Description

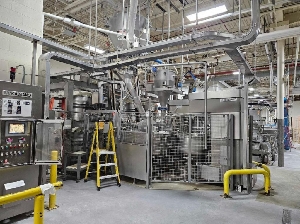

Complete Pizza Production Line:

- Output: up to 6000 pizzas per hour depending on the application

- Pizza diameters: 8.85, 10.43, and 11.61 inches (225, 265 and 295 mm)

- Consisting of:

- Spiromatic:

- 2 outdoor silos, capacity 30 tons each, glass fiber polyester

- Spiral conveying

- Weighing hopper, capacity 440 lbs (200 kg)

- Spido 6 control

- Automatic water dosing

- Water cooling unit

- Sancassiano:

- Dosing station

- 2 pc. spiral mixers, Se 300

- 5 pc. bowls

- Bowl lift

- Movable robot for bowl transport

- Fully automatic system for pre dough:

- 4 tanks with each 1585 gallon (6000 liter capacity), double jacketed with cooling

- Yeast treatment system, to dissolve block yeast into liquid yeast

- Liquefying system for rework dough

- Fritsch:

- Preportioner, with starroller

- Relax-dough-processor, RDP 600 HV-L

- Satellite head 1100/200 HV-L

- Spiral cross roller 1100

- Sheeter head 1100/200 HV-L

- Sheeter head 1100/200 HV-L

- Flour removal brush 900/1100/1300

- Proofing belts, proofing time 10 minutes, 49′ (15 meters) above the line

- Hydraulic guillotine 1100

- Punching dies 10.43″,11.61″, 8.85″ (265, 295 and 225 mm)

- Docking roller

- Dough scrap removal

- Multispot tomato topping unit

- Retracting unit

- Dough scrap return into the mixer

- Digital control, Siemens S7, OP27

- Oven:

- Baking chamber 39.37″ x 708″ (1000 X 18000 mm)

- Baking time, between 1 and 3 minutes

- Stone plate belt

- Spiral cooler:

- Ambient cooling

- Infeed at 35.43″ (900 mm)

- Outfeed at 126″ (3200 mm)

- Full stainless steel execution, stainless steel belt

- CIP cleaning system for belt wash

- Decoration line:

- 3 pc. strewers for cheese, ham and vegetables

- 1 pc. slicer for cutting and topping of salami, ham and cheese, equipped with 4 separate cutting heads and pendulum movement

- 1 pc. spice strewer

- 1 pc. crème doser

- Pressing roller

- Water sprayer

- Spiral freezer:

- NH3 freezer

- Stainless steel execution

- Stainless steel belt

- CIP belt cleaning

- 2 evaporators, 5 fans

- Packaging:

- Packaging machine for foil bags

- Shrinkage tunnel

- Metal detector

- Horizontal carton packaging machine

- Freezer plant:

- 5 pc. GEA Grasso single stage screw compressor packages

- GEA Ecoflex PHE- type evaporator

- Spiromatic:

- Electrical: 3 X 400 V – 50Hz

Unit is located in Iran

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.