Description

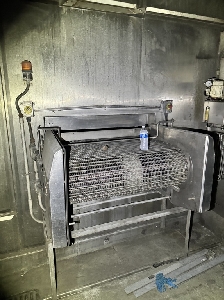

Used Frigoscandia GYRoCOMPACT GCM10TC/3 08-34-36 NS CCR Spiral Freezer with:

- Spiral stack:

- Conveyor dimensions:

- Width: 42 inches

- Active belt length: 1,115 feet

- Number of tiers: 34

- Active belt area: 3657 square feet

- Maximum product clearance: 2.375 inches

- Link height: 800 millimeters

- Counter current vertical air flow

- Counter clockwise rotation

- Conveyor dimensions:

- Evaporator and Fans:

- Stainless steel evaporator stand

- Stainless steel tube/aluminum fin evaporator

- Refrigeration requirement: 105 tons at -40°F

- Nominal coil rating: 190 TR

- LVS refrigerant feed system

- Ammonia refrigerant

- Hot gas and/or water defrost

- Aluminum fan blades housed in stainless steel frames

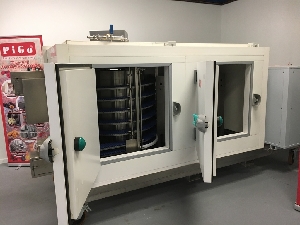

- Enclosure, Floors, and Decking:

- Stainless steel modular floor

- Polystyrene floor insulation

- Electric floor heating cable

- Stainless steel plenum and aluminum mezzanine

- Level 1 caulked enclosure

- 4 inch thick polyisocyanurate walls

- Plug door for fan motor removal

- LED lighting package

- Stainless interior and white enamel exterior

- Overall dimensions:

- Length: 36 feet 9 inches

- Width: 15 feet 9 inches

- Height: 15 feet 1-1/8 inches

- Infeed elevation: 2 feet 5-3/8 inches

- Outfeed elevation: 12 feet 4-3/45 inches

- Controls:

- Touchscreen control panel

- NEMA 4X stainless steel enclosure

- Allen Bradley PanelView 1000 Plus HDMI

- Allen Bradley Powerflex 525 VFD for drives

- Allen Bradley PLC with (2) ethernet ports

- Touchscreen control panel

- Auxiliary:

- Product height limiter with sensor

- Fan driven air balance tunnel

- Automatic air balance control

- Stainless steel site built floor

- Clean-in-place system/standard duty

- Satellite cleaning system

- Extended infeed with belt defroster

- Air defrost system with air dryer and receiver

- Plug door for fan motor removal

- Product and project specific inclusions:

- Stainless steel main fan motors

- Stainless steel outfeed motor, belt dryer, and air balance motors

- Moving access door

- VFD's for each fan with manual bypass capability

- Sloped top on control panel, pneumatic panel, and CIP cabinet

- Alternative mezzanine hatch

- Additional CIP circuits

- Solid UHMW rails where structurally possible

- Drip pan beneath belt dryer motor

- Tray for CIP chemicals

- Alternative scraper design with standoffs

- Additional clearance between outfeed motor and guarding/enclosure

- Additional door for access to clean between infeed and wall

- Air balance tunnel designed to eliminate rivets

- Guards upgraded for easy removal

- Relocate outfeed motor to allow for improved hygiene and clean ability

- Freezer Utility Requirements:

- Spiral conveyor, fans, evaporator and controls:

- Power: 61 kilowatts

- Potable water: 72 gallons per minute at 59°F, 45 psi

- Cleaning system:

- Power: 7.6 kilowatts

- Potable water: 26 gallon per minute at 140°F, 51 psi

- Air requirements: 16 square cubic feet per minute at 65 psi

- Air defrost system:

- 39 square cubic feet per minute at 101.5 psi

- 86°F pressure dewpoint

- Spiral conveyor, fans, evaporator and controls:

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.