Used Fenco Stainless Steel Spiral Pasteurizer and Spiral Cooling System

Click image for full size.

Having trouble viewing media for this Fenco ?

Click here for full page view of all Equipment Media (8)

Click here for full page view of all Equipment Media (8)

Equipment Details

| Equipment # | E304895 |

| Item | Fenco Stainless Steel Spiral Pasteurizer and Spiral Cooling System |

| Category | Miscellaneous Equipment |

| Manufacturer | Fenco |

Equipment Description

New Fenco spiral pasteurizer and cooling systems:

- Output: Up to 400 pouches per minute, depending on application

- Air pasteurizing system with holding:

- Pouch position into belt: 4 pieces across (side by side) |□□□□|

- Pouch max dimensions: (L) 140 x (W) 84 x (H) 40 mm

- Pasteurizer holds filled pouches at 192°F (core temperature) for 5

minutes - Air temperature inside: Up to 220°F

- Primary Thermal Fluid: steam at max 6 bar (min 3 bar)

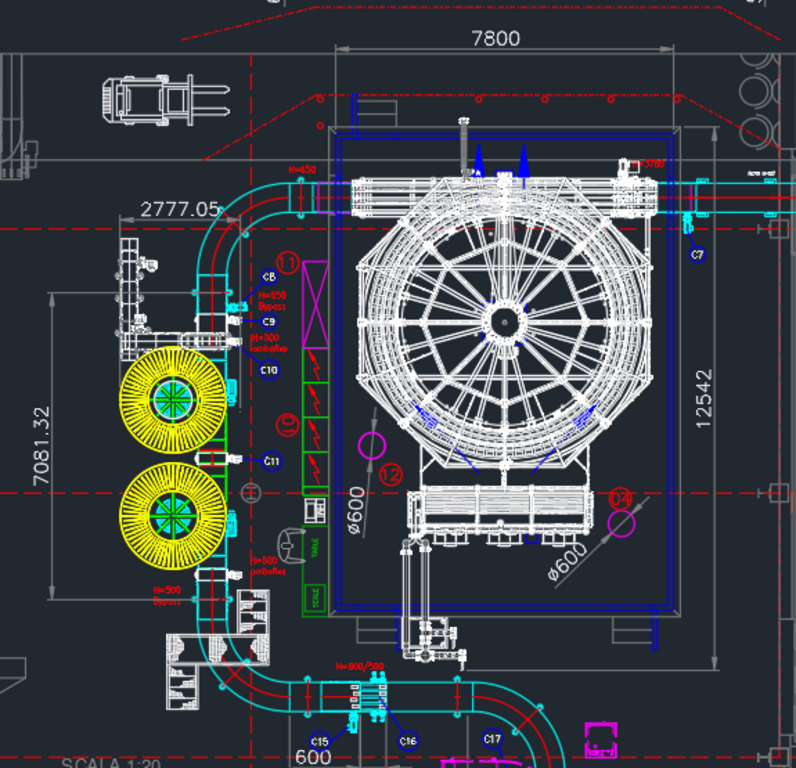

- SPIRAL design and technical data:

- Belt width: approximately 800 mm

- Drum diameter: 4000 mm

- Number of drums: 1

- Number of tiers: 8

- Tier pitch: 150 mm approx.

- In feed height: 1900 ±100 mm

- Out feed height: 900 ±100 mm

- Cabin max height: 10 feet

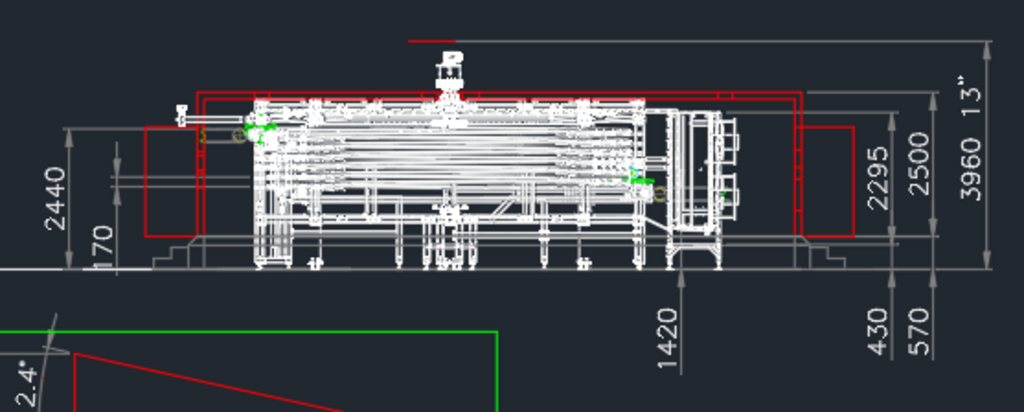

- Air cooling system:

- Cooler cools down the pouches to 90°F (core temperature)

- Dwell time: 20 minutes (adjustable)

- Air cooling temperature: 40°F (adjustable)

- Primary Thermal fluid: chilled water between 28°F–32°F

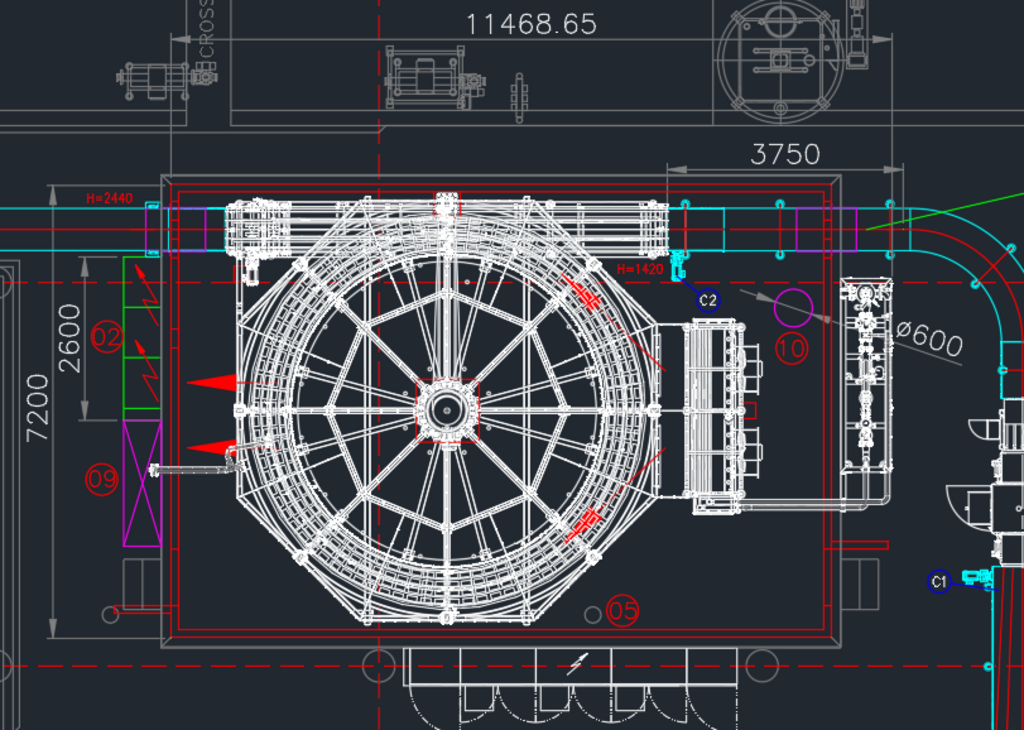

- SPIRAL design and technical data:

- Belt width: ~800 mm

- Drum diameter: 5000 mm

- Number of drum: 1

- Number of tiers: 24

- Tier pitch: 150 mm approx.

- In feed height: 3600 ±100 mm

- Out feed height: 900 ±100 mm

- Cabin max height: 15 feet

- Pouch accumulation:

- To collect the pouches in case of any stoppages of the secondary

packaging, working with logic FIFO (First in First out).

Buffer – accumulation capacity: ~ 7 minutes (±10% tolerance

depending on the pouch handling conditions) composed of:- Stailess steel frame with sliding guides with low friction coefficient

plastic material - Adjustable feet

- Plastic flexible belt composed with modular belt type food grade in plastic material.

The belt allows for good product support and high air cross-flow

- Stailess steel frame with sliding guides with low friction coefficient

- To collect the pouches in case of any stoppages of the secondary

- 2 POUCH ALIGNERS AND ACCELERATING BELTS

- To increase the interspace between the rows due to the high speed of the filler (25-26 m/min) vs the lower speed of the secondary packaging (15-16 m/min). One system is posizioned just after the pouch filler, the second one just before the secondary packaging input. The system is totally automatic and fully equipped of sensors for a perfect pouch handling. Composed of:

- Stailess steel frame with sliding guides with low friction coefficient plastic material

- Adjustable feet

- Plastic flexible belt composed with modular belt type food grade in plastic material.The belt allows for good product support and high air cross-flow.

- To increase the interspace between the rows due to the high speed of the filler (25-26 m/min) vs the lower speed of the secondary packaging (15-16 m/min). One system is posizioned just after the pouch filler, the second one just before the secondary packaging input. The system is totally automatic and fully equipped of sensors for a perfect pouch handling. Composed of:

- Systems are designed to be in an insulated room. None of the insulation panels are included in the system.

Photos are representative, screenshots of unit drawings included

Location Details:

South Central USThis machine is located at a client’s facility in South Central US. To coordinate an inspection of this item, please contact your SIGMA sales team.

Call us at (812) 303-8383.Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this Fenco Stainless Steel Spiral Pasteurizer and Spiral Cooling System?

Request an email quote or call us at (812) 303-8383 for more information.