Guide to End Load and Side Load Case Packers

How case packers can aid your production

A case packer is a type of equipment that can help you efficiently package your products to ensure you’re meeting production requirements and utilizing your space to the fullest. There is a wide variety of case packers, ranging anywhere from automatic to semi-automatic as well as various types of loading styles.

Topics We’ll Cover

- Types of case packers- How end load and side load case packers work

- Why you should use an end load and side load case packer

- What you need to know before buying an end load and side load case packer

- Products to use with an end load and side load case packer

- Manufacturers we offer

Types of Case Pckers

Two common loading styles in case packers are bottom load and end load and side load.

Bottom Load

- loads products vertically up through the bottom of a case

Photo Source: Massman LLC

End Load and Side Load

- both ends are open and the product is pushed to one side

Photo Source: Orbit Equipments

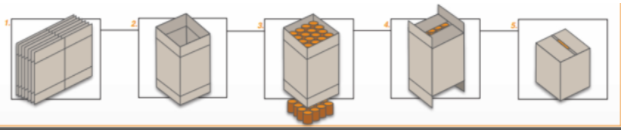

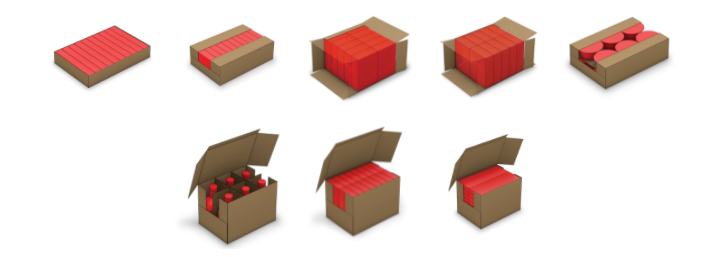

Of these two types of loading styles, this guide will cover everything you need to know about the end load and side load case packers.This style of case packer is designed to collect your product according to your desired pack pattern and then efficiently push-load your product through the end or side of the erected case. A pack pattern is the orientation in which your product needs to be packed into your case.

The pack pattern of a case packer is so important because this determines the specific way the product needs to be placed inside the machine in order to fit into its case. The number of items you are packing into your case will determine the type of pack pattern you will need. If there are many items, the layers should have different patterns so that the items can be packed tightly together and avoid any damages during transit.

Examples of different types of pack patterns:

Photo Source: Douglas

Once your product has been properly packed into the case in its specified pack pattern, it can move onto the gluing and sealing portion of the production.

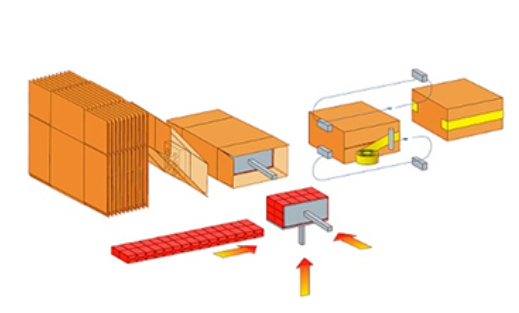

How end load and side load case packers work

During production, the case packer takes the cases off the magazine and then erects them. At the same time, the product is going down the assembly line in a single formation. The case packer then begins continuously stacking the product for whatever pack pattern has been specified. The product is then pushed into the end or side of the case. After the product has been loaded into the case, it will be moved down the assembly line until it’s glued or sealed in the final case.

The kind of product you are packing into your cases will determine how they should be sealed.

- Glue: works best if you are packing a heavy product that has a high output and needs a long-term bond for sealing. This is an inexpensive option but does require a compression step to hold the flaps in place.

- Tape: this method will completely seal the flaps of your case, leaving no gaps or room for any dust or contaminants Tape systems can handle varying carton sizes and work best with slow or infrequent production. Tape heads are easier to maintain than glue systems due to their simplicity but they do come with the drawback of having to change the tape roll out.

Why you should use an end load and side load case packer

Now that you've learned all about how these case packers work, you're probably wondering what benefits will this machine bring to your production. Below are the top 3 reasons why you should be using an end load and side load case packer to package your products.

Integrating an end load and side load case packer into your production line will give you high speed and high output of products. This ultimately ensures that you’re meeting your production requirements. The reason tightly fitted products can be packed so quickly with an end load and side load case packer is because both sides of the case are open. If you push the product into a case that has one side closed, air will get trapped and slow down the packing process.

Stability

If you are working with products that don’t stack neatly, such as cylinders or rolls, getting them to fit into your case can be a challenge. With an end load and side load case packer, the product can be loaded with more stability and uniformity than other case packers can.

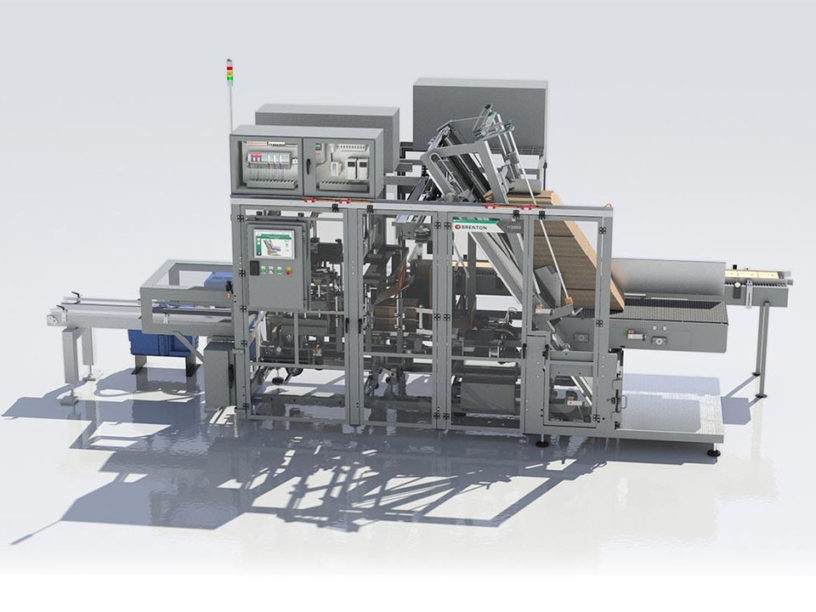

Photo Source: BrentonSecurity

Using an end load and side load case packer can provide a more secure and gentle method for packing fragile products such as glass bottles. Pushing the product in through the side is a much smoother transition than if you were using a drop packer. Although we recommend an end load or side load case packer for fragile products, if you are using a top loader, there are settings that offer a soft drop so that it will not damage or break your products.

What you need to know before buying an

end load and side load case packer

End load and side load case packers are very technical and complex machines that can sometimes be difficult to incorporate into your production.

That’s why we always recommend utilizing our engineering services when purchasing a case packer. This ensures that your new piece of equipment can be correctly integrated into your assembly line and guarantees your product will properly fit into your boxes and then be stacked uniformly onto your pallets.

Before you purchase an end load and side load case packer, our sales team asks that you:

- Send us samples of the product you would like to run through the machine. This gives us insight into what kind of pattern and orientation this case packer needs to run on and determines speed requirements, spacing dimensions, and more.

- Stick with using one case size per case packer. These machines are built to size and it is expensive and time-consuming to reengineer these pieces to fit multiple sized boxes and cases.

If you have any other questions about how to get your end load and side load case packer ready to fit your product and production needs, we have a full team of engineering shop technicians that can assist you. You can contact our engineering services team by clicking here.

Products you should be using with an end load and side load case packer

Some common examples of products an end load and side load case packer can handle are cereal boxes, rolls of film, or almost any product you can find sitting in the aisles of a grocery store. Typically the products that are being packed with this machine require a little more stability than usual and are oftentimes fragile.

End load and side load case packers are best suited for handling:

- Cartons

- Bottles

- Or any product that takes a rigid- or semi-rigid shape

- Canisters

- Cans

Brands of case packers

We offer a wide variety of case packers made from a vast range of manufacturers

- Douglas

- BluePrint Automation

- Salwasser

- Combi Packaging

- MGS Machine

- Econocorp

- EDL Packaging Engineers

- Edson Packaging Machinery

- Hayssen

- Marchesini Group USA

- Thiele Technologies

- Volpak

- Rockford Midland

- Pester

- Econoseal

- DIMAC

- Smurfit-Stone Container Corporation

- ARPAC

- Brenton

- Schneider Packaging

Summary

If you’re looking for a machine that will help you increase production outputs and ensure that your product can be packaged and shipped correctly, then implementing an end load and side load case packer into your operations is a great place to start. Ready to purchase one now? Great! Browse our wide selection of case packers that are in stock and ready for a quick delivery. Still have a few questions? That’s great too! We have a team made up of equipment experts that are ready to discuss in detail any questions or concerns you may have. Get in contact with us here, or give us a call at (812) 303-8383.