A Guide to Glue Bottom Case Sealers

Streamlining Production with Efficient & Reliable Case Sealing Solutions

Topics We Will Cover:

- Category Summary

- Top Industries Include

- Manufacturers of Glue Bottom Seal Case Erector

- Why and When to Use Glue

- Left or Right Boxes and Machines

- How Does the Case Open: Vacuum Suction Cups vs Pin and Domes

- Types of Seals

- Glue Pattern

- Safety and Hot Glue

- Upstream and Downstream Equipment

- Questions to Consider When Buying a Glue Bottom Seal Case Erector

- Conclusion

Glue Bottom Case Sealers Summary:

These machines are also known as hot melt machines.

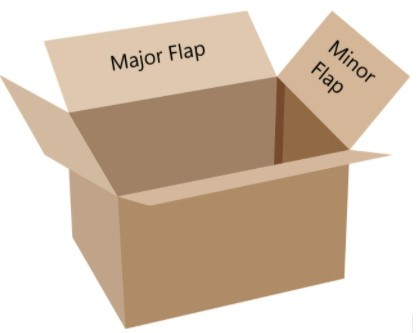

This machine works by folding the two bottom minor flaps, placing glue, usually in a specific pattern, and then folding the major flaps onto the glue. Once the flaps have been folded, a compression plate will ensure the folds of the box are held together securely by the glue.

It’s important to know the difference between major and minor flaps.

Minor flaps - are the smaller or shorter sides of the cardboard that are folded in to make the bottom of the box.

Major flaps - are the longer sides of cardboard that help close the bottom of the box/case.

It’s also important to note that there is also a type of glue bottom case erector that will fold one major flap completely, then glued and folded over the other major to completely seal the bottom of the box with no seams. Most companies that use this type of box are the beverage indury and are packaging heavy products that need a bottom with a complete seal. They are also commonly used with frozen foods so no added moisture can get into the box or industries that pack loose items to keep them in the box.

Top industries include:

- Liquor and beverage industries

- Automotive parts

- Frozen food

- Chemical

- Nutraceutical

- Pet foods

- Pharmaceutical

- Eggs/dairy products

Manufacturers of Glue Bottom Seal Case Erector:

Below are some of the manufacturers that SIGMA offers for the glue bottom seal case erector:

- Lantech

- Combi

- Pearson

- Marq

Why and When to Use Glue:

When customers are deciding how best to seal their cases and boxes, there are a few points to consider when deciding between glue and tape.

Glue is typically used for heavier products that need a tighter seal for the box to hold up. Glue is also ideal if your packaging atmosphere is dusty or moist (including freezing) as it won’t affect the adhesive in the glue.

If you don’t need the additional stability, then glue may not be the best solution for you.

Glue is primarily used for those who need high-speed capability and something that can run continuously. Because glue has a tighter bond, it also offers higher structural strength and thus, more integrity to the box that can hold up long term. Glue is also an excellent option for those who use their cases for branding and need to keep the appearance of the box.

However, if you don’t need these features, then tape may fit your needs better. Tape is typically used as a less expensive option as glue can be expensive and have additional maintenance costs associated with the glue heads needed for a proper seal.

Tape is also used when someone needs a flap seam completely sealed, making a better seal from the outside environment. Tape also has minimal operational risks meaning less of a safety risk and easier use.

Left or Right boxes and machines:

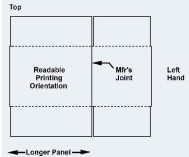

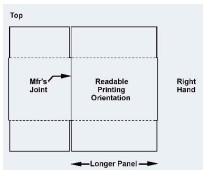

(Image Source: https://www.pmmi.org/sites/default/files/PMMI-B155-TR2.1.pdf)

A key to success with glue bottom seal case erectors is determining not only if the machine is right-handed or left-handed as well as if the box is right-handed or left-handed.

To determine if the box is right-handed or left-handed look at the writing on the box and the bigger panel on the box will determine the orientation. What this means is for a right-handed box, the length panel (the longer panel) will be on the right. For a left-handed box, the length panel will be on the left.

Just as important as knowing your box orientation, you need to also look a the orientation of your machine. If your machine is right-handed, it will need a right-handed box. The same applies if it is a left-handed machine it will need a left-handed box.

The way to determine a right-handed or left-handed machine is to look at the direction your cases are traveling when in the machine and where the control panels are located. If a case is moving from the left to the right, it is a right-handed machine. If the machine is moving cases from right to left of your production line, then the machine is considered a left-handed machine.

The best way to confirm if a box and a machine will be compatible is to send our team samples before making your purchase. Our team can determine the correct machine and box orientation for you in order to make sure your product can be packaged correctly. If you do not have boxes or samples yet, drawings of your product or any schematics can help when making the best determination for your equipment needs.

It’s also important to note that these machines cannot be run upside down and can ruin your boxes and the equipment. So ensuring you have the right equipment for your packaging is crucial to production success.

How Does the Case Open:

Vacuum Suction Cups vs Pin and Domes: Depending on the manufacturer, some equipment will open the case using a vacuum suction cup system, and others will use a pin and dome system.

Vacuum suction cups are used by a wide variety of brands because they are the standard in the market. However, those pieces can become clogged and wear out, meaning you’ll have to regularly maintain and replace them.

However, one manufacturer, Wexar, has created a “pin and dome” system that ensures that the box is perfectly square and provides more durability than vacuum cups. With the pin and dome, the pins are going to connect with the box to open it and the dome is going to hold the box, lifting the case.

Types of Seals: The type of seal you are looking for also will determine what kind of machine you will need for your production line. There are two main types of seal: a vertical seal and a side seal.

While self-explanatory for the most part, a side seal will build the box and have the glue heads seal the box while it is moving horizontally, so operators can visually see the seal and confirm them. The vertical seal will seal the box from the bottom of the box, keeping it in the final orientation.

Both types of the seal will use a compression plate to confirm the glue is sealed to the major flaps and give you a finished and assembled box or case.

Glue Pattern:

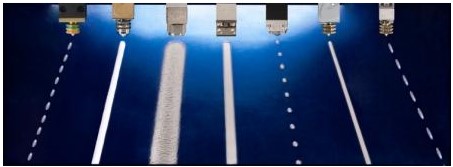

(Source: adhesives.org)

When using a glue bottom seal case erector, it’s important to decide how much glue you will need to successfully seal your case. Glue is an expensive material so you won’t want to use any more glue than is necessary. That’s why most glue bottom seal case erectors will come with a device known as a stitch controller.

A stitch controller can be programmed to give a spray or bead pattern for your glue to make sure your case is secure and won’t fall through, but you won’t use any more glue than you need. These glue patterns can be similar to morse code in the sense that it uses long and short sprays and beads to help ensure you are using glue efficiently.

The spray pattern for your product will be based on your product, in order to determine where the glue needs to be placed for optimum box integrity and security. Depending on the weight distribution, the glue may need to be added to specific parts on the major flaps in order to ensure the box will not break during transit or use.

You will also want to consider different spray or bead nozzles for the spray patterns you will need. The best way to make all of these determinations is to send out team samples and your dedicated technical sales specialist will work with our integration and shop team to provide a solution to your project needs.

Safety and Hot Glue: Utilizing hot glue can be a serious safety concern and should be considered when deciding to use a glue bottom seal case erector.

Glue can typically be 375 degrees Fahrenheit. Meaning that if an operator comes into contact with the glue, their skin can be severely damaged or completely destroyed. When deciding if you need a glue bottom case erector, keep this safety issue in mind and ensure your team is properly trained to maintain and operate the machine without injury.

Upstream and Downstream Equipment:

When adding a glue bottom seal case erector, you may want to upgrade the machinery you are integrating this machine with.

Most upstream equipment associated with the glue bottom case erector is:

Downstream equipment after the case has been sealed and assembled, including:

- Partioners

- Labeler

Should you need any of these pieces of machinery or need to integrate them into your production line, our team can assist you. For sales help on finding your next piece of equipment, reach out to our sales team by clicking this link: (LINK OUT)

For those who need help integrating their equipment as well, we have a dedicated integration team to assist you with your next project. To see those options and get your project started, please follow this link: (LINK OUT)

Questions to consider when buying a glue bottom seal case erector:

- Do you have samples or drawings to provide?

- Do you know what orientation your boxes are?

- Do you know what type of machine orientation you need for your machine?

- What are the minimum and maximum case dimensions?

- If you are selling the unit, where is the glue unit?

- What are your electrical and air requirements?

- What production output rate will you need?

- How will you get the machine to or from your facility?

- Will you need any setup or set-to-size services to fit your specific cases?

You will also want to consider what add ons or additional costs will be associated with the equipment. And that you may need to buy a separate glue system and integrate it in. If this is the case, SIGMA can help with our integration team and our SIGMA Surplus division which regularly sells MRO spare parts to configure your equipment to your needs.

Conclusion:

Whether you are looking to buy or sell a glue bottom seal case erector, our team can assist you with both. To get your next project started, contact us using the button below:

Contact