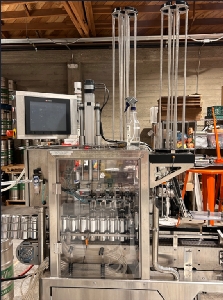

Description

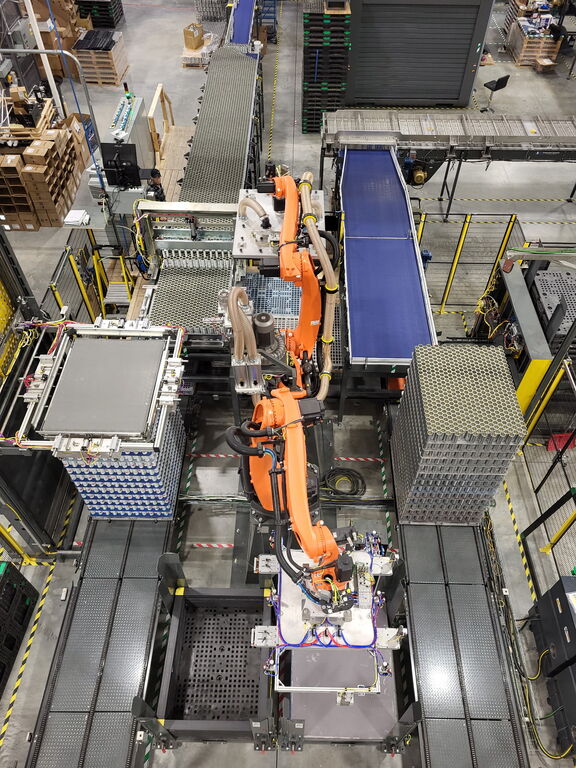

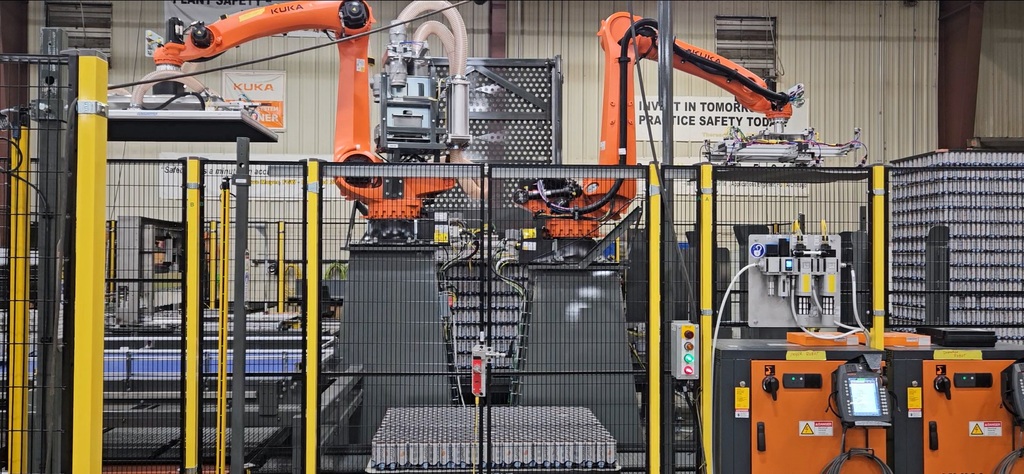

Used Barry-Wehmiller Can Palletizing And Depalletizing System with:

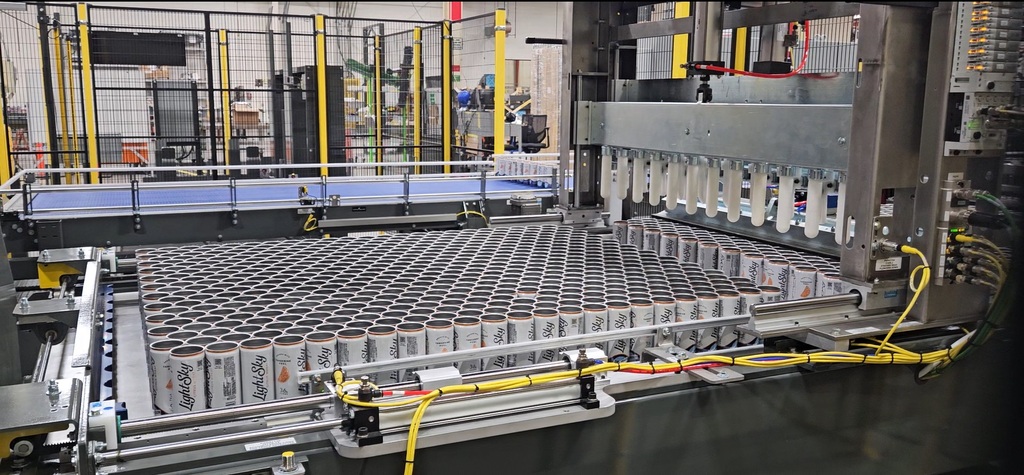

- Production speed: up to 500 cans per minute, depending on application

- Maximum load height: 110 inches

- Two robot system

- Fanuc M410iC/315 for layer handling:

- R-30iB robot controller

- Teach pendant with 32.6 foot cable

- DCS safety software

- Fanuc M410iC/185 for layer pick-up:

- R-30iB robot controller

- Teach pendant with 32.6 foot cable

- DCS safety software

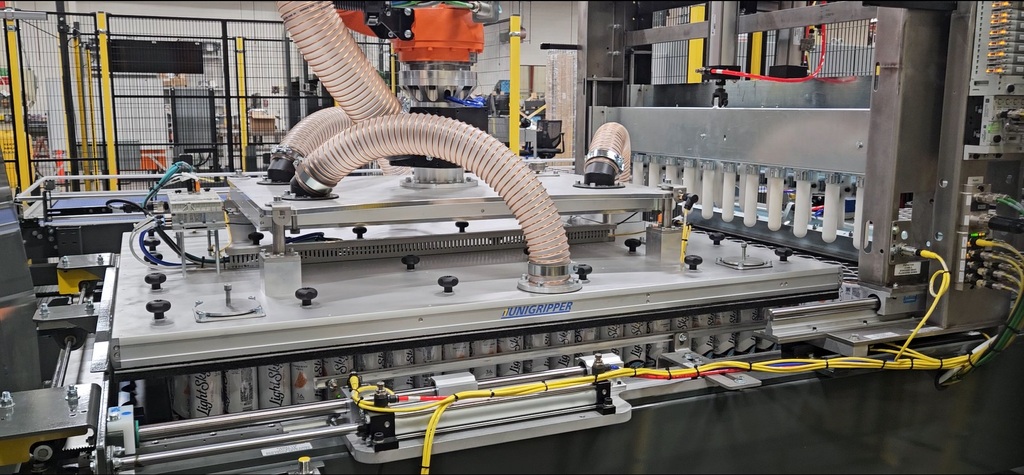

- Vacuum assembly for layer pick-up

- Vacuum/Mechanical assembly for top frame and sheet pick-up

- Accumulator with one drive: 28 feet

- Layer staging pickup bed: 6 feet

- Change parts for 200, 204, and 211 can styles

- Layer separation assembly with pneumatic end stop

- Dual hoppers for slip sheets and top frames

- Layer pad indexing separator

- Indexing layer centering assembly

- Model R 6C pallet stacker and dispenser

- Powered roller conveyance for pallets:

- CDLR pallet loading conveyor length: 6 feet

- Pallet unbuilding roller chain conveyor length: 20 feet

- Roller chain conveyor for empty pallets with (2) right angle transfers: 18 feet

- Empty pallet stacking/unstacking conveyor: 8 feet

- Pallet building roller chain conveyor: 20 feet

- Full pallet turntable strapping conveyor: 15 feet

- CDLR pallet unloading conveyor: 6 feet

- Conveyor height: 18 inches

- Allen-Bradley CompactLogix PLC with PanelView touch screen HMI

- Signode MHB-TP12 Pallet Strapper:

- Adjustable tension range: 30 - 85 pounds

- Model PSD109 strap dispense with strap accumulation and take-up tower

- Compatible strap style: 1612 Tenax Strap

- Right angle pulley assembly

- Isometric Air Conveyor:

- Plenum construction with Magnehelic style pressure gauges

- Perforated stainless steel top hold down

- Suspa lift system for up to (4) adjustable hold down can heights

- Airfoil blower wheel

- Axial vane inlet damper

- Color touch screen HMI

- Rockwell ControlLogix PLC

- Approximate overall system dimensions:

- Length: 120 feet

- Width: 60 feet

- Clearance height: 18 feet

- Allowable ambient temperature range: 42° F - 90° F

- Air requirements: 80 PSI (5.5 bar)

- System electrical requirements: 3 Phase, 60 Hz, 480 Volts (±10%)

Previously used in palletizing/depalletizing 200, 204, and 211 style cans

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.