Sigma Arm Mixers Overview

Universal Machines That Can Keep Up With Your Production Needs

Sigma Arm Mixers can be found in our Mixer and Blender category. The body of this mixer is designed to rotate for ease of product removal, making it ideal for paste or powder products. Sigma mixers come in a variety of sizes, capacities and styles, including single or double arms. Their mixing bowls can also be tipped at different angles, so depending on your production needs, you can go with either a manual or automatic tipping bowl.

In this guide, we’re going to cover:

- Functions of a Sigma Arm Mixer

- Advantages of a Sigma Arm Mixer

- Types of Blades

- Discharge Options

- Integration into a Production Line

- Common Manufacturers

Functions of a Sigma Arm Mixer

The operations of a sigma arm mixer begin with the materials being loaded into the bowl through the top of the container. When completing this step, you will want to keep the material between 40 - 65% of the mixer’s volumetric capacity. If you need help determining the capacity or volume of your mixer, check out our reference guide here. Once the material is loaded in and is ready to be combined, the mixer’s jacket, if equipped, will help maintain the required temperature conditions, whether that be hot or cold. Once the material is thoroughly mixed, it is then discharged through the bottom of the mixer.

Advantages of Using a Sigma Arm Mixer

The biggest and most important benefit of using this mixer is that no materials will be left unmixed. The consistency of mixtures is achieved by the different speeds and rotation patterns of the mixer’s blades. With all of the materials being pulled in and mixed together so thoroughly, you can be assured that each of your products includes the exact amount of ingredients needed.

Another advantage of incorporating a sigma arm mixer into your production is that it's a very versatile machine. Meaning it can mix a variety of materials, ranging from liquids, semi-liquids, doughs, putties, to very abrasive materials. This mixer can also handle small batches or large loads of materials. So if you have to change operations, product types, quantities, or ingredients, this mixer will be able to shift projects with you.

Types of Blades

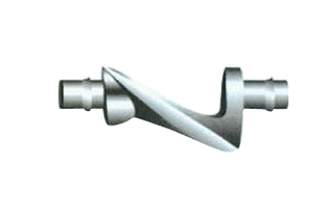

Sigma blade - this is the most common blade and is used for typical applications are chocolates, sealants, and adhesives.

Source: Abster Equipments

Masticator Blade - this is the strongest blade available and its typical applications are rubber, plastics, and abrasive materials.

Source: Abster Equipments

Dispersion Blade - this type of blade provides less sheer force and is great for mixing reinforced fiber products

Source: Orbis Machinery

Native Blade - also called the fishtail blade, and typical applications are for slurries and cellulose

Source: Adinath International

Discharge Options

Tilt Discharge - this is the most common option and works by turning a handle on the mixer or it can be done automatically

Bottom discharge - is a swing away door, a ball valve, or a discharge screw that construes the product into a form or shape for further processing

Integration into Production Line

If you are buying a mixer, you may need additional equipment so that it can be seamlessly integrated into your production line. This could include

- Laminator

- Sheeter

- Proofer

- Oven

- Conveyor

- Freezer

- Cartoner

If you’re not sure where to start, we have an integration team that can help you find the pieces you need to make your operations flow smoothly.

Common Manufacturers

When purchasing a sigma arm mixer, you will typically see the following manufacturer brands,

- Peerless Food Equipment

- Paul O. Abbe

- Shaffer Manufacturing Corp

- Werner and Pfleiderer

Summary

A sigma arm mixer can be a great addition to your production because it can handle a wide variety of products and will help with quality control by giving you the assurance that your materials are being mixed consistently every time.

To view our available mixers click here, or if you would like to learn more about the mixers we offer, click the button below.