A Comprehensive Guide to Stainless Steel Kettles

Choosing the Right Unit for Your Operation

Stainless steel kettles come in many different shapes and sizes, making them capable of working in multiple industries that call for heating or cooking liquid products. They are often found in facilities that are producing products like soup, sauces, candy, and even jellies and soaps. By adding a kettle to your operations, you will provide efficient and effective heat transfer to your product, giving it a consistent temperature.

In this document, we’ll go over the following to help you determine the right kettle for your production line.

- What is a Stainless Steel Kettle?

- Pressure and vacuum kettles

- Agitation in kettles

- Common discharges

- Jacket sizes and ratings

- Kettle positioning on a production line

- Popular manufacturers

- Industries that use kettles

What is a Stainless Steel Kettle?

Kettles are popular processing machines that are utilized for cooking or heating liquid products. They come in a variety of sizes with capacities ranging from five to 1,000 gallons, with some able to hold much more. Kettles are designed with jackets that go around either a part of the machine or the entire unit in order to heat the product inside. Either steam, electricity or gas circulates through the jacket in order to heat the kettle. Electric and gas tend to be used in smaller-sized kettles while steam can be used on any sized kettle.

Some models come equipped with agitation mechanisms. These systems can mix a bulk of product inside the kettle to produce a uniform blend and give it a consistent temperature. They also keep the product from sticking against the kettle wall.

Kettles can come with different lid styles. Common options include two-piece, three-piece, hinged, or lift-off lids.

Pressure and vacuum kettles

Pressure and vacuum kettles act like pressure cookers you may find in your kitchen, only on a much larger scale. They are designed to speed up the cooking process while also preventing discoloration and flavor loss. They are mainly used for jams, jellies and other preserves. These kettles are also heated through jackets using electricity, steam or gas. Depending on your needs, these models can come equipped with agitation. We typically keep several 10 to 400-gallon pressure and vacuum kettles in our inventory.

Agitation methods in kettles

Agitation in your kettle allows you to create and maintain a consistent product. It blends batches of product of various viscosities while transferring heat evenly throughout the kettle. It also keeps your product from sticking to the walls.

Some common types of agitator methods include:

- Scrape

- Paddles

- Propeller

- Sweep

Single-motion

The single-motion scrape is a popular agitation design used in many kettles. The scrape moves along the inside to remove product from the kettle walls.

Double-motion

The double-motion scrape uses counter-rotating agitator bars. It rotates the product clockwise and counterclockwise to create a consistent blend and heat throughout a product.

Triple-motion

A triple-motion design uses a combination of different agitator methods to create a uniform product inside the kettle.

Common discharges

Kettles come equipped with various ways to discharge your product. Some units have to be manually tilted to pour the product out. Most kettles that use manual tilting mechanisms are on the smaller side. A manual tilt wouldn’t be as practical on a larger unit. Other models discharge the product through the bottom of the machine. However, bottom-style discharge systems tend to release product at a slower rate compared to a tilt discharge.

Some kettle models have tilt cylinders that are powered by water or air pressure. These allow the operator to easily pull the agitation system out of the machine as well as tilt the kettle to pour out the product.

Jacket sizes and ratings

Different jacket sizes are something else to keep in mind when purchasing a kettle. The most common sizes are half-jacketed or full, but some units have two-thirds coverage. With a jacket, an operator can control the temperature of the product inside the kettle. However, you can only heat so much of the kettle, depending on your jacket size. Half-jacket kettles only heat the bottom half of the machine. On the other hand, a fully covered kettle can heat the entire unit. As we previously covered, the jackets heat the kettle by circulating steam, electricity or gas.

When working with kettles, it’s important to pay attention to the jacket rating for the safety of you and your employees. These National Board ratings tell you the maximum working PSI you can run while at a certain temperature. Our kettles come with these ratings to prevent them from bursting and causing injuries.

Kettle position in a production line

Upstream:

- Pumps

Downstream:

- Pumps

- Tanks

- Fillers

- Sealers

- Labeler

- Forklift

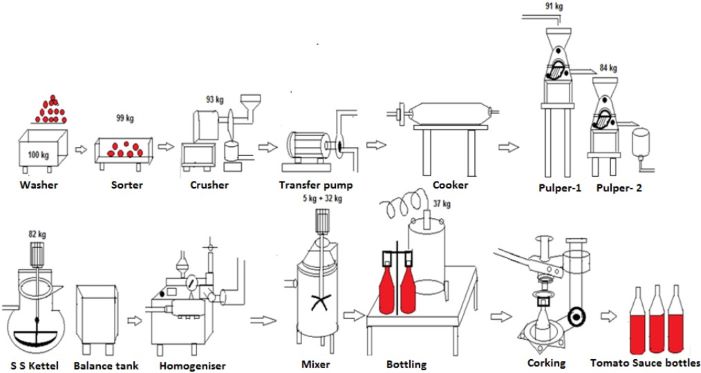

Below is an example of where a kettle would be positioned in a tomato sauce production line.

Popular kettle manufacturers

- Groen

Common industries

- Food processing

- Pharmaceutical

- Dairy

- Pet food

- Beverage

- Baby food

Summary

Kettles are used in several industries because of their ability to efficiently heat, melt, blend and cook a variety of liquid products. Some kettles have relatively simple designs, while others are more complex and include various agitation systems and discharge methods. With our wide selection of kettles, we’ll be able to find the right machine that best suits your needs.

Click here to view our section of Stainless Steel Kettles.

If you’re interested in one of our kettles, please reach out to our sales team by clicking the button below.