Description

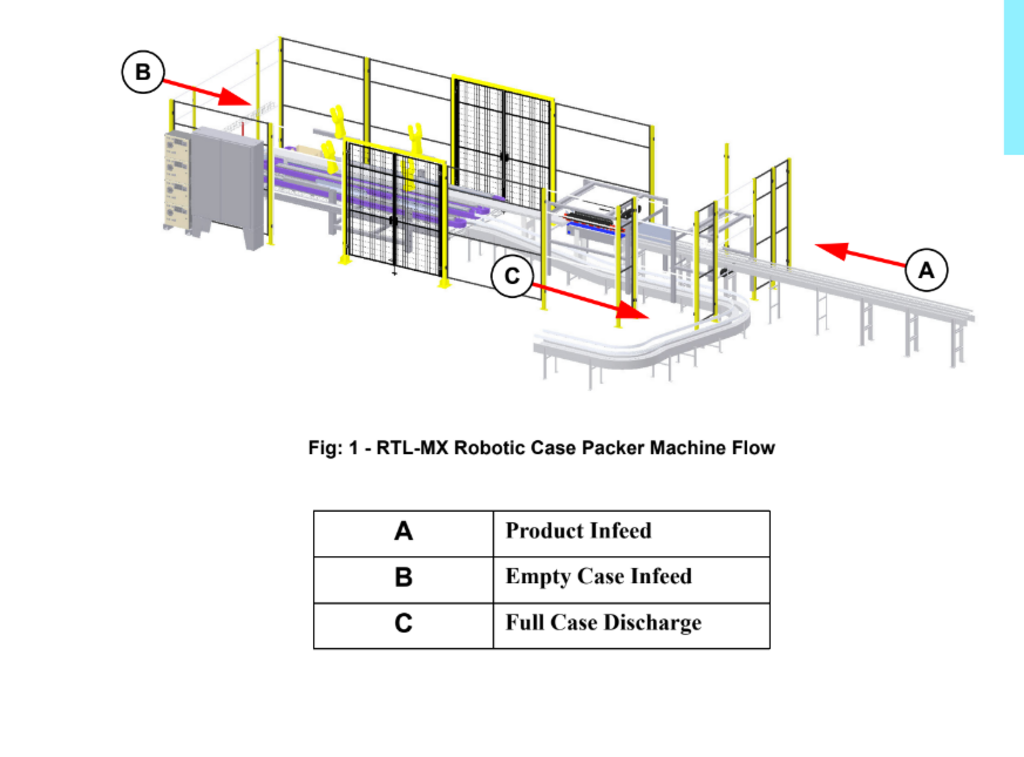

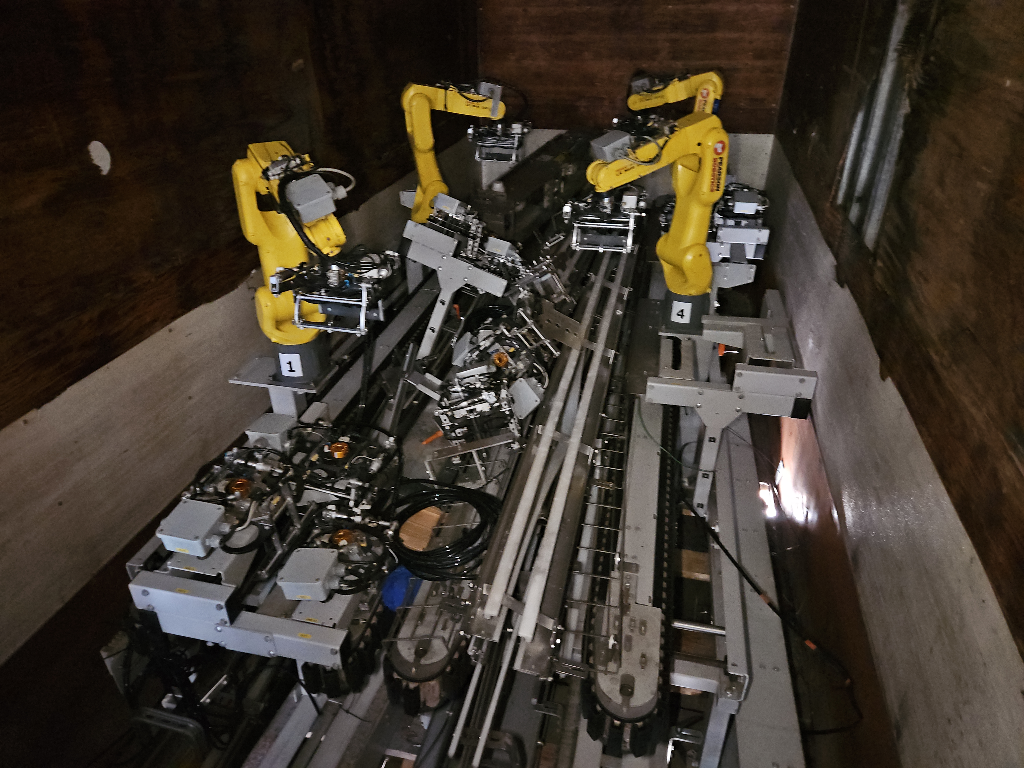

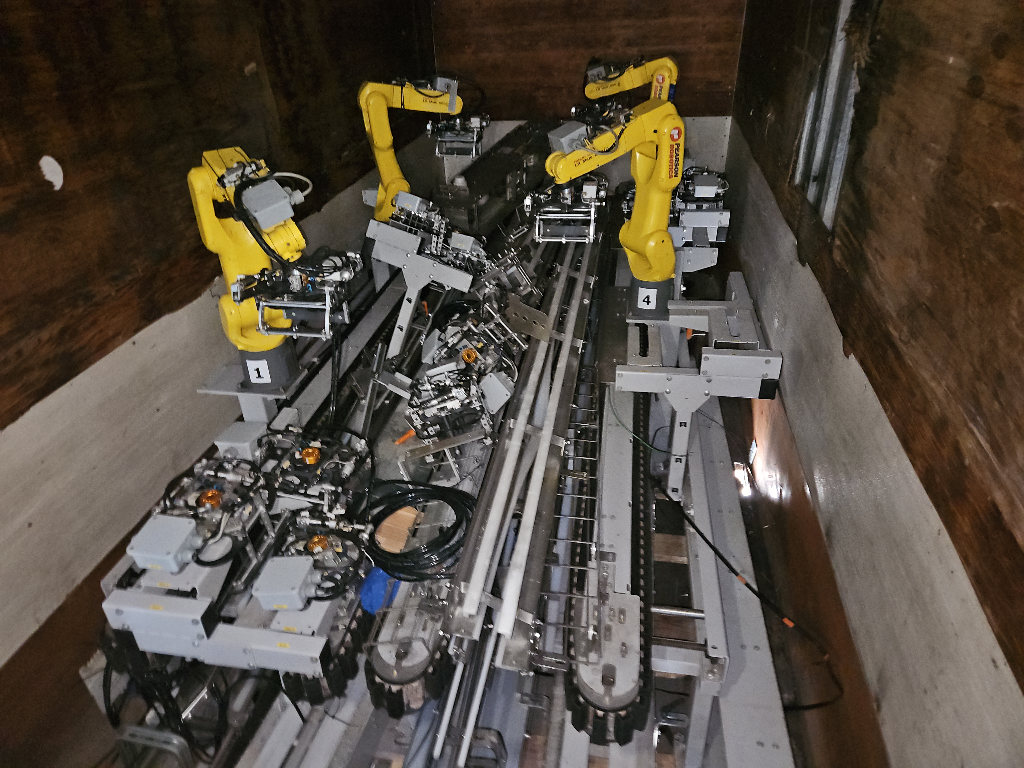

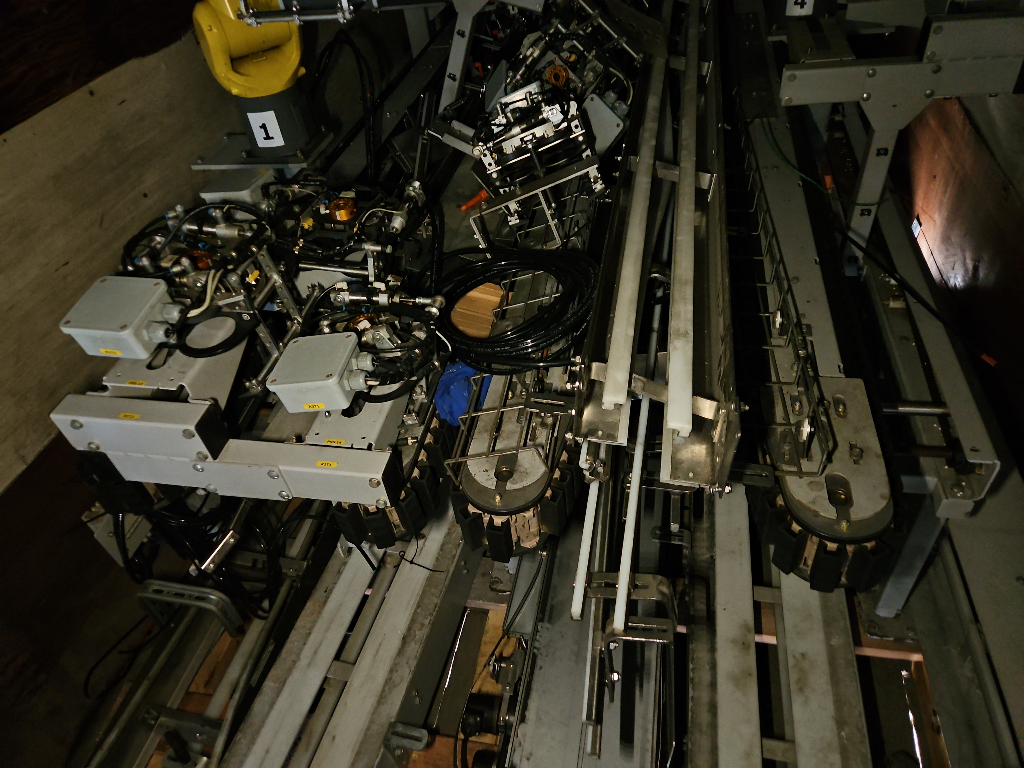

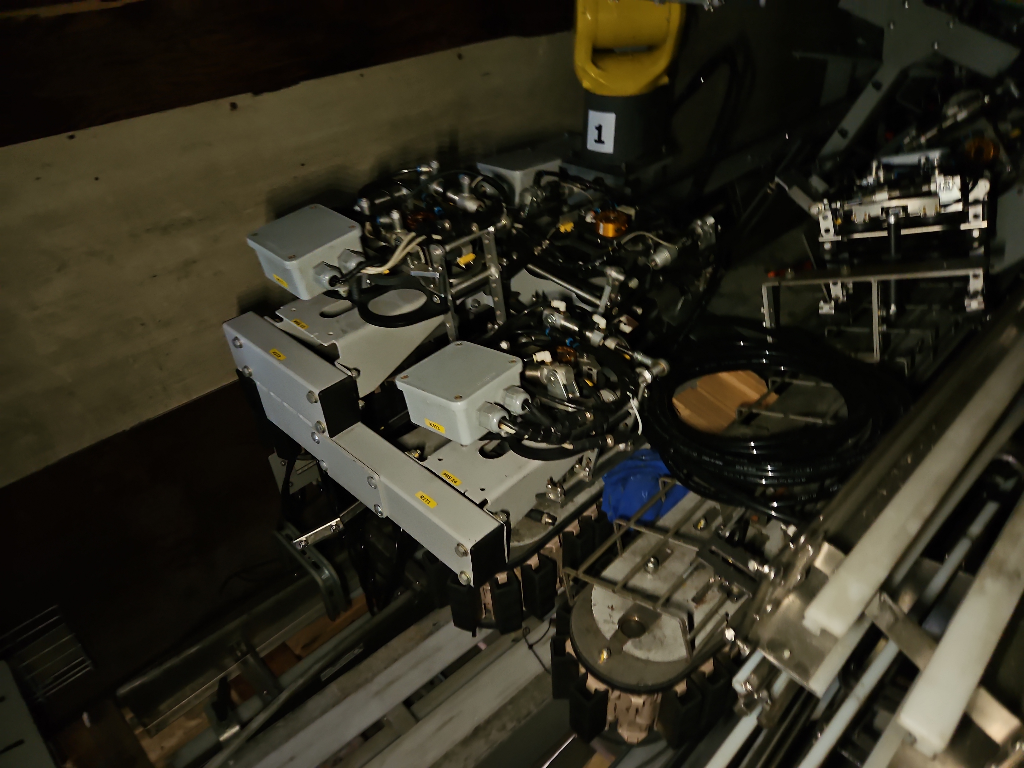

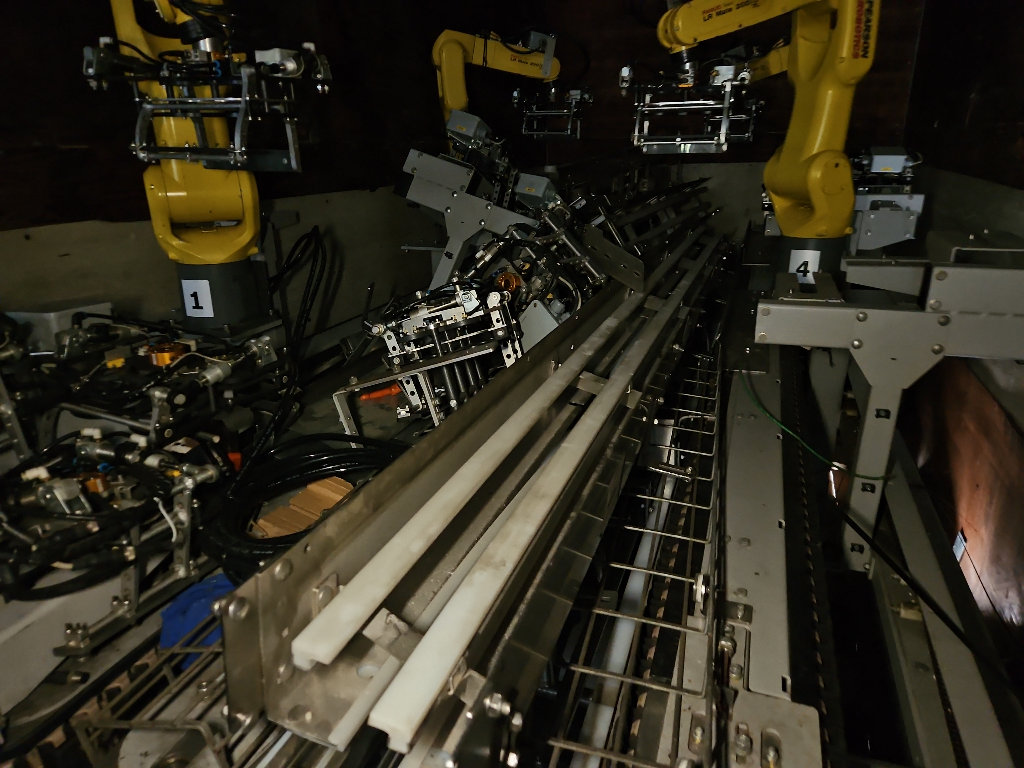

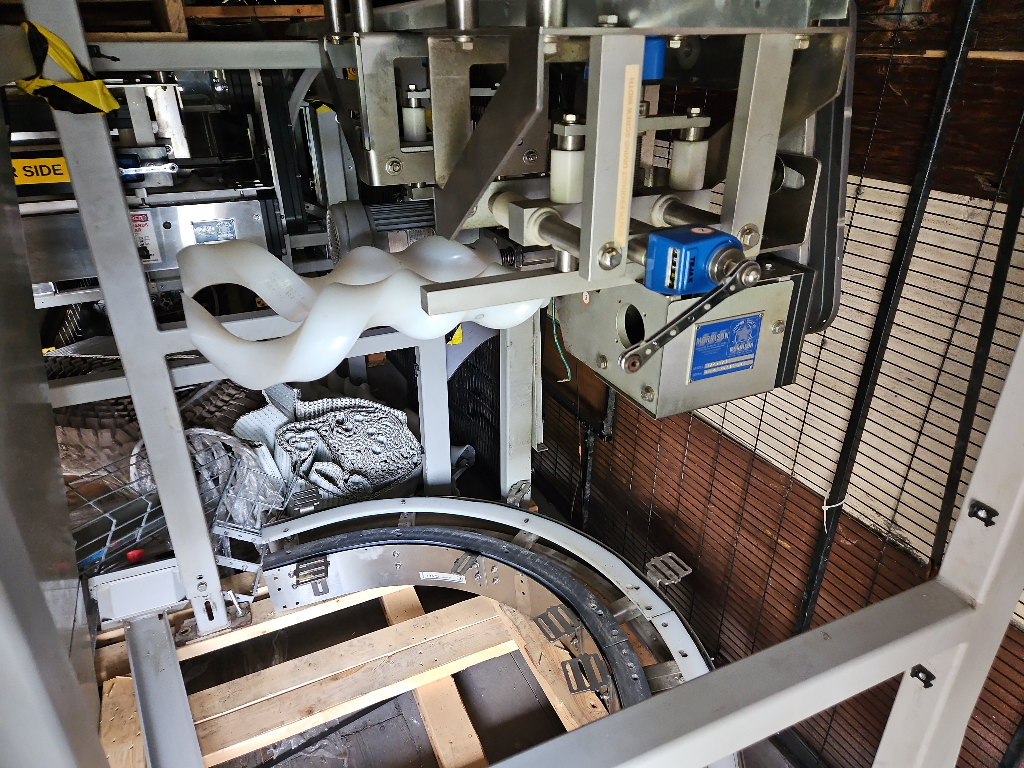

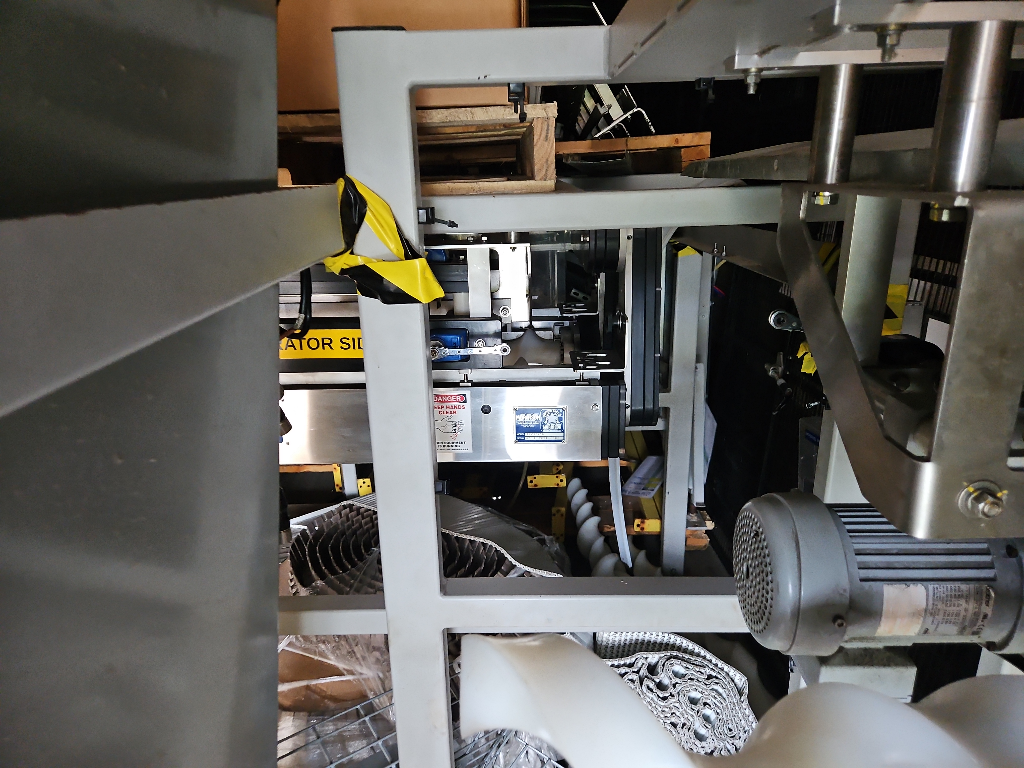

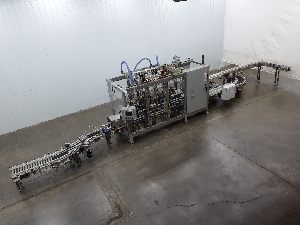

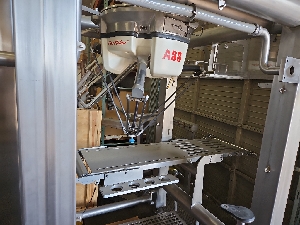

Products are transported in random orientation from the customer freezer to the robotic packing cell via a modular plastic chain conveyor designed to prevent ice build-up. A 2D vision camera determines and communicates the orientation of the trays to each of the four robots that share the workload to achieve the required rates. All four robots are equipped with two end-of-arm tools to accommodate single-stack and dual-stack recipes. To reduce downtime between recipe changes, automatic tool change functionality is enabled with the simple click of a button on the HMI.

With a dual stack pattern, the plenums deploy and retract alternately to ensure that the picked trays are aligned and to avoid interference with other products on the conveyor. Before placement into the case, the two plenums shift together so the tray lips don’t snag on the cases during insertion.

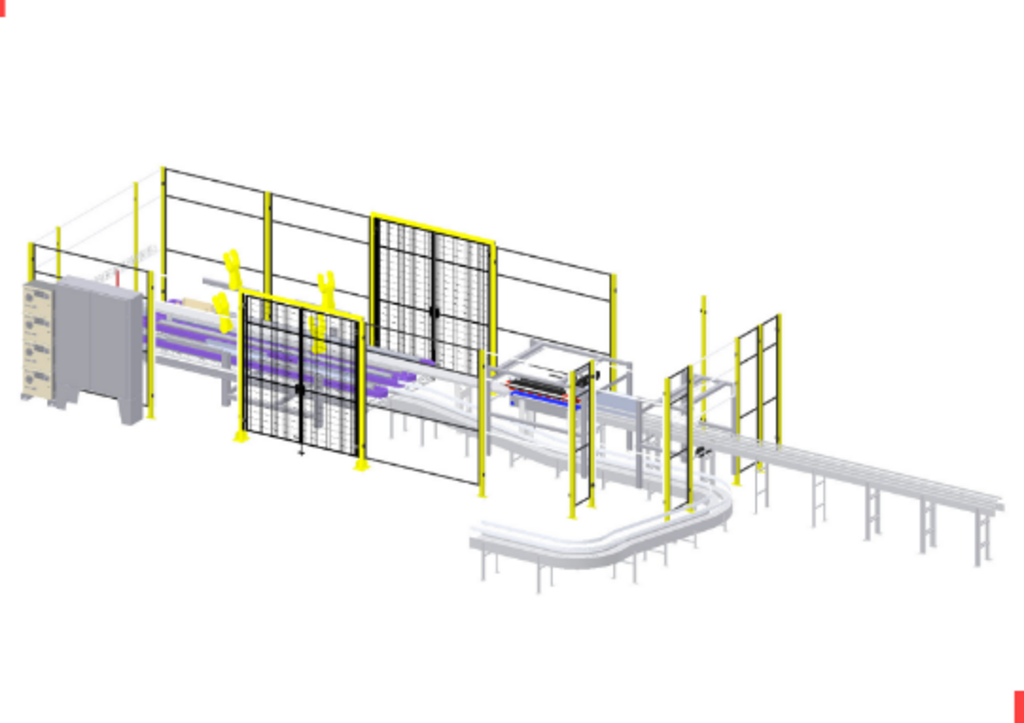

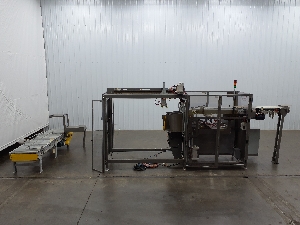

Empty cases enter the cell one at a time onto the side belt transfer conveyors before being filled and released downstream.

To safeguard the line in the event of a robot fault, the product conveyor continues running as robots shift to safe mode, and an automatic plowing device diverts product to a belt near the customer’s hand pack station so operations can continue manually.

Used Pearson Robotic Case Packer with:

- Production speed: up to 1500 products a minute, depending on application

- Case support: chipboard cartons, corrugated cases, bliss boxes, trays, and warehouse totes

- Supported pack patterns: vertical, horizontal, interleaved, stacked, on edge, on end, rainbow or variety packs, bulk and shelf-ready

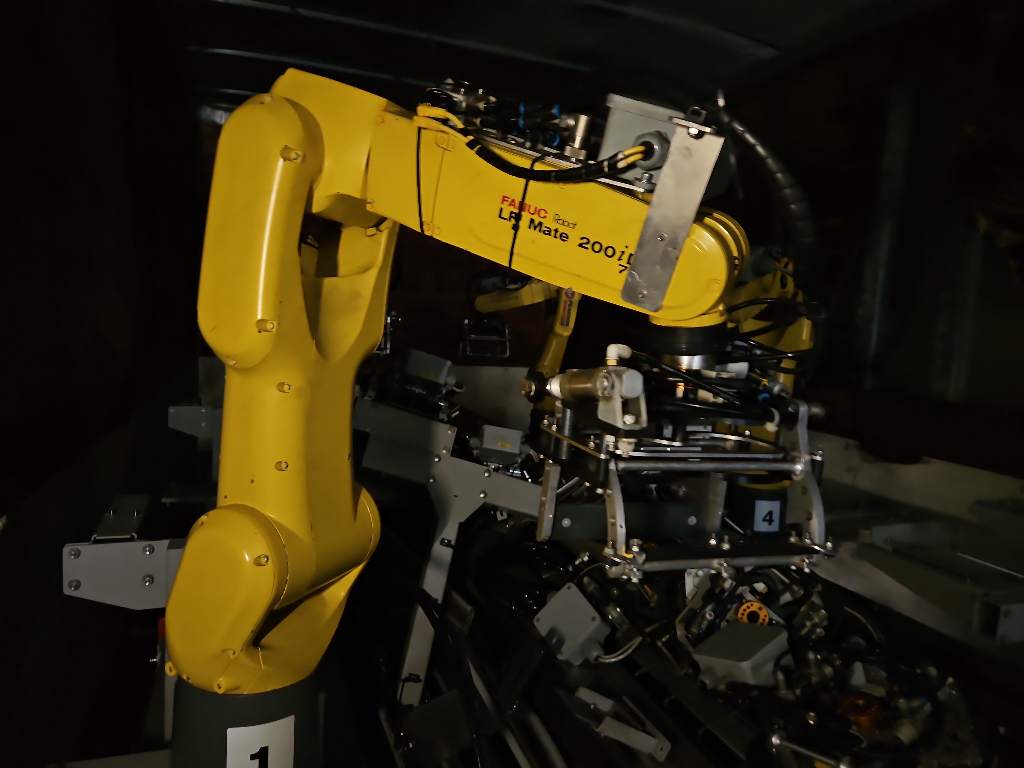

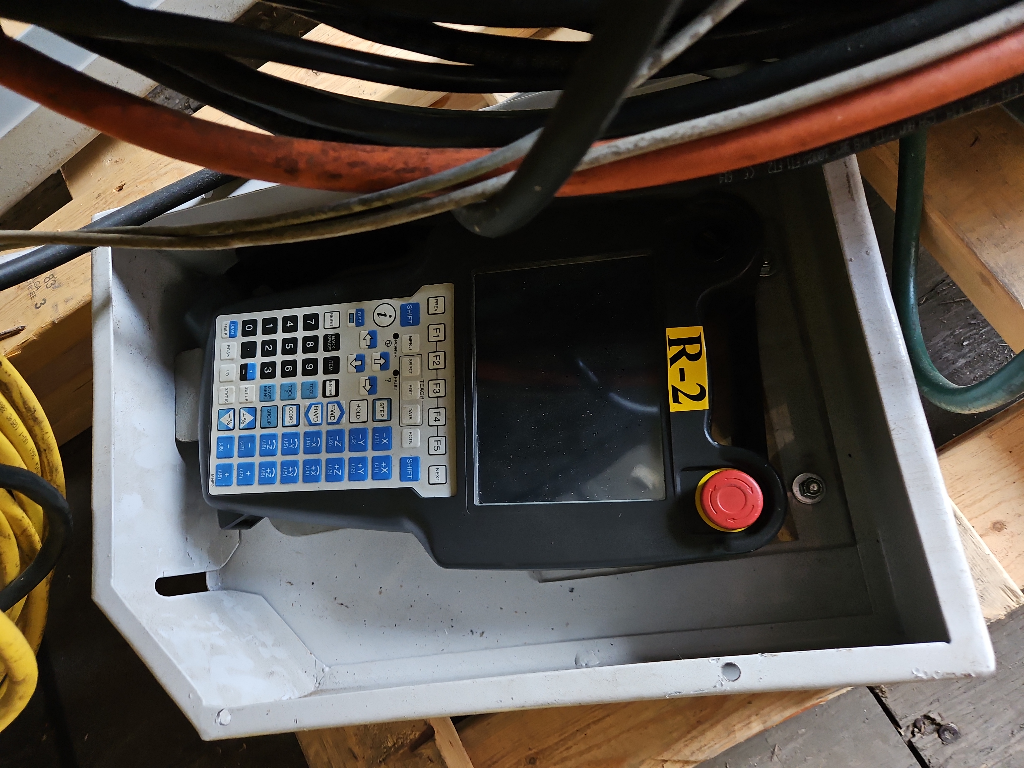

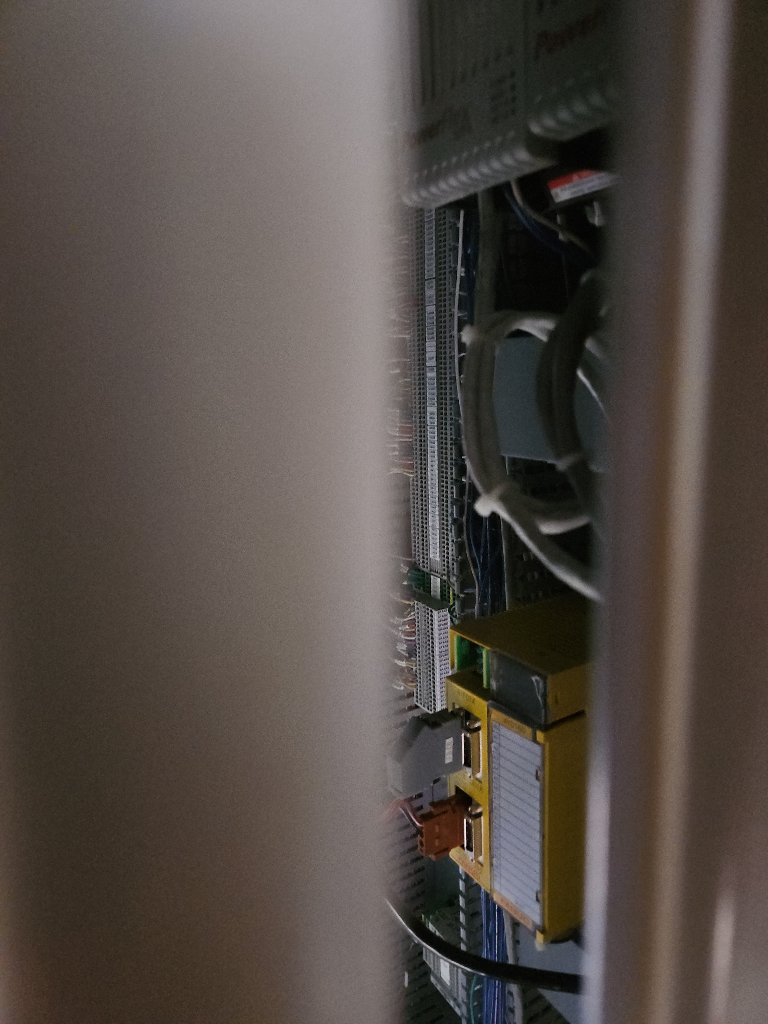

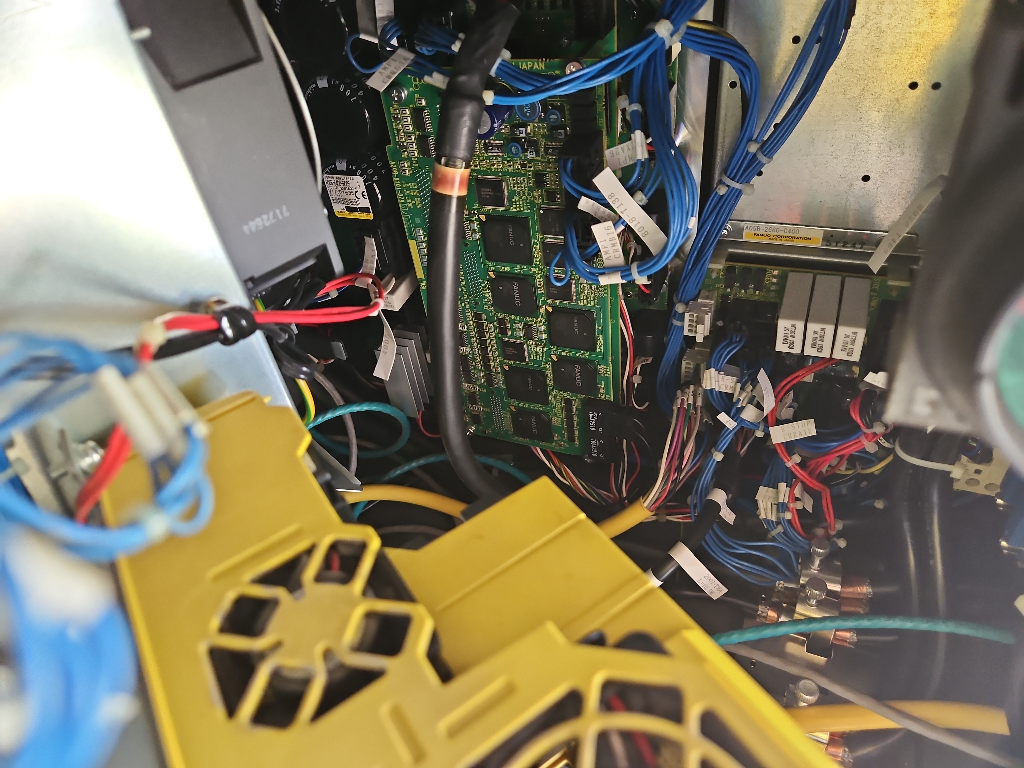

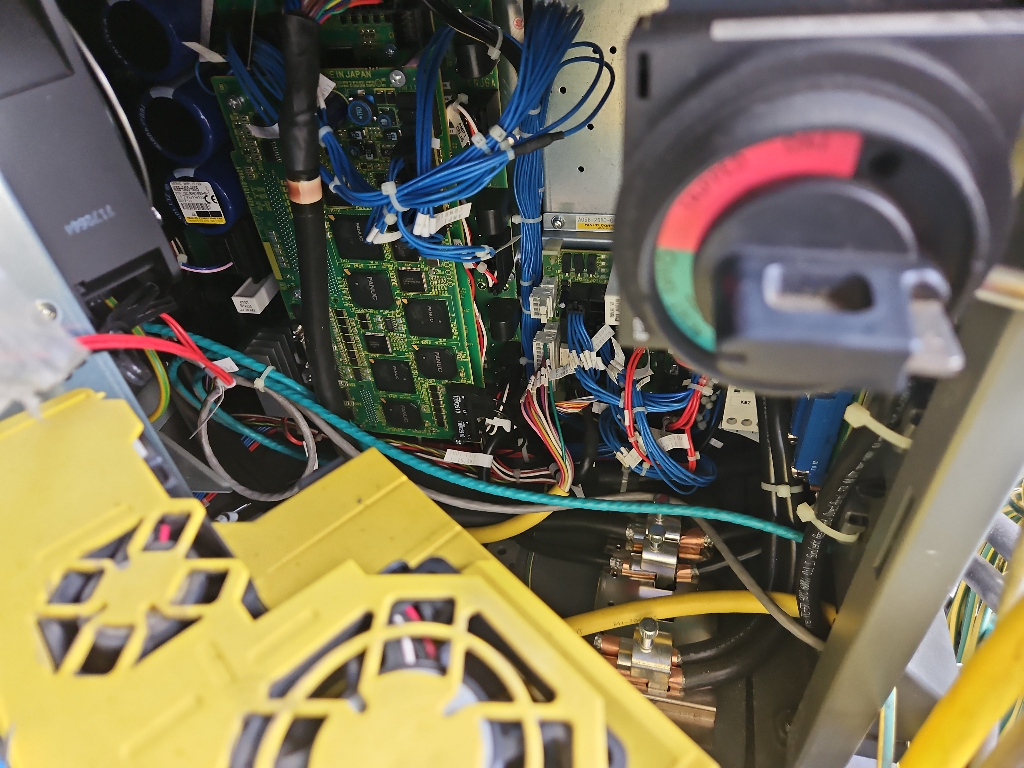

- (4) Fanuc LRmate 200iD/7L case packing robot arms:

- Six axes control

- Payload capacity: 15.43 pounds

- Maximum horizontal reach: 35.9 inches

- Vision guidance and line tracking to inspect, detect, sort and manipulate products on the fly or balance the load between robots

- Continuous case motion design for higher speed applications and reduced wear

- Application-specific end-of-arm tool with optional automatic tool changeover

- Programming language: pack ml

- Safety guarding: fencing

- Compressed air consumption: 14.758 SCFM @ 80 PSI

- Electrical: 3 phase, 60 hertz, 480 volts

Last application: production speed: 250 parts per minute with 4 and 8 pack trays/cases. Product weight was 970 and 980 grams. 34 ounce laundry sent containers.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.