Search Terms: "shrink wrap machine"

Plastics Equipment ×19 Used Items

Page 1 of 2

PLASTIC INJECTION MOLDING is a method to obtain molded products by injecting plastic materials molten by heat into a mold, and then cooling and solidifying them. The method is suitable for the mass production of products with complicated shapes, and takes a large part in the area of plastic processing. (pool chemical buckets, aerosol caps, plasticware, legos) BLOW MOLDING is a process for forming plastic objects in which plastic is melted, put in a mold, and then shaped by having compressed air blown into it. (Water bottles, shampoo bottles, orange barrels/cones) EXTRUSION is a process of converting a solid plastic mass, pellet or powder into a melted form where it is pushed through a die into a shape. This shape is then moved through various secondary operations where it is cooled then cut, coiled or experiences a variety of other possible operations. (PVC water and sewer pipes, plastic tubing for oxygen, drinking straws) There is a uniqueness to each primary process. Extrusion is continuous, injection molding is discontinuous and blow molding would also be considered continuous.

Search Within Plastics Equipment

Semi Automatic Blow Molding Kit

Used Semi Automatic Blow Molding Kit with; Lu Tai LT-2L Semi automatic stretch blow molding machine with integrated heat machine Suitable for 20-2250 milliliters Most heavy caliber...

Kawaguchi KS365s Injection Molding Machine

Used Kawaguchi KS365s Injection Molding Machine with: Clamping tonnage: 365 tons Screw diameter: 72 mm Shot volume: 1120 cubic cm Injection press: 1404 kg/cm

CMPP 1000/D/H/2 Extrusion Blow Mold Machine

Used CMP 1000/D/H/2 Extrusion Blow Mold Machine with: De-Flashing system Screw Diameter - 50 mm Blowing capacity - 10 ml Screw Speed:0-75 Maximum Die Diameter - 60 mm Oil Tank Capacity - 200...

Uniloy 350 R-1 Blow Molding Machine 4 Heads

Used Uniloy 350 R-1 Blow Molding Machine with: 4 heads 8 inches between heads Capacity: from 1 to 4 liters Shoot size: 900 grams 50 CFM Previously produced dairy bottles

Liberty RS 3500 Blow Molding Machine

Used Liberty RS 3500 Blow Molding Machine with: 10 heads Distance between heads: 4 inches Capacity: from 150 ml to 900 ml Shoot size: 1100 grams 70 CFM Previously used for dairy bottles

Uniloy Model 350 R3 Plastic Mold Injecting Machine

Used Uniloy Plastic Mold Injecting Machine with: 125 horsepower motor Clamp dimensions: 44 inches wide x 15 inches tall Capacity: 4 to 12 liters Shoot size: 1100 grams

Uniloy 350 R-2 Blow Molding Machine 4 Heads

Used Uniloy 350 R-2 Blow Molding Machine with: 4 heads Distance between heads: 8 inches Capacity: from 1 to 4 liters Shoot size: 1100 grams 50 CFM Previously produced dairy bottles

Uniloy Model 350 R4 Plastic Mold Injecting Machine

Used Uniloy Plastic Mold Injecting Machine with: 125 horsepower motor Clamp dimensions: 44 inches wide x 15 inches tall Capacity: 4 to 12 liters Shoot size: 1100 grams

Fischer FHB 106-1 Blow Molding Machine

Used Fischer FHB 106-1 Blow Molding Machine with: 80 millimeter extruder Extruder output: 220 pounds per hour Mold dimensions: 360 millimeter (14.17 inch) width x (2) 130 millimeter (5.12 inch) depth...

Uniloy 350R4 7 Head Blow Molding Machine

Used Uniloy Blow Molder with: Molding heads: Number of heads: 7 Programmable Shot capacity: 1,600 grams MACO 8000 control/programmer Includes Uniloy model 10041 trimmer Can accommodate gallon...

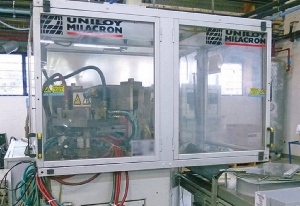

Uniloy Milacron IBS 70 Blow Molding Machine

Used Uniloy Blow Molding Machine with: Injection unit: Diameter: 44mm / 1.7 inches Motor: hydraulic L/D ratio: 21:4 Maximum shot size: 216 grams Clamp force injection mold: 63 tons Clamp...

Engel ES700/250 250 Ton Injection Mold Machine

Used Engel ES700/250 Injection Mold Machine with: Shot Size: 15.9 ounces Tie Bar Spacing: 21.02 inches x 18.03 inches Platen Size: 32.68 inches x 29.69 inches Daylight: 7.87 inches - 41.73 inches Clamp...

Uniloy Model 350R3 4 Head Blow Molding Machine

Used Uniloy Blow Molder with: Head configuration: Number of heads: 4 Centers: 11 inches Programmable heads Extruder size: 3.5 inches Nominal shot size: 1,100 grams Clamp force: 90 tons Platen...

Bekum H-121D Double Station Extrusion Blow Molder

Used Bekum H-121D with: Double station extrusion blow molding machine Capacity: 150 Ml to 6 liters Continual exit Last used for dairy bottles

Bekum H-121D Double Station Extrusion Blow Molder

Used Bekum H-121D with: Double station extrusion blow molding machine Capacity: 150 Ml to 6 liters Continual exit Last used for dairy bottles

Showing 1-15 of 19 Items