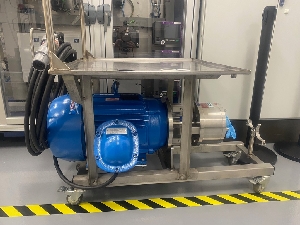

Used Silverson 450LS Multistage Inline High Shear Mixer/Colloid Mill 10 Horsepower Up To 1100 GPM 316L SS

Description

Silverson’s line of high shear In-Line mixers offers a great many advantages to the processor—speed, versatility, self-pumping, aeration-free, guaranteed efficiency. At the heart of every mixer is Silverson’s high performance rotor/stator workhead.

- Multistage

- Operation:

- Stage 1: The high-speed rotation of the rotor blades within the precision-machined mixing workhead exerts a powerful suction, drawing liquid and solid materials into the rotor/stator assembly

- Stage 2: Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator

- Stage 3: This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle

- Output: up to 1100 gallons per minute depending on application

- No bypassing: product cannot bypass the precision rotor/stator workhead

- Interchangeable workheads: currently equiped with a general purpose disintegrating head

- Tri-clamp style fitting

- 2 inch inlet/outlet

- 10 horsepower motor: 3600 rpm

- Electrical:

- Volts: 230/460

- Frequency: 60 HZ

- Phase 3

- 316L stainless steel contact parts

Silverson inline mixers offer:

- Aeration-free operation

- Self-pumping functionality

- No bypassing for consistent mixing

- Interchangeable workheads

- Sanitary construction for hygienic processing

- Easy maintenance

- Lower power requirements for cost-effective operation

- Elimination of agglomerates and fish eyes

- Creation of stable emulsions and suspensions

- Particle size reduction

- Rapid dissolution of solids

- Acceleration of reactions

Different workheads for different operations (change parts not included)

- General Purpose Disintegrating Head: Used for a wide range of applications, this head will give the greatest throughput. Suitable for the blending of liquids of similar or greatly varying viscosities, its uses include the disintegration of solid and semi-solid materials

- Square Hole High Shear Screen: The configuration and fine internal tolerances of this stator provide exceptionally high shear rates which are ideal for the rapid size reduction of soluble and insoluble granular solids. It is also suitable for the preparation of emulsions, gels and thickeners and fine collodial suspensions

- Slotted Disintegrating Head: For the disintegration of fibrous materials such as animal and vegetable tissue, as well as the disintegration and solubilization of “elastic” materials such as rubbers and polymers

- Emulsor Screens: These screens are suitable for liquid/liquid preparations and are especially useful for all emulsions. Emulsor screens are available in fine or medium perforations

Last used in a cosmetics facility

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.