Description

New Fenco spiral pasteurizer and cooling systems:

- Output: Up to 400 pouches per minute, depending on application

- Air pasteurizing system with holding:

- Pouch position into belt: 4 pieces across (side by side) |□□□□|

- Pouch max dimensions: (L) 140 x (W) 84 x (H) 40 mm

- Pasteurizer holds filled pouches at 192°F (core temperature) for 5

minutes - Air temperature inside: Up to 220°F

- Primary Thermal Fluid: steam at max 6 bar (min 3 bar)

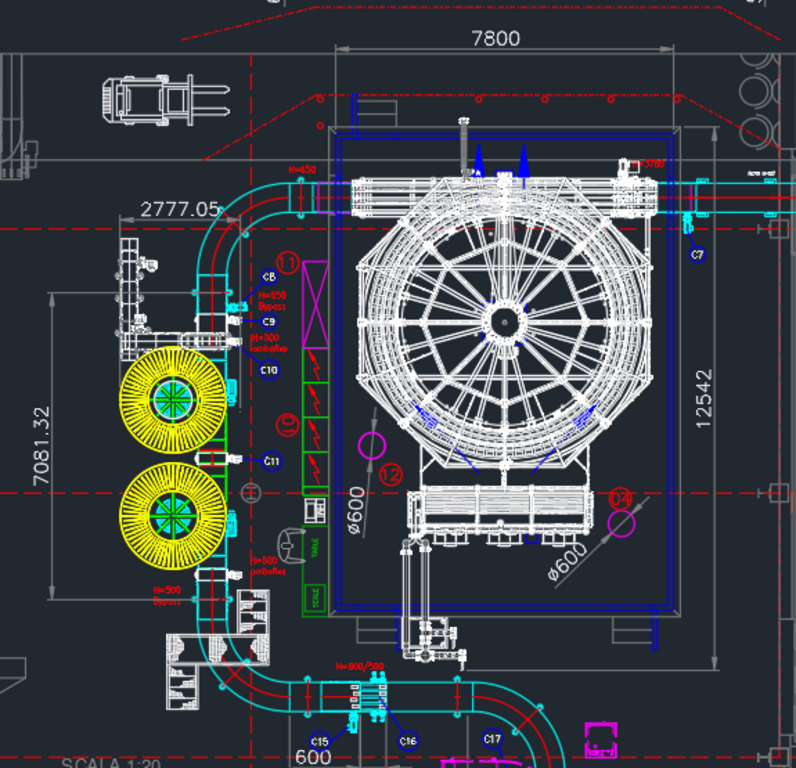

- SPIRAL design and technical data:

- Belt width: approximately 800 mm

- Drum diameter: 4000 mm

- Number of drums: 1

- Number of tiers: 8

- Tier pitch: 150 mm approx.

- In feed height: 1900 ±100 mm

- Out feed height: 900 ±100 mm

- Cabin max height: 10 feet

- Air cooling system:

- Cooler cools down the pouches to 90°F (core temperature)

- Dwell time: 20 minutes (adjustable)

- Air cooling temperature: 40°F (adjustable)

- Primary Thermal fluid: chilled water between 28°F–32°F

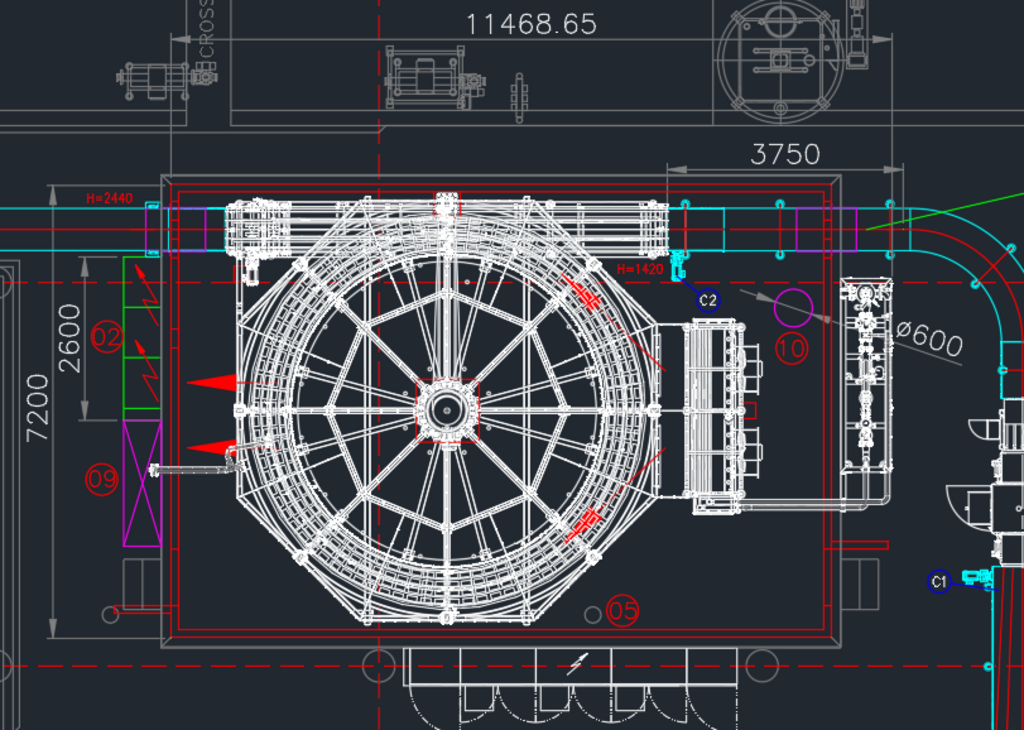

- SPIRAL design and technical data:

- Belt width: ~800 mm

- Drum diameter: 5000 mm

- Number of drum: 1

- Number of tiers: 24

- Tier pitch: 150 mm approx.

- In feed height: 3600 ±100 mm

- Out feed height: 900 ±100 mm

- Cabin max height: 15 feet

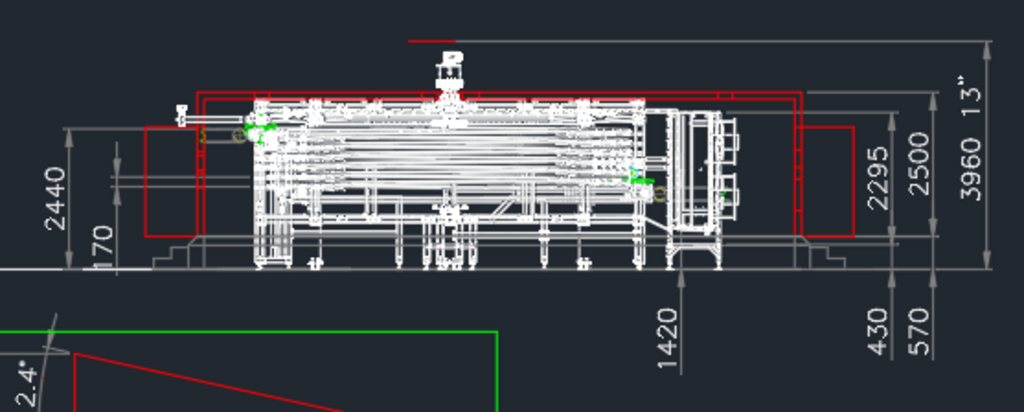

- Pouch accumulation:

- To collect the pouches in case of any stoppages of the secondary

packaging, working with logic FIFO (First in First out).

Buffer – accumulation capacity: ~ 7 minutes (±10% tolerance

depending on the pouch handling conditions) composed of:- Stailess steel frame with sliding guides with low friction coefficient

plastic material - Adjustable feet

- Plastic flexible belt composed with modular belt type food grade in plastic material.

The belt allows for good product support and high air cross-flow

- Stailess steel frame with sliding guides with low friction coefficient

- To collect the pouches in case of any stoppages of the secondary

- 2 POUCH ALIGNERS AND ACCELERATING BELTS

- To increase the interspace between the rows due to the high speed of the filler (25-26 m/min) vs the lower speed of the secondary packaging (15-16 m/min). One system is posizioned just after the pouch filler, the second one just before the secondary packaging input. The system is totally automatic and fully equipped of sensors for a perfect pouch handling. Composed of:

- Stailess steel frame with sliding guides with low friction coefficient plastic material

- Adjustable feet

- Plastic flexible belt composed with modular belt type food grade in plastic material.The belt allows for good product support and high air cross-flow.

- To increase the interspace between the rows due to the high speed of the filler (25-26 m/min) vs the lower speed of the secondary packaging (15-16 m/min). One system is posizioned just after the pouch filler, the second one just before the secondary packaging input. The system is totally automatic and fully equipped of sensors for a perfect pouch handling. Composed of:

- Systems are designed to be in an insulated room. None of the insulation panels are included in the system.

Photos are representative, screenshots of unit drawings included

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.