Description

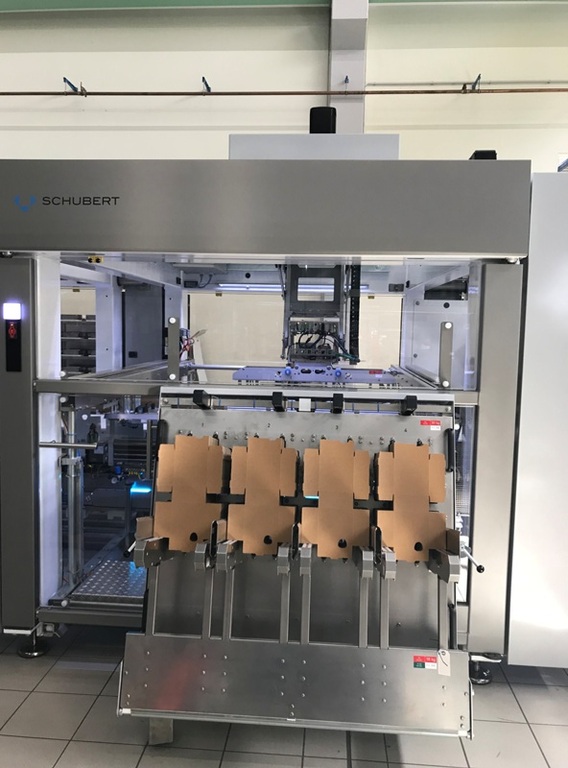

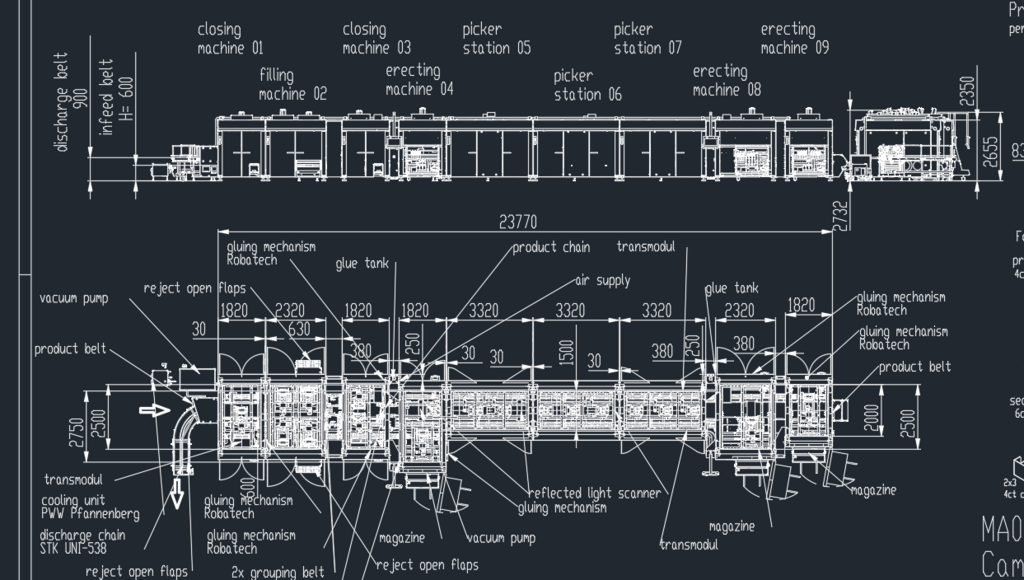

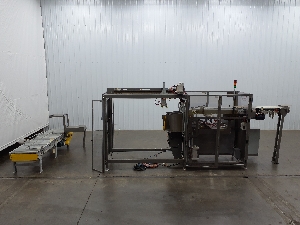

New Schubert Carton Caser:

- Product and Production Rates:

- There are three (3) different pouch sizes:

- Pouches are laying flat bar code up gusset leading

- Four (4) lanes of pouches at 112.5ppm per lane or total 450ppm

- Cartoner Rate including surge: 540ppm

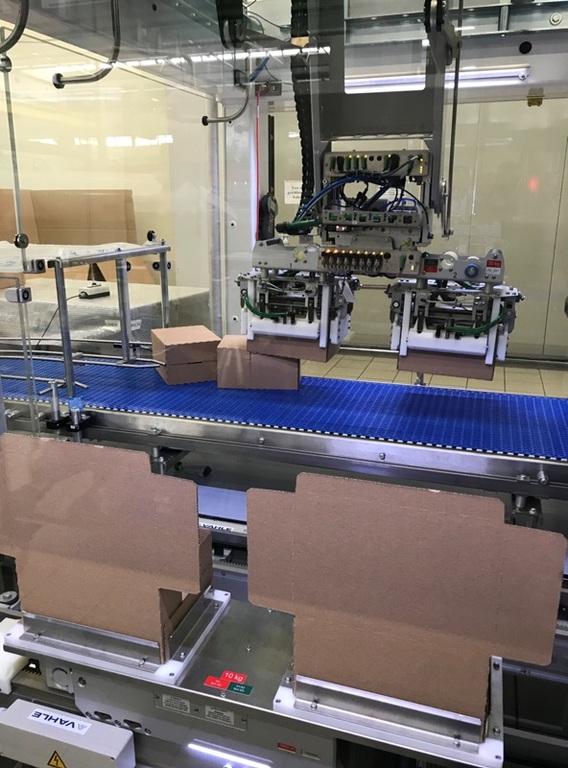

- Carton Packing: All cartons are wrap-around style cartons, using glue

- Packing 4, 6, and 12 count cartons

- Case packing (4 count cartons only)

- There are three (3) different pouch sizes:

- For the 4 count cartons, the pouches are placed oriented standing upright (standing on the gusseted end) at 135 cartons per minute

- Pouch A erected carton dimensions:

- Length: 133 mm

- Width: 62.5 mm

- Height: 134.5 mm

- Pouch B and C carton case dimensions:

- Length: 133 mm

- Width: 62.5 mm

- Height: 165.5 mm

- Pouch A erected carton dimensions:

- For the 6 count cartons, the pouches are placed oriented standing upright (standing on the gusseted end) single file into the displable carton at 90 cartons per minute (pouch B and C only):

- Erected carton dimensions:

- Length: 201.5 mm

- Width: 81.5 mm

- Height: 169 mm

- Erected carton dimensions:

- For the 12 count cartons, the pouches are placed oriented standing upright (standing on the gusseted end) at 45 cartons per minute (pouch B and C only)

- Erected carton dimensions:

- Length: 225 mm

- Width: 110 mm

- Height: 171 mm

- Erected carton dimensions:

- Case Packing:

- The 4 count cartons only need to be packaged into wrap-around cases using glue for closing

- 6 cartons per case, 23 cases per minute

- Pouch A erected case dimensions:

- Length: 284 mm

- Width: 201 mm

- Height: 145 mm

- Pouch B and C erected case dimensions:

- Length: 284 mm

- Width: 201 mm

- Height: 176 mm

- Pouch A erected case dimensions:

- Transfer unit with magazine

- Used to transfer carton blanks, corrugated cardboard to the TLM packaging line

- Quick changeover tools for magazines which pivot to assist changeovers

- Using a 3-axis robot type TLM-F3

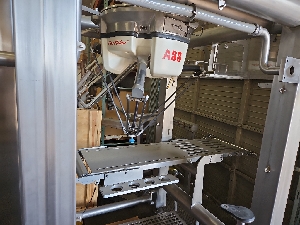

- TLM-F44 Robot with vision system

- Module consisting of robot arms with drives and vision system

- Utilized for picking and placing randomly placed product

- 4 axis robots controlled by servo motors

- Product specific tooling

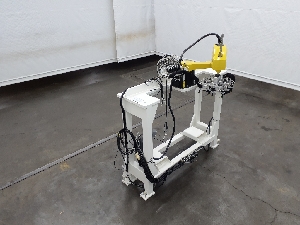

- TLM-F2 Robot

- Used for automated positioning transfer and loading of product controlled by servo drives

- Programmable via a “teach-in” motion sequence

- Format specific tooling for each size/configuration

- Use of quick changeover pneumatic clamping with a programmable code to verify correct tooling use

- Transmodule

- Intelligent system used for complete transport of products and packages

- Using an integrated vacuum pump

- Move autonomously with speeds up to 4.5 m/s

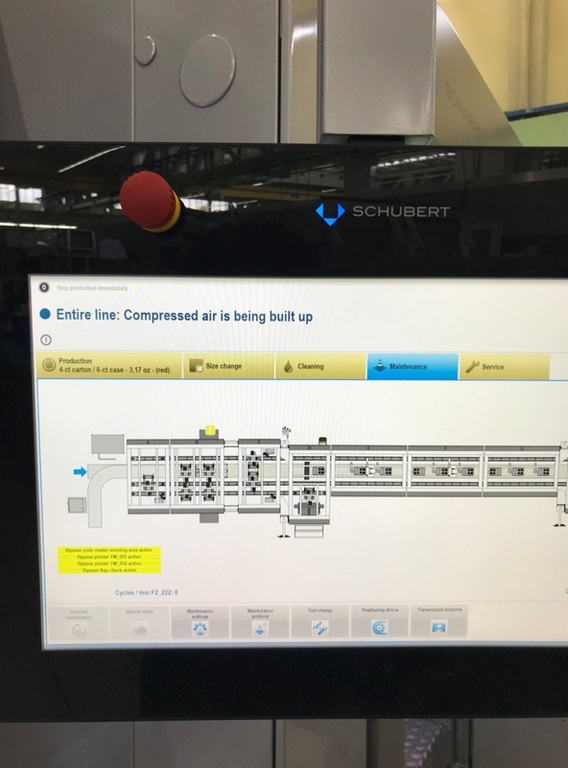

- VMS control system with operator terminal

- Decentralized control system

- Flash card stores all configuration data.

- Electrical supply: 460 V, 60 Hz, 3 phase

- NC programming: Standard laptop with Schubert software

- Hot melt glue system: NORDSON

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.