Exploring Automatic Tray Sealers & Their Benefits

Keeping Your Products Fresh with an Airtight Seal

Automatic Tray Sealers use heat to seal plastic films to the sealing flanges of various types of trays. They have the ability to give products a fantastic presentation while keeping it fresh. When purchasing this versatile machine, you’ll be able to consistently seal your product with a leak-proof package that’s also practical to consumers.

We will cover the following in this article.

- What an automatic tray sealer does

- Inline vs. rotary tray sealers

- Benefits of an automatic tray sealer

- Various tray types and shapes

- Various film types

- Modified Atmosphere Packaging (MAP)

- Upstream and downstream equipment

- Preferred manufacturers

- Popular industries

- Summary

What does an automatic tray sealer do?

Automatic tray sealers are essential if your facility is running fresh or prepared food placed in a tray. Trays are loaded into the sealing nest of these machines, where a plastic film is placed over the sealing flanges of the tray and heat-sealed. Some tray sealers use a vacuum or nitrogen to extend the shelf life of products. These pieces of equipment can either be inline or rotary.

Inline vs rotary sealers

Inline sealers

Inline tray sealers use conveyors to push trays filled with product down a line and into the sealing nest. This is where the plastic films are applied to be heat-sealed. Once sealed, the packaged product is pushed onto another conveyor, removing it from the nest where it will continue down the production line.

[Source: MULTIVAC]

Rotary sealers

Instead of using conveyors to move trays through the machine, rotary tray sealers utilize a turntable. Trays are placed into the sealing nest in the turntable, which rotates to separate stations to carry out the sealing process. Plastic film is placed over the sealing flange of the trays in one section before moving to the next station to be heat-sealed.

[Pictured above: Koch Ilpra FP800 4 Station Rotary Tray Sealer]

Benefits of an automatic tray sealer

- Keeps the product fresh

- Leakproof in most applications

- Uses recyclable materials and can be recycled afterward

- Excellent presentation

- Convenient for customers

- Tamper-evident seals

Automatic tray sealers are versatile machines that can run a wide range of tray types as well as various films. They can be modified to fit the specific needs of your product with the proper change parts from the OEM.

Various tray types and shapes

- Plastic

- Board

- Ovenable paperboard

- Foam

- Aluminum

- Renewable raw materials

- Rectangular

- Round

- Oval

- Multiple cavities

- Slice pack

Various film types

- Perforated

- Anti–Fog

- Freezable

- Heat resistant

- Peelable

- Resealable

- Barrier

Modified Atmosphere Packaging (MAP)

Some tray sealers have a Modified Atmosphere Packaging system to help extend the shelf life of fresh food products. The gas inside the package helps extend the shelf life of the product. Different types of food require different gas compositions to get the best freshness result. For instance, red meat needs high oxygen to maintain its red color. Bread requires low oxygen to avoid mold. Vegetables often need a three-gas mixture to keep them fresh.

These MAP tray sealers can be either automatic or semi-automatic. Below is an example of a semi-automatic MAP tray sealer.

[Source: Zhucheng Yide Machinery Co., Ltd.]

SIGMA Equipment keeps several modified atmosphere tray sealers in stock.

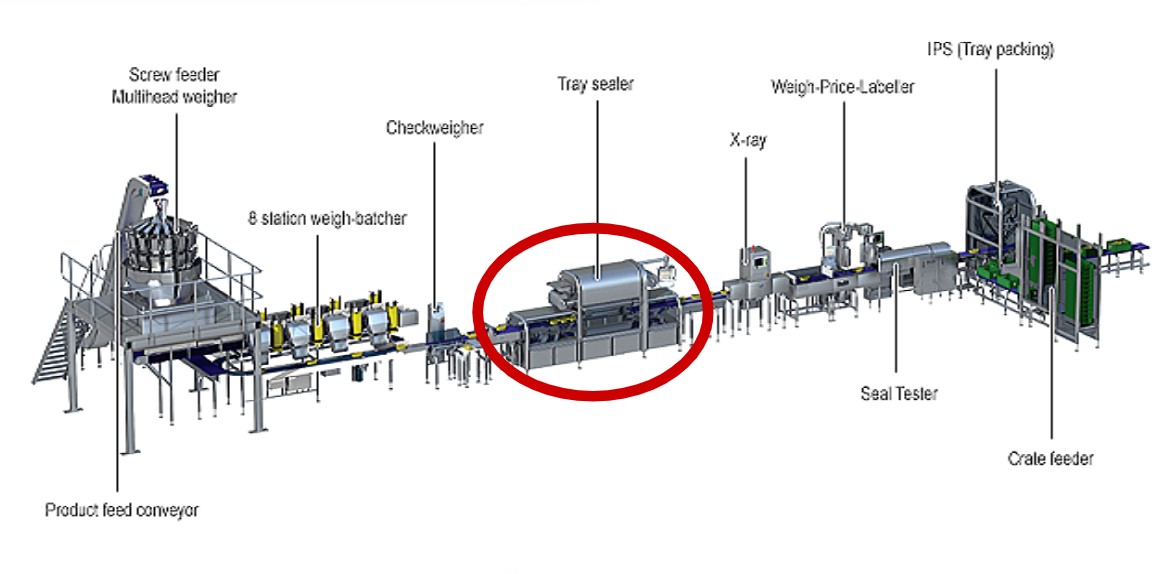

Upstream/Downstream

A tray sealer's placement on a production line often depends on the product. Below are some common machines used in the same production line as an automatic tray sealer.

Upstream Equipment

- Denester

- Fillers

- Product Inspection Equipment

- Conveyor

Downstream Equipment

- Conveyor

[Source: ISHIDA]

Preferred manufacturers

- Orics

- Reiser

- AmeriPak

Industries used in

Automatic tray sealers are usually found in medium to large-scale operations. They are mainly used in the food industry for several products, including:

- Fresh product

- Meat

- Frozen meals

- Ready-made meals

- Snacks

These machines are also used in the medical industry. They are primarily used to seal medical devices that must be kept sterile yet readily accessible. These types of products include:

- Artificial joints

- Implants

- Medication

- Syringes

Summary

The automatic tray sealer’s versatility makes it a great solution for a wide array of packaging applications. The machine has the ability to apply several types of film to the sealing flanges of multiple different trays. If your facility runs prepared food, purchasing a tray sealer will provide you with great-looking products that stay fresh longer and are convenient for your customers.

Our shop services can calibrate your automatic tray sealer to the specific needs of your products.

If you’re ready to add this piece of equipment to your operations, contact our sales team by clicking below. We’ll find the machine that’s right for you.