Description

The Silverson Flashblend FLB60 is a high shear system for rapid incorporation of a wide range of powders, including problematic gums and thickeners. The Flashblend is designed to incorporate powders on a continuous and semi-continuous basis at rates of up to 30,000 lbs/hour. The system can handle a wide range of viscosities, from low-viscosity products to highly viscous gels

- How it works: The Silverson Flashblend is designed to rapidly wet out and disperse a wide range of powders into liquids. The system is based on proven technology combined with new techniques which stem from specific research into powders which are difficult to hydrate. The result is a mixer which can produce agglomerate-free homogeneous dispersion

- Stage 1: The process liquid is pumped at high velocity into the venturi chamber and passes into the In-Line mixer. The combination of the pump, venturi and the pumping action of the In-Line mixer creates a vacuum in the venturi chamber

- Stage 2: When powder is present in the hopper, the powder feed valve can be opened. The vacuum rapidly draws the powder down into the venturi chamber where it passes with the liquid stream at high velocity into the rotor/stator assembly of the In-Line mixer

- Stage 3 The liquid/powder mix is then subjected to intense mechanical and hydraulic shear which ensures that it is completely dispersed and agglomerate-free. The resultant product is then passed back to the process vessel by the pumping action of the machine

- Advantages

- Suitable for large-scale production requirements

- Consistently delivers agglomerate-free products

- Ensures high repeatability for consistent results

- Rapid mixing speed for increased efficiency

- Minimizes aeration during the mixing process

- Improve vessel hygiene

- Viscous liquids can be incorporated into the bulk liquid via the hopper

- Liquid additives can also be pumped directly into the venturi

Specs

- Typical powder flow rate: up to 550 pounds per minute, depending on application

- A wide range of workheads and screens are available for Silverson high shear mixers (at an additional cost). These interchangeable workheads offer great versatility by allowing the machine to be adapted to perform a wide range of mixing operations including emulsifying, homogenizing, disintegrating, dissolving, dispersing, blending, particle size reduction and de-agglomerating

- Hopper volume: 10.5 cubic feet

- Mixing system

- 3 inch inlet/outlet

- APV centrifugal pump:

- Maximum viscosity 150 cP

- Maximum capacity 116 m³/h

- Maximum pressure of 25 bar

- 3 inch inlet

- 2 inch outlet

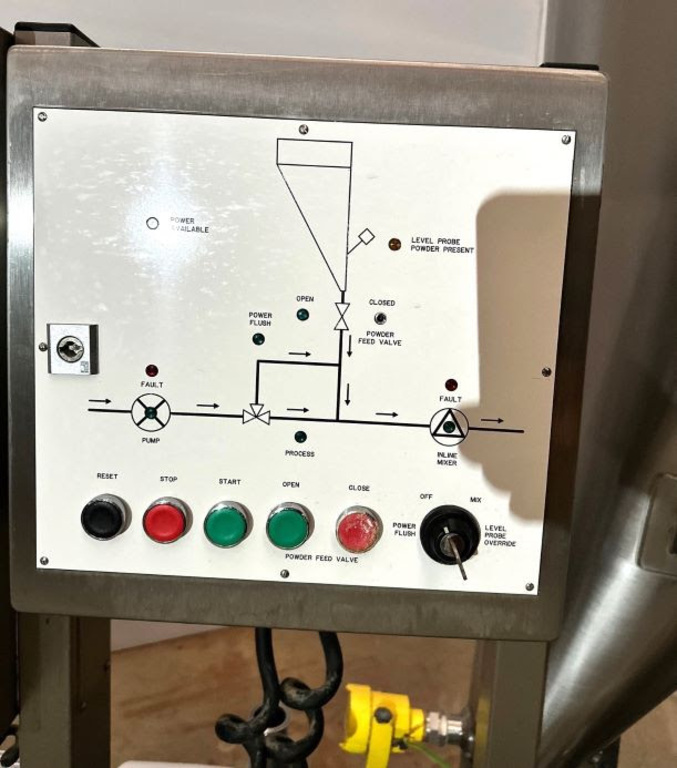

- Push button controls

- Start/Stop

- Open/close

- Reset

- Power flush

- Level probe override

- 30 horsepower shear motor

- 25 horsepower centrifugal motor

- Electrical:

- Volts: 230/460

- Frequency: 60 Hz

- Phase 3

- 316 stainless steel construction

Approximate overall dimensions: 79"L x 40.5"W x 75"H

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.