Description

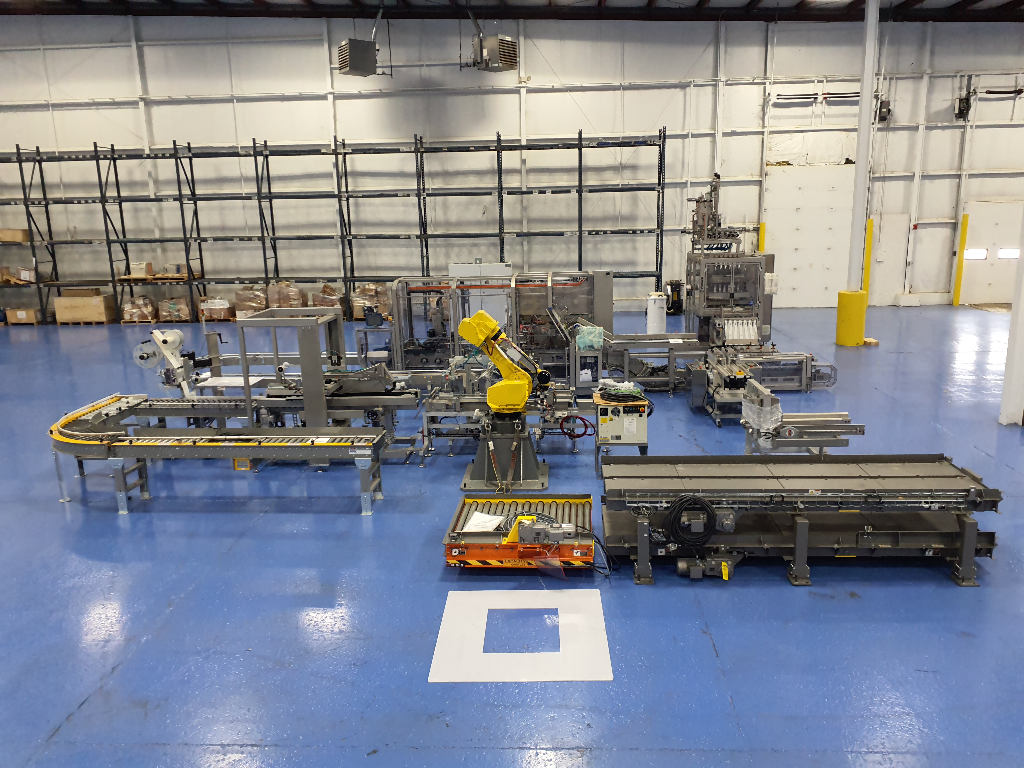

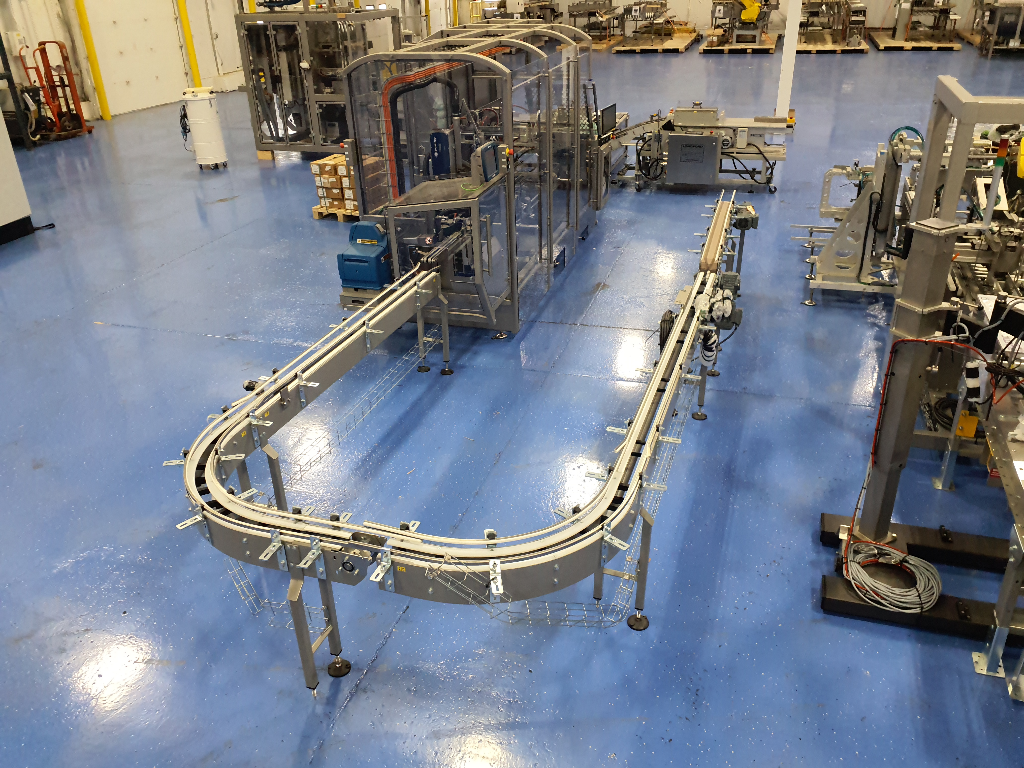

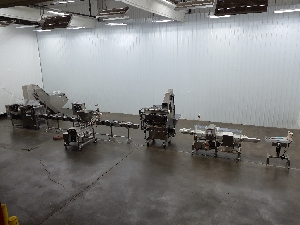

Liquid Stickpack System with:

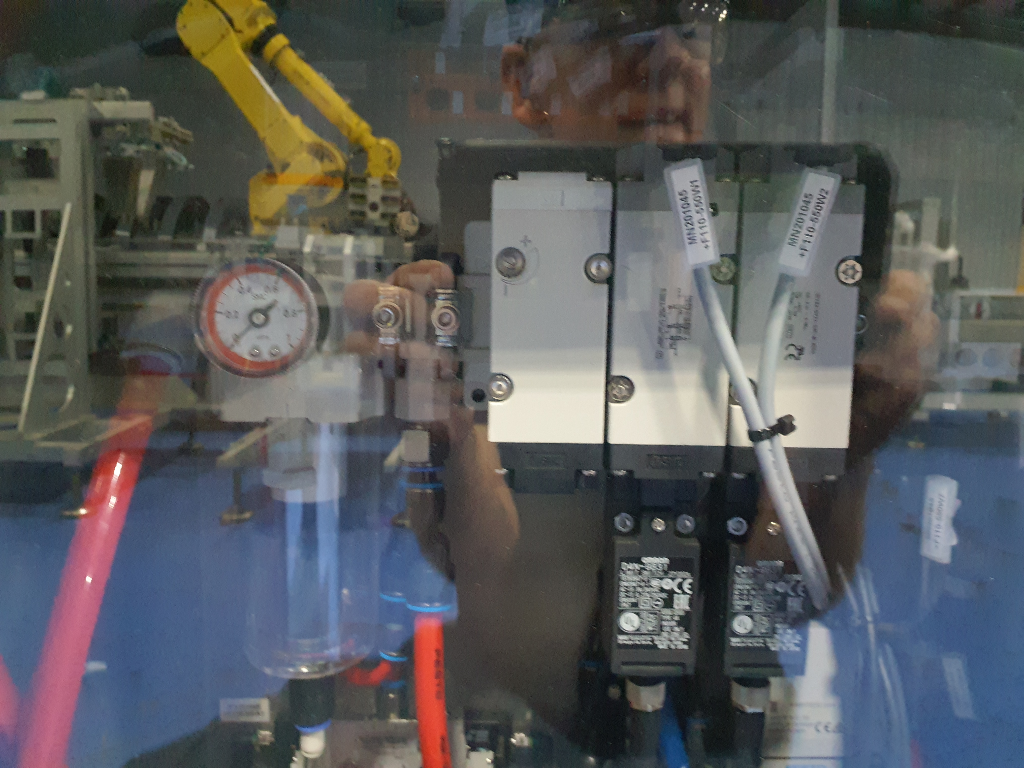

- Pressurized AISI-316L Stainless Steel 25 Liter Hopper:

- Hygienic clamp connection for installation of the level sensors

- Full CIP system

- (5) clamps for tank cover

- Tank pressure: between 3 and 6 bar depending on application

- Relief valve

- Pressure gauge

- Pressure regulator

- Vibration Level sensor

- AISI-316L stainless steel construction

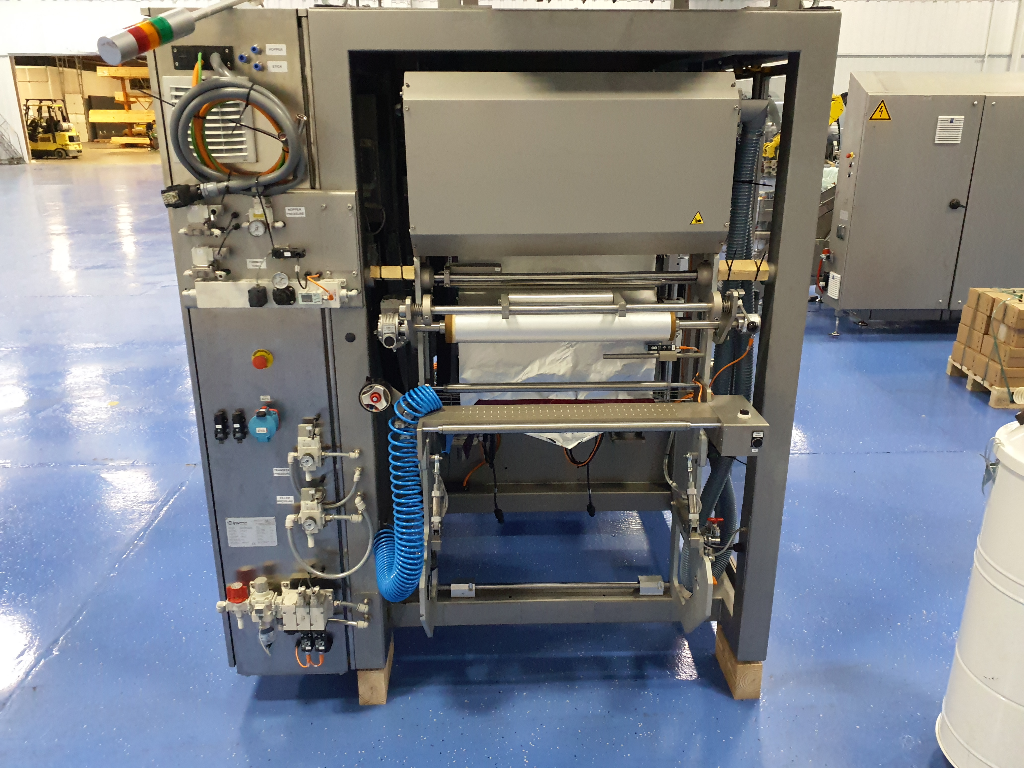

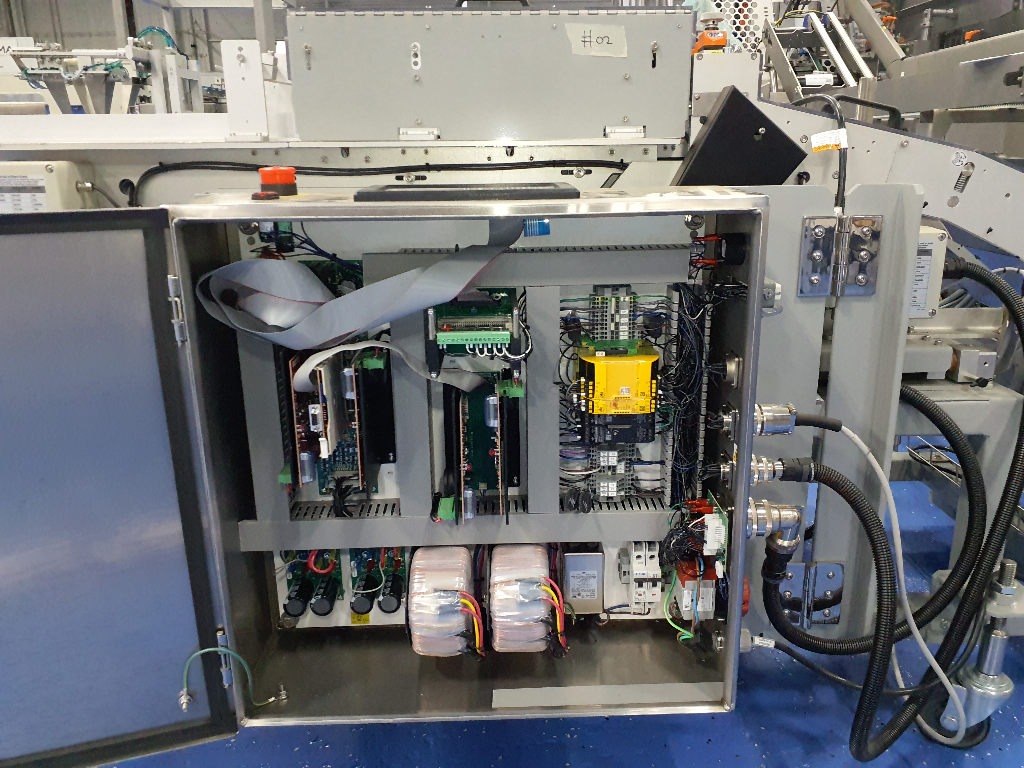

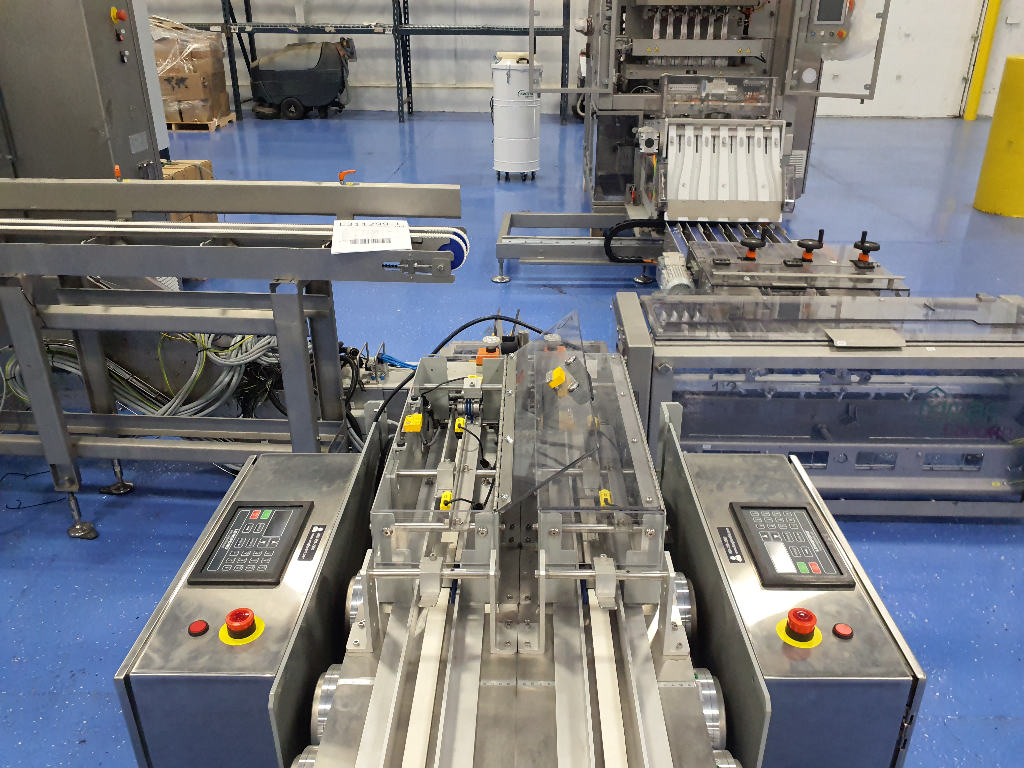

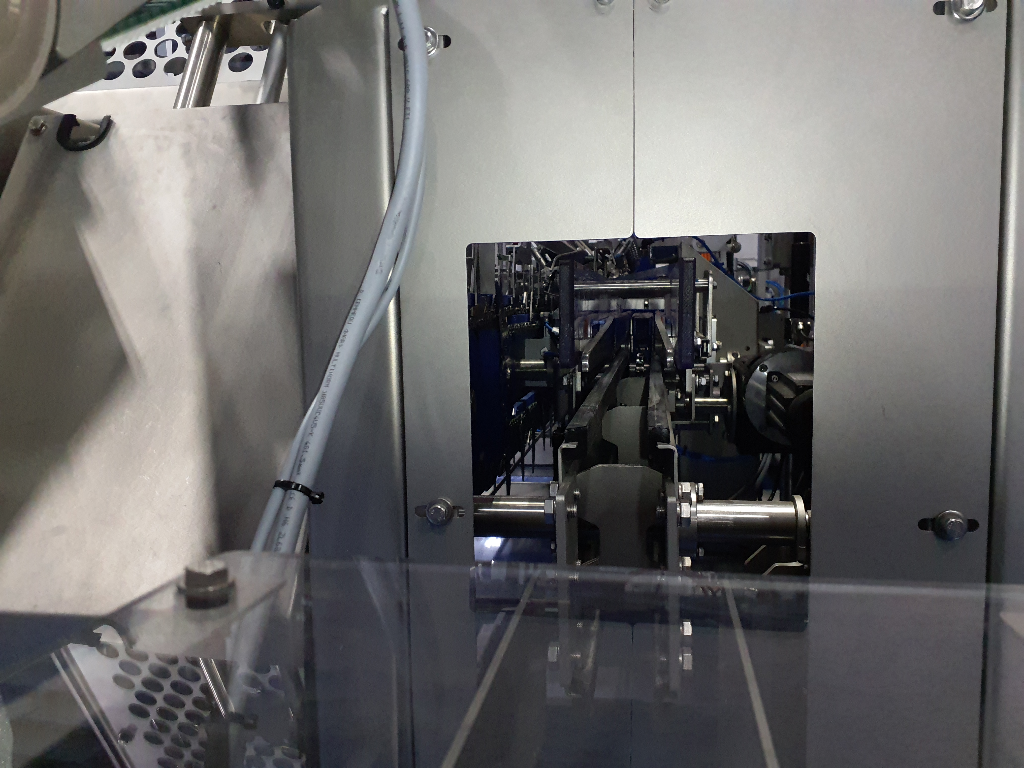

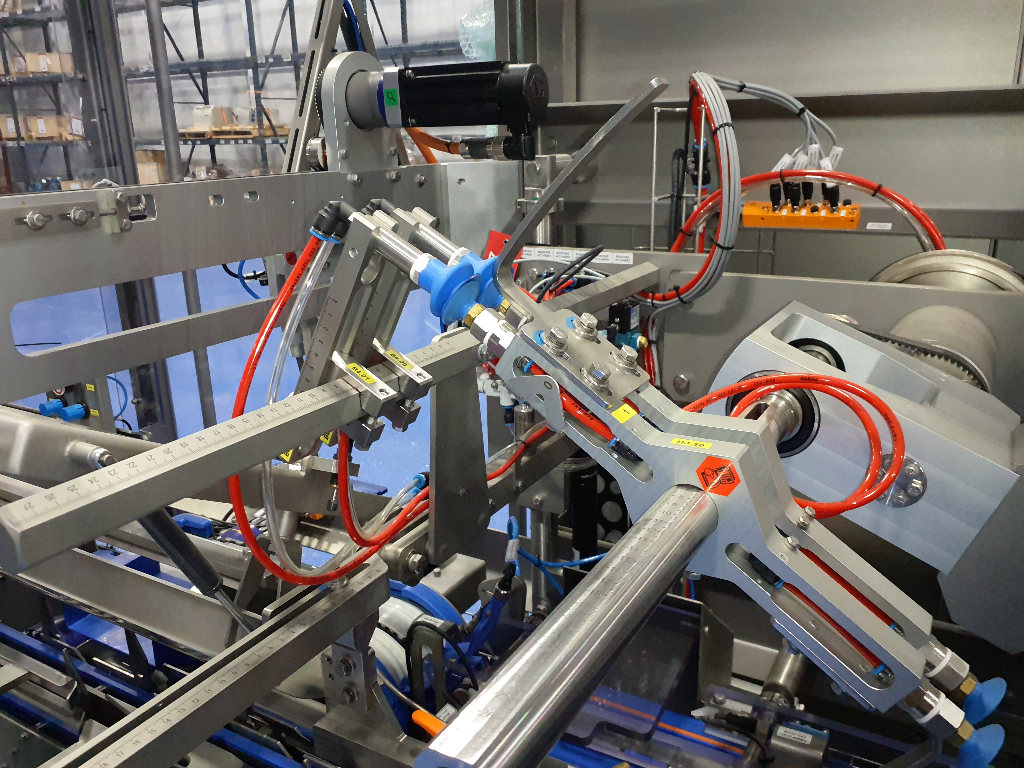

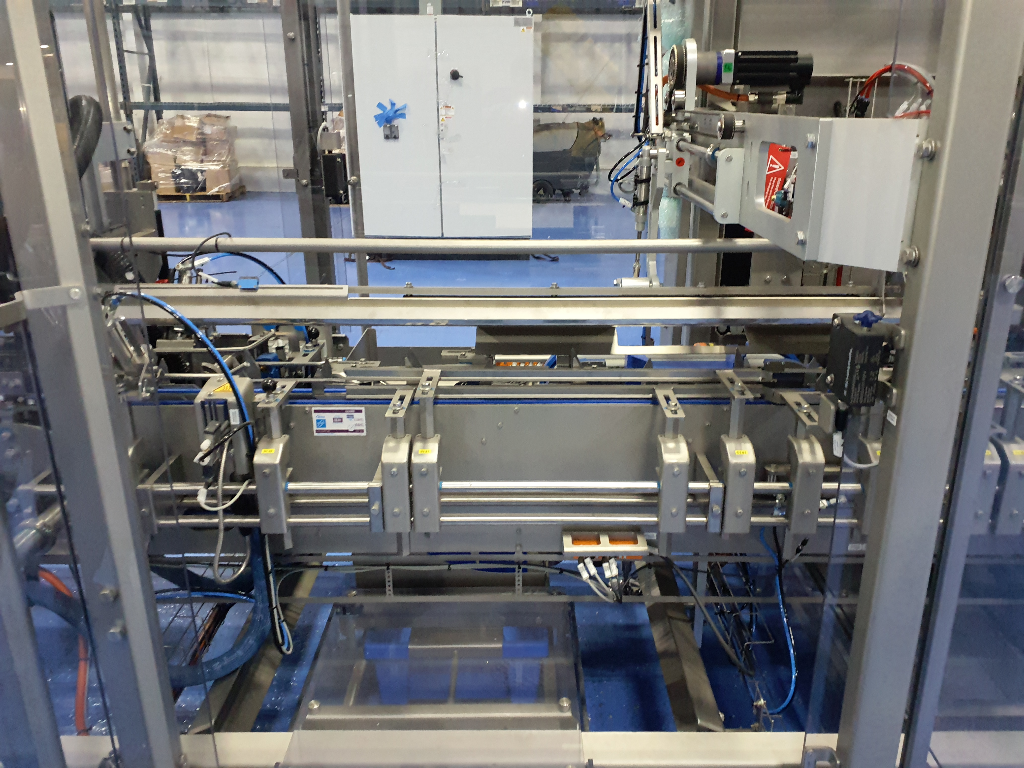

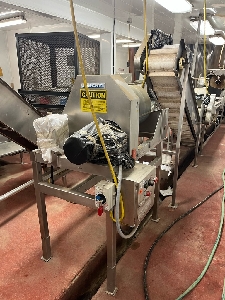

- INV Pack 6 Lane Stick Pack Machine:

- Production output rate:

- Up to 50 stickpacks/lane per minute (depending on application)

- Up to 300 stickpacks per minute (depending on application)

- Current stickpack specifications:

- Liquid (5.7 mL)

- Bag size:

- Length: 75 mm

- Width: 50 mm

- High-precision forming shoulders for 3-sided seal

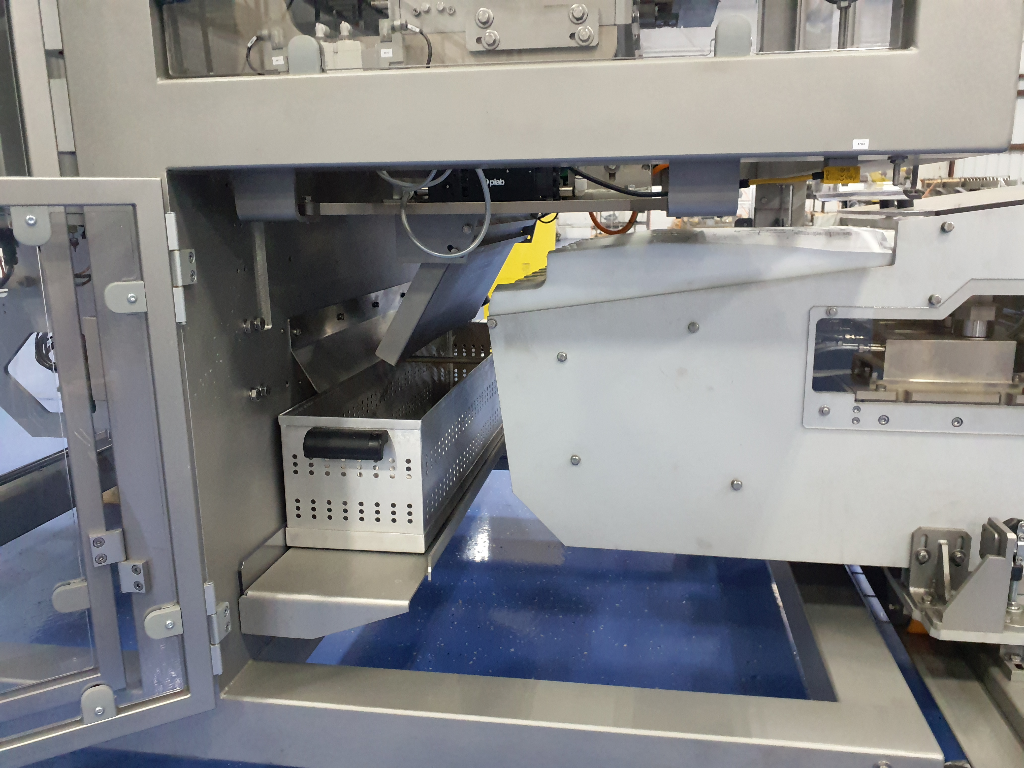

- Horizontal tear notch and side

- Horizontal diamond-tipped sealers

- Horizontal straight cut station

- Photocell for vertical film centering

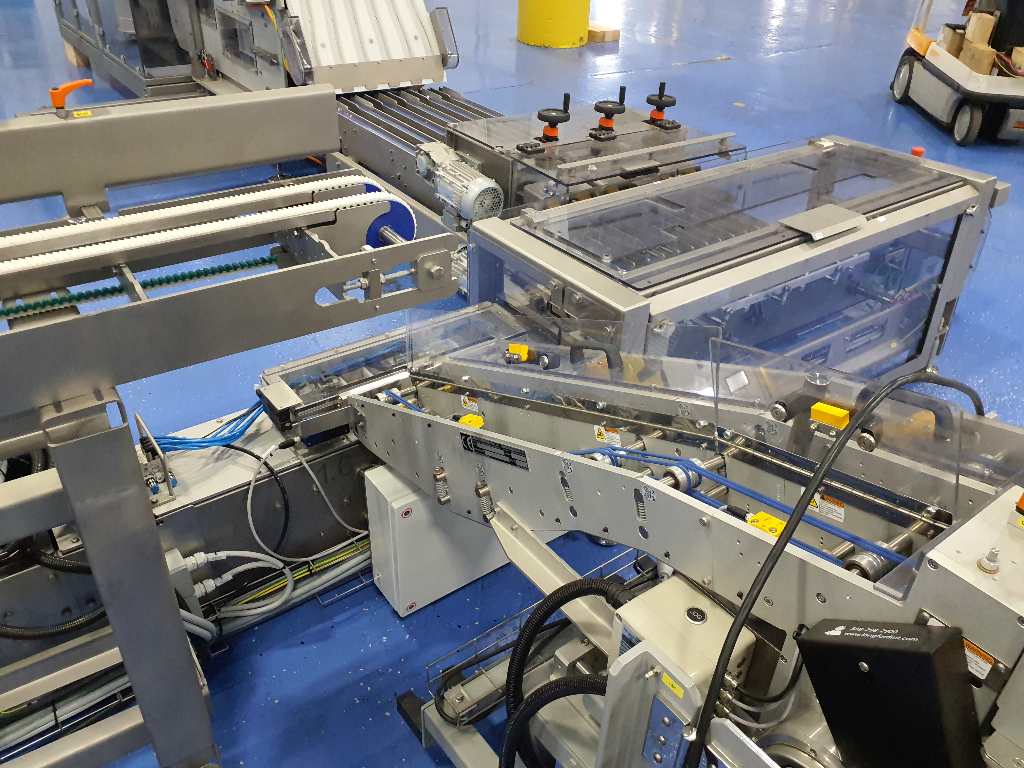

- Reel splicer table

- Ultrasonic spliced reel detection system

- Reel automatic alignment system

- End of reel alert

- Centralized side seal trimmer

- Scrap foil aspirator

- Masca K1030-HDP Laser Coder

- Nitrogen gas detection system

- Air pressure installation:

- Working pressure: 6 bar

- Maximum pressure: 7 bar

- Consumption: 1000 l/m

- 316 stainless steel contact parts

- Electrical: 480 volts, 60 hertz, 3 phase

- Production output rate:

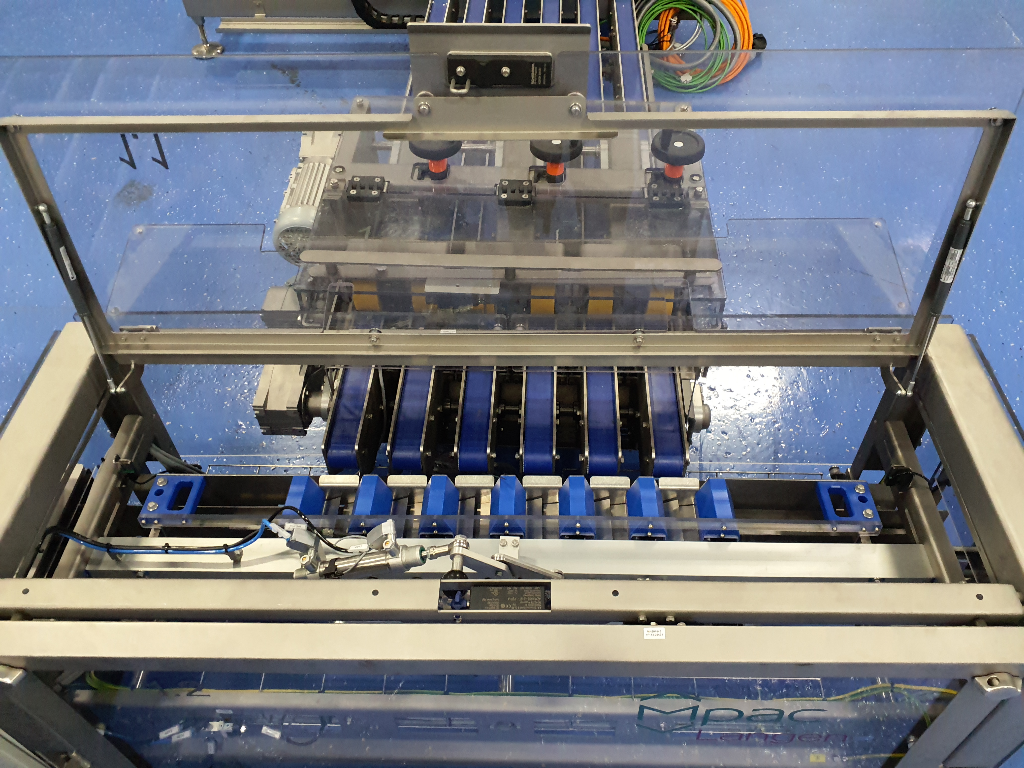

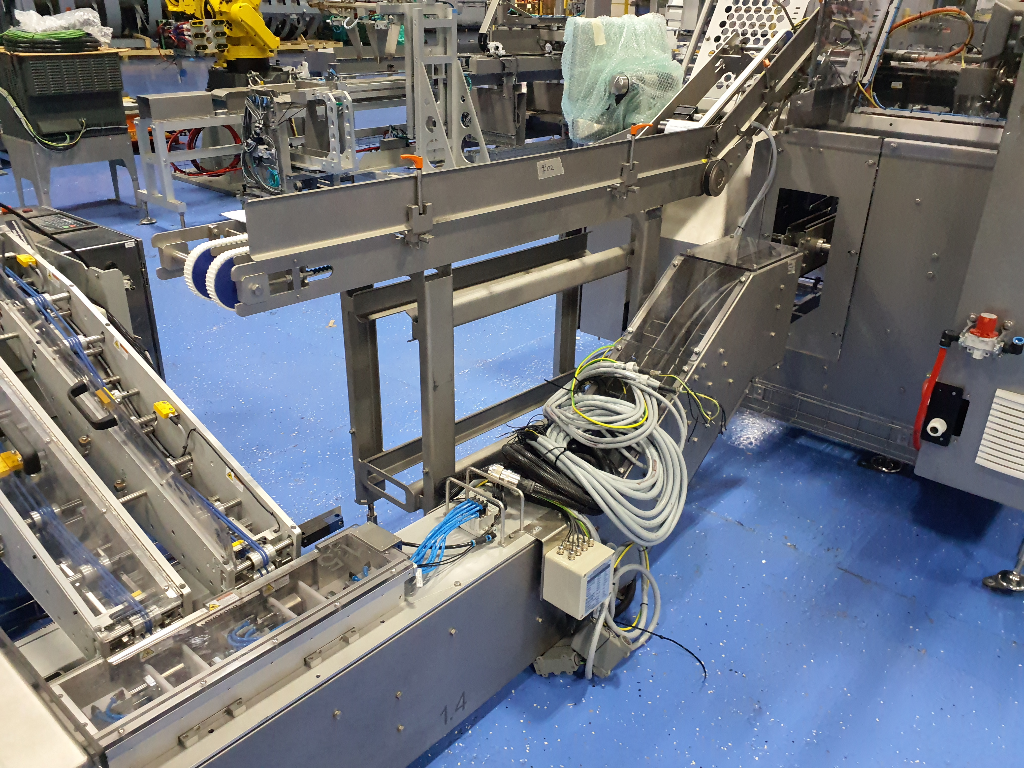

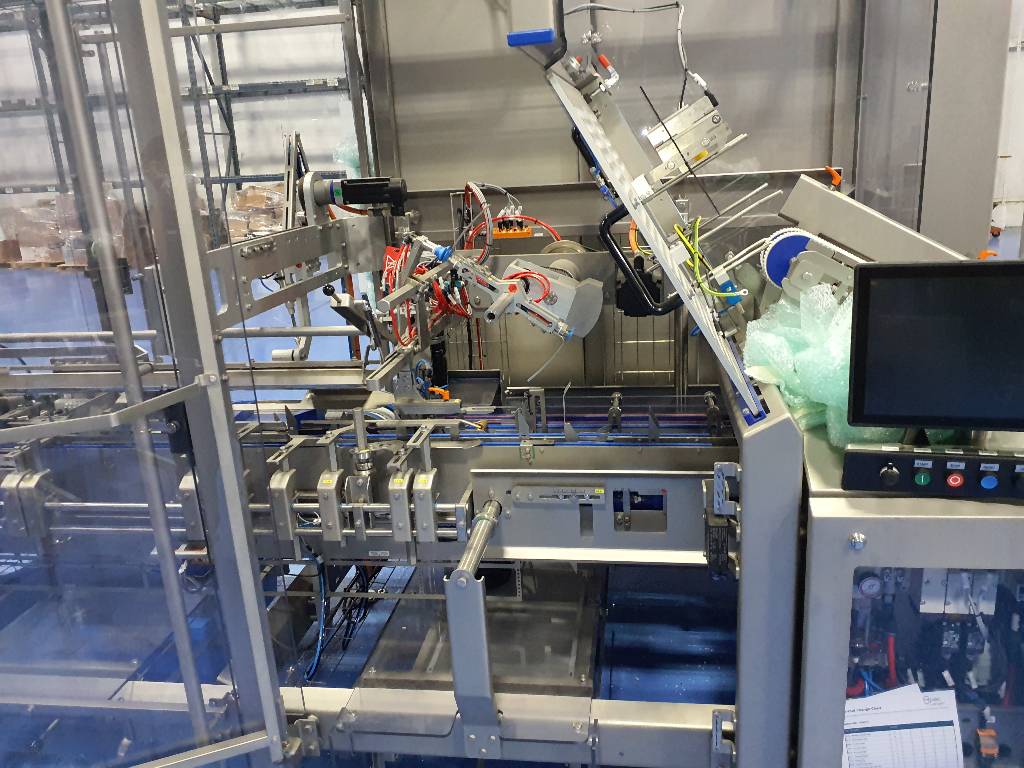

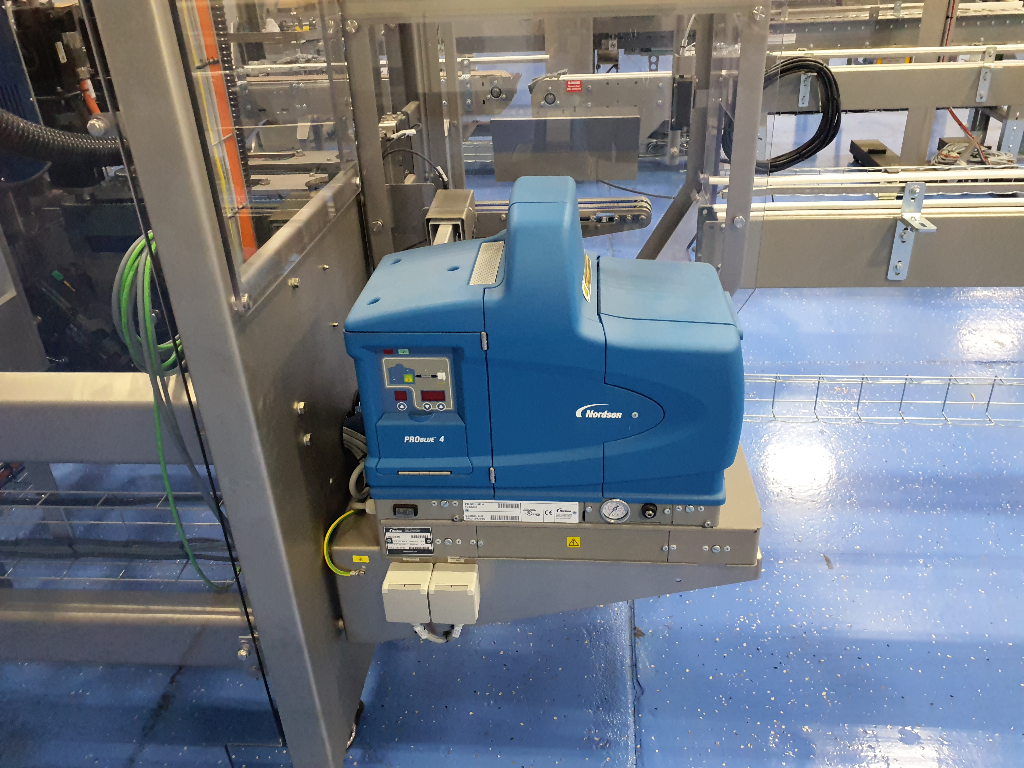

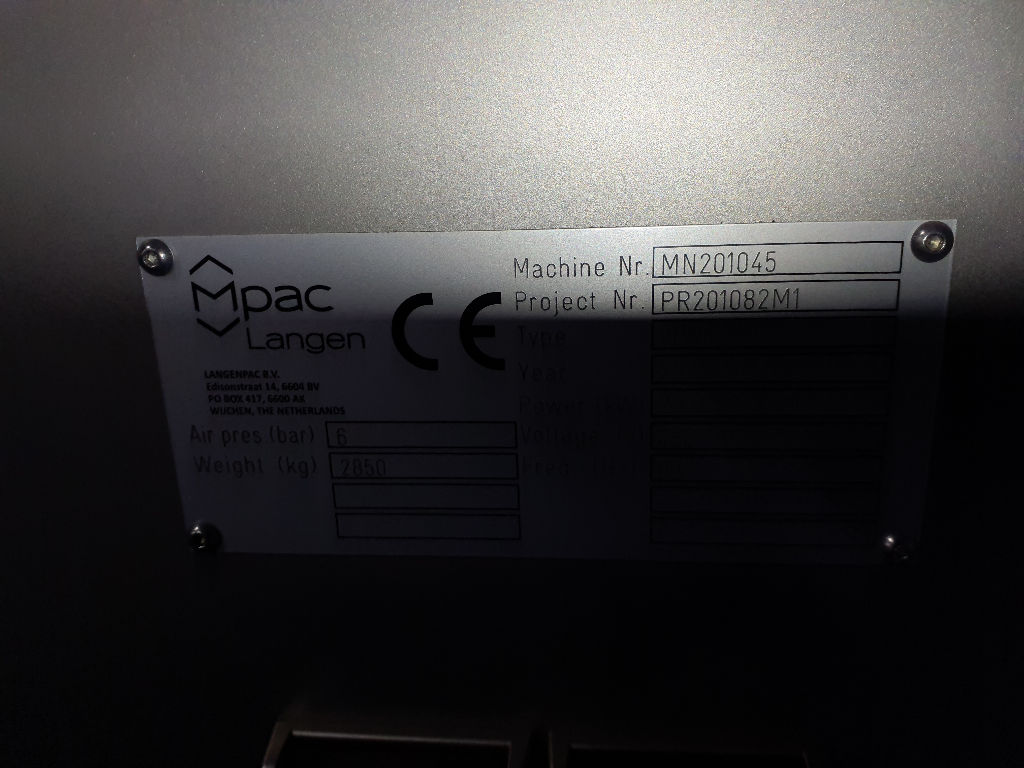

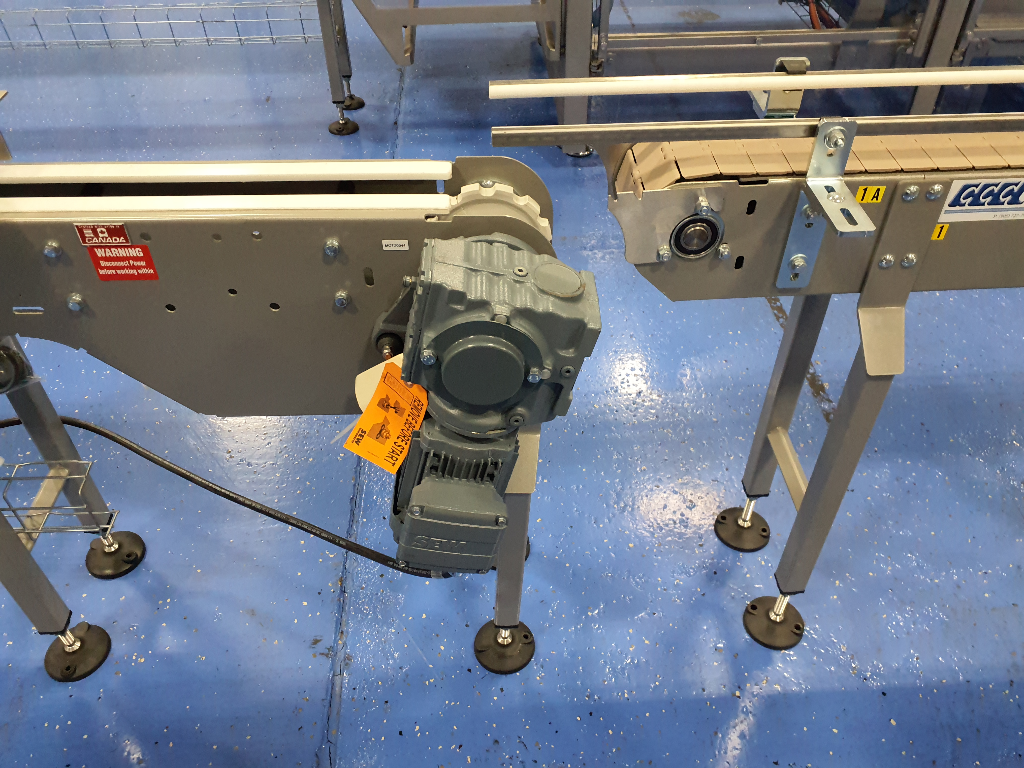

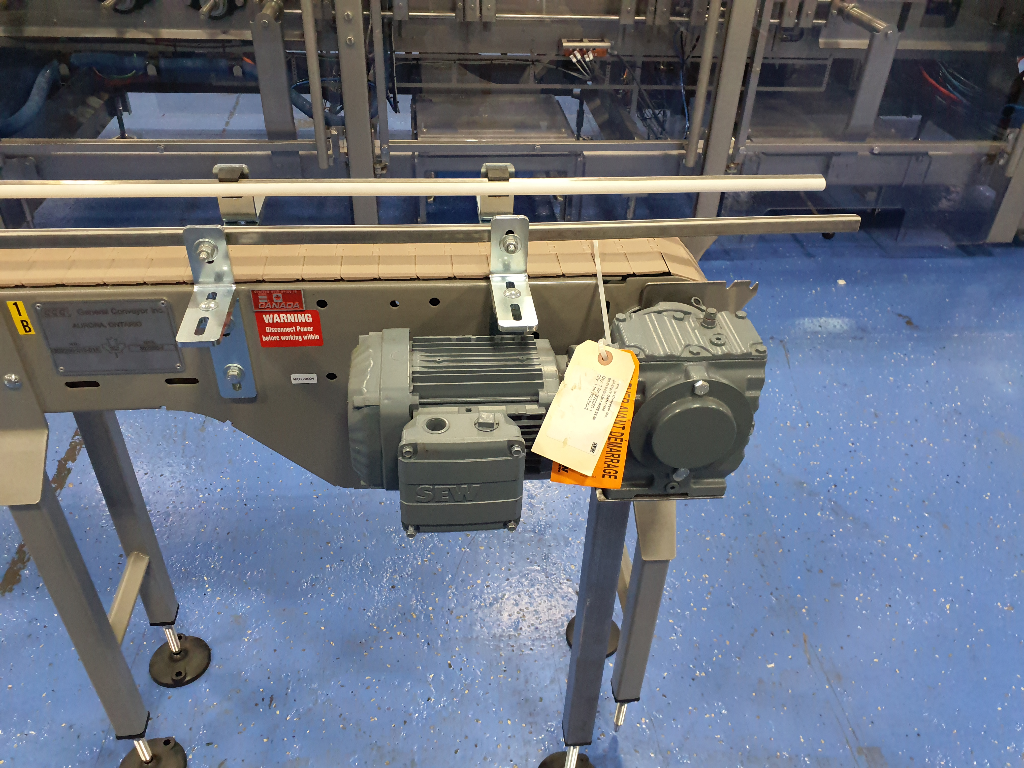

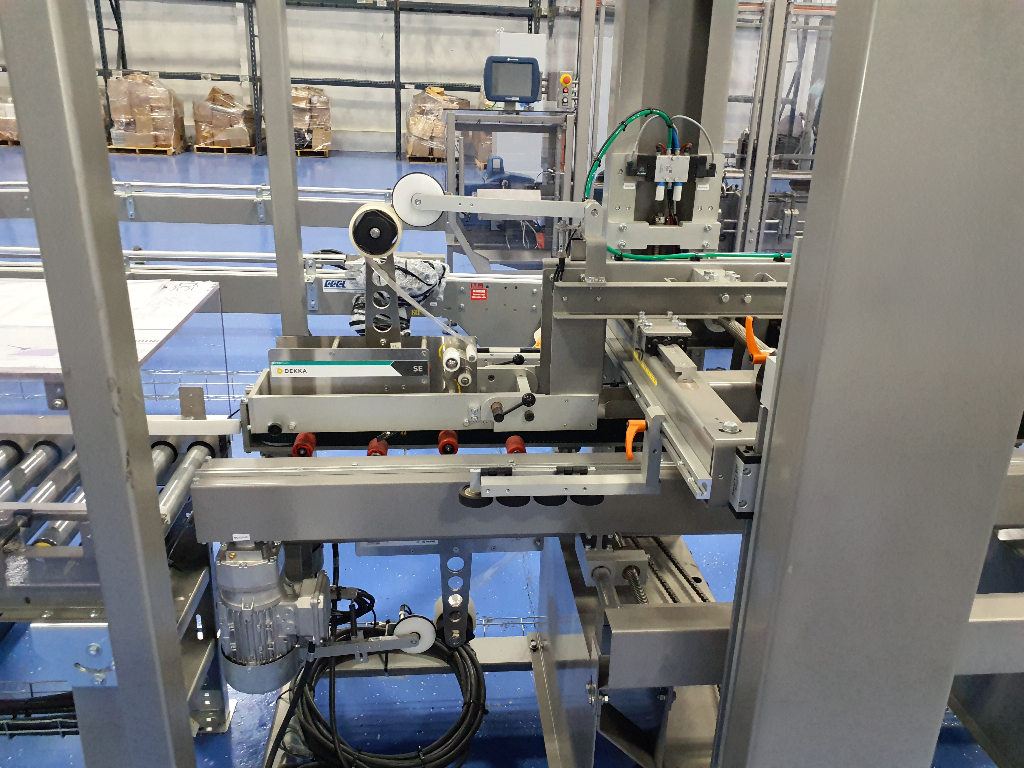

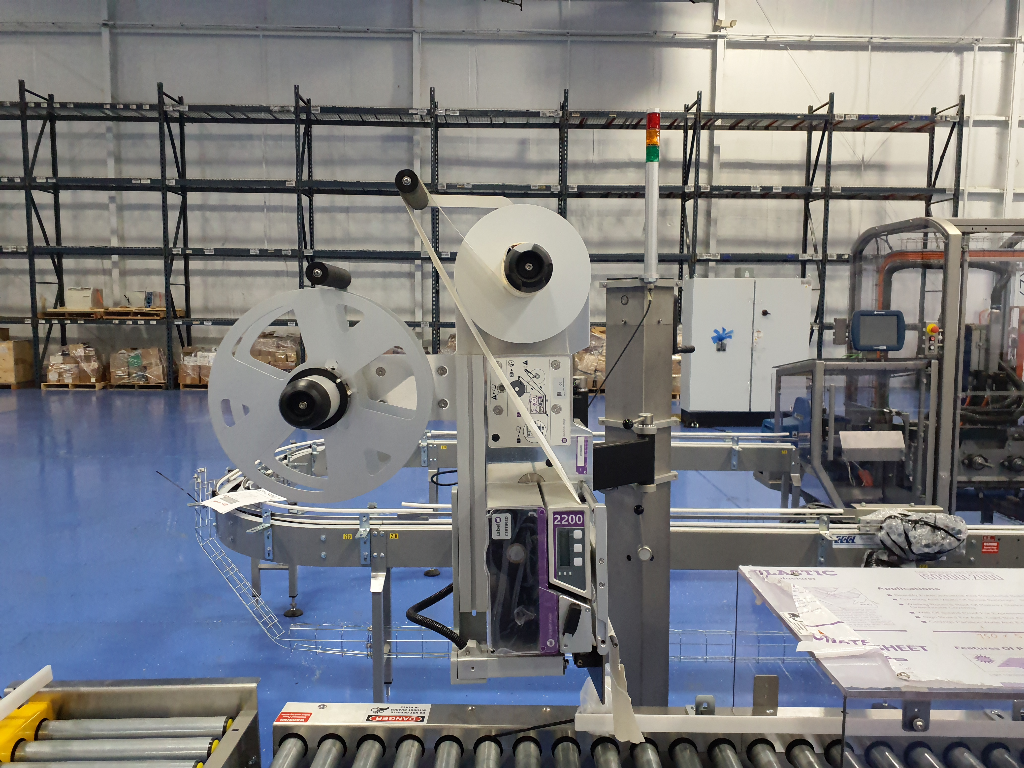

- Mpac Langen Automatic Glue Horizontal Cartoner:

- Carton speed: up to 10 cartons per minute (depending on application)

- Current carton dimensions:

- Length: 150 mm

- Height: 55 mm

- Depth: 75 mm

- Product shape: rectangular

- Operating temperature: > 5°C (41°F) and < 40°C (104°F)

- Air consumption: 398 Nltr/min

- Operating pressure of compressed air: 6 bar (87 psi)

- Electrical: 480 volts, 60 hertz, 3 phase

- Maximum measured sound level: < 80 decibels

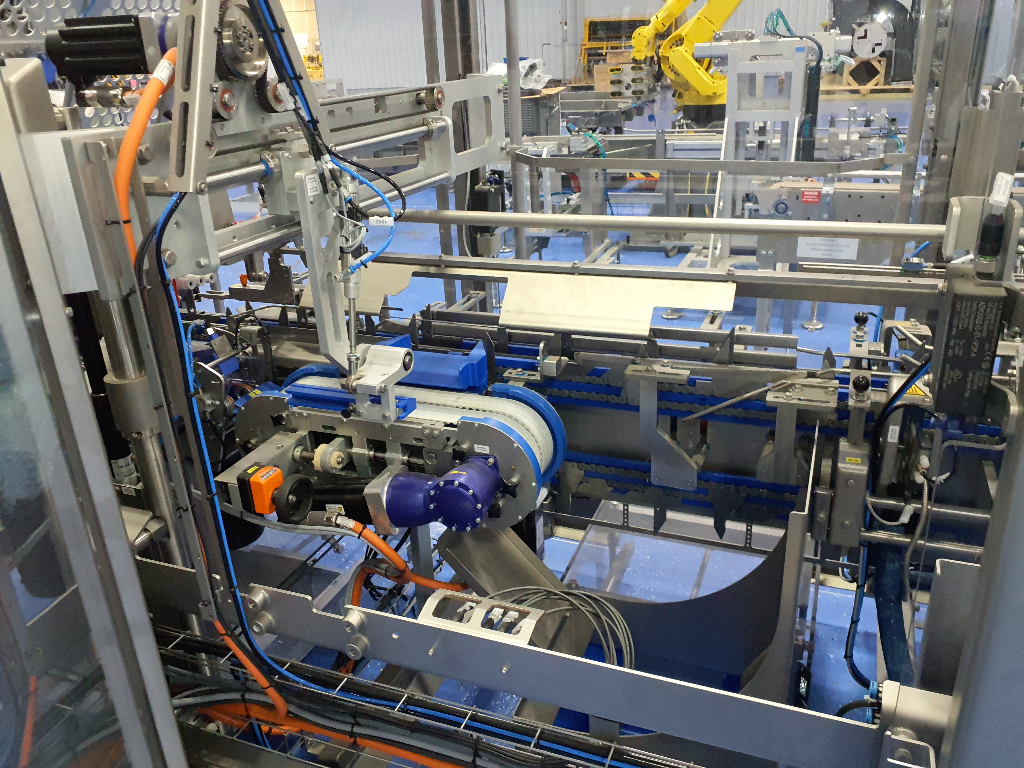

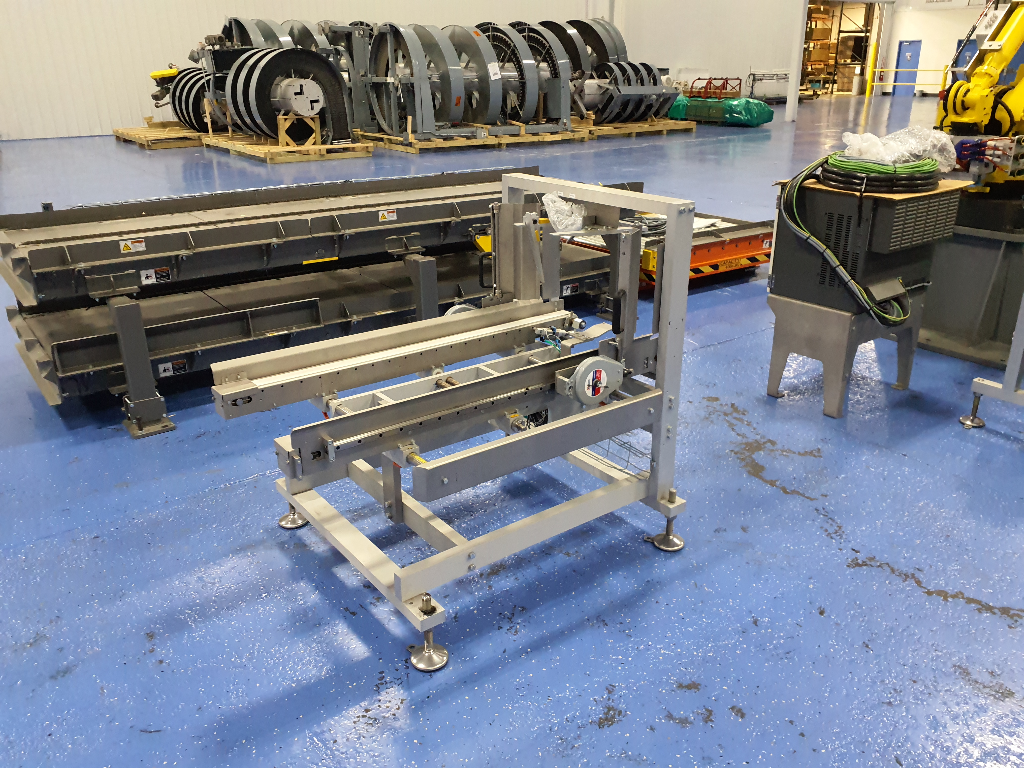

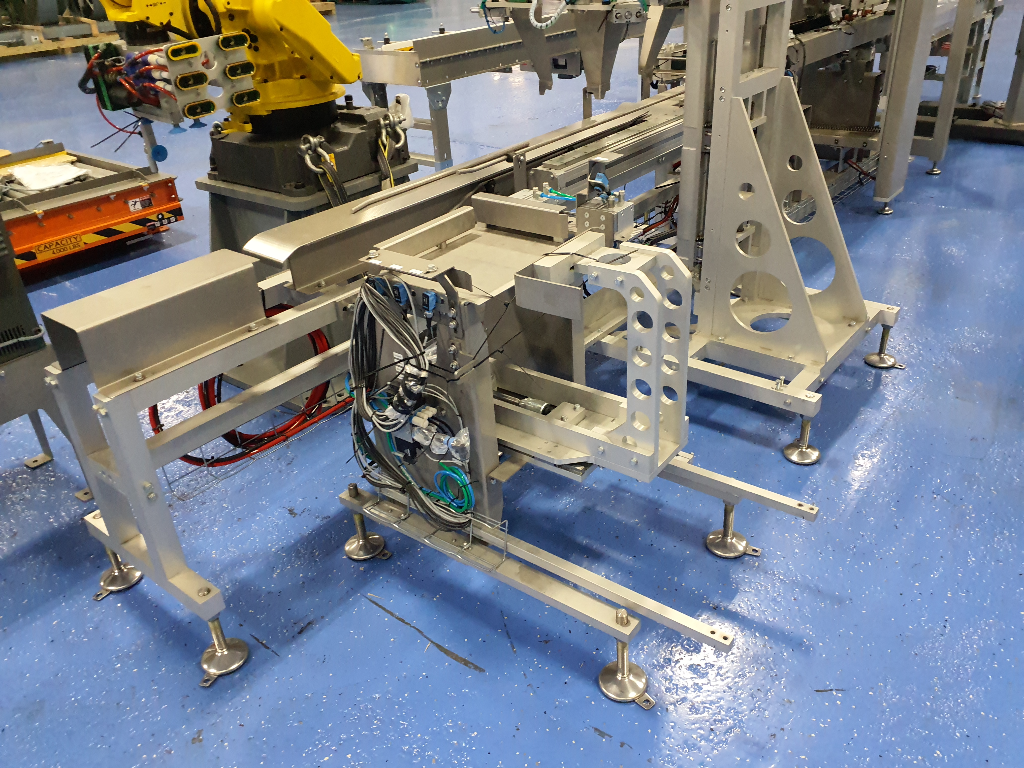

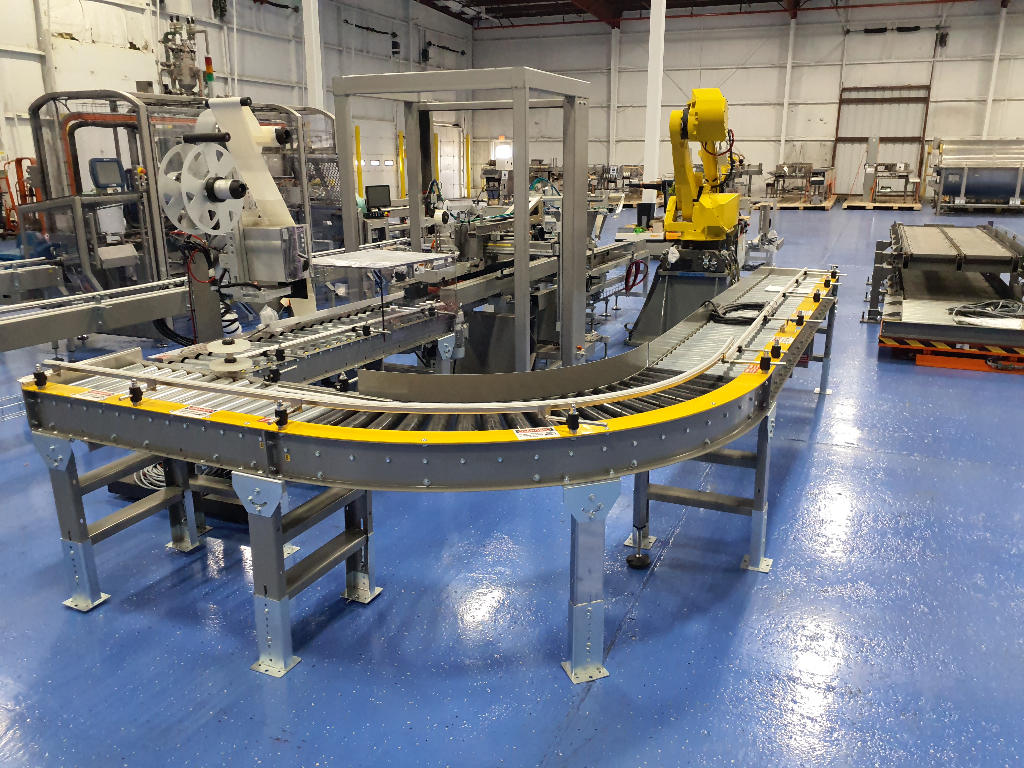

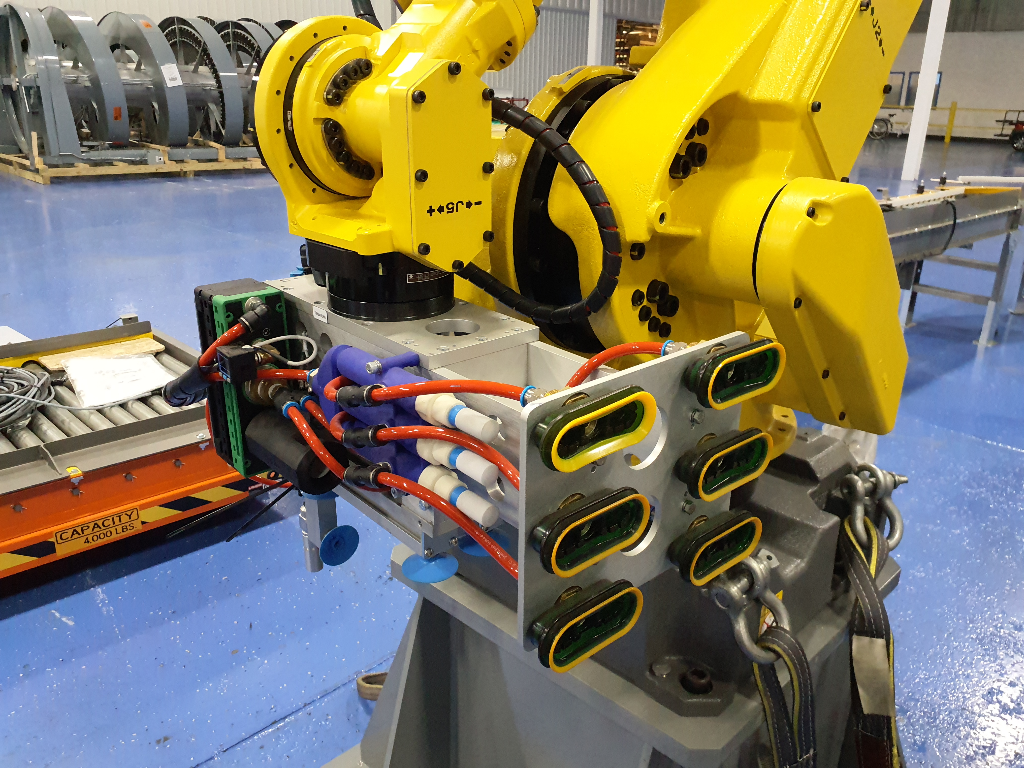

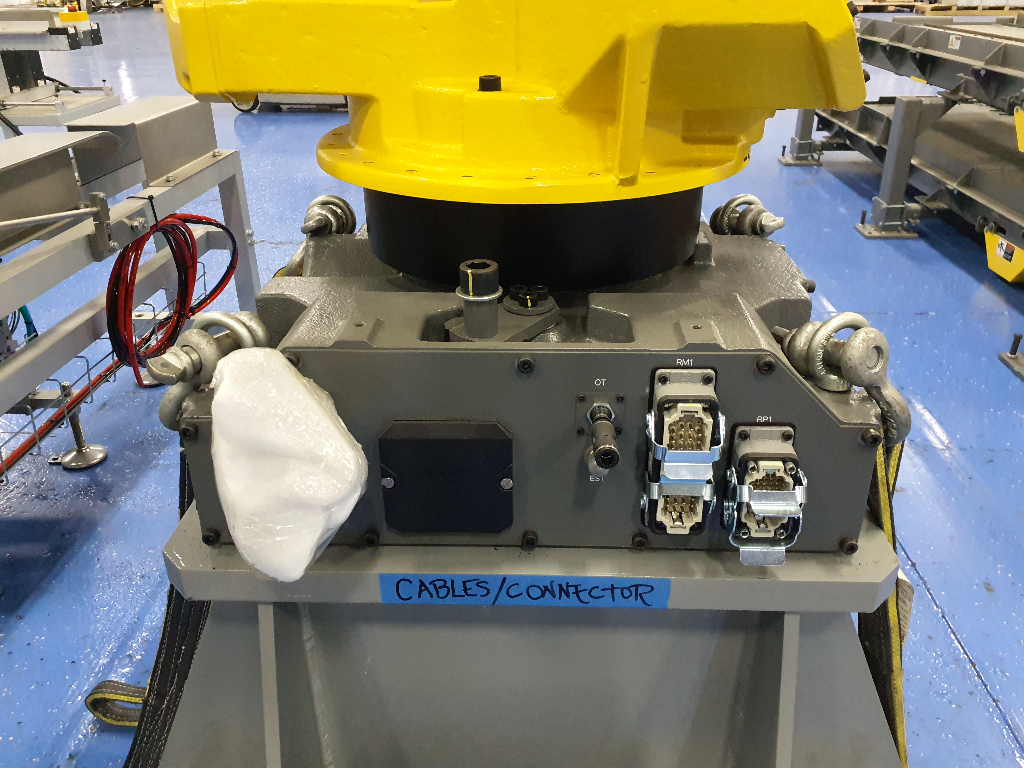

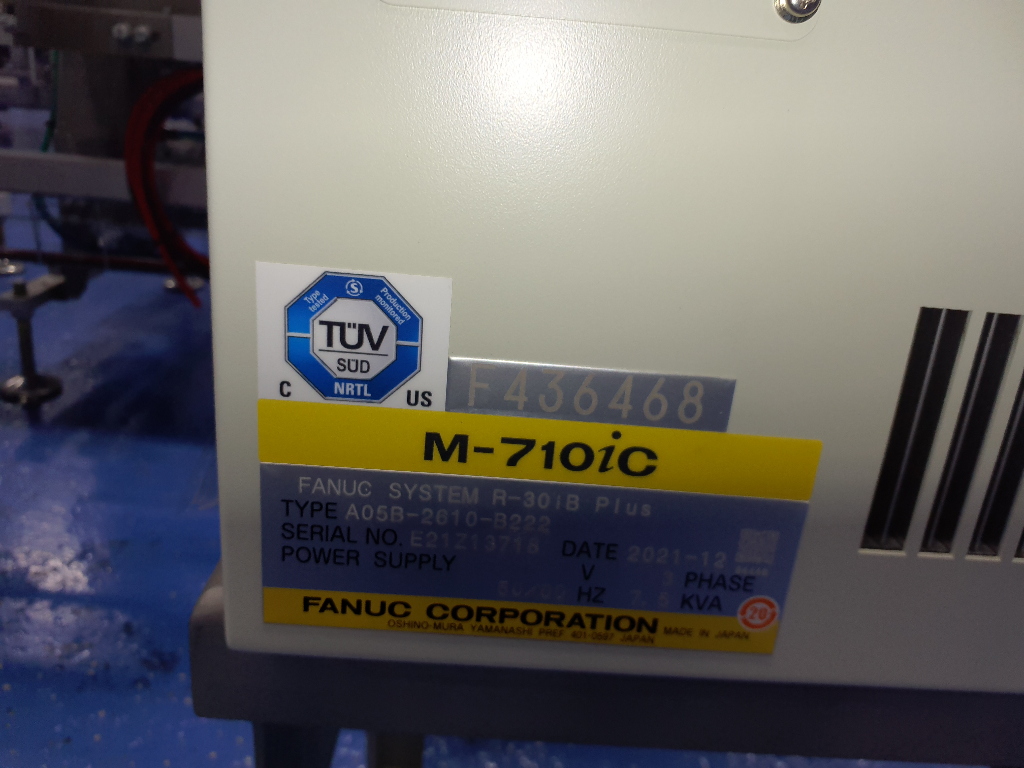

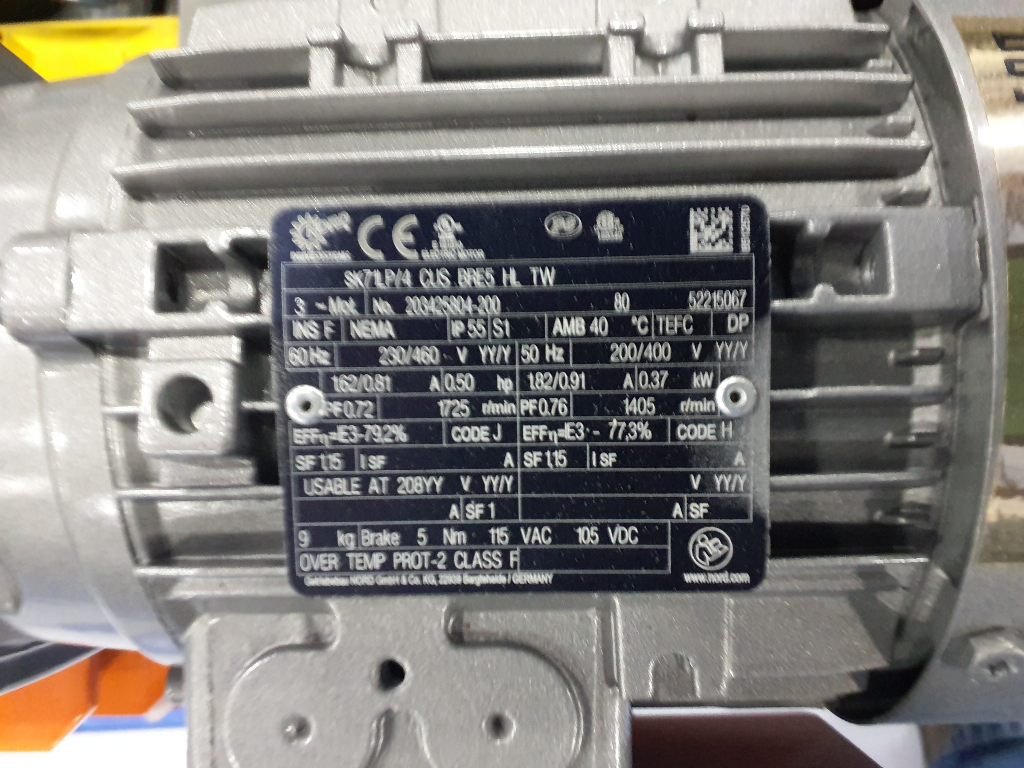

- LRC-700 Robotic Palletizing and Case Packing System:

- Cartons received upstream at maximum rate of 17 cartons per minute

- Fanuc M-710/50H Robotic Arm:

- Maximum payload: 50kg

- R-30iB controller with HandlingTool Software

- Vacuum suction operation

- Maximum reach: 2050 mm

- 5-axes motion

- Motion range: 225 to 720 degrees

- Floor mounted

- Robot End-of-Arm tool to pick both carton and cases

- Robot Work Cell enclosure:

- Wire mesh fence

- Safety interlocked access doors

- Guarding to comply with category 3 safety requirements

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.