Description

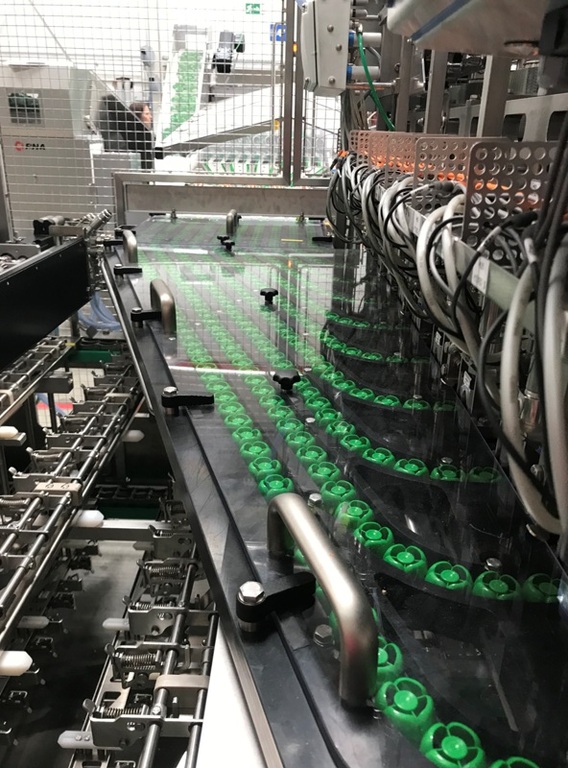

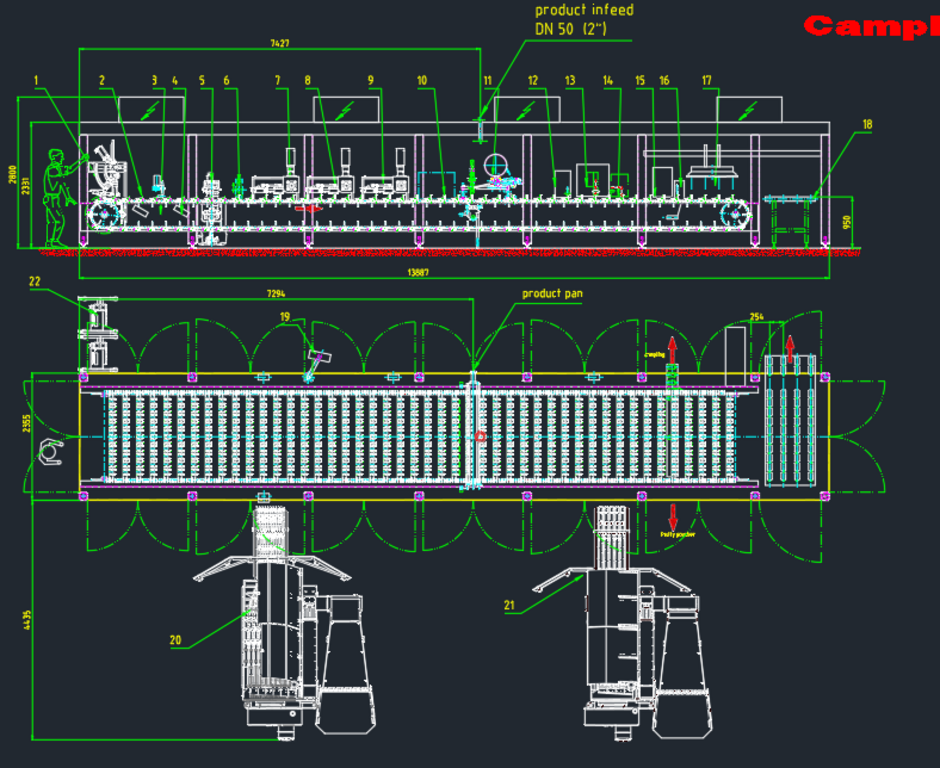

New Waldner Dosomat 20 inline filler with 10 heads

- Premade pouch with spout. Spout inner diameter: 8 mm assembling and welding of spout into the premade pouch done on the DOSOMAT prior to filling

- Up 40 cycles per minute/400 pouches per minute depending on the application

- 10 lanes

- Pouch A dimensions:

- Width: 84 mm

- Height: 109 mm

- Gusset Opening: 40 mm

- Capacity: 90 grams

- Pouch B dimensions:

- Width: 84 mm

- Height: 120 mm

- Gusset Opening: 40 mm

- Capacity: 99 grams

- Pouch C dimensions:

- Width: 84 mm

- Height: 140 mm

- Gusset Opening: 40 mm

- Capacity: 113 grams

- Fill capacity: electronically infinitely adjustable, depending on product consistency and head space in the pouch

- Hot fill, approximately 90° C

- Closure: Screw cap, 1 size, fitting on the spout used.

- Pouch magazine: up to 300 pouches per lane

- Vacuum pouch denester

- Pouch check:

- No pouch no fill

- No pouch no seal

- automatic stop after 5 consecutive missing pouches

- Inkjet coder

- Barcode scanner

- Vision inspection system

- Pouch opening: vacuum cups

- Pouch Open Check: Performed by inserting a checking cone with sensors into the open pouches. If not open, no filling or sealing will take place

- Reject conveyor: Discharges bad pouches or unopened pouches

- Spout Infeed: Using a bulk hopper, spouts are fed to the unscrambler.

- Spout Unscrambling: Separated and oriented spouts are fed to a 10-lane vertical shaft to be inserted into the pouches

- Spout Emptying Function: Extra spouts can be emptied out of the system at a color change

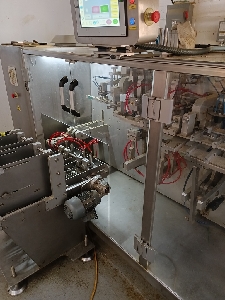

- Spout Insert: The spouts are taken out of the vertical drop shaft by a servo-controlled gripper unit and inserted into the pouches. There, at the same time the first sealing of the pouch is executed.

- Sealing:

- Sealing Station 1: 10 sealing stations weld the spouts to the pouches using hot seal heads with adjustable parameters (temperature, pressure & time)

- Sealing Station 2: Similar to SS1 and required to achieve proper sealing

- Seal Weld Cooling Station: Water cooled sealing tools ensure quick solidification of the seal between spouts and pouch

- Vacuum Leak Test: Rapid vacuum leak (less than 0.8 second) ensures seal integrity. Leaking pouches are rejected

- Reject Conveyor: Pouches that are registered as “reject” are discharged from the machine

- Filling:

- Piston Dosing Filler 1: Fill valves are lowered onto the spouts and seals it off during filling process allowing for proper pouch filling and avoiding potential product contaminations on the exterior of the pouches.

- No pouch no fill ensures only open present pouches to be filled. Servo-assisted lowering and lifting the fill valves away

- Temperature Sensor: Pouches less than 90° C will be rejected.

- Spout Cleaning: Steam nozzles for cleaning outside of spouts

- Capping:

- Screw Cap Feed & Unscramble: Unscramble, orient and feed 10-lane distribution

- Screw Cap Emptying Function: Extra screw caps can be emptied out of the system at a color change

- Screw Cap Setter: Pick-&-Place servo assisted set the screw caps onto the filled pouches

- Screw Cap Closing: Stepper motors close the caps to adjustable pre-set torque

- Camera Inspection: 100% Vision system after screw cap is applied. Will inspect against and illuminated background cap orientation, seal width/height, shoulder width/height, missing or partial date code

- Rejection/Sampling: The rejection conveyor manages all “rejected” pouches. It can also be used for sampling a complete line of pouches for QA inspection

- Discharge: Pouches are discharged spouts trailing with bar codes facing up

- Control unit: suitable for wet room operation. Machine controls and motion control Allen-Bradley, 480 V 3 Ph 60 Hz, 24 Volt Dc Control Voltage, approx. 40 kW connected load. The complete electric / control system is housed in a cabinet IP-65. This is separate from the machine. The control unit is programmed so that all stations are automatically switched on with automatic start and switched off one after another on evacuation.

- Programming software: ControlLogix 5000

- HMI: PanelView Plus6 15”, Win CE

- Servo Controllers: Kinetix 6500

- Variable Frequency Drives: Powerflex 40P

- Servo Motion: ControlLogix L72

- Safety PLC: GuardLogix L62S

- Compressed air: FESTO Filter/Regulator, approx. 300 l/min with 6 bar, (10.6 CFM @ 90 PSIG).

- Unit is enclosed in safety doors

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.