Guide to Round Tanks

Helping you find the right tank for your production needs

Being a staple in nearly every industry, round tanks play an essential part in storing mass amounts of product. Even though their function may seem pretty standard, it is vital to your operations that you choose the correct tank. A misstep in this buying process could lead to slowing down production which will cost you and your company a lot of time and money.

The following information will guide you through the different types of tanks and help you determine what kind of round tank will best fit your needs.

- Tank Sizes

- Tank Materials

- Tank Styles

- Tank Bottoms

- Tank Lids

- Tank Sanitary Valves

Tank Sizes

Tanks come in a multitude of sizes and can range anywhere from 100 gallons to 20,000 gallons. When purchasing a round tank, it is very important to know that you are buying the right size. If you aren’t sure the current size of a tank, an easy way of determining this is by using Capacity and Volume Equations. Following these formulas will help you find the exact volume of various sized and shaped containers such as tanks, kettles, mixers, blenders, and more.

Another way you can easily determine the volume of a tank is by using a volume calculator. This resource lets you select the exact type of round tank you are working with and customize it to match your correct measurement unit, whether it be gallons, imperial gallons, liters, cubic meters, or cubic feet.

.

Tank Materials

The type of round tank material you will need depends on what type of product you are wanting to store. Most tank materials boil down to 2 types, stainless steel and non-stainless steel.

Stainless Steel Tanks - Most commonly used in the food and pharmaceutical industries for storing liquids like water or chemicals, thanks to their non-absorbent and anti-corrosive qualities.

Non-Stainless Steel Tanks - These can also be used for storing water and chemicals, but if it has a food-grade coating, can also be used for melting chocolate and other confections. They can be made of carbon steel, fiberglass, plastic, poly, glass-lined, or other materials depending on your needs.

Tank Styles

The top five most common styles of round tanks are Single-Walled, Jacketed, Vertical, Horizontal, and Agitated.

Single-Walled Tanks

Single-walled tanks are an excellent choice for products that do not require much insulation or control of temperature. Some common applications you will find this style in are CIP Tanks, Balance Tanks, Juice Tanks, Totes, Surge Tanks, and Water Tanks.

Jacketed Tanks

A jacketed tank has an additional enclosure that allows for both heating and cooling when it is filled with fluid. These tanks are typically used for food processes such as mixing, blending, cooking, heating, and cooling. There are a few different types of jacket styles, including:

Conventional - commonly used for high-pressure applications

Dimpled - the dimples provide turbulence in this lightweight yet still durable option

Half Pipe Coil - provides flexibility because they can be divided into zones

Vertical Tanks

Verticle tanks are great if you need to store a large amount of product because of their stability and structure. Some other benefits of using a vertical tank are they empty very efficiently due to gravity and their upright design allows you to fully utilize your space.

Horizontal Tanks

If you’re looking for a tank to store your liquids that is easy to move and transport, then a horizontal tank might fit your needs. These tanks are most commonly used for beverage or chemical storage and because of their orientation, they can easily be moved around.

Agitated Tanks

An agitated tank is one that uses a motor and bladed attachment to stir, mix, or move the product that it is storing. This movement can either sweep the product from the walls of the tank or actually scrap the product off the walls to prevent build-up.

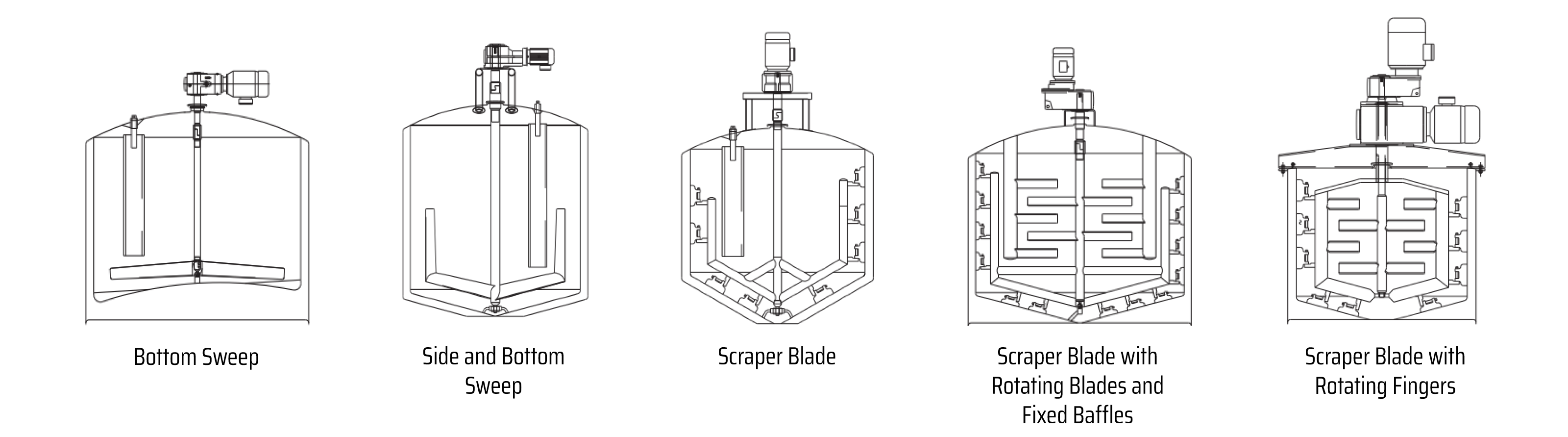

Types of Agitation

Bottom Sweep - Usually used on cone, flat, or dish bottom tanks and makes sure heat is properly distributed to the walls.

Side and Bottom Sweep - Blades have contact with both side and bottom of the tank and help avoid any burning or freezing of products.

Scraper Blade - Scrapes product from both the sidewalls and bottom of the tank using UHMW, nylon, or Teflon blades.

Scraper Blade with Rotating Blades and Fixed Baffles - The rotating blades create subtle agitation while the scraper blades keep the product from sticking to the walls.

Scraper Blade with Rotating Fingers - The rotating fingers create heavy agitation while the scraper blades scour the tank and keep the product from sticking to the walls.

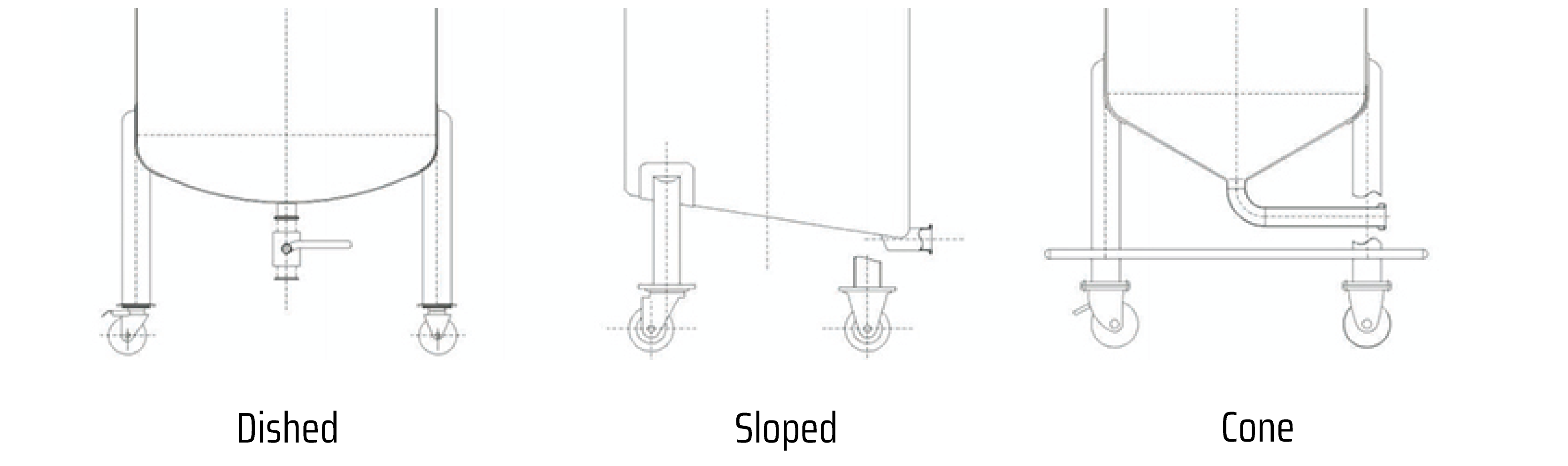

Tank Bottoms

It is important to know what type of tank bottom will work best with your product and production type. Below are the three most common tank bottom types and the benefits they provide.

Dished - offers strength, enhanced draining and flow patterns but requires an increased height

Sloped - offers good draining but as the slope angle increases, so does the difficulty in mixing solids

Cone - offers excellent draining, especially with slurries, but doesn’t work well with solids suspension

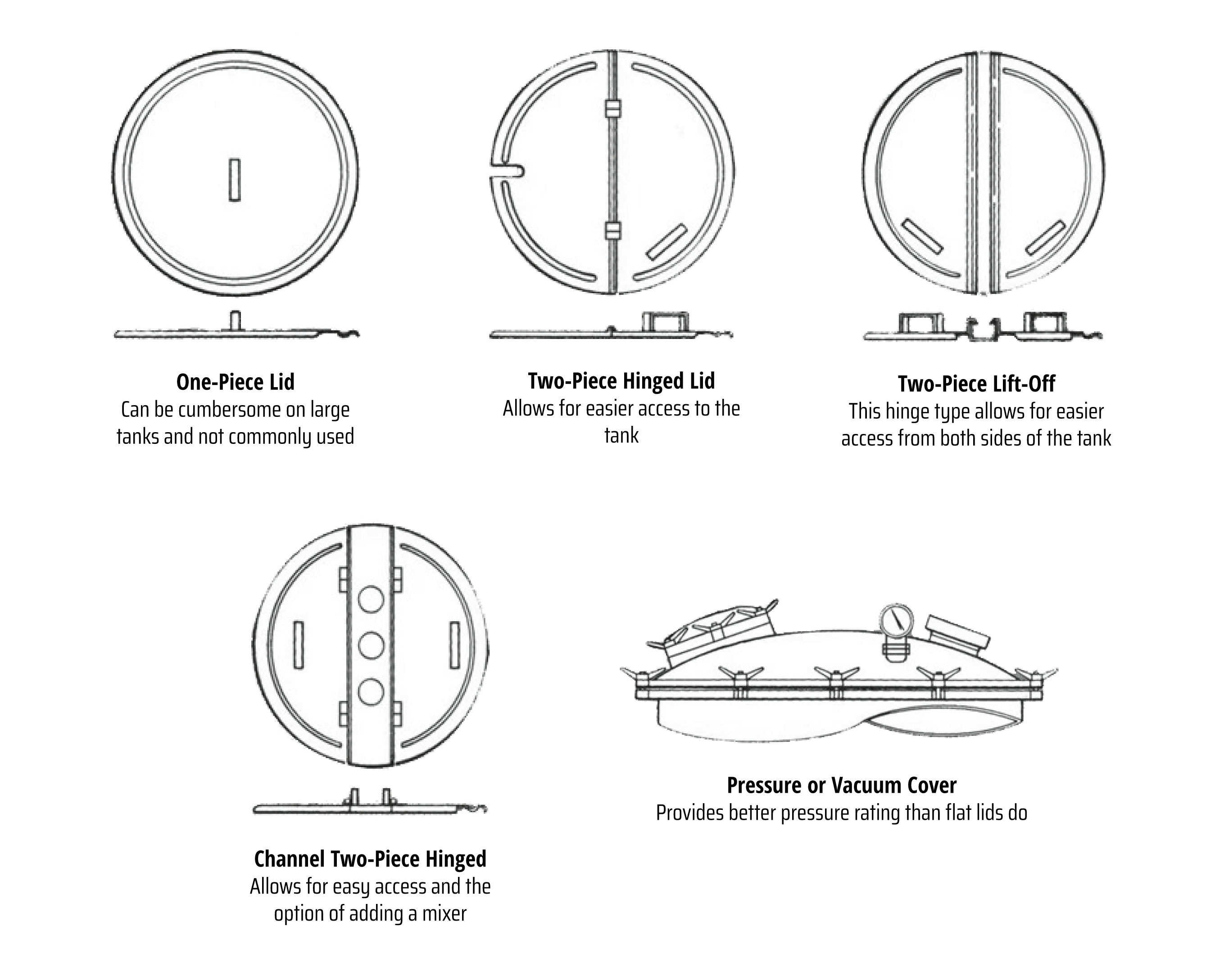

Tank Lids

Sanitary Valves

Depending on which industry you are working in, the type of sanitary valve your tank needs can vary. These valve types help ensure that your product receives the highest possible level of sanitation.

tank needs can vary. These valve types help ensure that your product receives the highest possible level of sanitation.

Butterfly - consists of a disc connected to a shaft that rotates to stop the flow

Diaphragm - made up of flexible material that is compressed to stop the flow

Pinch/Clamp - valve is lined with tubing that is clamped to stop the flow

Plug - consists of a cylinder shape with an opening that controls the flow

Seat - a plate is pressed into a seat to stop the flow

Summary

Knowing the difference between tank materials, styles, bottoms, slides, and valves is so important before you make the final decision of which tank to buy. Implementing the wrong type of tank can affect your product and put a serious hold on your production. To keep things running correctly and smoothly, we can help you choose the right tank the first time around.

If you have any more questions about which round tank is right for you or if you’re still unsure about the different kinds of tanks, please reach out to us. SIGMA would love to help answer your questions and help you make your production as efficient as it can be.

Contact

Sources: SIGMA Thermal, Zwirner Equipment, Walker Engineered Products, Alibaba, Highland Equipment, Lee Industries