Description

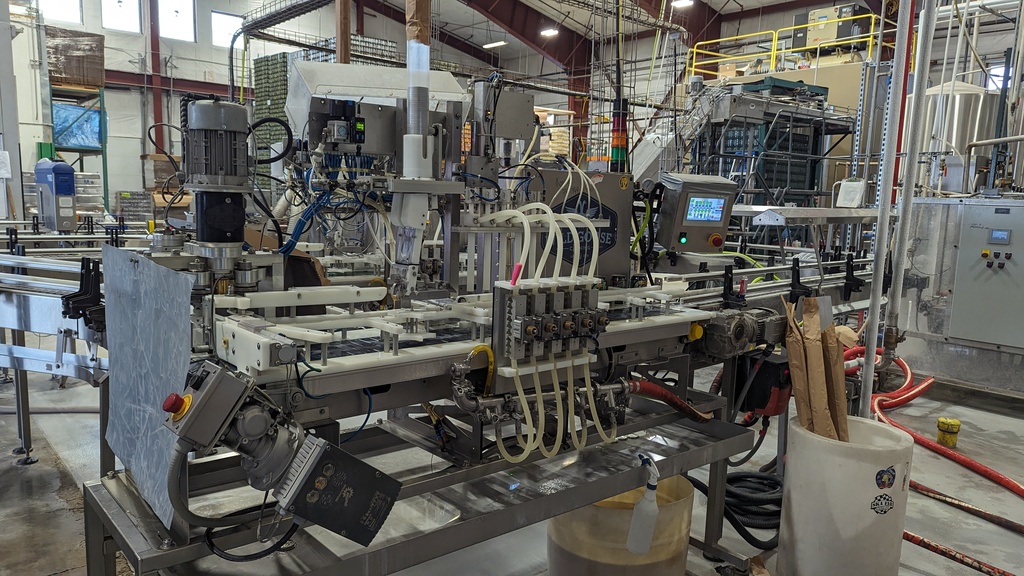

Used Beverage Production Line with:

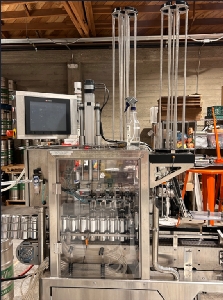

- (1) Wild Goose WGC -250 Evolution

- Serial: WGC-0242

- Year: 2015

- Throughput: up to 40 cans per minute each, depending on can sizes and performance

- (5) Fill heads

- Can size capabilities:

- 12 oz

- 16 oz

- 19.2 oz

- CO2 pre-purge station

- Automatic lid dropper

- Single-head seamer

- Air requirements: 100 PSI

- Electrical requirements:

- 115 volts

- 50/60Hz

- Single Phase

- Stainless steel construction

- (1) Wild Goose WGC -250 Evolution

- Serial: WGC-0550

- Throughput: up to 40 cans per minute each, depending on can sizes and performance

- (5) Fill heads

- Can size capabilities:

- 12 oz

- 16 oz

- 19.2 oz

- CO2 pre-purge station

- Automatic lid dropper

- Single-head seamer

- Air requirements: 100 PSI

- Electrical requirements:

- 115 volts

- 50/60Hz

- Single Phase

- Stainless steel construction

- Paktech CCA120 Can Carrier Applicator

- Serial: CCA120-06-51

- Year: 2017

- Output: up to 125 cans per minute, depending on product size

- Current setup:

- 12 ounces:

- 4 pack

- 6 pack

- 8 pack

- 16 ounce cans:

- 4 pack

- 6 pack

- 8 pack

- 12 ounces:

- Electrical requirements:

- 120 volts

- 60 Hz

- Single phase

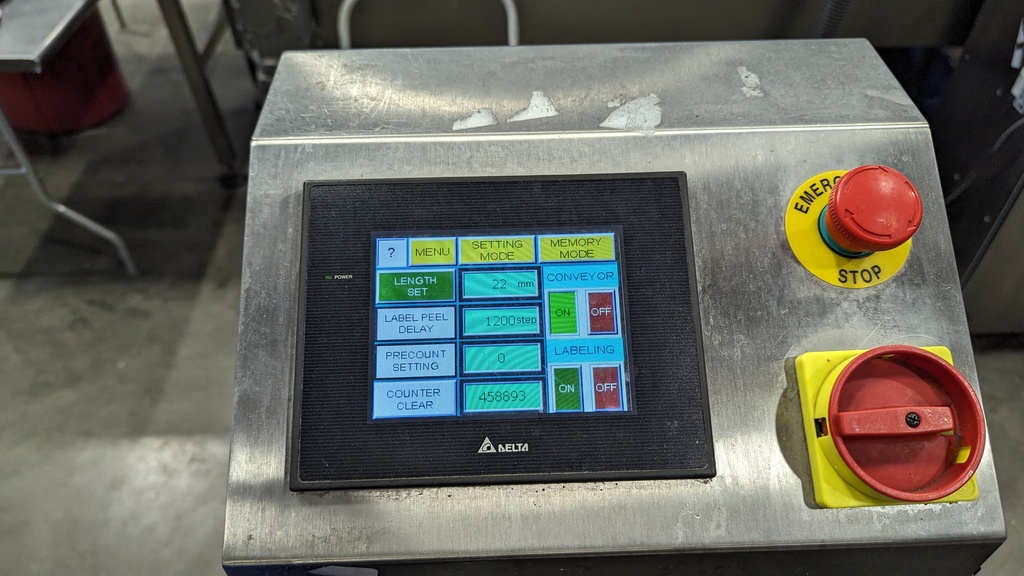

- Pack Leader PL-501 Wrap Around Labeler

- Serial: 00130PL50100010803

- Year: 2019

- Plastic-top conveyor

- Electrical requirements:

- 110 volts

- 60 Hz

- Single Phase

- Stainless steel frame

- Markem-Imaje 9450 Continuous Inkjet Printer

- Serial: US17220073

- Year: 2017

- Print speed: Up to 6.6 millimeters per second

- Mono-jet printhead

- Print resolution:

- G head: 71 dots per square inch

- M head: 115 dots per square inch

- Character height: 1.2 millimeters to 11.2 millimeters

- Touchscreen controls

- Weight: 25 pounds

- Table-top or vertical mounting

- Electrical requirements:

- 100/240 volts

- 50/60 Hz

- Filtec 3-G Photon Level Inspection with Reject

- Serial: 118767

- Operating speed:

- Cans: up to 2400, depending on can size

- Bottles: up to 1400, depending on bottle size

- Inspects for:

- Underfill/Overfill

- Missing cap/missing lid

- Pressure/vacuum detection

- High/cocked cap detection or high cork

- Label detection

- Down bottle/down can

- High/low foam

- Smashed bottle/bulged can

- Missing foil seal under non-metal cap

- Vent tube detection

- Air consumption: 0.5 SCFM

- Electrical requirements:

- 115/230 volts

- 50-60 Hz

- Single Phase

- Amps: 2/1

- Stainless steel construction

- Bevco Blow-Off (Air Knife) tunnel

- Removes moisture off cans for labeling

- Stainless steel construction

- Bevco conveyors

- Single file

- Spiral drying conveyor

- Conveyor splitter

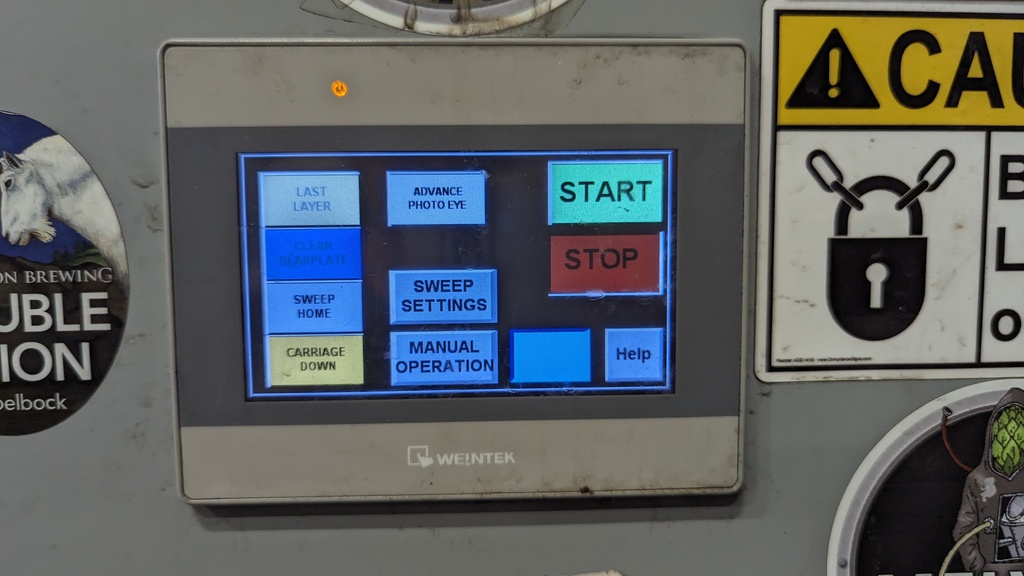

- Ska Fabricating Can-I-Bus Depalletizer with Twist Rinse

- Output: up to 400 cans per minute depending on application

- Pallet dimensions:

- Length: 44 inches

- Width: 56 inches

- Lifting capacity: 400 pounds

- 12-ounce, 16-ounce, and 19.2-ounce twist rinse

- Automated tier sheet removal

- Electrical:

- Volts: 208/230

- Frequency: 60 Hz

- Phase 1

- Air requirements: 20 psi

- Steel construction

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.