Description

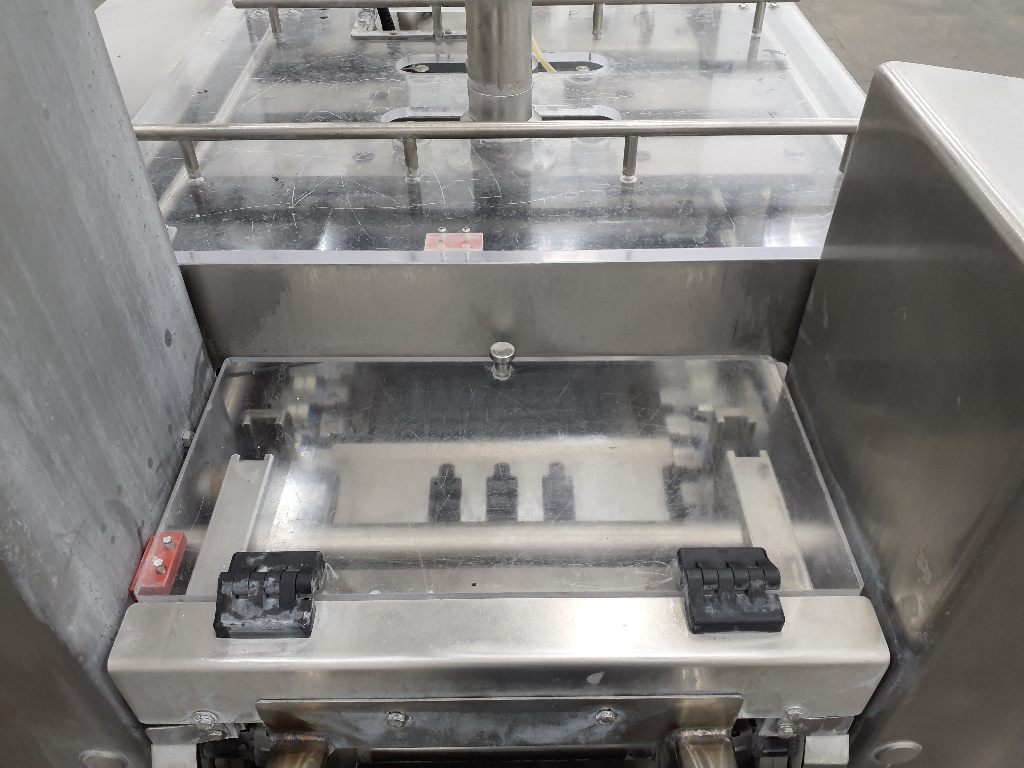

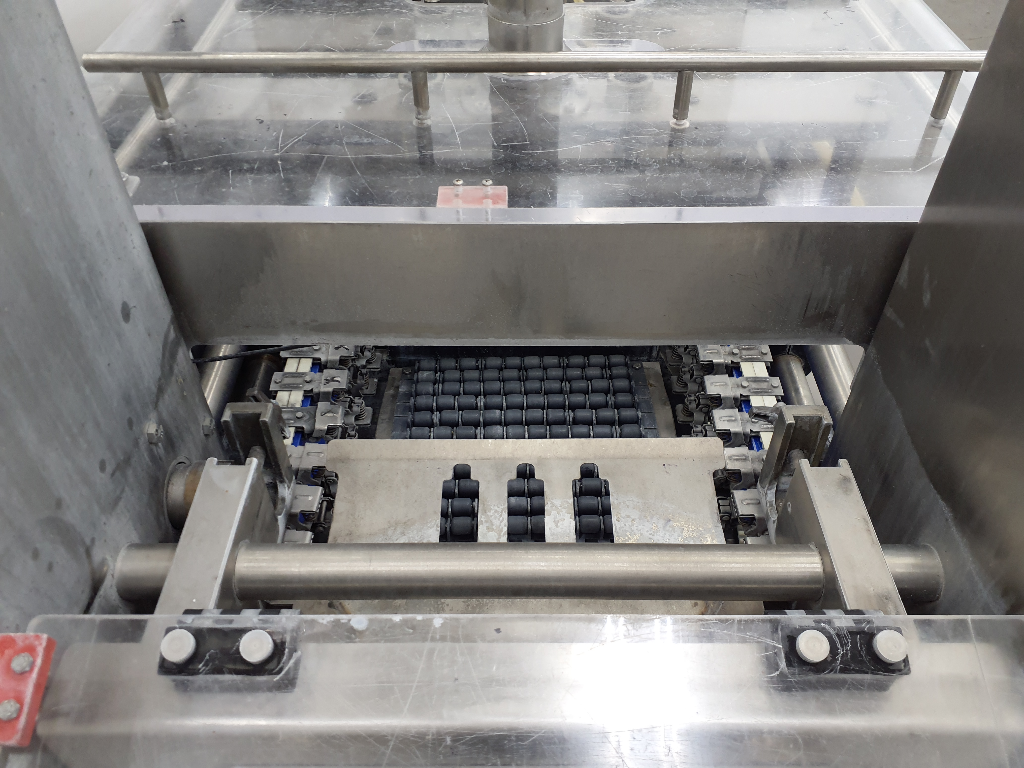

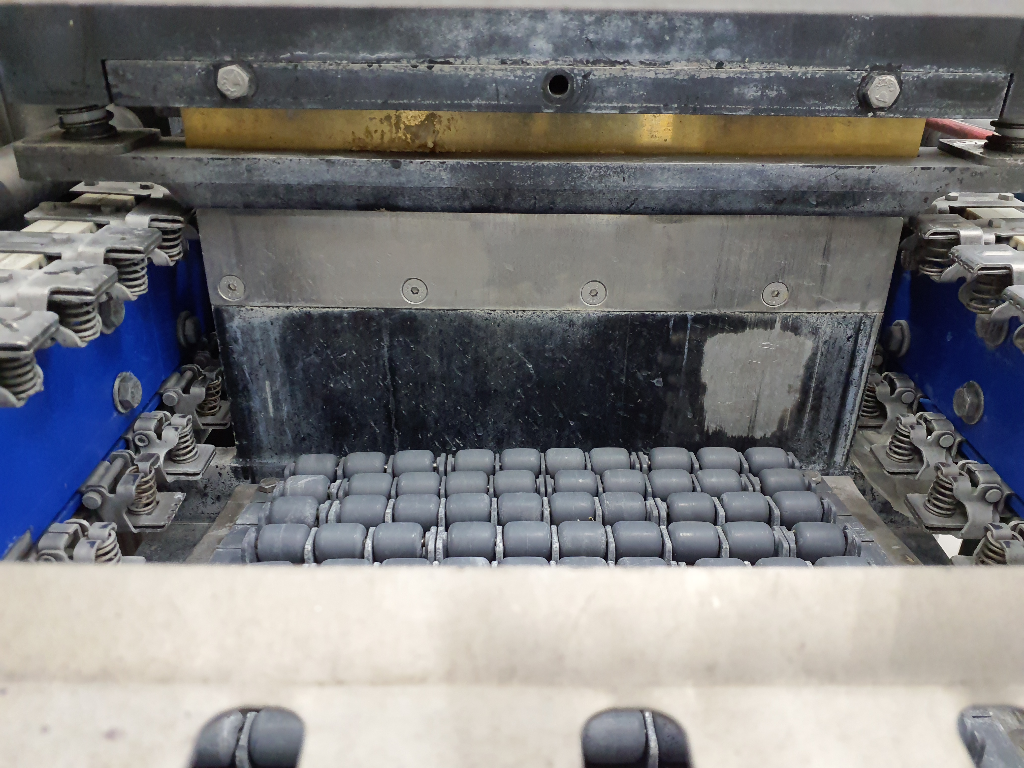

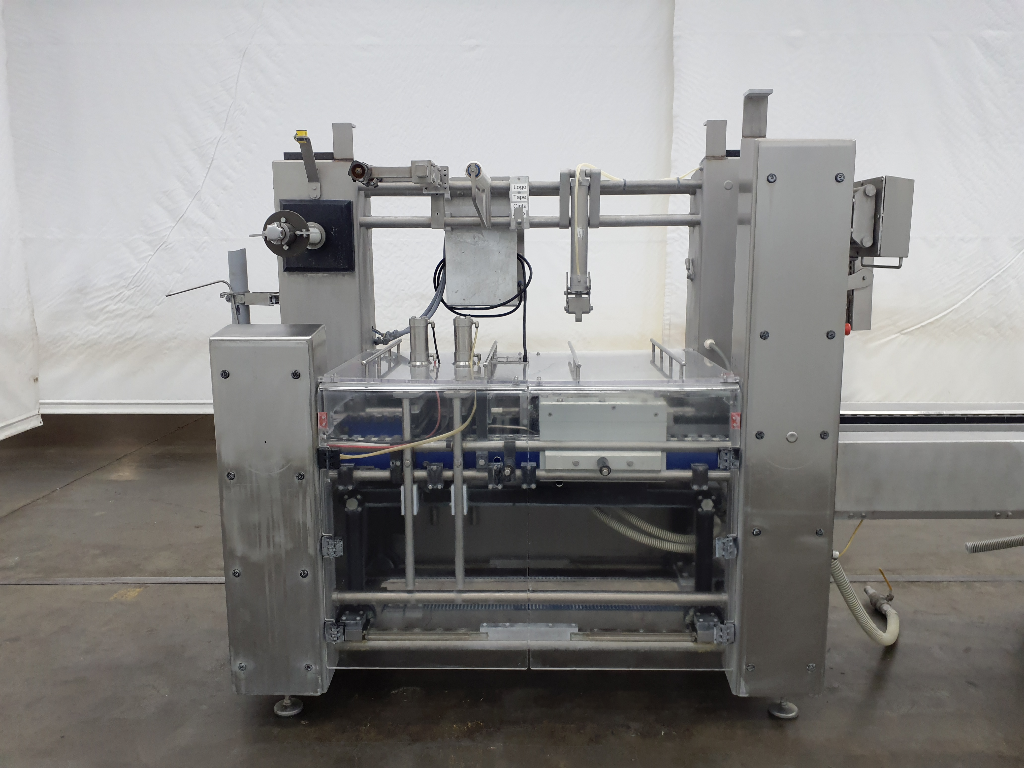

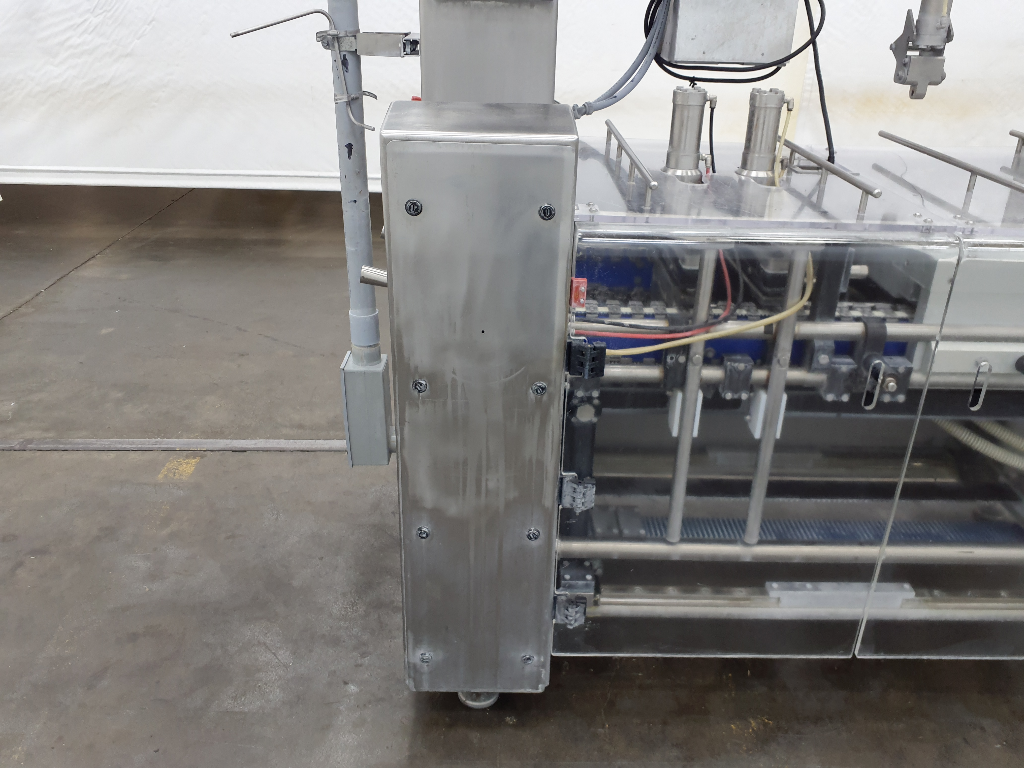

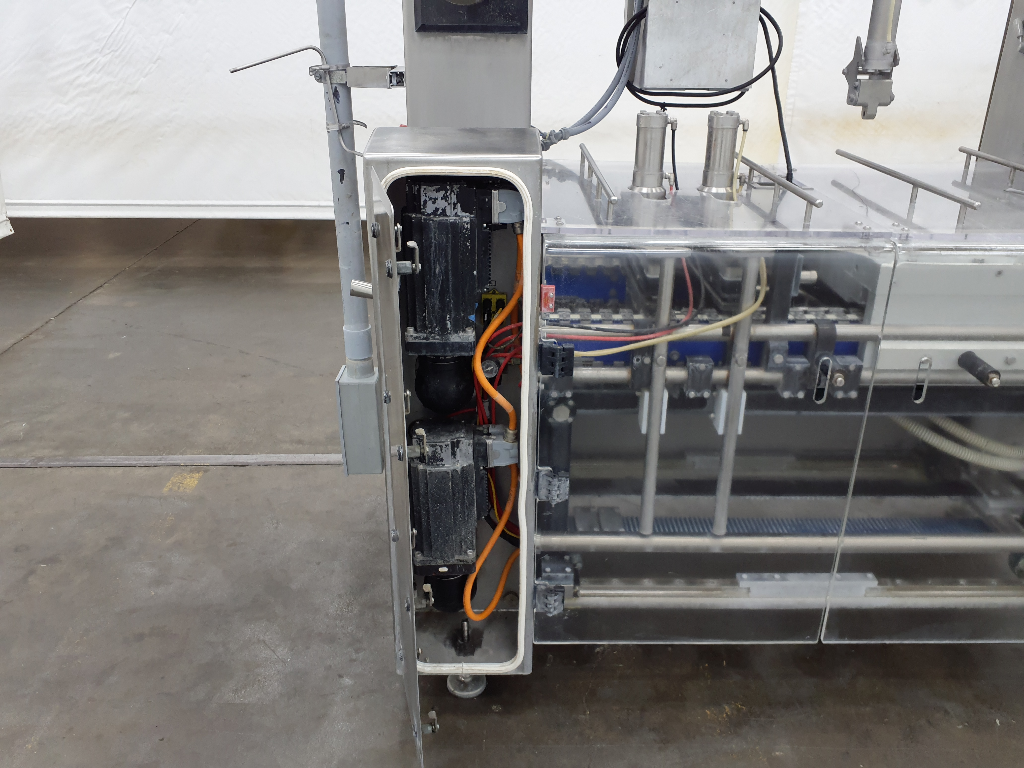

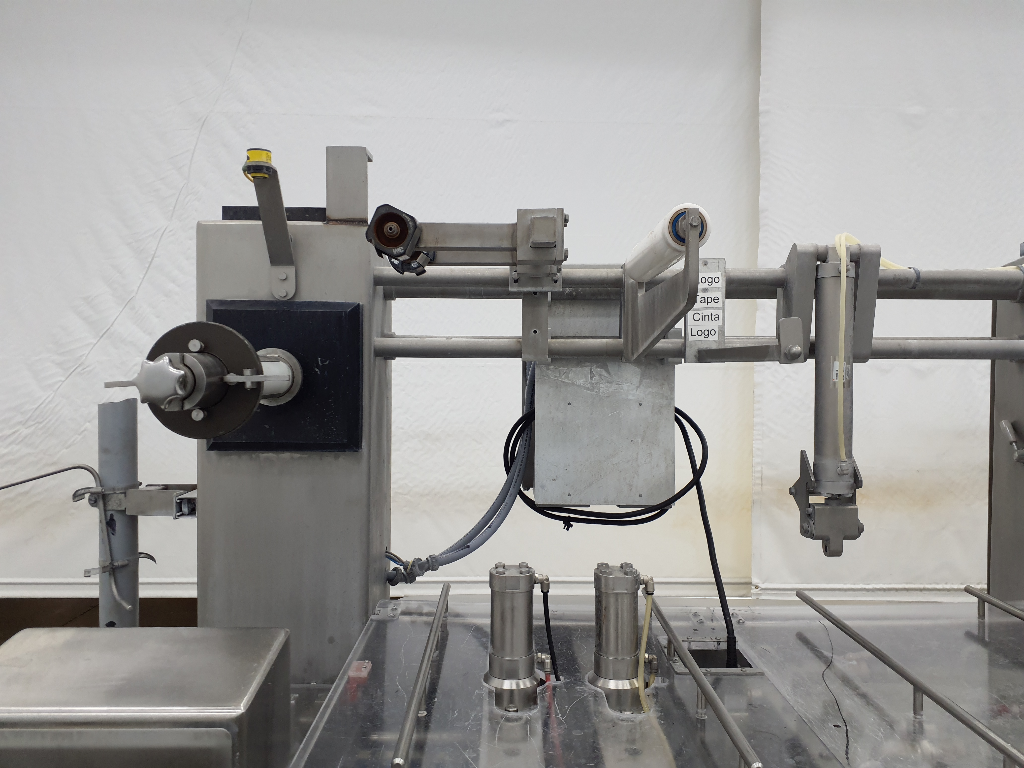

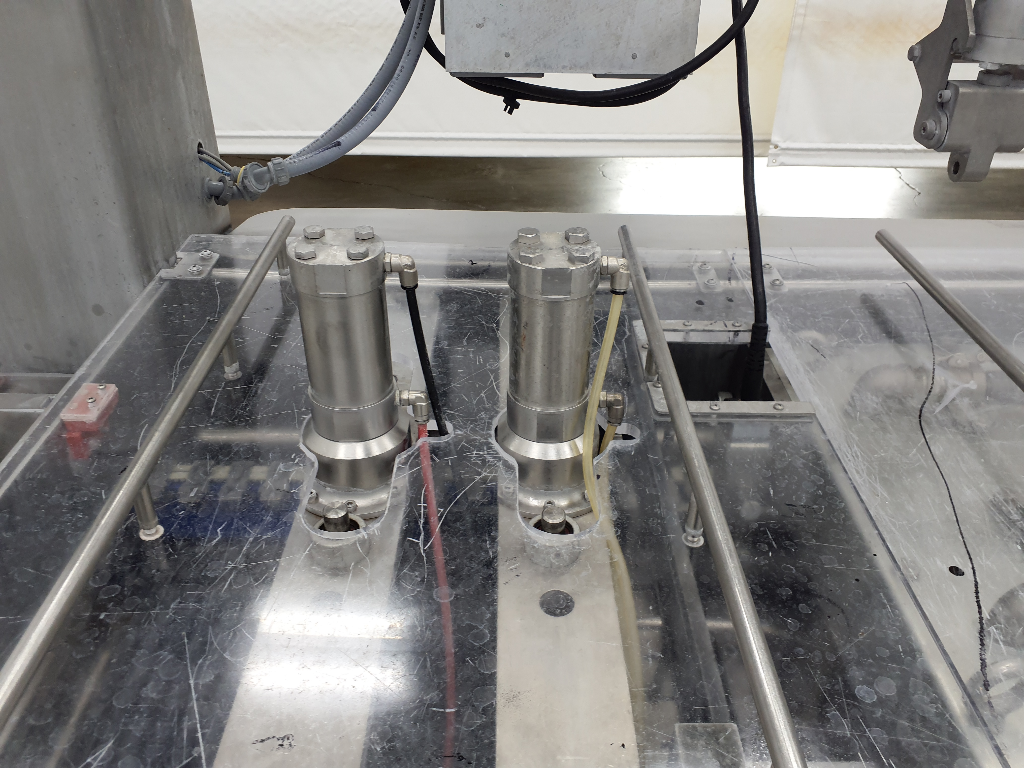

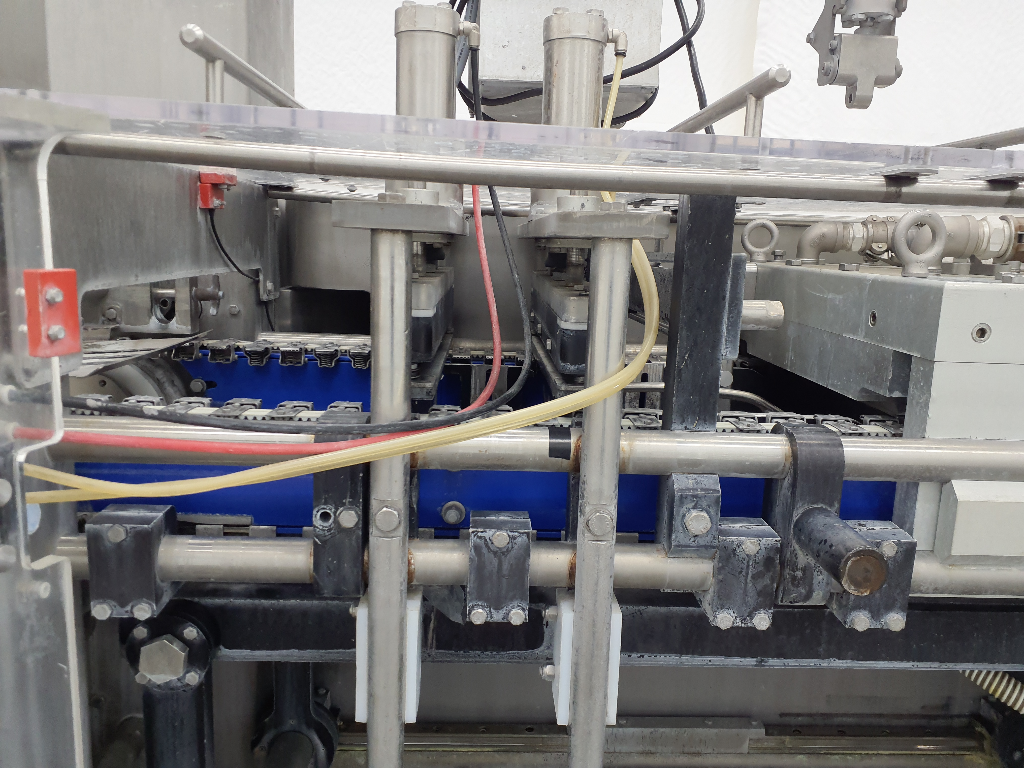

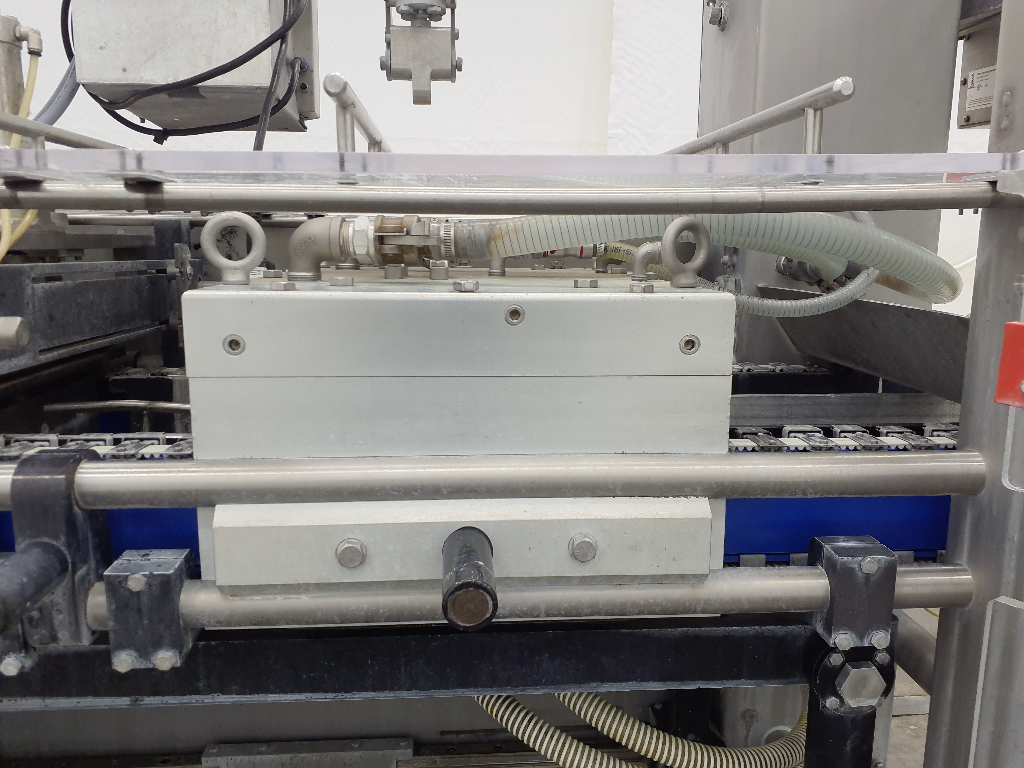

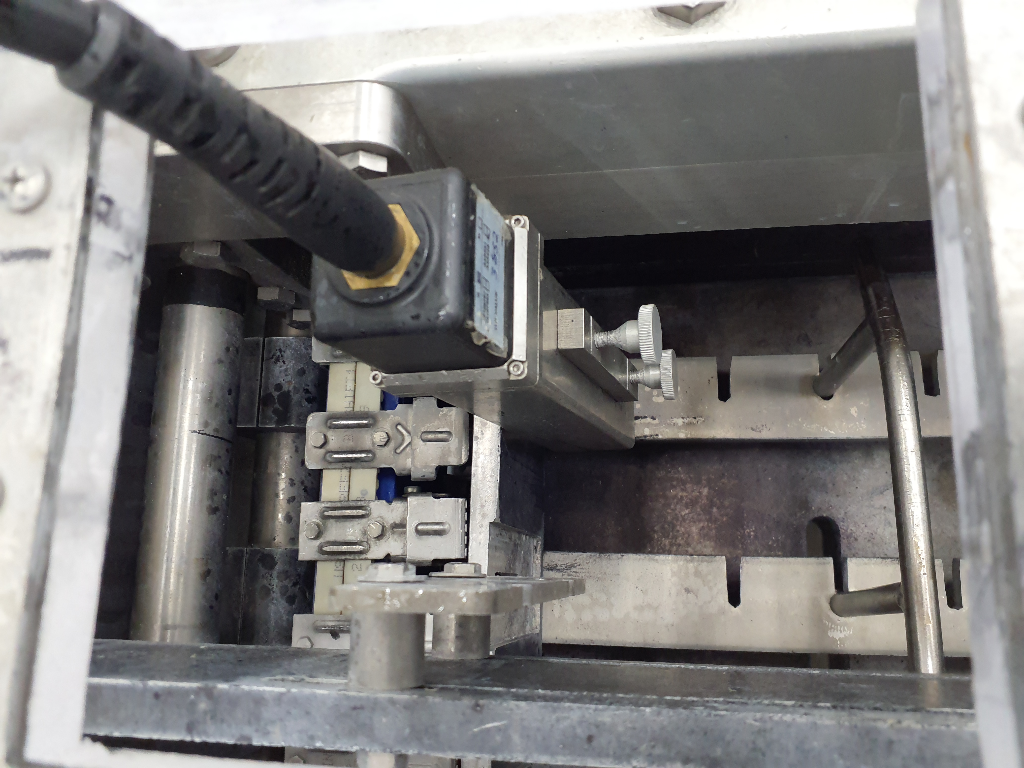

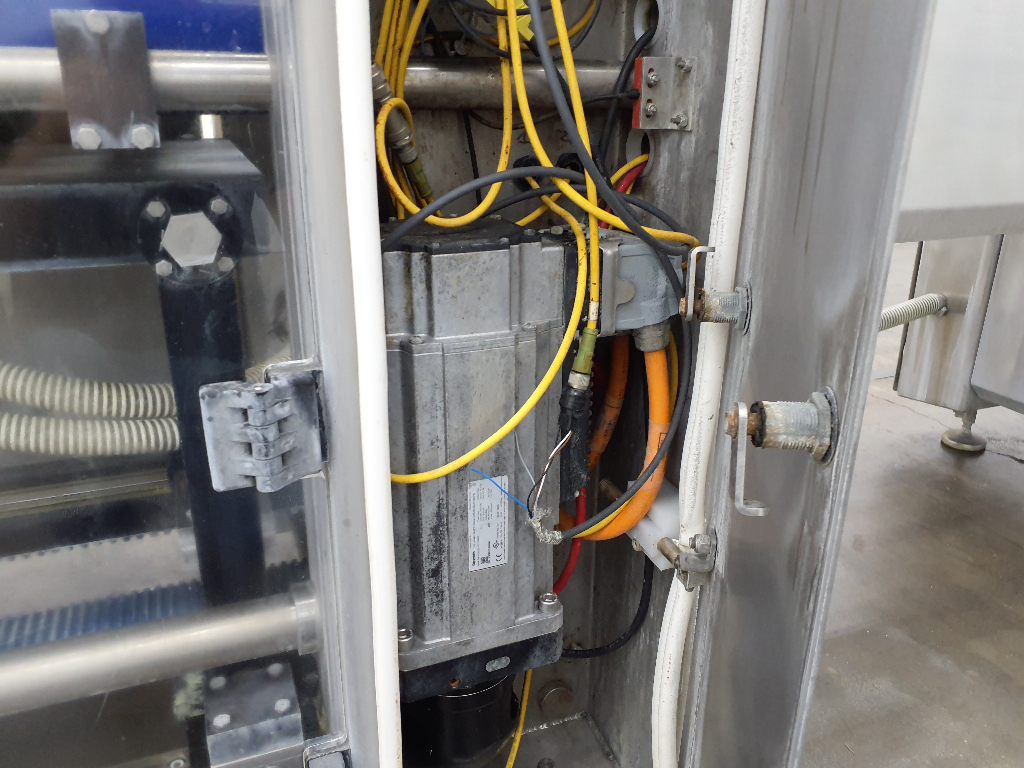

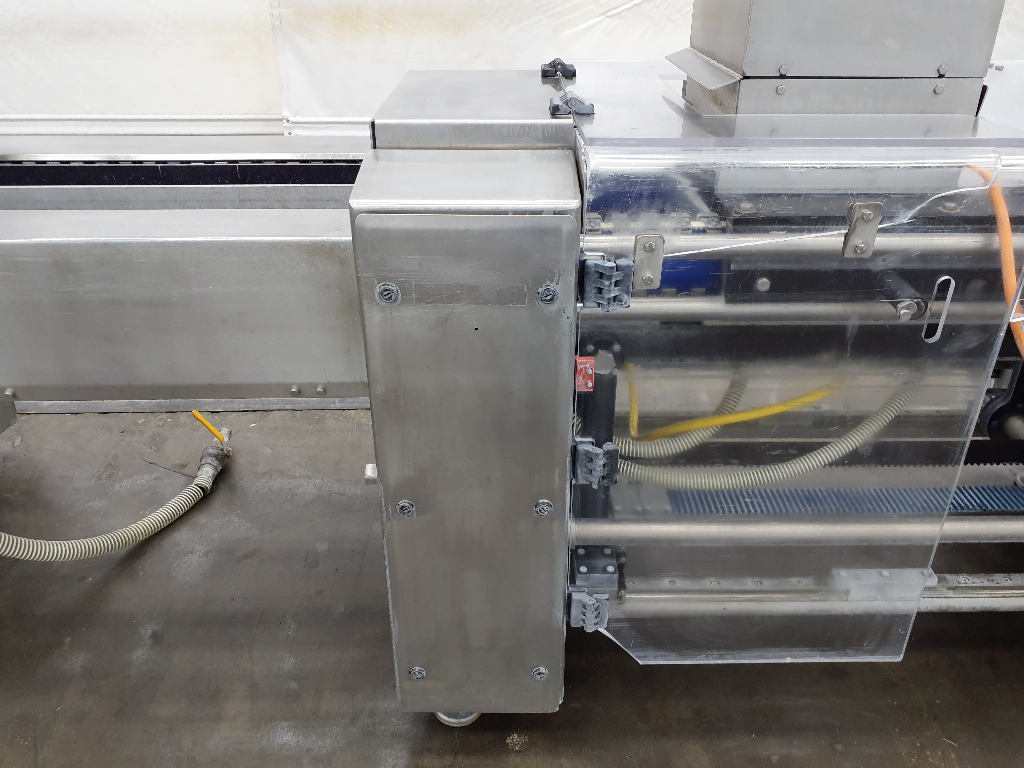

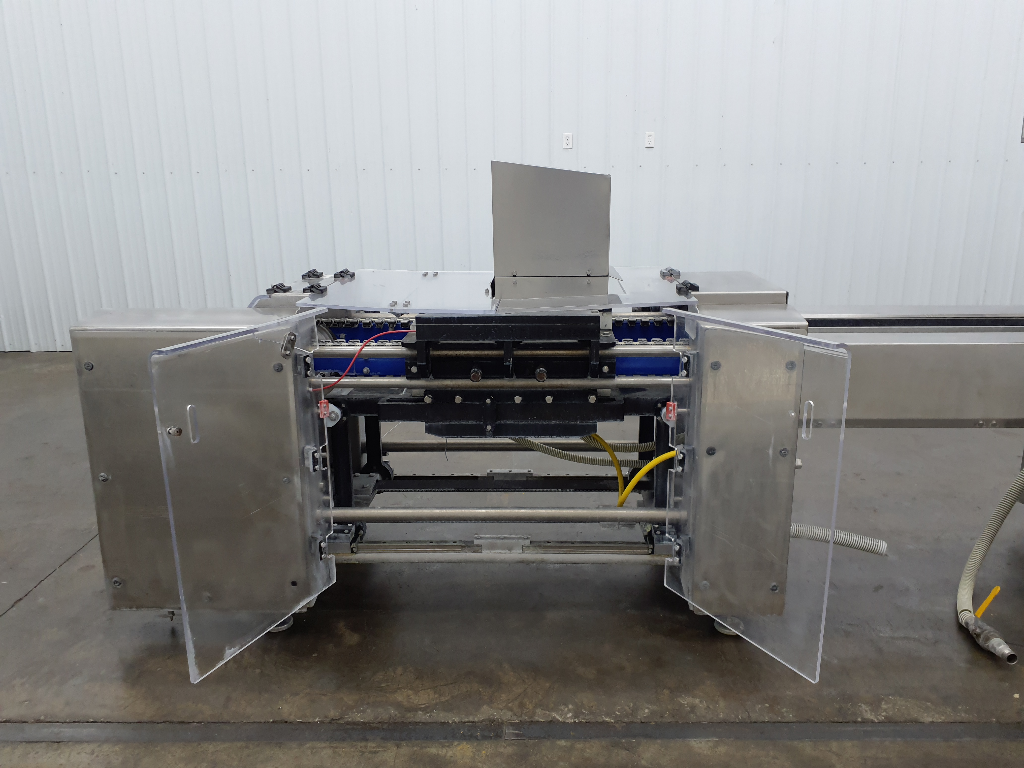

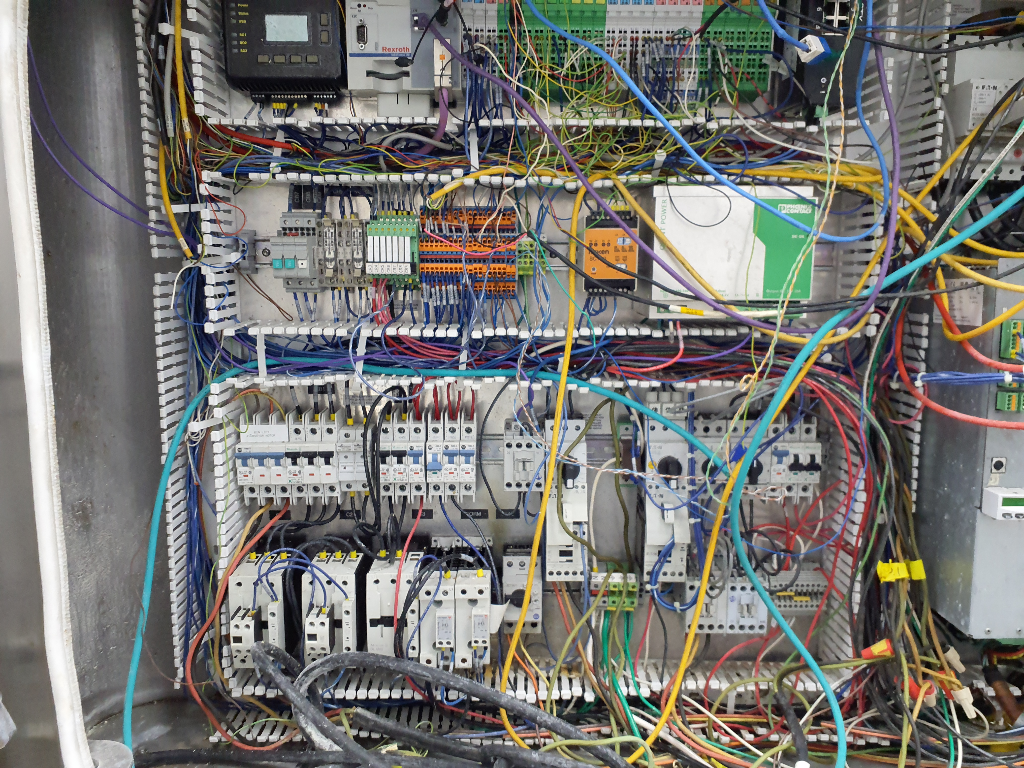

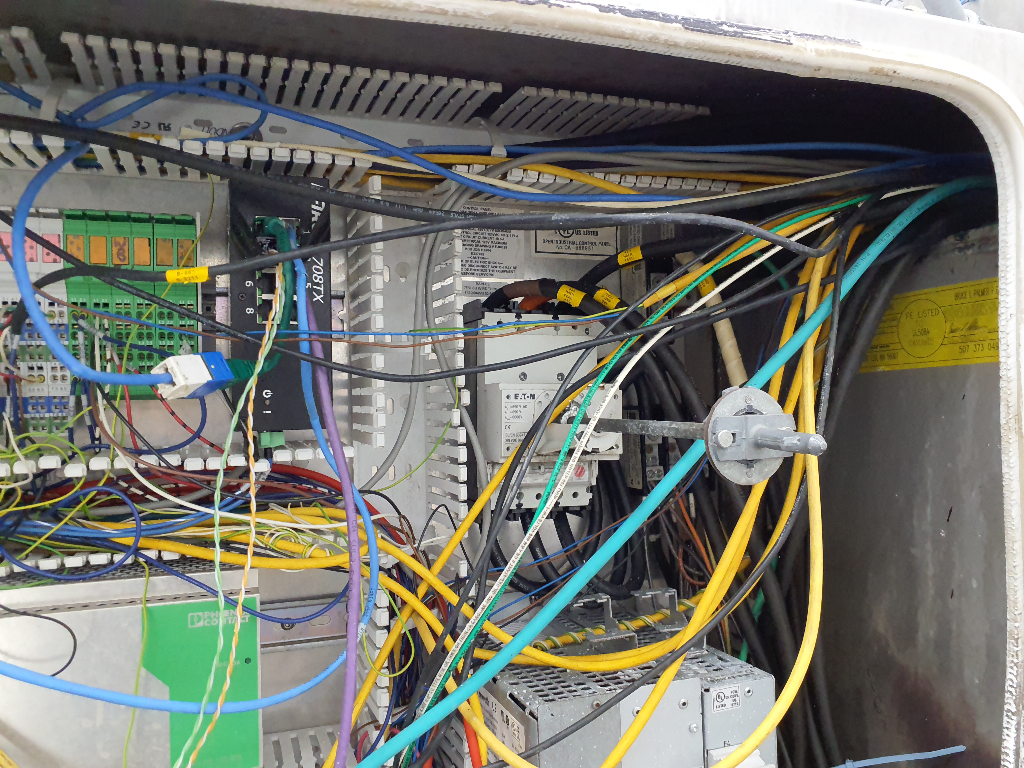

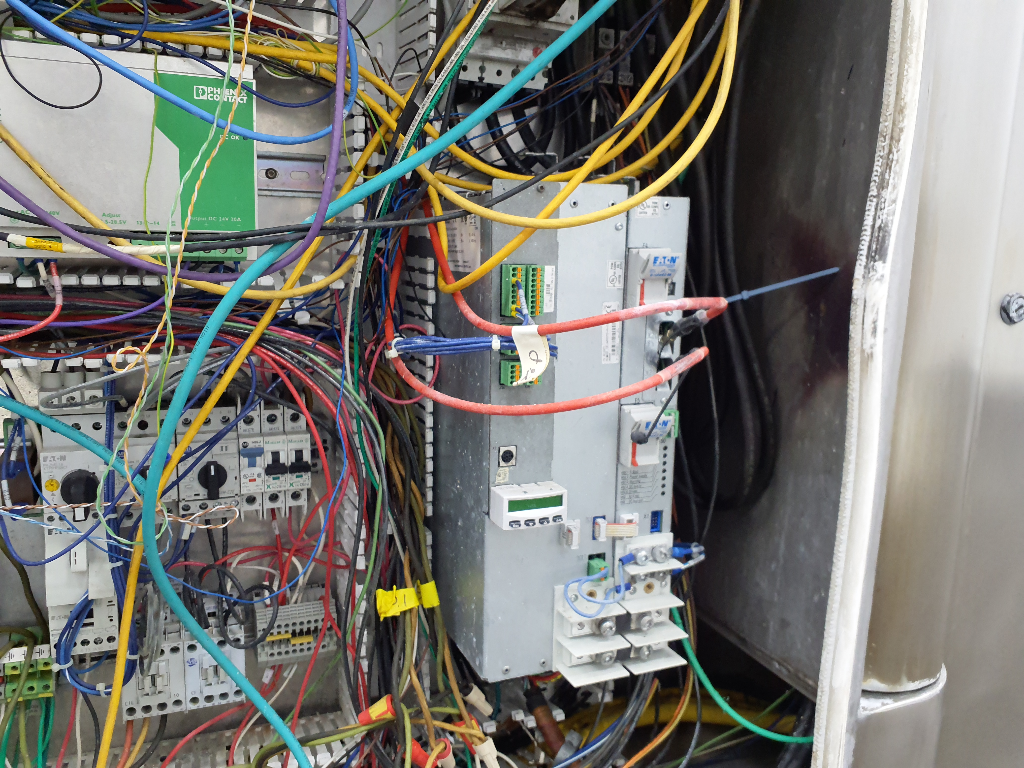

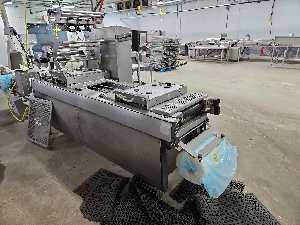

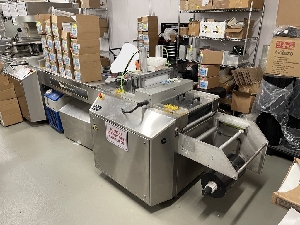

Used CP Packaging Gen 1 VisionPak Rollstock Thermoformer with:

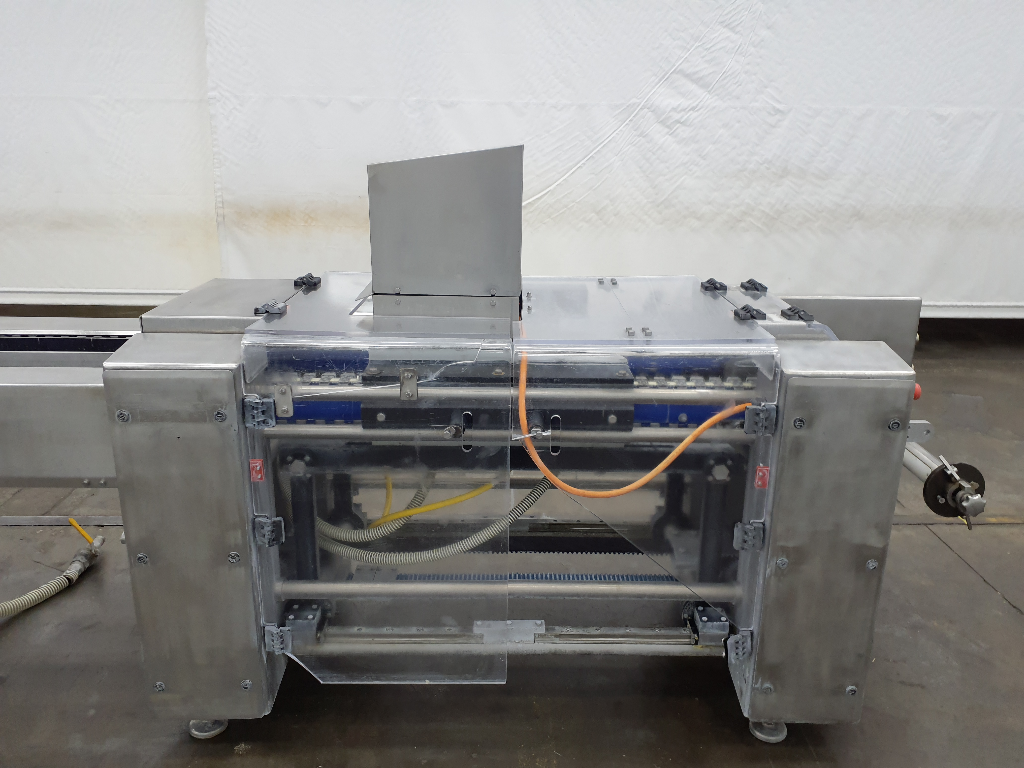

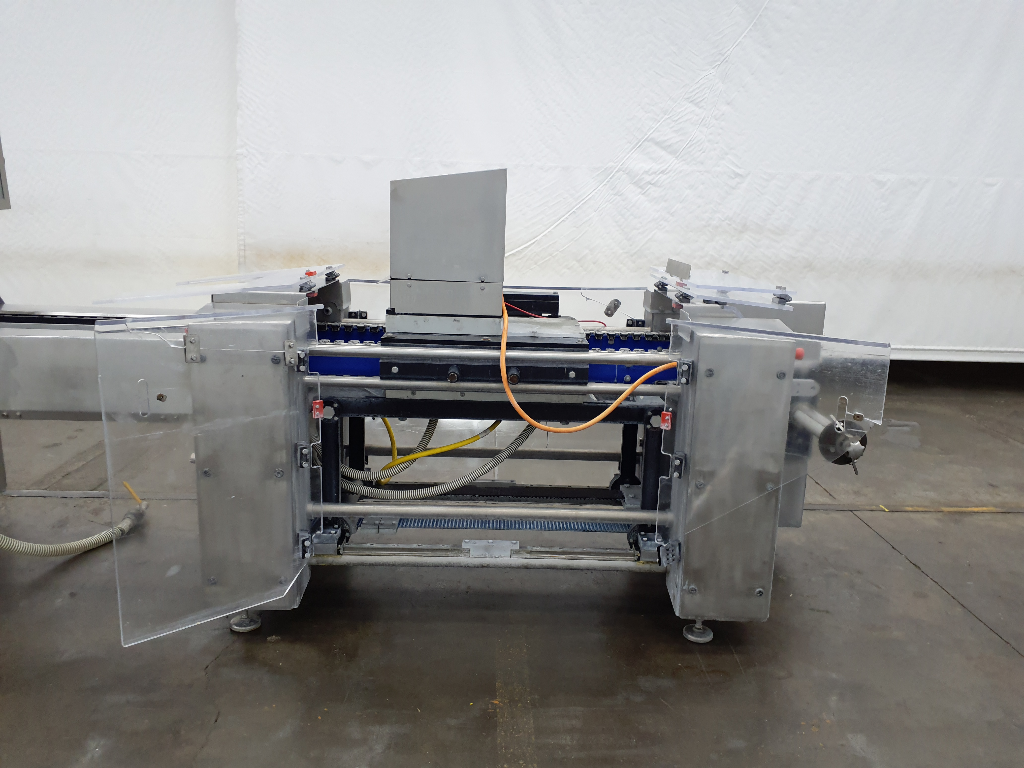

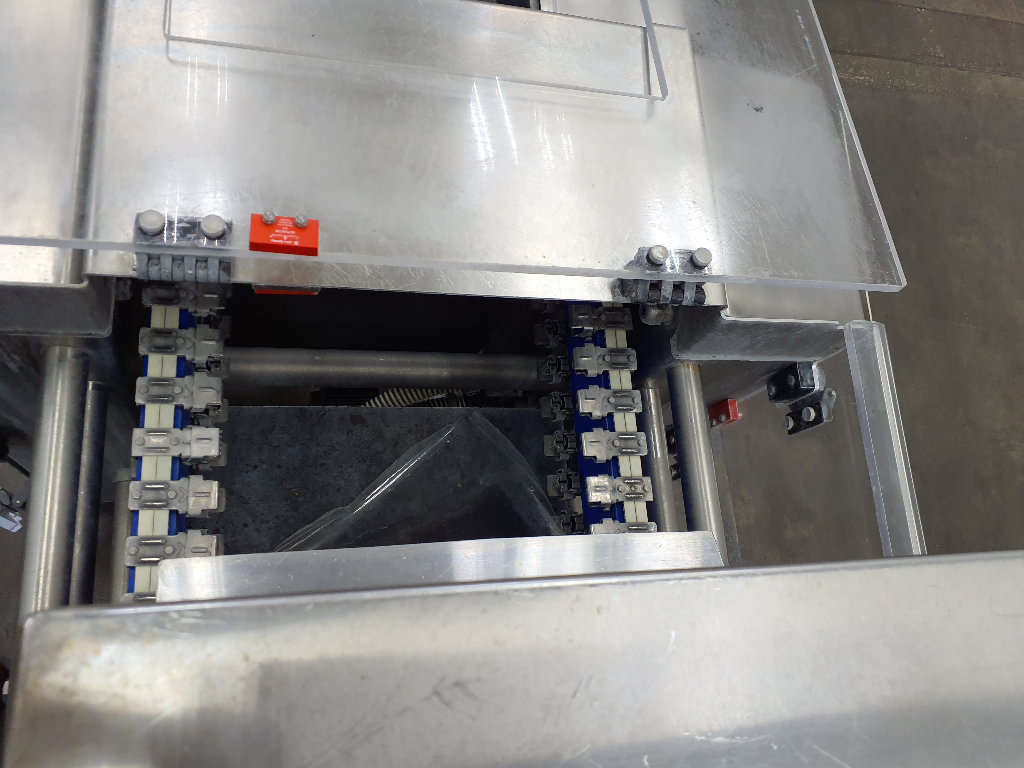

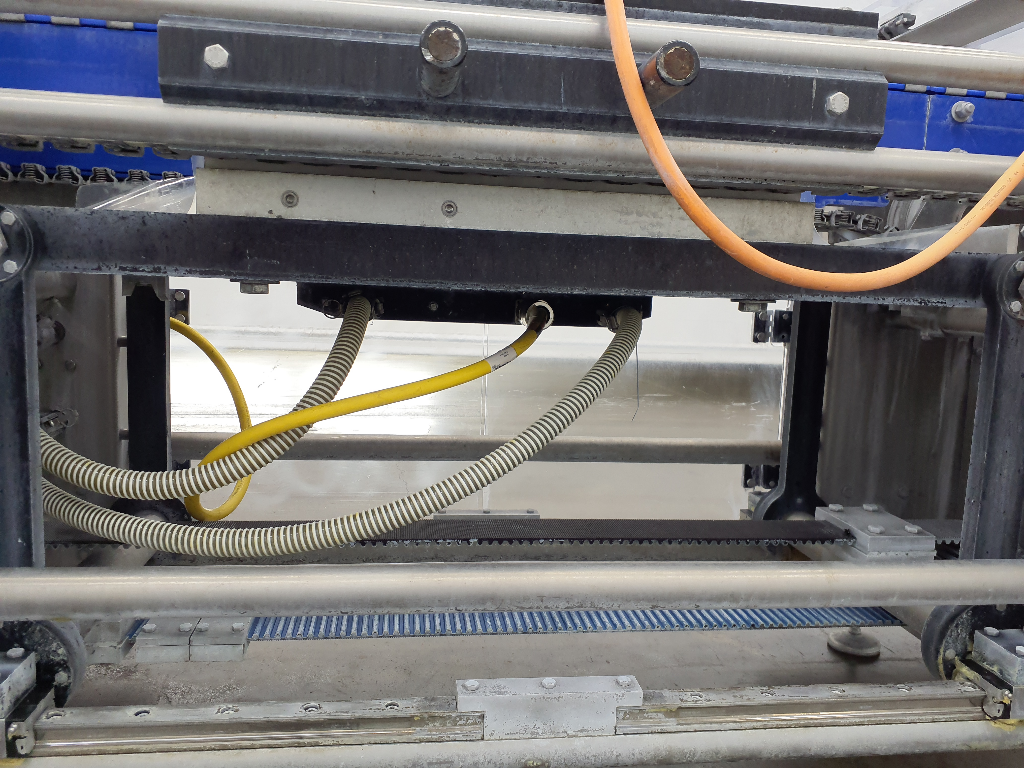

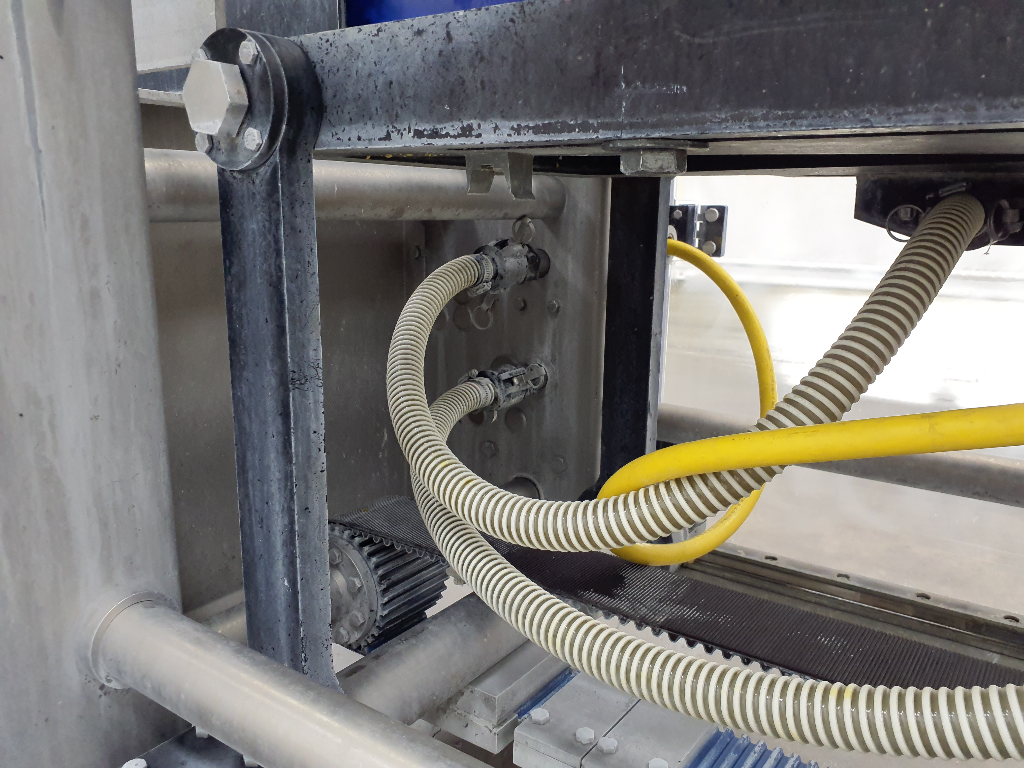

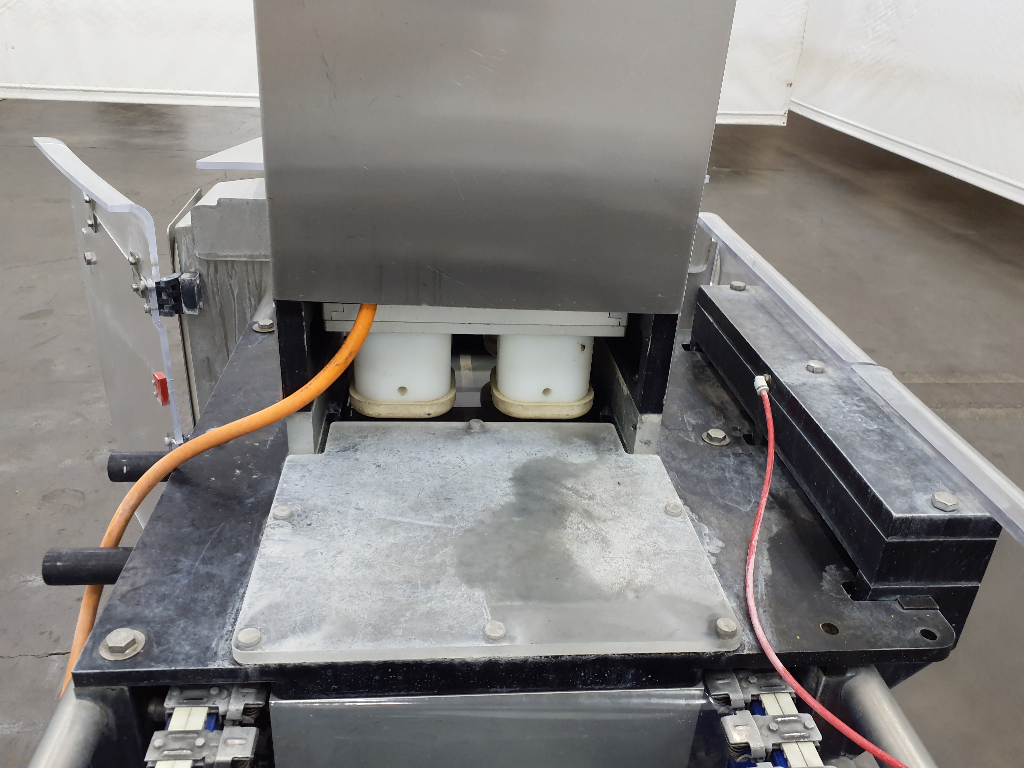

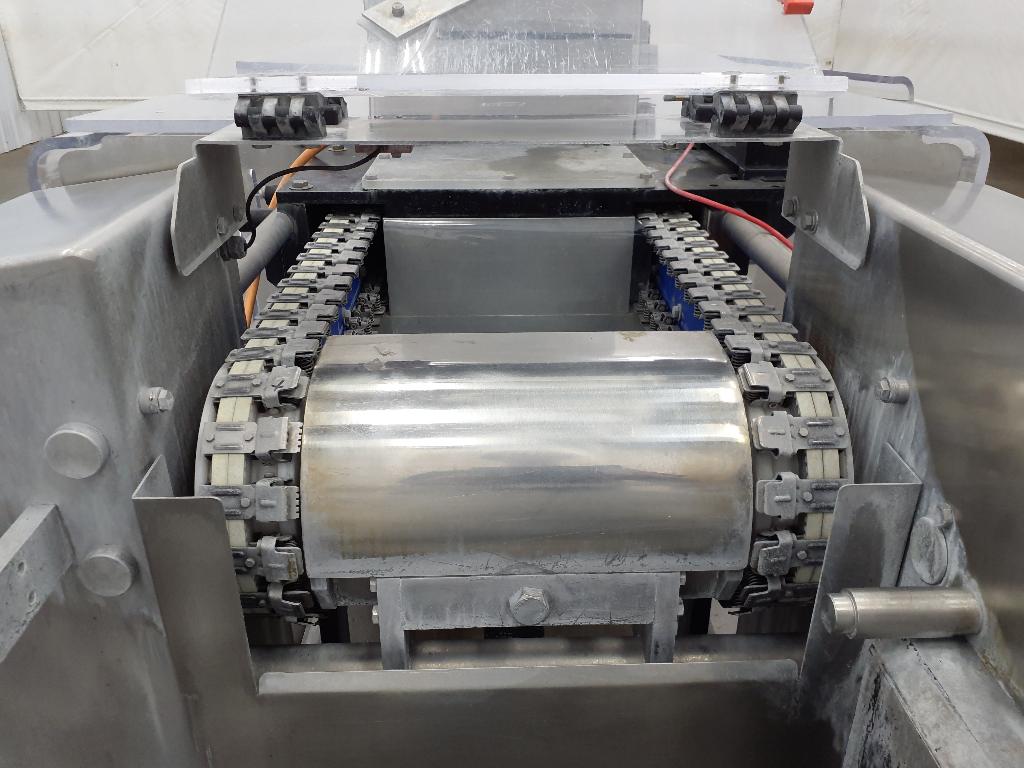

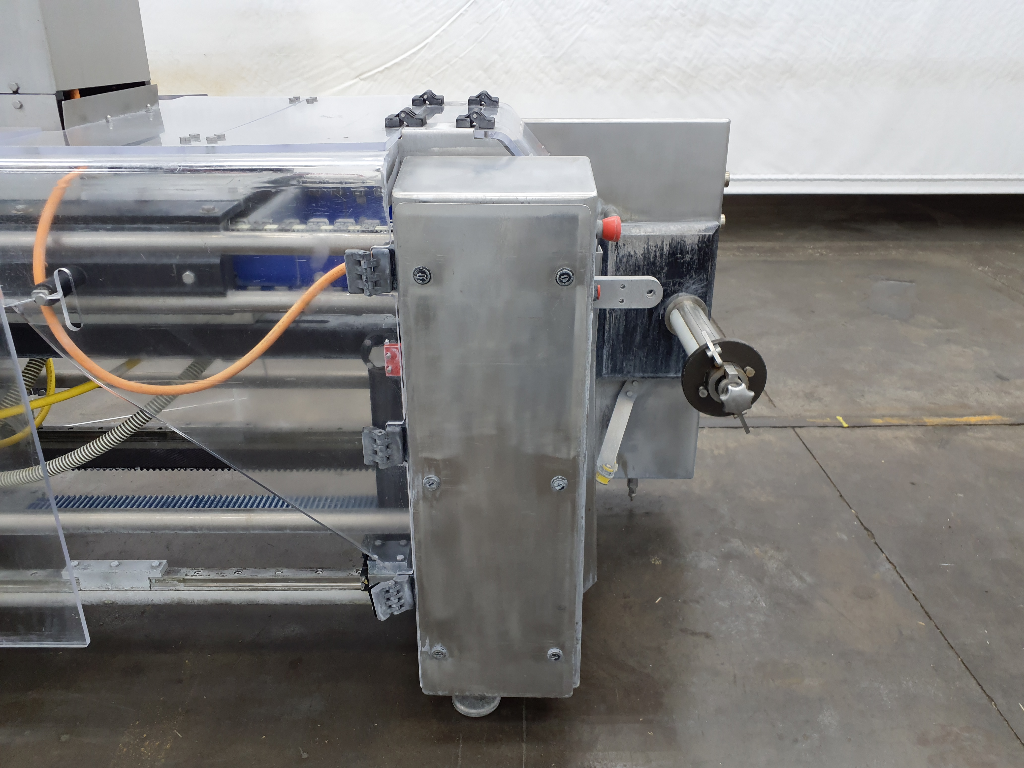

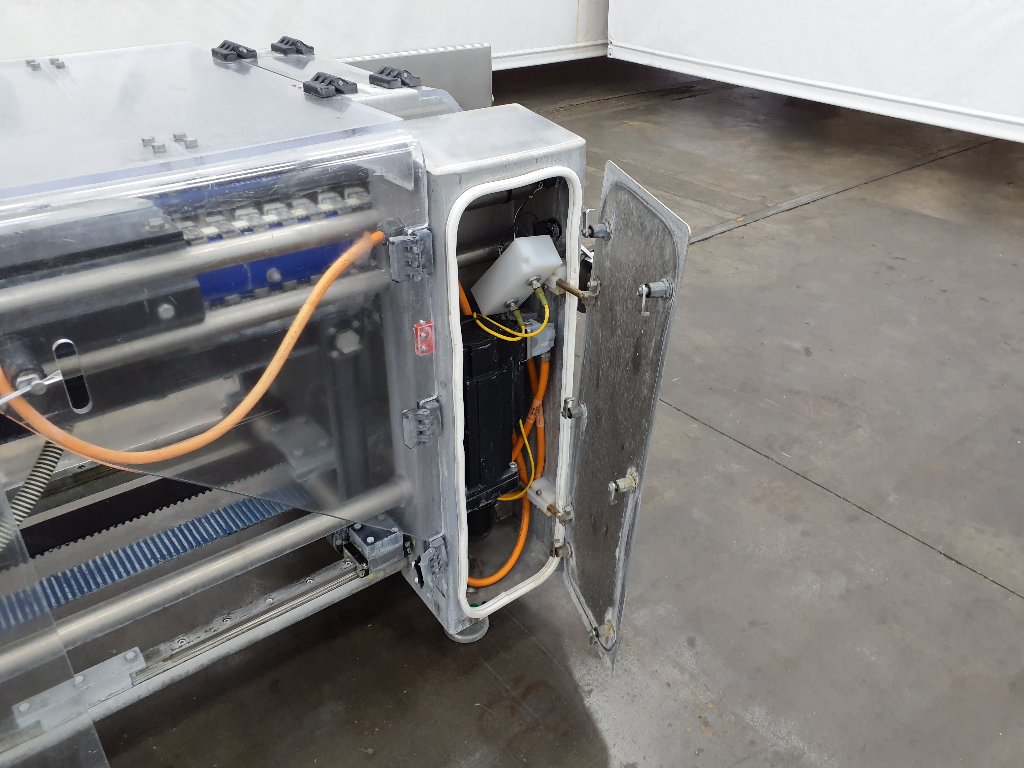

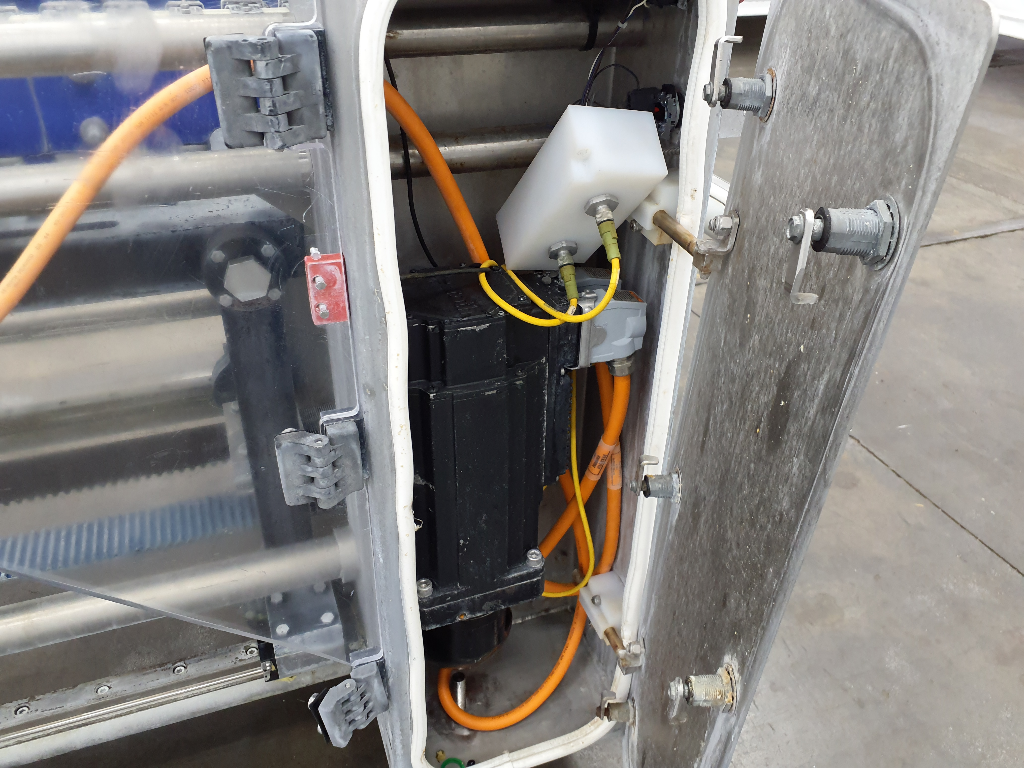

The VisionPak machine takes semi-rigid and rigid film applications. The film is loaded onto the bottom film mandrel and fed into the transport chain. The machine then forms the film into the desired package. When the bottom form has been made, the transport chain carries the film into the loading zone. In the loading zone, the product is placed into the package. After the package is loaded, the clip chain carries the package to the sealing station. Top film is brought against the bottom film and sealed in the seal station. Upon exiting the seal station, the package travels through the cutoff area and is discharged from the machine.

- Currently set up to seal a 12.31" x 16.213" - see attached documents for CAD drawing

- Package 12.3125" index 1 x 1 vacuum

- Output: up to 14 cycles per minute

- Sealing dimensions:

- total (set of 4): 12.813" long x 16.713" wide

- individual: 5.656" wide x 7.607" long

- 81 inch long loading section

- 54 inch long forming section

- Discharge height from ground: 35.5 inches

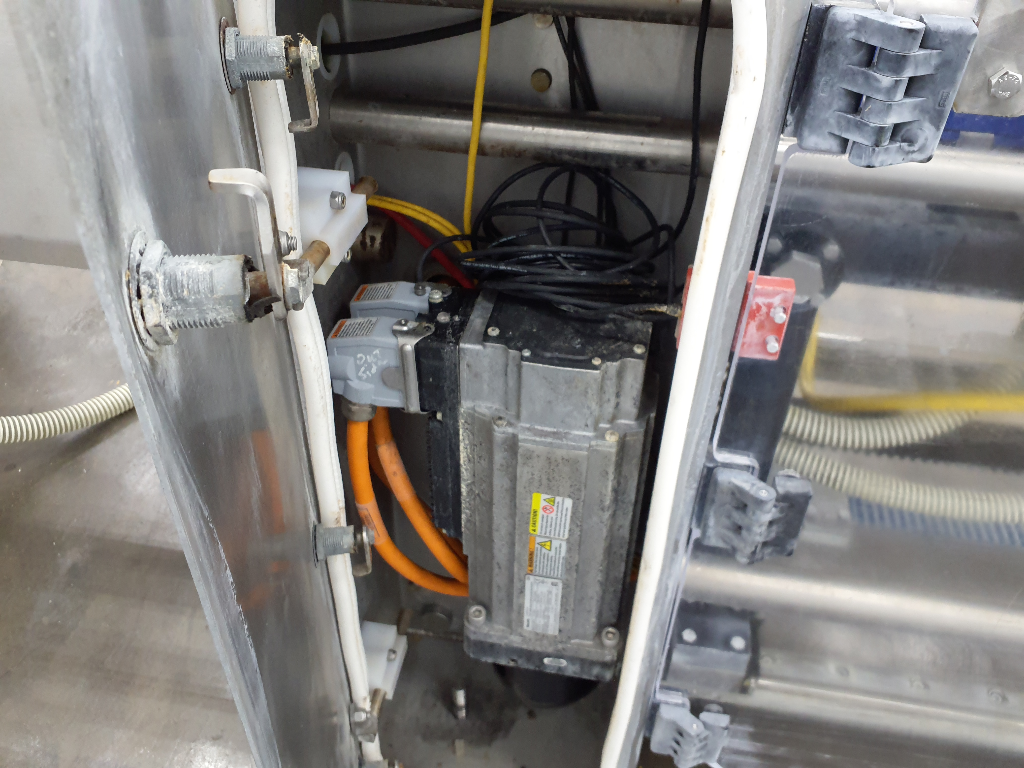

- Main vacuum: Busch 25 horsepower

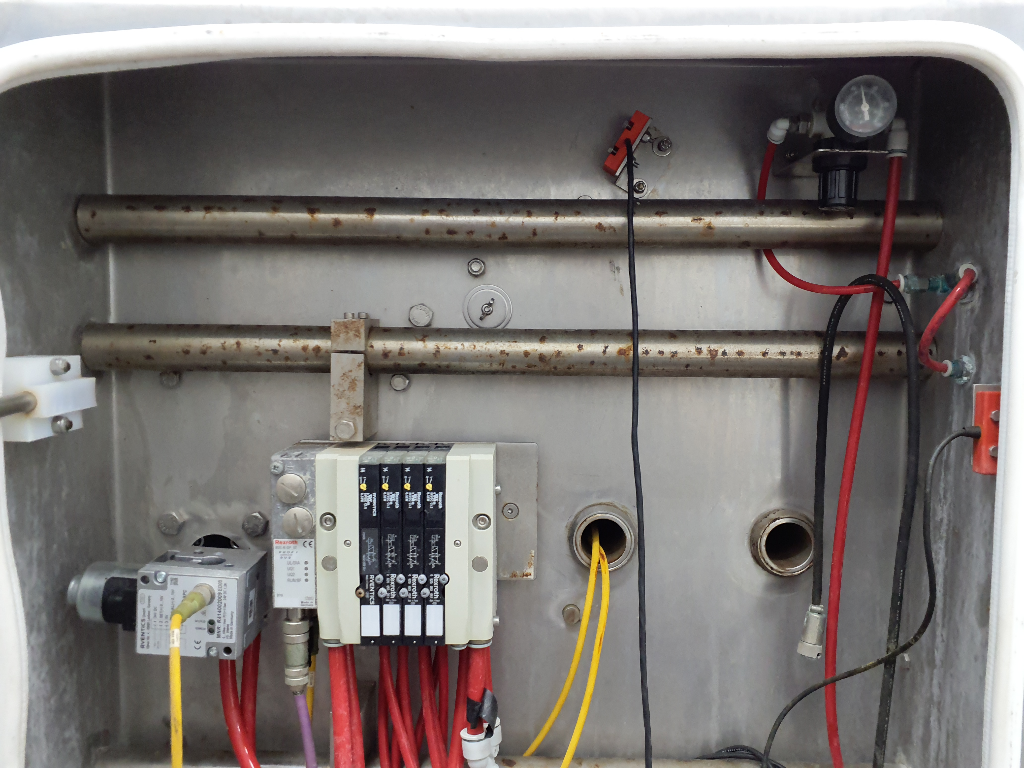

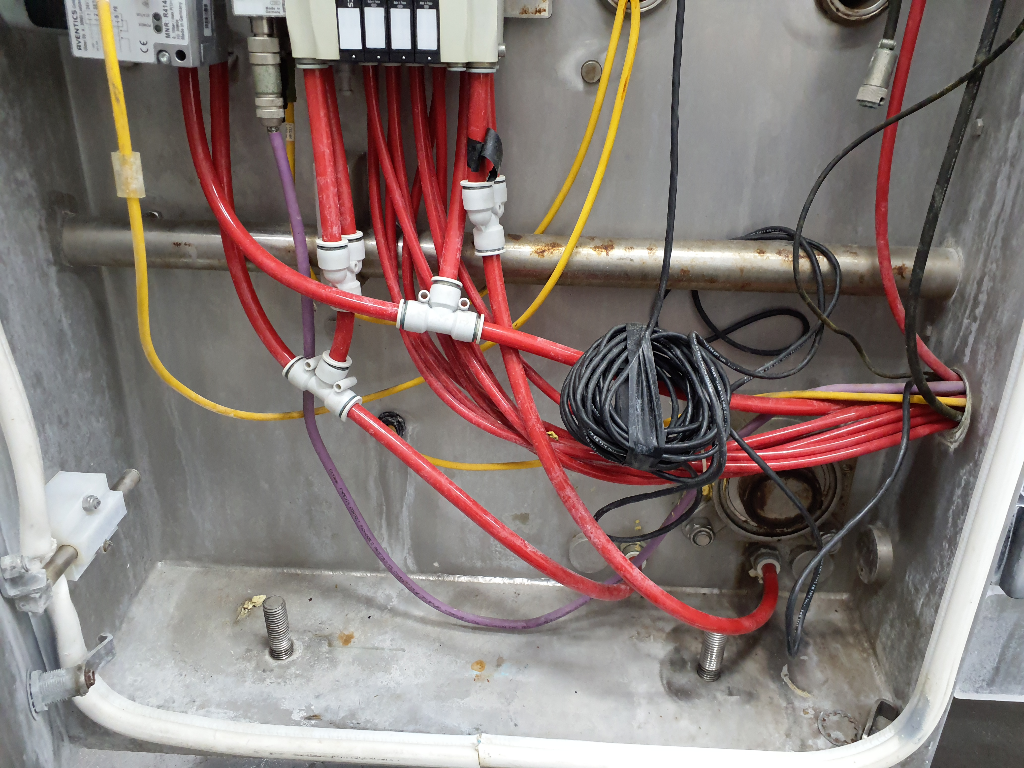

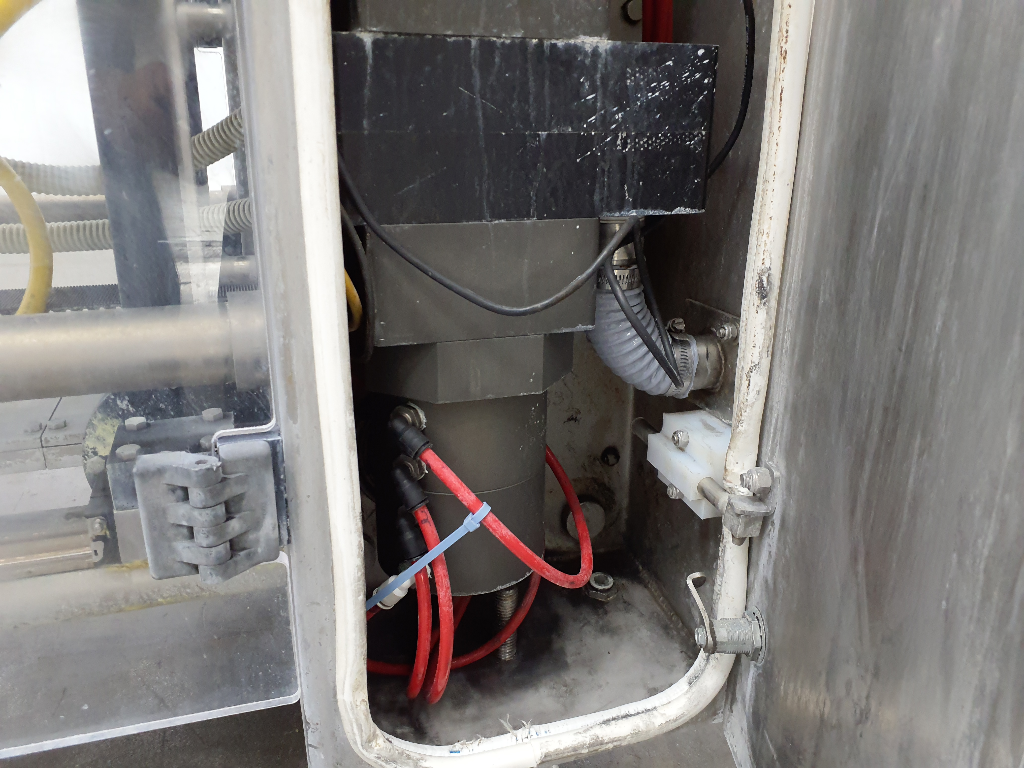

- Forming pump: busch 5 horsepower with 3" NPT vacuum fitting

- Cooling water: 30-50 gallons per hour @ 40 psi, 40-50 degrees Fahrenheit

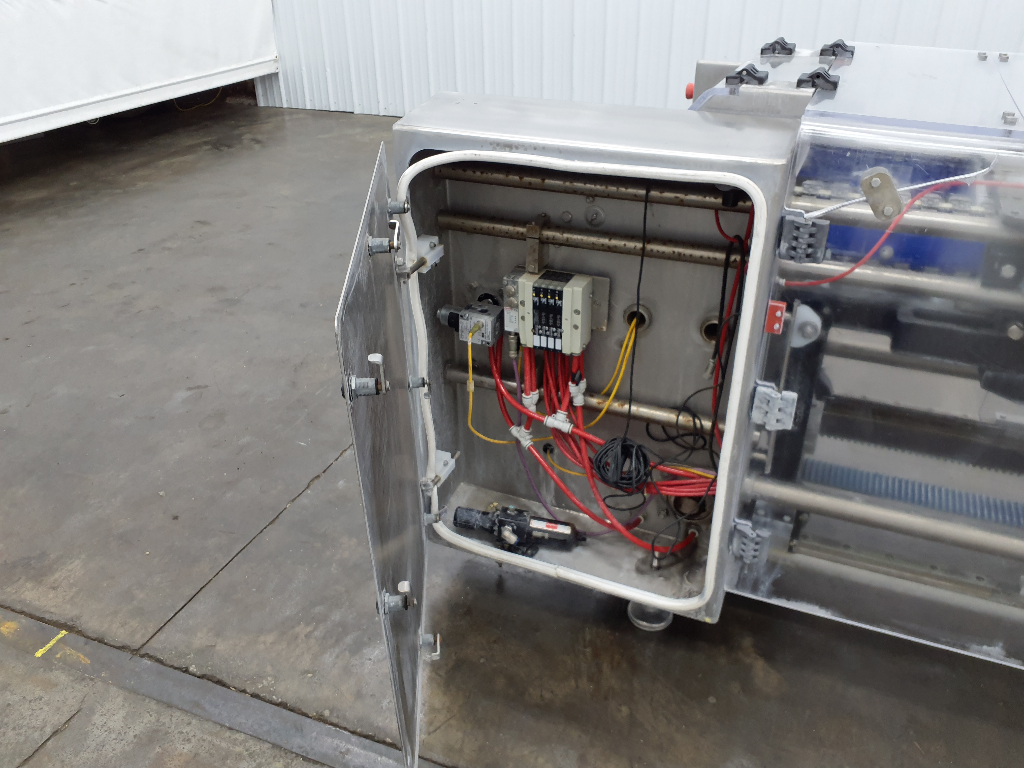

- Air supply: 2-3 CFM dry air at 80-90 psi (1" air feed(clean air))

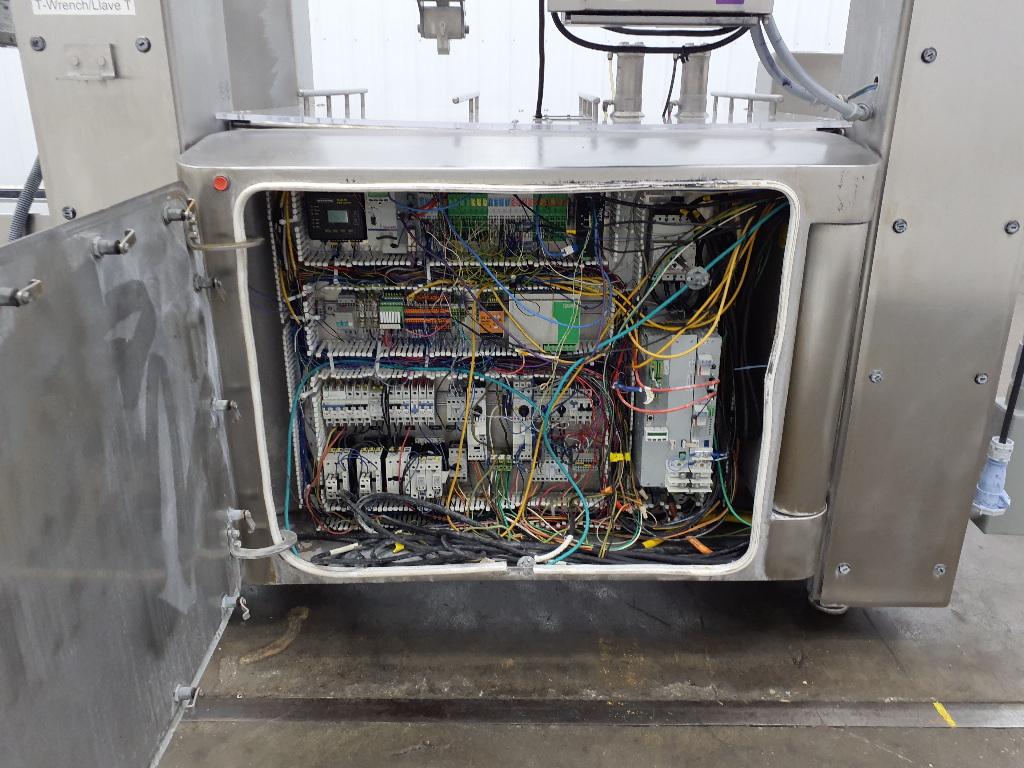

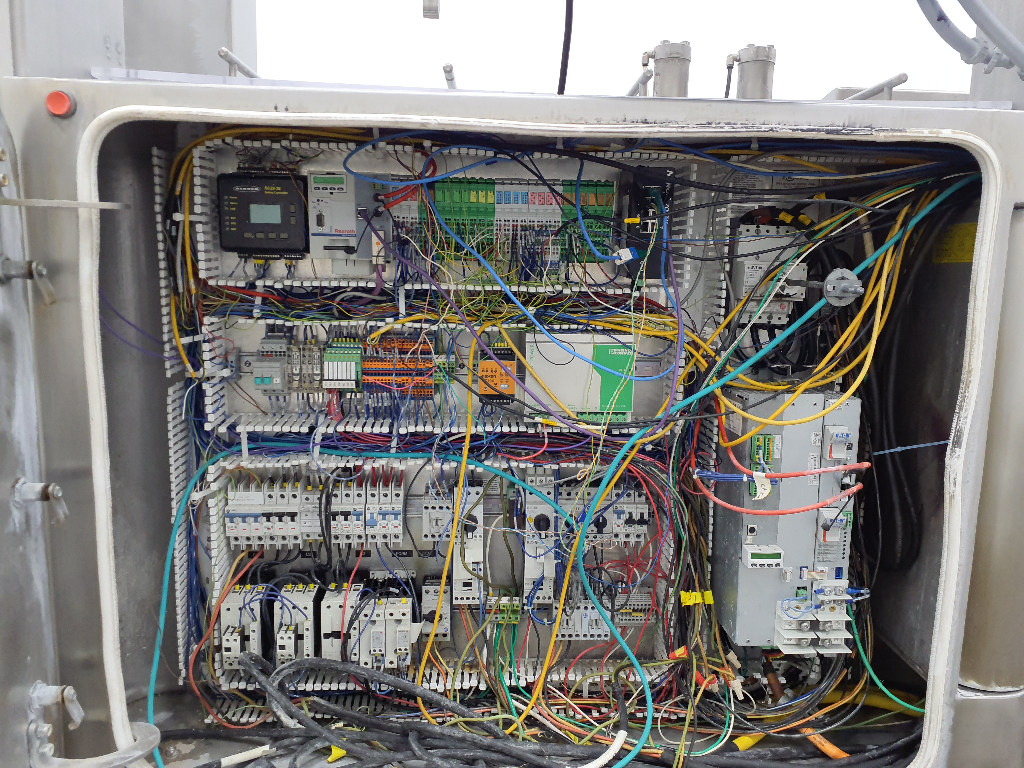

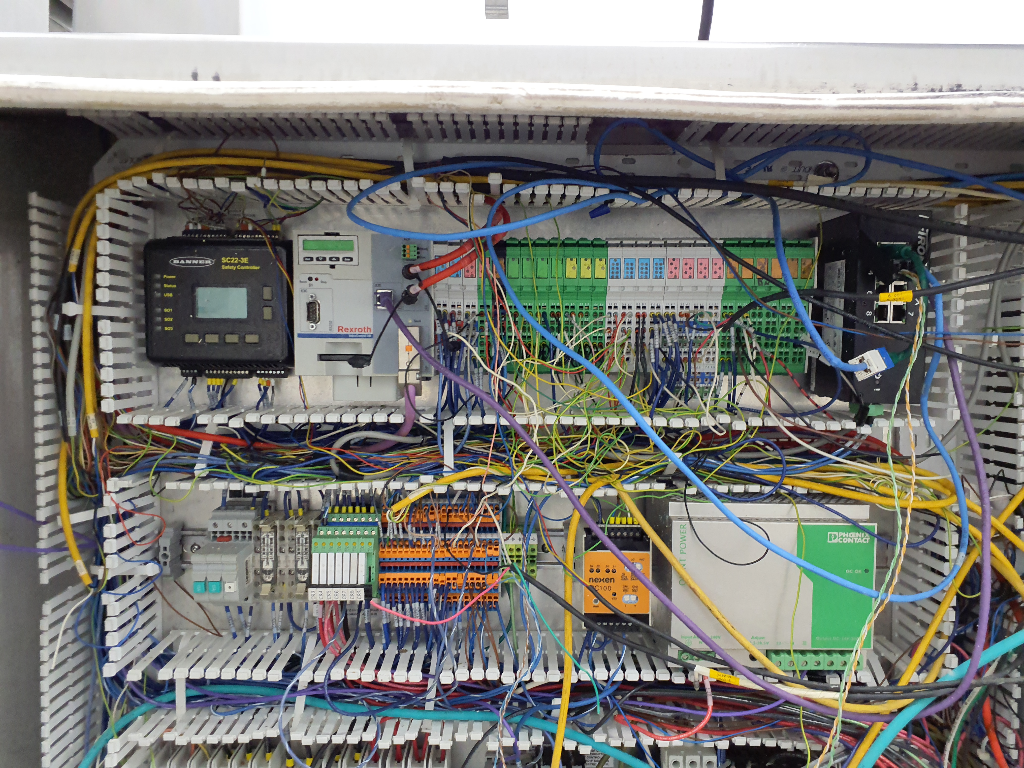

- Electrical specifications: 230 volts / 3 phase / 100 amp / 50/60 hertz

Product last ran: beef

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.