A Guide to Low Profile Stretch Wrappers

The Most Versatile Piece of Equipment in the Industry and in Your Production Line

The low-profile stretch wrapper is one of the most common pieces of equipment in any production line. They are designed so that pallet jacks can access them using ramps. After the item is placed on the turntable, an operator must attach the tail of the film to the pallet. The base then rotates as the film carriage moves up or down, wrapping the pallet. After the pallet is wrapped, the operator must cut the film, smoothing the tail onto the pallet. Low-profile turntables can generally support 4,000 pounds or less.

What You Will Learn:

- Where They Fit in the Production Line

- Manufacturers

- Wulftec Stretch Wrapper Setup and Training

- How to Erect and Lay Down a Wulftec Stretch Wrapper Mast

- Features

- Mast Heights and Why They Are Important

- Low Profile vs High Profile

- Questions to ask Yourself

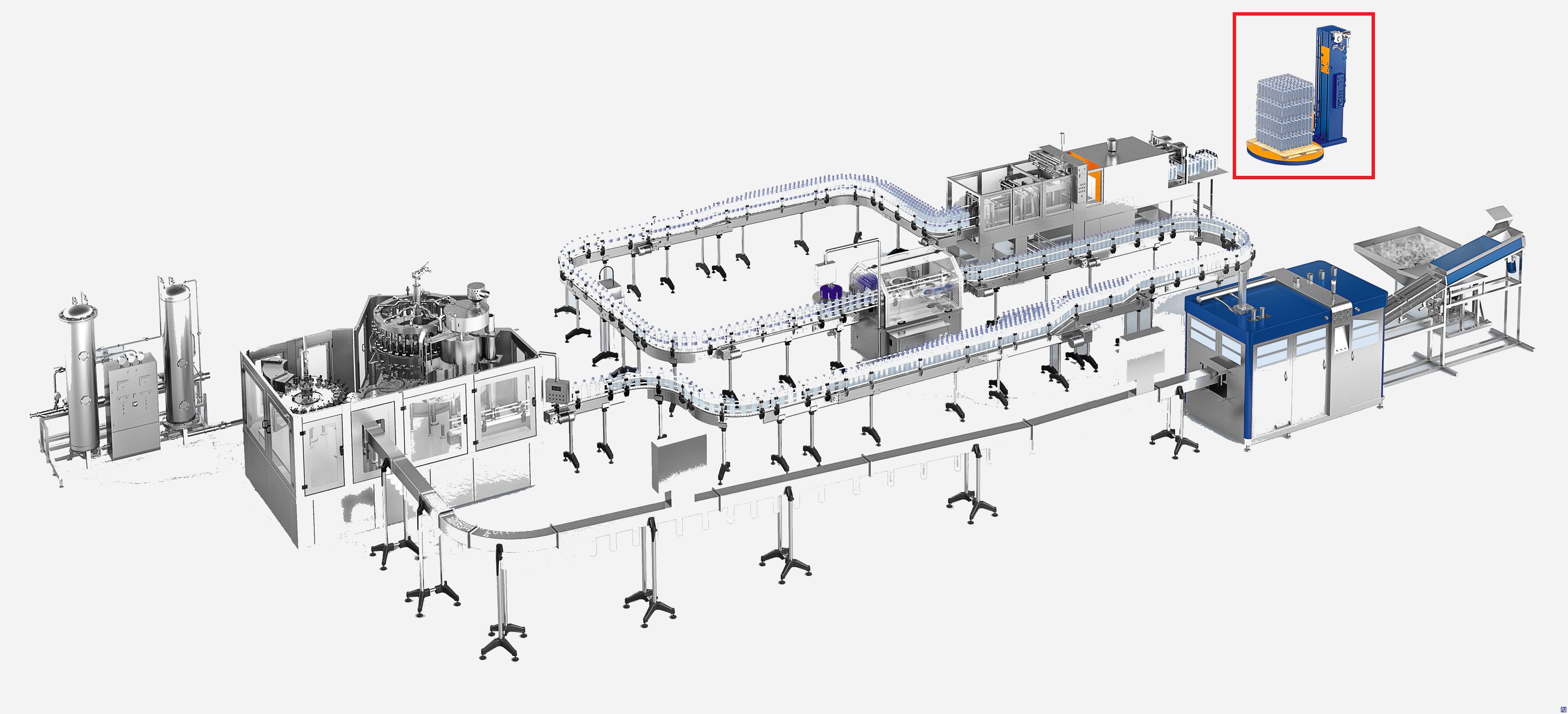

Where They Fit In The Production Line:

The low-profile stretch wrapper is ideal for any production facility and is typically the last step in the packaging line. Found here:

Source: https://www.hermis.biz/products/products/filling-line/#glr-2

Once a product is wrapped in plastic it is ready to move on to the storage or shipping process to head to its final destination.

Manufacturers:

There are many different manufacturers of these machines, but the two that we recommend using are:

- Wulftec

- Lantech

Wulftec Stretch Wrapper Setup and Training:

SIGMA Equipment sells used equipment for both brands but has recently partnered with Wulftec to start selling new low-profile stretch wrappers. With this we have been able to work with them on training videos, including this training and setup video:

Some Tips Include:

- Connecting the pin-type connections on the machine as these will be disconnected when they arrive at your location.

- Test the error codes when setting up the panel.

- When threading film, place the film straight down with the arrows facing up and pull the film through the rollers.

- Run testing with your speeds to make sure they meet your specifications.

- Use your height sensor to make sure it wraps the whole pallet.

How to Erect and Lay Down a Wulftec Stretch Wrapper Mast:

One of the most common questions that our team receives is how to properly set up the mast on a stretch wrapper once it arrives at your facility. Our team has created a video along with some steps on how to properly set up the machine without damaging it. Our example uses the two forklift method.

Steps:

1. Use rigging materials to properly and safely raise up the mast and lay it back down if needed. This can include a fork attachment if using a forklift, clevises, and straps.

2. Use 2 forklift operators to help lift the mast while the other operator pushes the bottom of the machine on a skid to help align. It’s important to note that each forklift operator must be in sync and communicate because they can damage the machine if one person is moving too fast or too slow.

3. After the machine is erected you will want to use the 2 bolts in the back of the machine to tighten and ensure the stretch wrapper mast is in place and secure.

4. Next, you will want to connect the cables for the motor of the turntable and for the photo-eye.

Features:

Each machine has its own features and when looking to see which machine is best for you on our website, here are some features to consider for your needs:

- Ramps

- Ability to lay down the mast

- Extended or standard mast

- Scales

- Dual-platform capabilities

- Counterbalance secured for transport

Mast Heights and Why They Are Important:

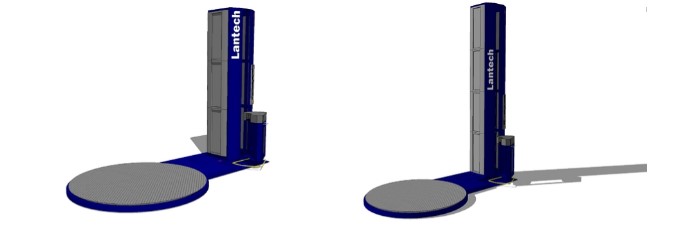

One of the most commonly overlooked features of a low-profile stretch wrapper is the mast height. This is exactly what it sounds like, the height of the mast that wraps the plastic around your packaging. Depending on the height of your product, you may need an extended mast, and the best way to determine this is to measure the product on the pallet you plan on wrapping it to. A standard masthead is typically 80 inches (6ft 8 in). If your load raises above the 80-inch mark then you will need an extended mast low profile stretch wrapper. These masts can extend to 110 inches.

Standard 80” Height Extended 110”

Source: https://www.lantech.com/

Low Profile vs High Profile:

Another way stretch wrappers can differ is if they are low-profile or high-profile. When deciding between the two, it’s important to weigh the pros and cons of both. A low-profile stretch wrapper has the turntable on the floor. Because of this, safety is more controlled and offers flexibility on what you can wrap and where it can be placed in the production line. It also decreases the chance of damage to the machine.

Source: https://taylormhc.com/wp-content/uploads/2020/02/Orion-Flex-Series-Stretch-Wrappers.pdf

A high-profile turntable sits above the floor at a height that a forklift can load and unload pallets efficiently (typically 10 - 14 inches off of the ground). Because of this, these machines can be ineffective if a forklift is out of service and are not as versatile because a manual pallet jack cannot be used. However, a high-profile stretch wrapper can help with oversized or overhung loads without dragging on a frame and doesn’t have some of the maintenance issues with low-profile stretch wrappers due to where the drives are located.

Source: https://taylormhc.com/wp-content/uploads/2020/02/Orion-Flex-Series-Stretch-Wrappers.pdf

You will want to consider what you are wrapping and how your production facility operates when deciding between low-profile and high-profile stretch wrappers.

Questions to Ask Yourself Before Purchasing:

Nearly every facility can benefit from a stretch wrapper, and when you are deciding to purchase your next low-profile stretch wrapper, consider these questions before buying:

- What is the maximum wrap height?

- What is the stretch film’s width?

- What is the cycle count you are looking for?

- How many loads per hour are you looking for?

- Will you need a circular turntable or a square?

- If circular what diameter do you need?

- If square what is the length/width you need?

- Will you need a product height photo-eye?

- What is the pre-stretch percentage of film you will be using?

- What options will you need for your production?

- Independent carriage up/down speed control

- Independent top/bottom wrap count controls

- Adjustable turntable speed

- Extended mast

- Extended base

- Top platen hold down

- Cut and clamp

- Dual turntables

- Cold temperature package

- Weigh scale and display

- Will you need a ramp?

- What electrical requirements will you need?

Conclusion:

SIGMA Equipment offers plenty of new and used low-profile stretch wrappers and we can help you find what you need. These machines are in-stock and ready to be sent out from our dock in 24 hours. To get started with your next project with SIGMA, click the button below to contact us:

Looking to Buy Looking to Sell