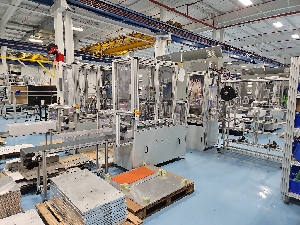

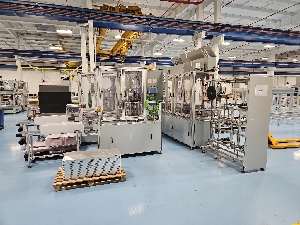

Used Unused Spee-Dee Powder Filling Line: Includes Unscrambler, Filler, Capper, Labeler, And Case Packer

Description

Unused Turnkey Powder Filling Line:

- Powder feed rate: 6000 pounds per hour

- Filler output: Up to 120 bottles per minute depending on the application

- Line includes:

- Ska Fab depalletizer

- Arrowhead bottle conveyor and lowerator

- New England NEHCPCL-48 bottle unscrambler

- Spee-Dee 12 pocket rotary filler with 36" base

- Twin auger powder filling feeder

- Checkweigher

- Supersack powder transfer system

- New England NERCC-6 6-head chuck capper with feeder

- PE Labellers SL Mod Plus 540-6-M-4P-0-1-0-0-0 rotary labeler

- Camera inspection system for labels

- Polypack shrink bundler

- Douglas Trivex case packer

- Case labeler

- Change parts for capper includes: 33mm, 38mm, 45mm, 53mm, 63mm, 89mm, 110mm, 120mm cap sizes

- Bottle unscrambler has ionized air cleaner

- Cases up to 25 per minute (150 products per minute)

- Case Range:

- Length: 4-15 inches

- Width: 4-10 inches

- Height: 4.5-12 inches

- Common applications

- Powdered food packaging

- Protein powder, collagen, or meal replacement powders

- Nutraceuticals and health supplements

- Baking mixes, flour, or spices

- Pharmaceutical-grade dry fills

- Dry chemical powders

- Industrial additive packaging

- Agricultural or feed supplements

- Stainless steel and food grade contact parts

Part of the line has been installed, project was cancelled and never ran.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.