Used Slidell Fischbein Big Bag Filling and Sealing System

Click image for full size.

Having trouble viewing media for this Slidell Packaging Equipment Specialists VFN-9902?

Click here for full page view of all Equipment Media (75)

Slidell Packaging Equipment Specialists VFN-9902 Videos

Click here for full page view of all Equipment Media (75)

Equipment Details

| Equipment # | G1706 |

| Item | Slidell Fischbein Big Bag Filling and Sealing System |

| Category |

Filler Net Weight Filler |

| Manufacturer |

Slidell Packaging Equipment Specialists Slidell Packaging Equipment Specialists |

| Model | VFN-9902 |

Equipment Description

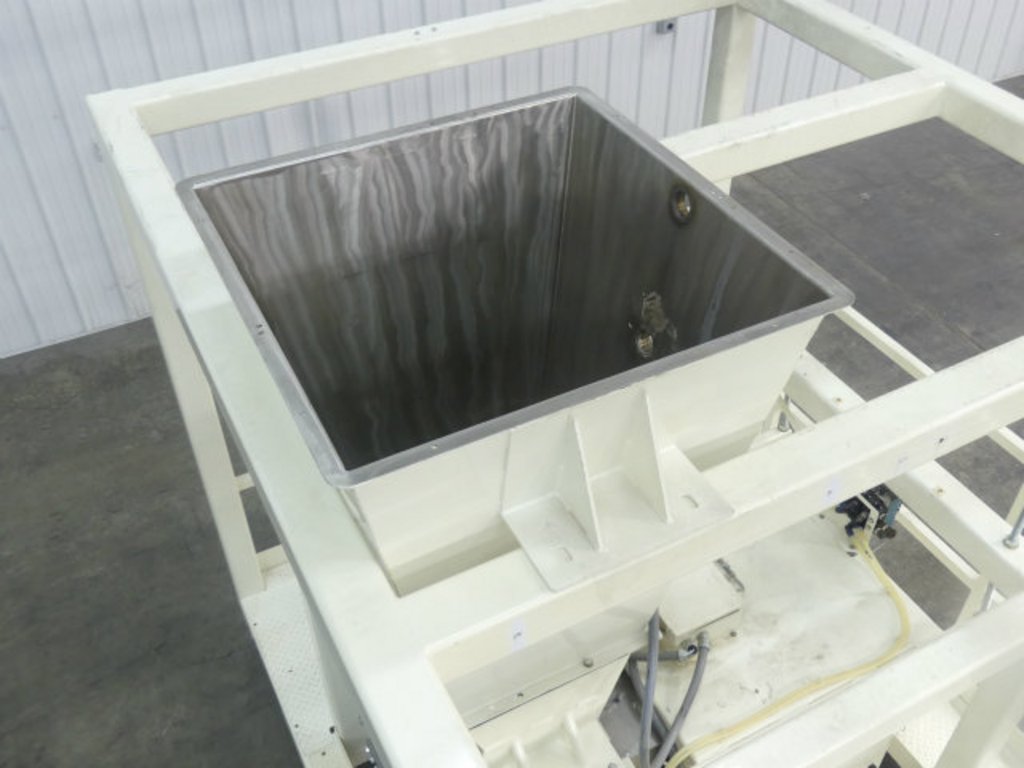

Used Slidell and Fischbein Bag Filling Sealing System with:

- Bag filling and filling system for free flowing product

- Semi-automatic - operator places bag to be filled on the bag hanger underneath the weigh feeder

- System includes:

- Tubar tote dumper

- Mezzanine

- Slidell weigh feeder

- Fischbein bag sealer

- V-belt outfeed conveyor

- Tubar tote dumper

- Hydraulic

- Maximum lifting capacity: 2,000 pounds

- Maximum tote dimensions: 40 long x 50 inches wide x 60 inches tall

- Discharge height: 17.83 feet

- Funnel discharge with pneumatic gate valve

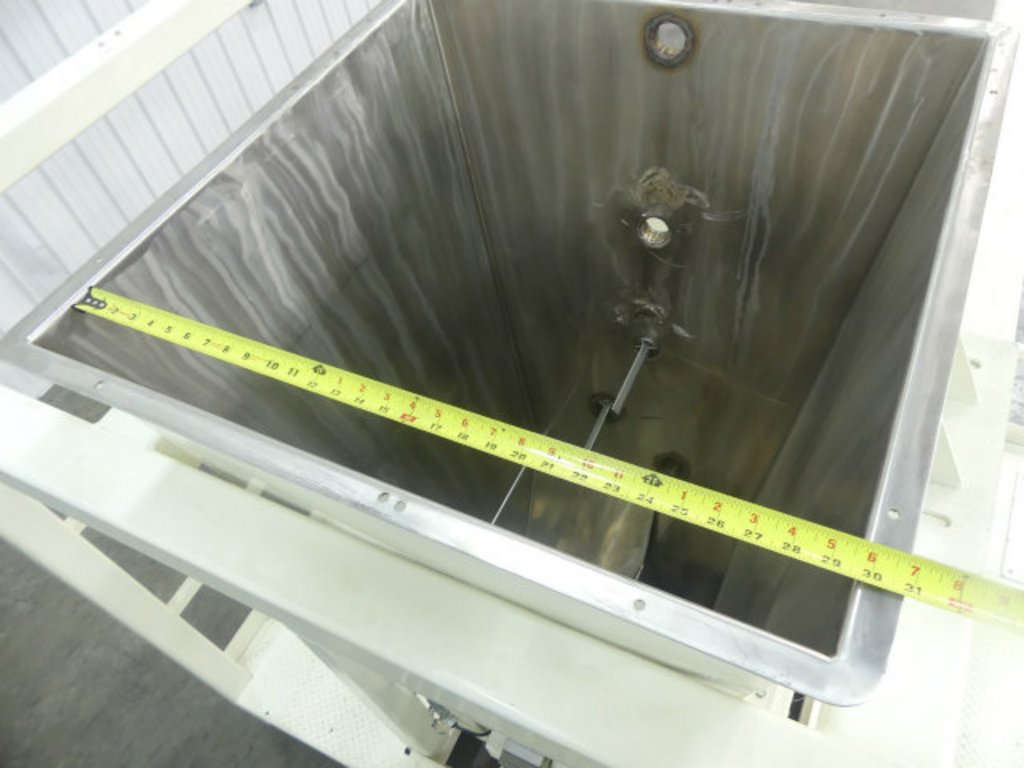

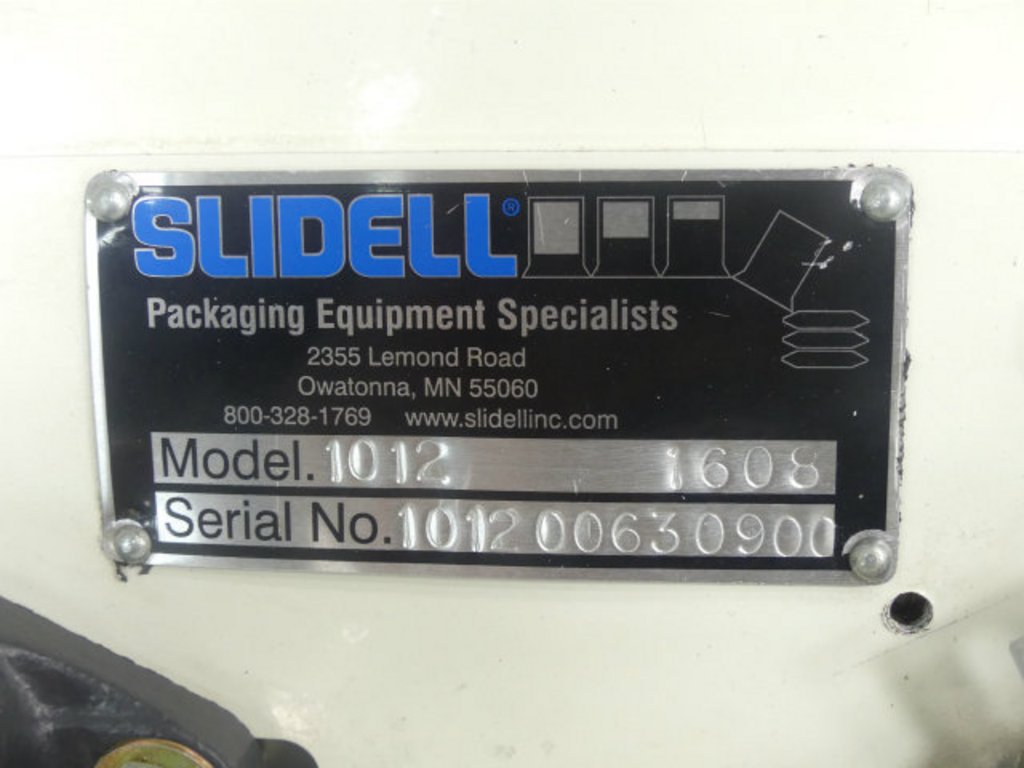

- Slidell VFN-9902 weigh feeder

- Hopper capacity: approximately 13 cubic feet

- Hopper product level switches

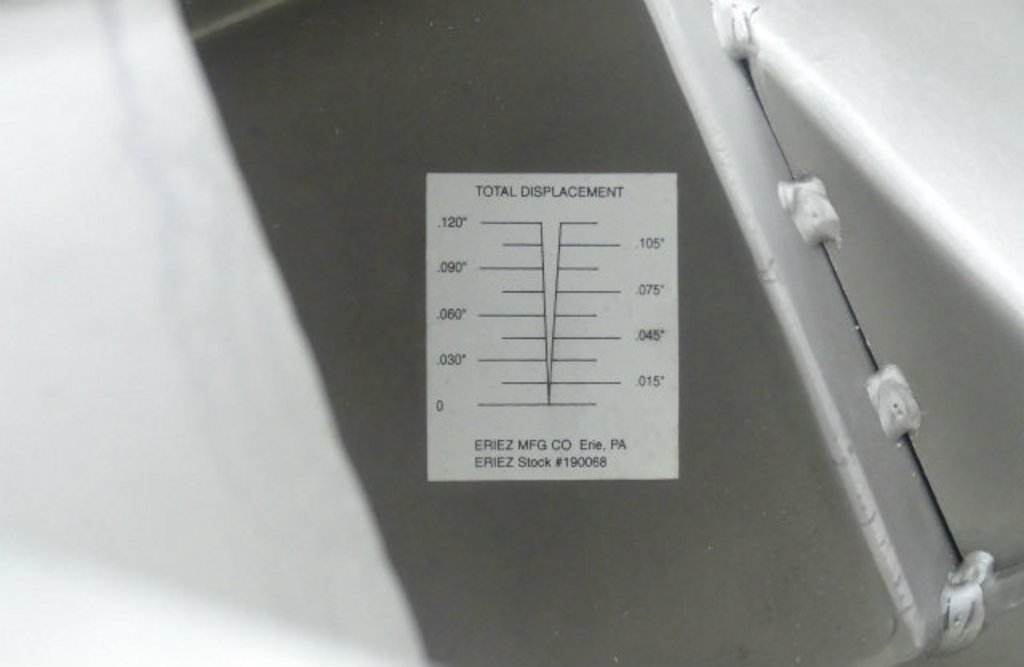

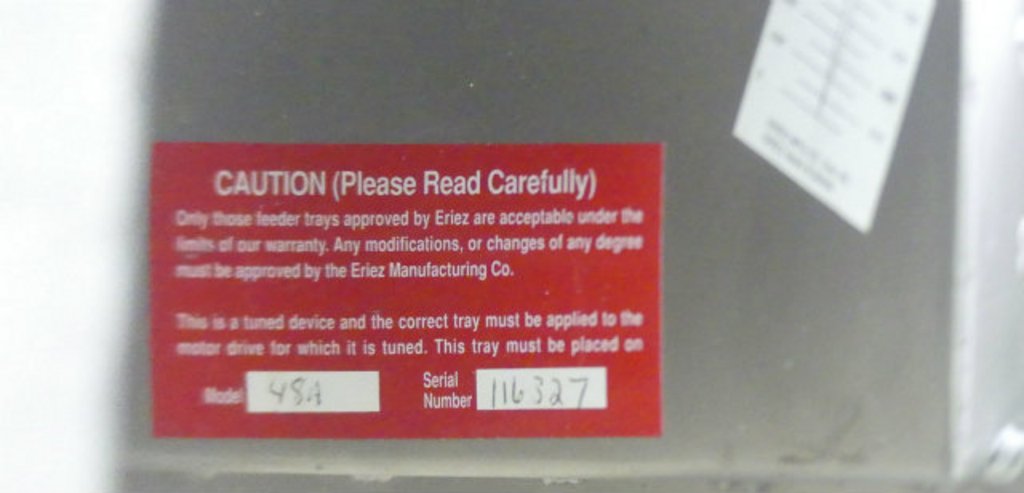

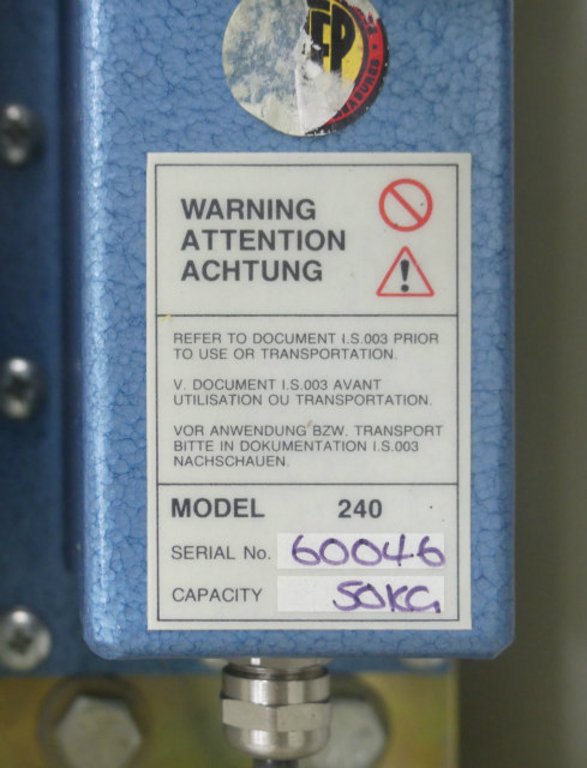

- Vibratory feeders deliver product from hopper to conveyorized weighing area

- Mezzanine

- Elevated surface area: 122 inches x 106 inches

- Platform height - standing area to floor: 127 inches

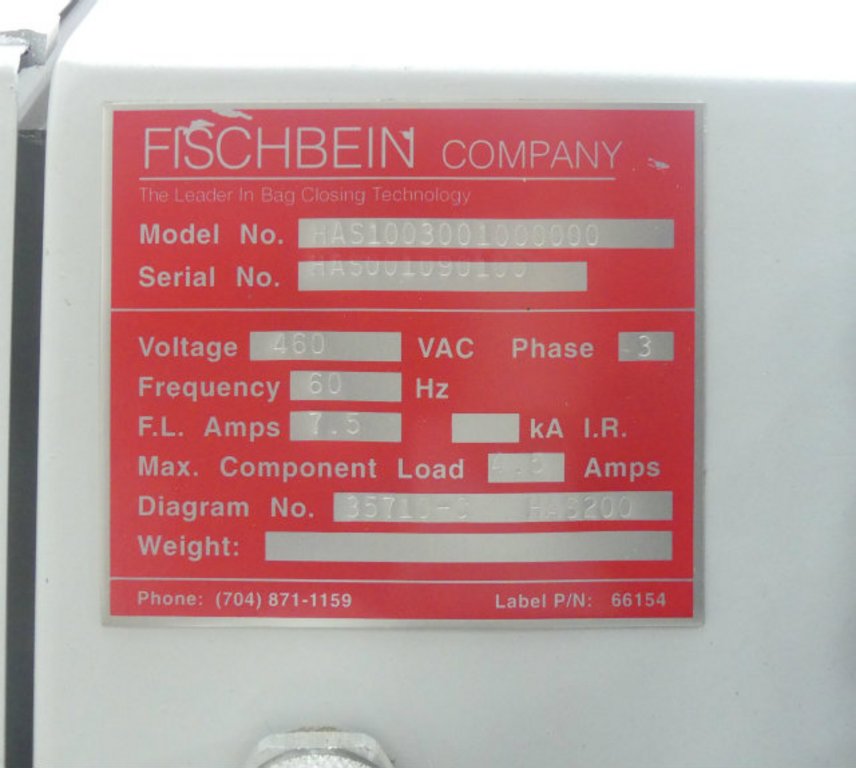

- Fischbein HAS 200 bag sealer

- Hot air sealer

- Right to left product flow

- Sealing area length: 36 inches

- Digital temperature controls

- Bag types: heat sealable structures in pillow and gusseted bags

- Maximum bag thickness: 10 mils

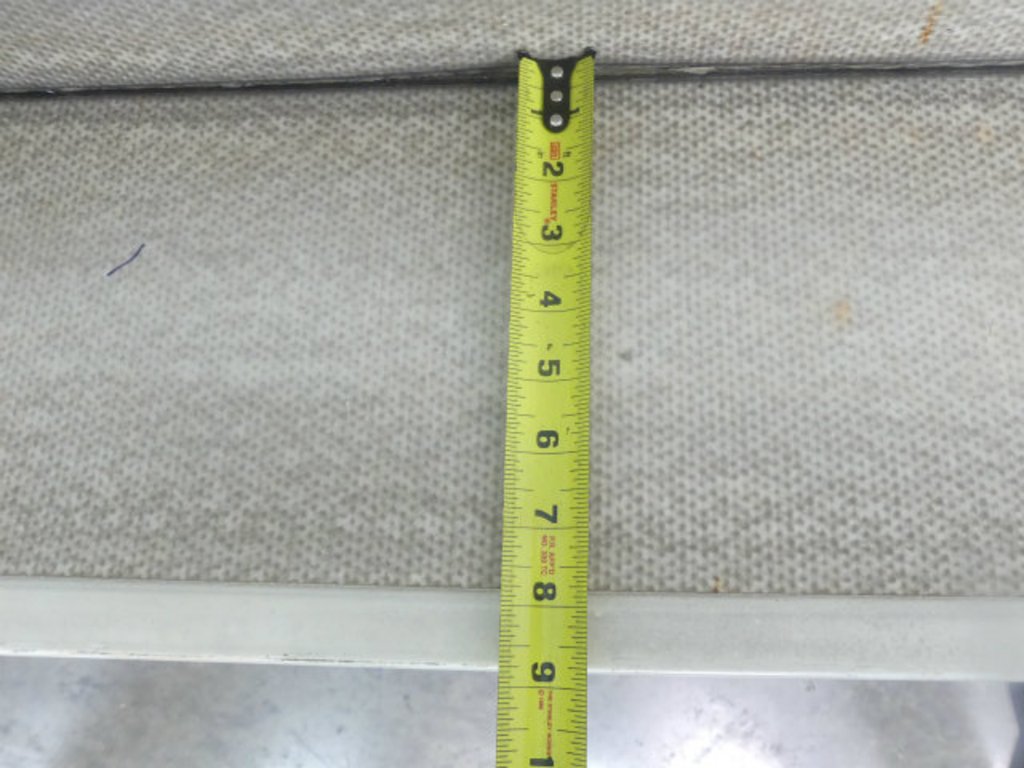

- Free bag top: 6 inches, minimum

- V-belt outfeed conveyor

- Conveyor length: 153 inches

- Belt widths: 7.75 inches

- Conveyor height: 20 inches

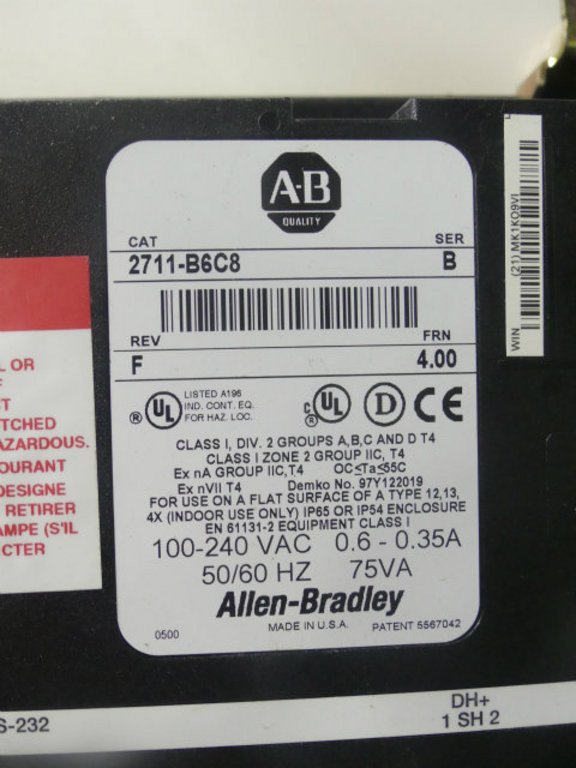

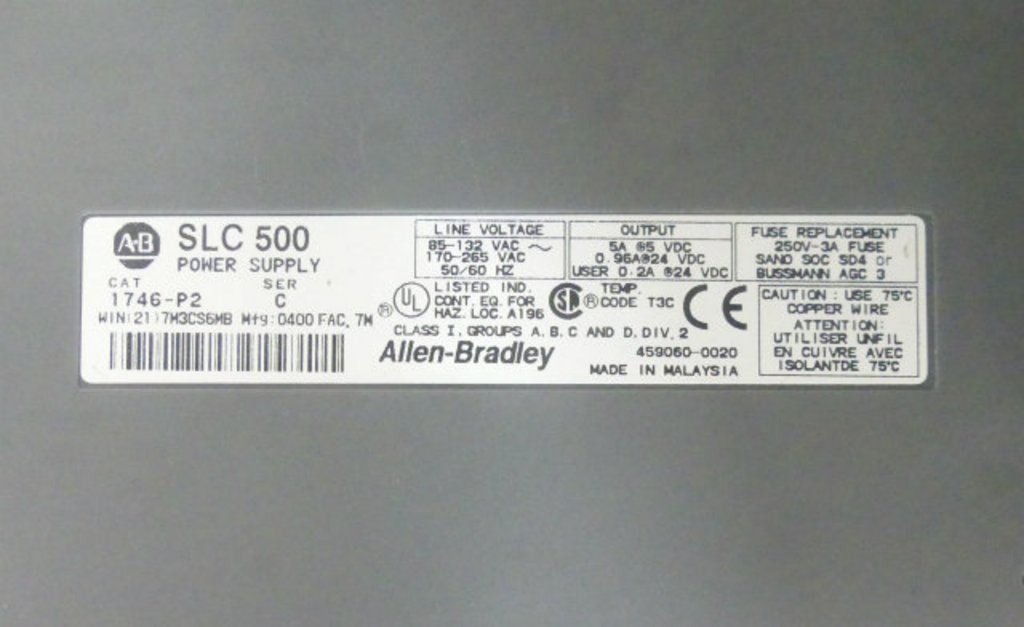

- Allen-Bradley PanelView 600 HMI

- Allen-Bradley programmable logic controls

- Output: approximately 20 bags per minute - depending on product, fill amount, and bag type

- Painted mild steel frame with stainless steel contact parts

- Originally designed to run pellets

Location Details:

Evansville, INThis machine is located at SIGMA Equipment's warehouses in Evansville, IN. You are always welcome to visit, however we request 48 hours notice to ensure access to your requested machine.

Call us at (812) 303-8383 to schedule an inspection visit.

Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this Slidell Fischbein Big Bag Filling and Sealing System?

Request an email quote or call us at (812) 303-8383 for more information.