Chuck Cappers and When To Use Them

Introduction to Chuck Cappers

Chuck cappers, a type of automatic capping machine, uses a device called a ”chuck” to grip a cap, place it on a bottle and then tighten the cap. Due to their consistency and speed, chuck cappers are most commonly used for packaging food and beverage products. A chuck capper is better for the slower side of production, but a few numbered machines can work for higher production. They are used most commonly in production lines to increase both efficiency and effectiveness. However, it can be used in a variety of industries.

- Types of Chucks

- Types of Capping Heads and Cappers

- Choosing the right Chuck Capper for you

- Chuck Cappers vs. Spindle Capper

Types of Chucks

A chuck is the key element of this capper that grips the cap and then spins it onto the bottle until it is securely fastened. There are numerous forms and sizes of chucks to fit various types of caps. The type of cap that you need generally depends on the industry you are in, your product, and the speed of the production line. There are many chucks available to fit your production needs, but the 3 main chucks include:

Capping Headset- Uses machinery and technology to maximize sealing efficiency. A capping headset is a chuck that would likely be best used in a company that produces easily spoiled products or products that need to be packaged expertly

Figure 1.1 (Source: changeparts.com)

Flex Chuck- a chuck that adapts to the cap size in order to fit multiple sizes of cap on one line. A flex chuck would likely belong best in either a company that switches between cap sizes, perhaps a food company manufacturing two sizes of one product

Figure 1.2 (Source: changeparts.com)

Standard Chuck - Chuck is used for one size to maximize efficiency and speed. A standard chuck would be likely best used in a larger facility or on a longer production line where the same product is being capped at a high speed

Figure 1.3 (Source: changeparts.com)

Types of Chuck Cappers

There are multiple additional types of chucks as well, and each one has individual applications that serve certain purposes. It’s important to choose the right one for your applications as is choosing the right type of Chuck Capper. In addition to multiple types of Chucks, multiple types of Chuck Cappers exist as well. The two primary types are:In-line chuck capper- has one head in the middle that will screw the caps on the bottles. This is usually for smaller or slower production lines.

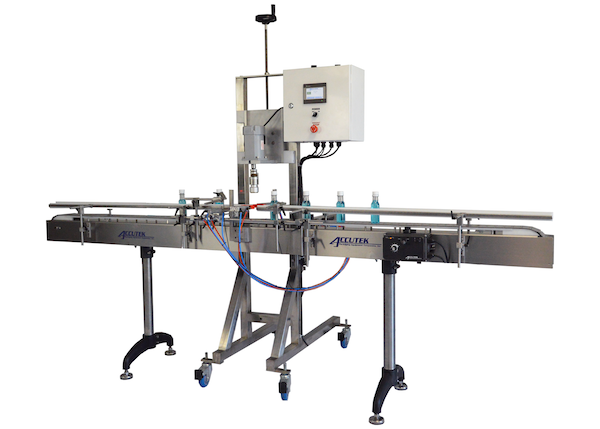

(Source: accutekpackaging.com)

Rotary chuck capper- has multiple heads to screw the caps onto bottles. This unit works more quickly for bigger industries or faster production.

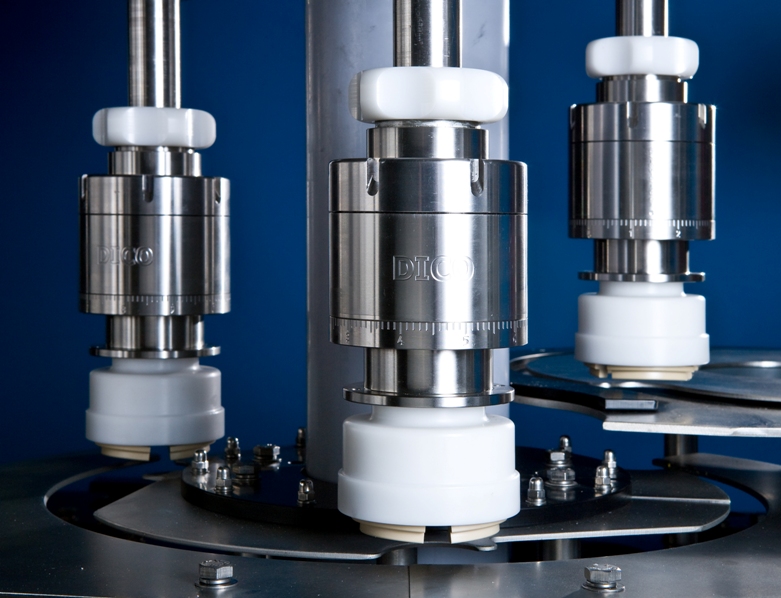

(Source: bpdm.com)

Choosing the right Chuck Capper for you

Which one should you use?

The difference between these two types of chuck cappers is the speed, where rotary chuck cappers are for faster production lines and inline chuck cappers are for slower lines. The output of your production will require what kind of chuck capper will work best. Once you know the number of bottles that need to be capped per minute, you’ll know which machine will help you keep up with production. Whether you have a small production line, or an enormous production line to handle, these machines can help meet any capping needs.

How to know if the chuck capper is right for your product?

These machines work best if you’re primarily just running one cap size. This is a very technical and involved machine that requires extensive setup, so switching between cap sizes constantly isn’t going to be optimal for the best production. These sizes need to be precise because of the speed and timing at which this machine operates.

Chuck Cappers are very specific because unless you have the right capper that is tuned to work with your exact container, your exact cap, and the exact speed you want to run, the capper won’t work the way you need it to. So, in order to make this process easier, we will always work with our engineering services shop to ensure that the machine is set up specifically for your product’s specifications. It’s expensive and time-consuming to change the machine set up once the specs are tailored to your product, so you will want to make sure that the machine is set up to how you desire. Setting up your machine correctly the first time will maximize your production and minimize modifications, which means delays.

What you need to know about your product before buying a machine?

In almost every case, the type and model of machine you need isn’t purely dependent on the speed you want to run and the size of the machine itself. The product that you’re running is extremely important to the process as well. That’s why before reaching out to buy a machine, it’s helpful to know the in’s and out’s of your product. We’ve listed some of the questions that are important to know in the case of Chuck cappers:

-

- Is it childproof?

- What is the cap size?

- What is the container’s height and diameter: its dimensions?

- What kind of speed do you need?

- How many bottles per minute are you looking to run?

- In addition, what kind of cap do you need for your product?

- Another thing to ask is how are the caps being fit onto your product?

- How are you getting the cap to your container?

- Do you have a waterfall, conveyor, etc?

- What does your production look like upstream and downstream?

- What is the torque?

- How tight do you need the cap to be placed?

We recommend that you send us samples of your product so that we know exactly what we're working with. In most instances, chuck cappers will be used in the food industry, so a majority of the time the production line will need an induction sealer or use a cap with an induction seal inside. When working with food there is no room for error. Another industry that chuck cappers are used in is pharmaceuticals, which is also a sector where room for error is extremely low.

That’s why the consistency and seals that these chuck cappers provide are essential for the quality control of your products. Chuck cappers can be used on a variety of products outside of the food industry as well. This means they will be used with a variety of caps. This includes glass bottle caps, chemical bucket cover types, needle cover caps, medicine bottle caps, nail polish caps, and numerous others. Each cap is individual to both the type of product and the bottle that you’re using.

-

Chuck Capper vs. Spindle Capper

Why choose a chuck sealer over a spindle capper? If you are running multiple products and need some more flexibility rather than accuracy, a spindle capper will be the right machine for you. If you have a smaller output, a spindle capper will work just fine. However, if you’re looking to produce an output of around 400-500 bottles per minute, you will need to use a chuck capper.

Disclaimer: While only utilizing one size for caps on production lines is usually the most efficient, this may not be the case for every customer. The Flex Chuck pictured (Figure 1.2) is useful for companies that are utilizing multiple cap sizes on one production line. This allows for customers to switch between a few sizes without having to switch chucks.

For Chuck Cappers available for purchase or to learn more, contact the SIGMA Sales team or visit us here: