Description

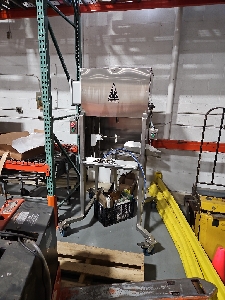

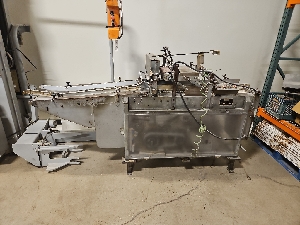

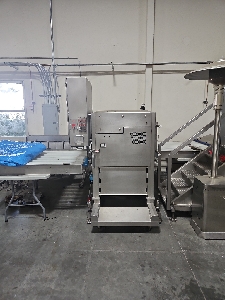

Used Backus Sormac bv Knife Peeler MS Vegetable Peeler with:

- The Sormac knife peelers MS are suitable for continuous peeling of pre-washed or pre-peeled root products, like potatoes, red beet, celeriac, etc.

- The produce to be peeled is conveyed by a transport auger through a horizontal, rotating drum. The inside of this drum is equipped with a large number of knives. The dwell time and peeling effect can be controlled by varying the RPM of the drum and the speed of the transport auger. The special shape of the drum and the way the knives are positioned effectively avoids the produce from being flat peeled.

- The peeling waste is separated from the peeled product immediately and ejected by the rotating drum. The waste can be collected for removal in a crate or waste transporter via the waste funnel at the base of the machine.

- Peeling waste capacity of 600 to 700 kg (1,323 to 1,543 pounds) per hour

- With 40% waste, the input capacity is 1,500 to 1,750 kg (3,307 to 3,858 pounds) per hour

- Features:

- Low energy consumption

- Just 3 motors for the entire peeler

- Knife life > 2,000 operating hours

- Effectively avoids flat peeling

- Easy to clean

- Higher yields than flat bed peelers

- Dimensions (inches):

- Peeler: 100 long x 54 wide x 84 high

- Infeed conveyor: 72 long x 54 wide

- Inspection table: 149 long x 26 wide

- Dipper: 150 long x 54 wide

- Stainless steel construction

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.