Description

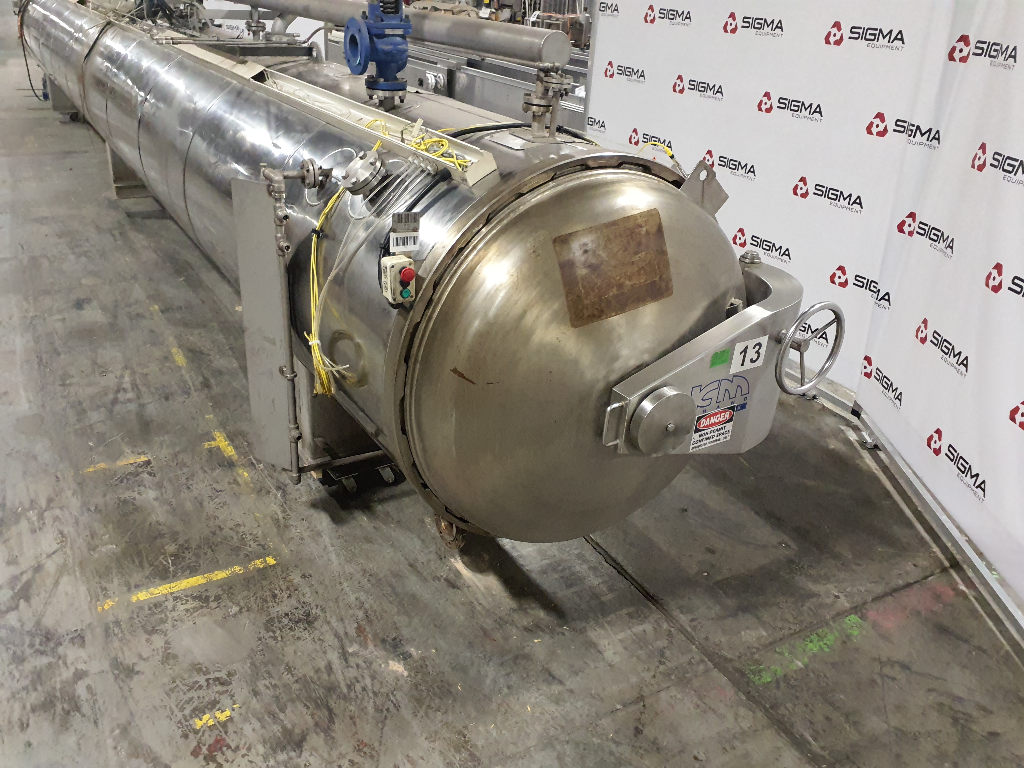

The KM Grandpack 12 Basket Static Steam Retort with Manual Loading is a high-performance, reliable solution for food processing and preservation. Designed for optimal heat distribution and consistent results, this retort ensures product quality while maximizing operational efficiency. With a manual loading system, it offers flexibility and ease of use, making it an ideal choice for medium to large-scale production. Built with durable materials and advanced technology, the Grandpack 12 provides excellent value for businesses seeking a cost-effective and dependable retort to meet their steam sterilization needs.

Used KM Grand Pack Retort with:

- Style:

- Static

- Steam

- Capacity: 12 baskets

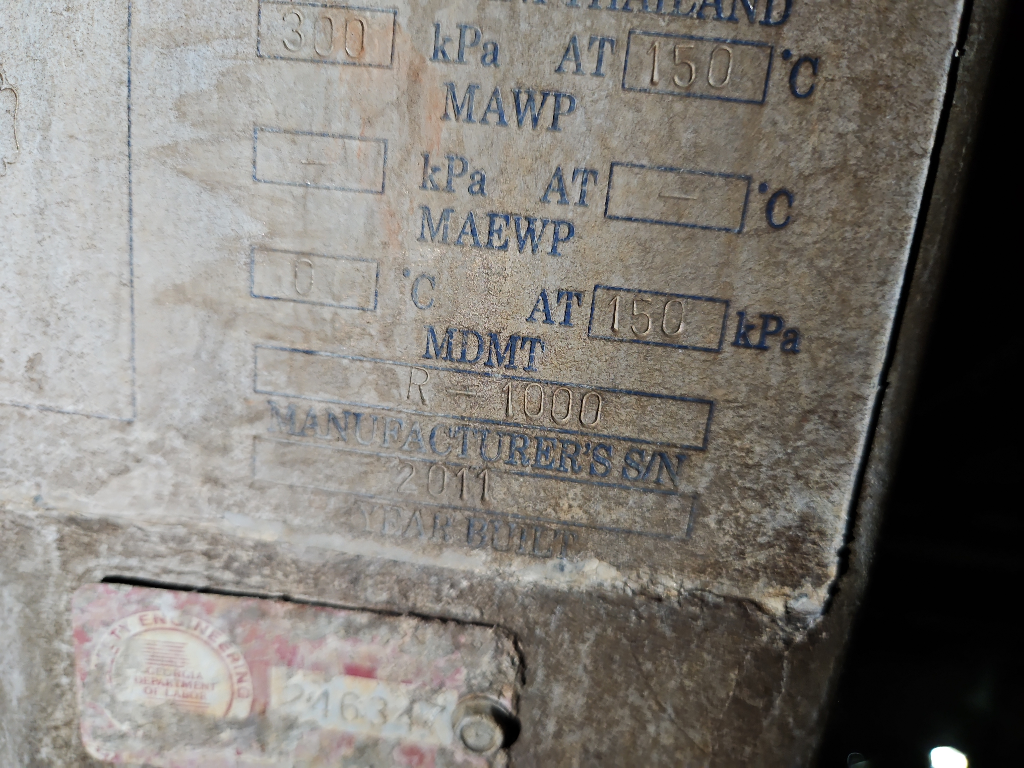

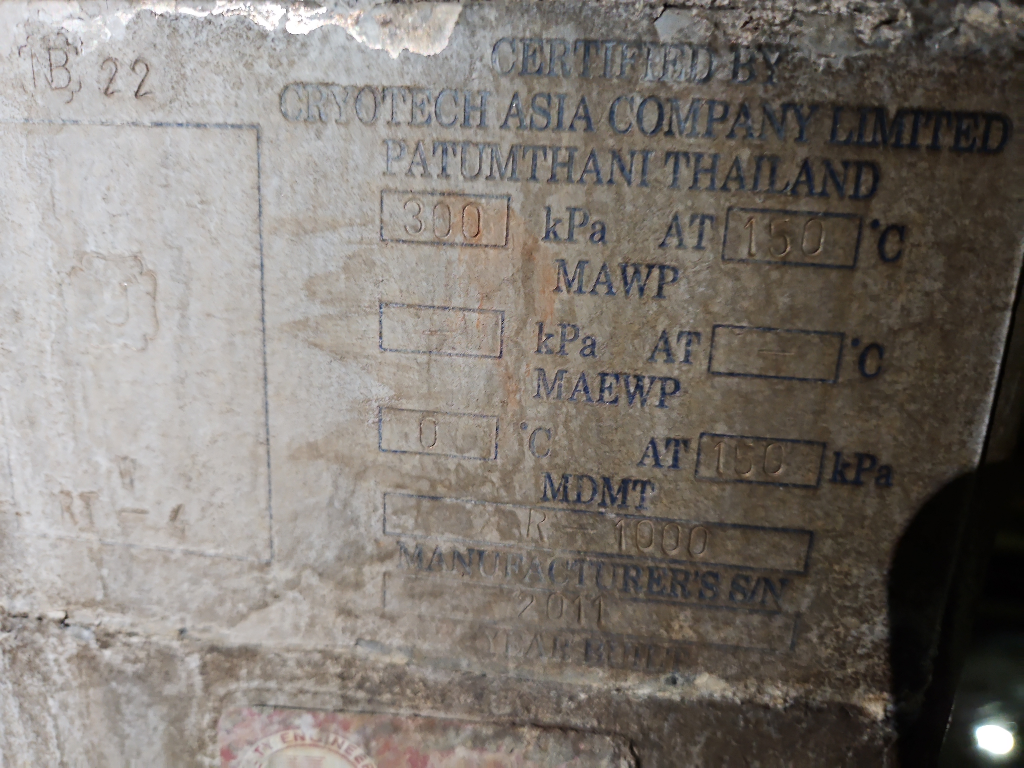

- Pressure rating:

- MAWP: 43.5 PSI at 302° F (300 kPa at 150° C)

- MDMT: 32° F at 43.5 PSI (0° C at 300 kPa)

- Basket dimensions (inches):

- Length: 40

- Width: 32

- Height: 27.5

- Chamber dimensions:

- Length: 41 feet

- Diameter: 48 inches

- Overall dimensions:

- Length: 44 feet

- Width: 54 inches

- Height: 54 inches

- Infeed:

- 2 Doors, Manual Swing Door

- Basket “Roller” rails with double stainless steel chain no. 80 and gear motor drive 3.0 HP for basket loading/unloading

- Double door locking system for safety once vessel has pressure inside

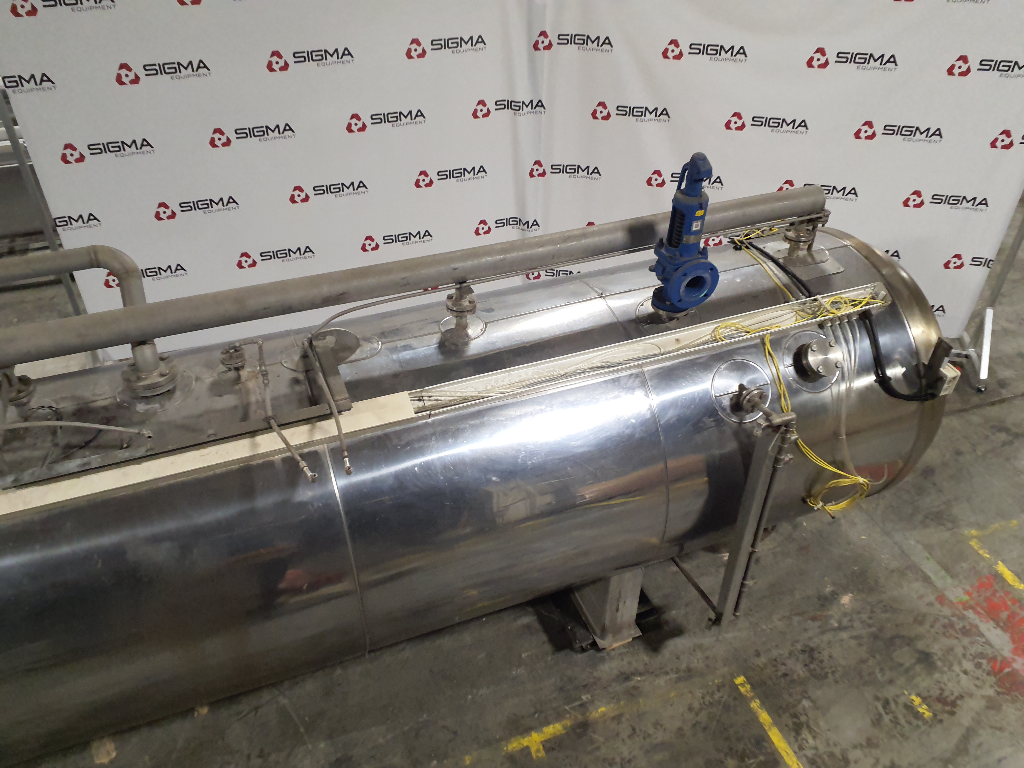

- Insulation: Thermal insulation 50 mm thick by rockwool 80K and mirror polished stainless steel cladding 0.7 mm thick.

- Block and bleed valves for air and water

- Sight glass with sensors for water level control

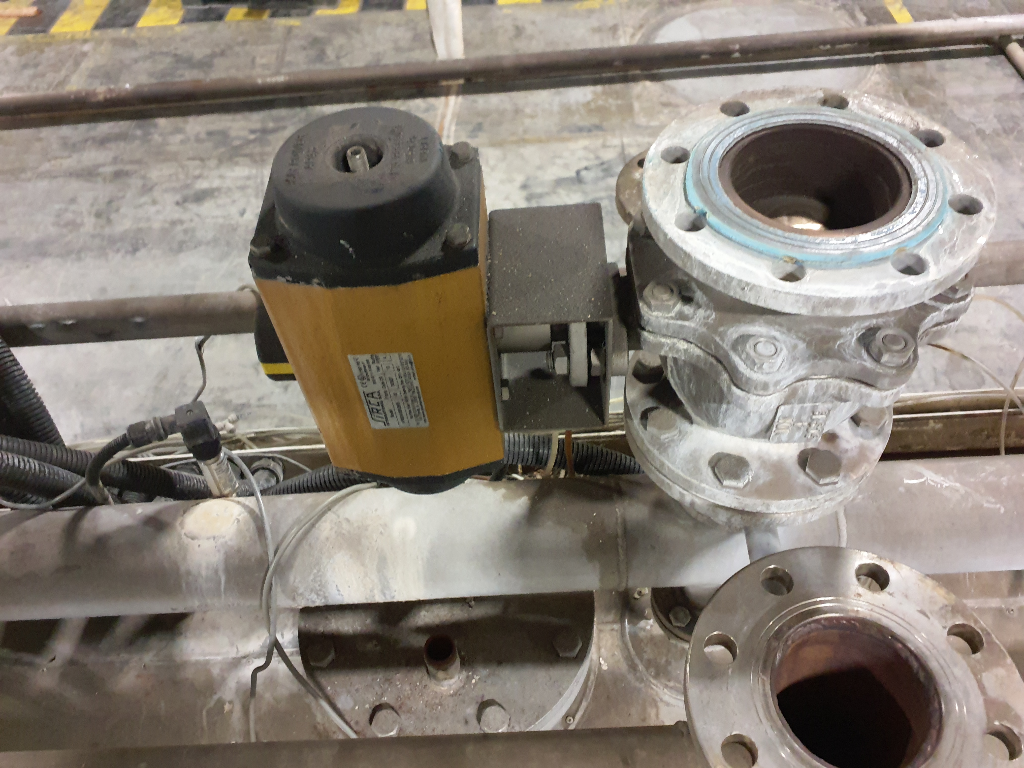

- Steam valve: brand "Spirax Sarco", type LE33 with body in cast iron

- Compressed Air Valve: brand "OMAL"

- Safety Valve: Brand "ARI" x 2 set (ASME U-stamp)

- Pressure Gauge: pressure guage in stainless steel cage 0-6 Bars

- Vessel Pressure Sensor: brand "ESI" Model "GS4200"

- MIG Thermometer: brand "Taylor" ,Scale 75-135 C.

- Digital Thermometer: brand "Wahl" online

- Circular Chart Recorder: brand "Honeywell" Model "DR4500AT" , with 1 pen for temperature recording

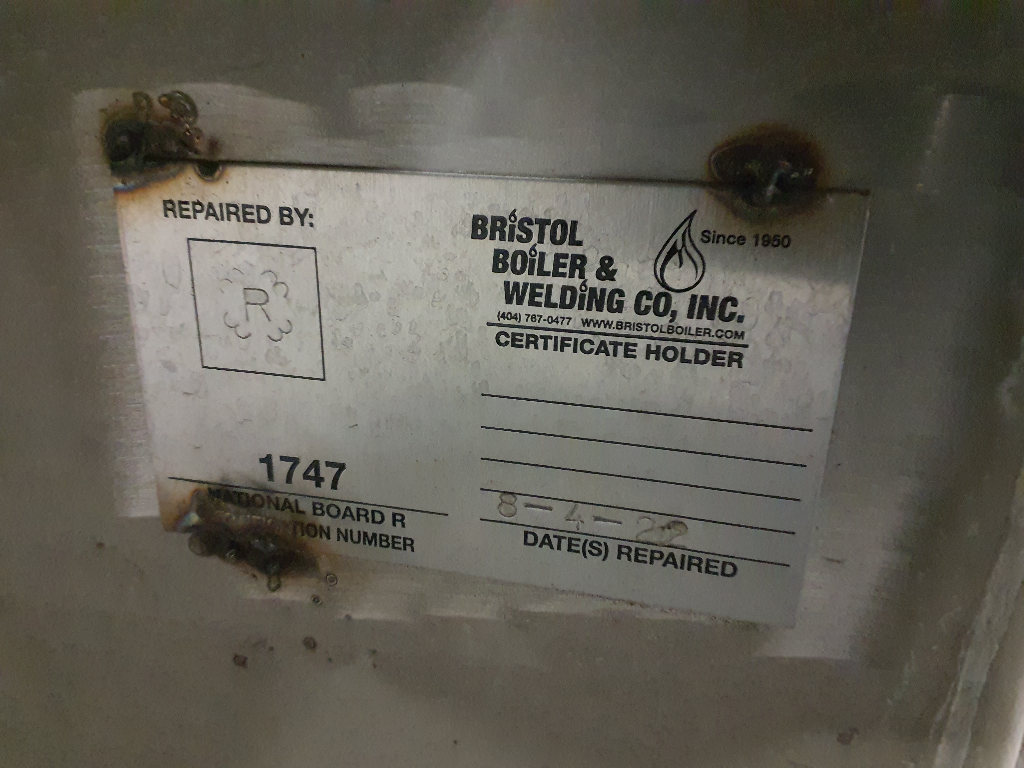

- ASME: ASME U-Stamp Certificate with National Board No. Registration to meet pressure vessel regulation in GA including engineering, manufacturing, testing, Inspection to ASME Section VIII, Division I, Edition 2021.

- Control system: Allen Bradley programmable logical controller (PLC) Model Micrologix 1400 for fully automatic operation

- Construction: stainless steel SUS 304 6mm thick

- Electrical:

- Electrical:

- Operating requirements: 3 phase, 60 hertz, 480 volts

- Control voltage: 120 volts (transformer included in control panel)

- Signal voltage: 24vdc (power supply included in control panel)

Last application: Tuna cans at a 5, 7, and 12 ounce weight. Typically cycle was 2 hours and 45 minutes. 4 pound product was also ran on this a 5 + hour cycle.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.