A Guide to Volumetric Fillers

Filling Containers with a Consistent Amount of Product

Volumetric Fillers are useful machines that fill several different containers, such as bottles, pouches, or boxes, with a preset amount of product. This piece of equipment is found in several different industries but is commonly used in the food industry. When you purchase this machine, you’ll be able to fill your packages up with the right amount of product each and every time, making it an efficient asset to your production line.

We’ll cover the following in this document:

- The Function of a Volumetric Filler

- Volumetric Filler vs. Auger Filler

- Placement in a production line

- Popular Manufacturers

- Common industries

The Function of a Volumetric Filler

The Volumetric Filler works to dispense a variety of products from cereal to sugar into a package. The operation of a Volumetric Filler begins when a product is dumped into its cylinder at the top of the machine. From there, the cylinder rotates until a preset amount of product is gathered before being dropped into a container. To make sure the right amount of product gets dispensed, this filler has a scraping mechanism that removes the excess product. The product will then be dropped into a container below. Once inside a container, the product would go to the next phase in the production line where it would likely go through a case sealer, pouch sealer, capper, or induction sealer.

Source: All-Fill Inc.

Volumetric Filler vs. Auger Filler

Volumetric and Auger fillers work with similar products and do similar jobs.

When using a Volumetric Filler, you’re going to be running more inexpensive items that are non-dusty and free-flowing, like salt.

These fillers are great if your priority is fill rate since they are able to move products faster than an Auger Filler.

On the other hand, Auger Fillers can work with a range of products that are non-free flowing and dusty such as flour and powdered milk. However, with the correct configurations, these machines are also capable of handling free-flowing products.

If you need to set up your filler to run specific products, we offer integration and shop services to configure your machine so it can be added to your production line seamlessly.

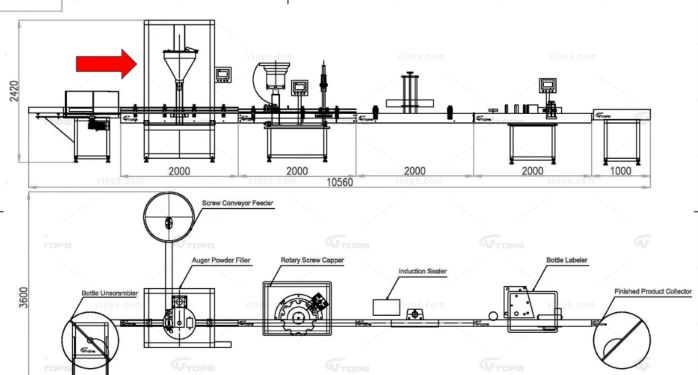

Volumetric Filler placement on the production line

Upstream Equipment

Downstream Equipment

- Labeler

Source: Zhengzhou Vtops Machinery Co Ltd

Popular Manufacturers

- Spee Dee Packaging Machinery Inc.

- All-Fill Advancing Packaging

- Simplex

Industries used in

- Food

- Pharmaceuticals

- Chemical

- Cosmetics

Summary

If you are looking to consistently and efficiently pack the right amount of product into your containers, you need to consider adding a Volumetric Filler to your production line. Useful in several industries, you can easily preset the cylinder to get the exact amount of product dispensed into your container or package. With this piece of equipment, you’ll know the precise amount of product went into each and every receptacle that passes through.

Click here to view our section of Volumetric Fillers.

If you're interested in our fillers, please contact our sales team by clicking the button below.