth noting that the list provided below is not comprehensive and there may be additional equipment that could enhance your operation.

Upstream Equipment for Accumulation Tables

Some potential upstream equipment that can come before an accumulation table can include the following.

- Fillers

- Cappers

- Labelers

Downstream Equipment for Accumulation Tables

Some potential downstream equipment that comes after an accumulation table or low-pressure conveyor can include the following.

- Filler

- Capper

- Labeler

- Conveyor

Upstream Equipment for Low-Pressure Conveyors

Some potential upstream equipment that can come before a low-pressure conveyor can include the following.

- Case Sealers

- Glue

- Tape

- Bundlers

Downstream Equipment for Low-Pressure Conveyors

Some potential downstream equipment that can come after a low-pressure conveyor can include the following.

Popular Manufacturers

Below are some of our favorite manufacturers for accumulation tables and low-pressure conveyors.

- Hytrol

- Krones

- AMS

- Accutek

Industries Used In

- Food and Beverage

- Pharmaceutical

- Household Goods

- Can be found in nearly every industry

Questions to Consider Before Buying or Selling

Buying

- Dimensions of the accumulation area?

- What product was last ran?

- Is the unit complete?

- When was it last in use?

- How many feeds do you have?

Selling

- What product are you running?

- What are your product dimensions?

- What’s your product’s weight?

Summary

Accumulation tables and low-pressure conveyors are vital components in material handling within production lines. They both use different systems to temporarily store and manage products, preventing congestion and ensuring smooth transitions between different stages of products. Accumulation tables and low-pressure conveyors share the goal of enhancing efficiency, minimizing disruptions, and preserving product quality throughout the manufacturing process.

If you’re interested in one of these units, contact our sales team to find the one that’s best suited for you and your product.