A Slat Counter Overview

Providing Accuracy & Quality Control in a Highly Controlled Industry

A slat counter is a machine that uses plastic bars, or slats, to count tablets or capsules into a bottle. The slats in the machine have cavities that are specific to the shape and size of the product, allowing for quality control and ensuring only one tablet/capsule is in each slat and there are no empty or double-filled slats. The machine can also detect discolored or broken tablets as well as foreign objects.

In this slat counter guide we will cover:

- Who uses them

- Where it falls in a production line

- Additional facts to note

- Why count instead of weighing

- Regulations and requirements

- Manufacturers

- What to consider when buying or selling

Who Uses Them:

Slat counters are primarily used in the pharmaceutical and nutraceutical industries, including companies such as bulk prescription manufacturers and larger pharmaceutical facilities. Some common products that these machines run include over-the-counter medications and nutritional supplements. An example of this would be the large bottles that come into a pharmacy that require the pharmacists to then count out the correct quantity of medication for a customer or patient.

Where They Fit In A Production Line:

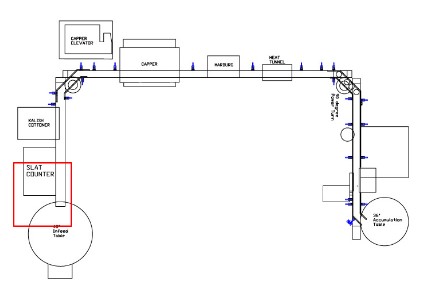

In a production line, these machines are normally at the start of the packaging process. Typically, they fall behind an infeed table and would come before a cottoner (the machine that adds cotton to the top of a filled bottle) or capper. Then they would continue down the production line

Upstream and Downstream Equipment It's important when looking at adding or updating a slat counter to your production line, you also think about what equipment may need to go with it, either upstream or downstream. Here are some of the common equipment pieces for both:

Upstream Equipment:

Downstream Equipment:

- Capper

- Cottoner

- Neck bander

- Labelers

Additional Facts to Note

As many know, the compliance laws that surround the pharmaceutical industry are strict and require a much higher standard for their production practices. This means that having an accurate tablet/capsule count per bottle is critical.

Those in the pharmaceutical industry also need to confirm that the tablets and capsules are consistent and provide quality assurance to customers. Slat counters can help point out imperfections such as broken, off-sized, off-color, or other product issues, this machine serves multiple purposes.

An additional benefit to these machines is the high volume capacity. Some machines can load up to 300 bottles per minute, depending on the application.

Why Count Instead of Weighing

In a simple answer, counting is more accurate than weighing. And the more accurate, the better when it comes to compliance. If a production team is counting, they are able to also better detect a damaged or faulty product. And when recalls and errors are so expensive, accuracy is key.

Counting also helps should a company need to trace back their product. Due to the controlled substances that many companies have to work with, having the ability to trace back product is crucial to keep their compliance.

Regulations and Requirements

Because the field is so regulated, most buyers and sellers will need to know a lot about the machine and the facility it ran in. Because of this, it is recommended that the machine is bought new and a factory acceptance test (FAT) is performed.

However, less regulated industries like the CBD or cannabis industries will allow for more leniency. This may require retooling and reconditioning a piece to then fit the needs of your product and thus, an additional cost will have to be considered. Our SIGMA Integration shop has the space and availability to help you with tooling and setting a piece of equipment to size. To see more information on their services, click this link: https://www.sigmaequipment.com/services/

Manufacturers:

Below are some of the key manufacturers for slat counters:

- Lakso - part of DT Industries

- IPS Thomas/Ascend Packaging Systems

- King - part of DT Industries

What To Consider When Buying or Selling

When you are deciding to buy or sell a slat counter, there are a few things you’ll need to consider. Including:

Buying ours:

- What type of product will you be running?

- Do you need any additional equipment?

- Will you need any change parts or additional slats?

- Do you need product inspection? Keep in mind that older models may not have product inspection.

- Do you need to run capsules or tablets?

- What size capsules will you need to run?

- How many lanes do you need? What orientation of the machine do you need?

- Do you need additional features including:

- Missing product detection

- Damaged product detection

- Reject

- Static eliminator

- Air filter

- Dust collector

Selling yours:

- What size and type of product last ran in the machine?

- What is the bottle height range of the machine?

- Are the infeed and outfeed conveyors included?

- Do you have an older model and is product inspection included in the machine?

- Any other equipment you are looking to sell that pairs with the slat counter?

- How many bottles per lane can this machine run?

- How many lanes does the machine have?

- Does your machine run right-to-left or left-to-right?

- Does the machine have additional features:

- Missing product detection

- Damaged product detection

- Reject

- Static eliminator

- Air filter

- Dust collector

Summary

In conclusion, these machines help you quickly produce the tablets and capsules you need to keep your production running, all while keeping quality in control. While used equipment can be a concern in most industries, these machines help with anyone increasing up production. To learn more about buying or selling your slat counter, click the buttons below.