Description

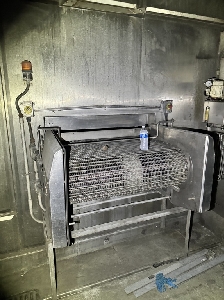

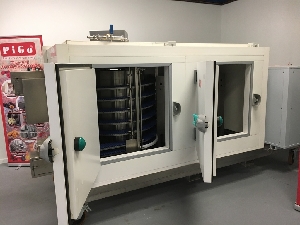

The Advanced spiral freezer is designed to freeze or chill delicate products such as meat patties, fish sticks, chicken parts, shrimp, prepared foods, etc., which could easily experience product damage problems. The spiral freezer is a continuous in-line-belt freezer designed to assure quality, gentle handling during the freezing process, and minimum weight loss of the product. Advanced's freezer is equipped with all stainless steel, heavy duty, spiral telescopic belting. The belt can be extended to change the pitch of the links. During operation, the extended belt approaches the rotating drum. One side of the belt telescopes in and causes it to turn around the rotating drum and travel upwards in a spiral. Thespiral freezer conveyor system is based on low tension over drive principle, which allows the belt to operate at low tension so as not to wear out the belt and achieve smooth operation. Products are fed directly from the production line onto the loading freezer belt. The belt quickly transports the product into the low temperature freezing zone; carrying it in a spiral along a rotating drum. When it reaches the top of the drum, the belt runs out of the freezer discharge port and gently discharges the product. Due to the large available belt surface, the product can be frozen in single layers or individually for I.Q.F. (Individually Quick Frozen) quality. The product can thus maintain its original load in shape & position throughout the freezing process.

- Low in high out operation

- Plastic mat top belting

- Infeed:

- Width: 28 inches

- Height: 43 inches

- Opening: 3.5 inches high

- Discharge:

- Width: 28 inches

- Height: 12.5 feet

- Opening: 3.5 inches high

- Infeed:

- 21 tiers

- Pitch: 5.5 inches

- Clearance: 3.5 inches

- Maximum product height: 2.5 inches

- Nitrogen freezing agent

- Automatic belt tensioner

- Clean in place center drum washer

- Belt washer manifold

- Variable frequency drive

- Electrical:

- Volts: 460

- Frequency: 60 Hz

- Phase 3

- Stainless steel construction

Overall dimensions (approximate): 30' L x 18.5' W x 16' H

Last running frozen meal tray:

- Output: 7500 pounds per hour

- Tray specs:

- Length 9.8 inches

- Width: 8.4 inches

- Height: 1.3 inches

- weighing 40 ounces

- Freezing retention time: 50 min

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.