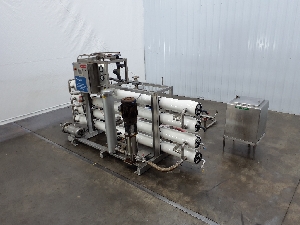

Description

Used MECO BES3000MSS Bottled Water Distiller with:

- Application: distillation using the process of vapor compression to produce distilled water. In this method, de-ionized or softened water (referred to as feedwater) is boiled inside the tubes of a vertical shell-and-tube heat exchanger called an “evaporator”. The boiling water rises to the top of the tube bundle where steam is released. The steam passes through a demister in the evaporator dome to remove any water droplets before entering the suction side of the compressor. The vapor compressor increases the pressure of the steam and discharges the steam down into the steam chest, which is the shell side of the vertical heat exchanger called the “calandria”. In the steam chest, or calandria, the compressed steam passes around the outside of the evaporator tubes and gives up its latent heat to the tubes and the water inside which causes boiling. As the latent heat is transferred, the steam condenses and becomes distillate. This distillate accumulates in the bottom of the calandria and is removed by the distillate pump. A portion of the feedwater in the bottom of the evaporator is removed and discharged to waste to control the rate of concentration in the evaporator. This discharge is referred to as blowdown. The entire process is continuous, and therefore requires a constant supply of feedwater and steam for heat input.

- Evaporator: Vertical tube type, with internal downcomer. All welded areas constructed of 316L SST.

- Distillate Piping: Sanitary type, 316L SST

- Feedwater & Blowdown Piping: Sanitary type, 316L SST tubing with polished ID.

- Heat Exchangers: Sanitary shell-and-tube type, double tubesheet, constructed of 316 & 316L SST

- Immersion Heater: Make up steam tank constructed of 304LSST.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.