A Guide to Tape Bottom Seal Case Erectors

Achieve a Streamlined Packaging Operation While Cutting Labor Costs

Increase your packaging output and lower labor costs by upgrading to a tape bottom seal case erector. With these machines, you can quickly form and seal cases, freeing up your team to focus on other critical aspects of your operation. Case erectors pay for themselves in the long run, providing you with consistently built cases without labor constraints.

In this article, we’ll go over the following:

- What is a Tape Bottom Seal Case Erector?

- Left-handed vs. Right-handed Cases

- How/Where customers use this machine

- Favored manufacturers

- Benefits and Features

- Industries Used In

- Summary

What is a Tape Bottom Seal Case Erector?

This type of case erector uses tape instead of glue to seal the bottom opening of a case. Tape is usually cheaper compared to glue, but glue is stronger and makes for more professional-looking packages. However, tape heads are easier to maintain.

Taping the case is done through a mechanical operation, which allows various-sized cases to be sealed.

Tape case erectors can have the case openings facing horizontally or vertically. They typically use two or three-inch tape - depending on the type of tape head being used.

Pin & Dome vs. Suction Case Erectors

There are two main types of case erectors: those that use a pin and dome mechanism or those that use suction to grab and form cases.

Pin & Dome Case Erectors

Pin and dome case erectors use pins to come down in between the corrugate and expand the case out. This style of case erector is ideal for heavier corrugated cases.

Suction Case Erectors

On the other hand, suction case erectors form cases by grabbing them from the side with a vacuum suction cup to pull the case out while the corners are formed. They are better suited for lighter corrugates and are generally more affordable.

Left-handed vs. Right-handed Cases

It’s crucial to know whether your machine requires a left or right-handed case. Most case erectors cannot run both left and right-handed cases at the same speed - or sometimes not at all. In some instances, machines are designed and tooled to run only one of the options.

How to tell the difference between left and right-handed cases?

To differentiate between left and right-handed cases, take a case and place it in front of you with the glue tab on the bottom. Then, place your hands on both sides of the case panels. The hand that is on the bigger panel will determine the case’s orientation. For example, if your right hand is on the bigger panel, the case is classified as a right-handed case.

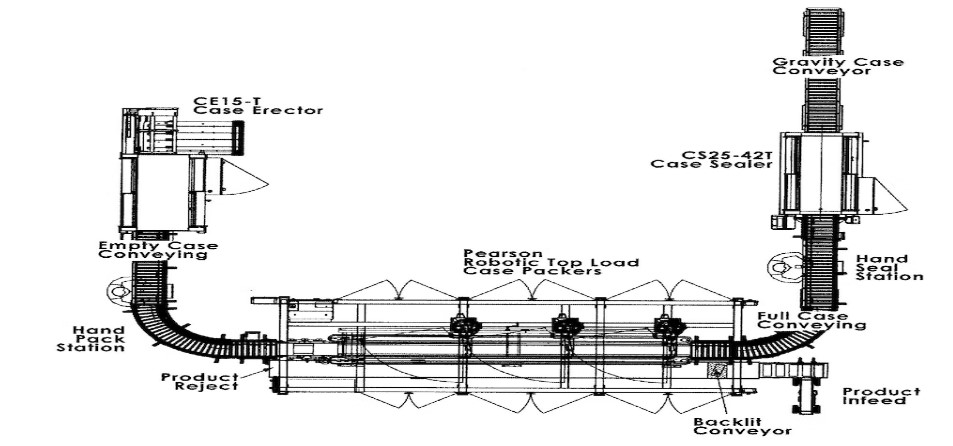

Upstream and Downstream Equipment

Upstream

- Filler

Downstream

- Labelers

Favored Manufacturers

- Pearson

- Combi

- Lantech

- Loveshaw

- MARQ Packaging Systems II, LLC

[Source: Packaging World]

Industries Used In

- Food & Beverage

- Cosmetic

- Pharmaceutical

- Distribution/Fulfillment Centers

Summary

Tape bottom case erectors are versatile machines used in almost every industry. These sought-after machines are for any customer looking to expand their capabilities and reduce their labor costs. Finding the right case erector to handle your specific case is crucial. That’s why we recommend customers send case samples so we can find the right machine for you.

Click here to view our inventory of tape bottom seal case erectors.

To purchase one of these units or determine which one suits your needs, click the button below to contact our sales team.