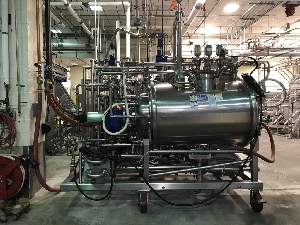

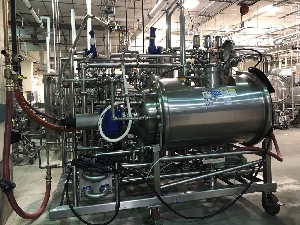

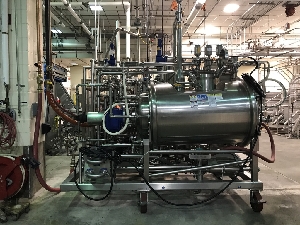

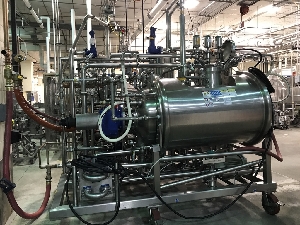

Used JBT Continuous 2 Shell Rotary Pressure Sterilizer/Cooker/Cooler For Cylindrical Metal Containers

Description

Closed cans enter the sterilizer directly from the closing machine with minimum waiting time. A feed device delivers the cans into the revolving reel of the first vessel. The reel, working in conjunction with the stationary spiral, advances the cans through the vessel. Cans never stand still. The continuous spiralling motion and rotation of the container through the vessel provide an even cook to every container. Every can is treated individually and undergoes exactly the same thermal process. At the end of the cooking process the cans are transferred to a water-filled cooling vessel where a similar process efficiently cools them.

- The Continuous Rotary Pressure Sterilizer agitates the can, permitting short-time, high-temperature cooking and rapid, efficient cooling in an automatic, continuous operation.

- Adapts to various canned food products

- Handles all types of cylindrical cans (conventional, stackable, with and without EOE, lithographed)

- Accommodates multiple process combinations within a single unit

- Quality of the product is improved by induced convection technology

- System consists of a cooker and cooler shell

- Cooker

- Capacity of 6,674 300x407mm 14 ounce cans

- Maximum working pressure: 45 psi at 292°F

- Dimensions:

- Length: 30 feet

- Diameter: 112 inches

- Cooler

- Capacity of 9,964 300x407mm 14 ounce cans

- Maximum working pressure: 45 psi

- Dimensions:

- Length: 46 feet

- Diameter: 112 inches

- Auto lubrication system

- Logitech control package

- Ceramic coating on cooker

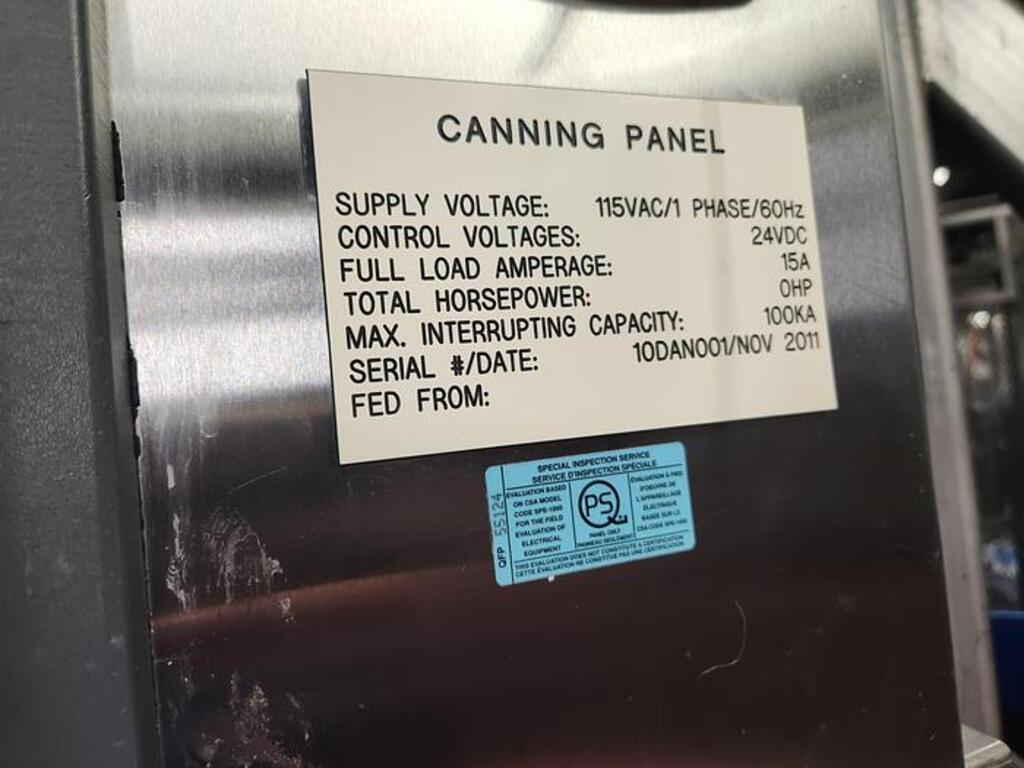

- Electrical:

- Volts: 600

- Frequency: 60 Hz

- Phase 3

- FLA: 45 amps

Product examples:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.