Description

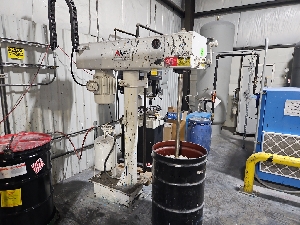

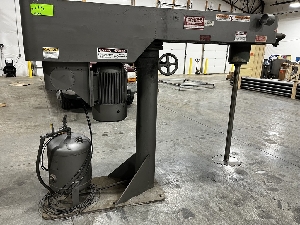

GEA top-drive high shear granulators are multi-purpose processors, equally suitable for the high speed dispersion of dry powders, aqueous or solvent granulations, effervescent products and melt pelletization. The angled position of the mixing blades combined with the rounded edges at the bottom of the vessel guarantee the typical rope-type movement for optimal flow of product during granulation. Several binder liquid spray systems are available to suit your process. Bowl and mixing blades are shaped and mounted to minimize clearance for maximum yield, without locally overheating the product. During a discharge cycle, the centrifugal force created by the rotation of the mixing arm will push the product in a natural way to a proportionally regulated outlet valve at the side without compacting the wet granules.

- Capacity: 1200 liters (nominal capacity: 1166 liters)

- Top driven mixer and chopper: No seals in direct contact with the product

- Bowl design for optimal granulation

- Full opening discharge for easy unloading of difficult products

- Wash In Place design

- (2) Removable process vessels

- Twin speed chopper and mixer

- Plunger outlet valve

- Operator controls

- 75 horsepower main blade motor

- 40 horsepower chopper motor

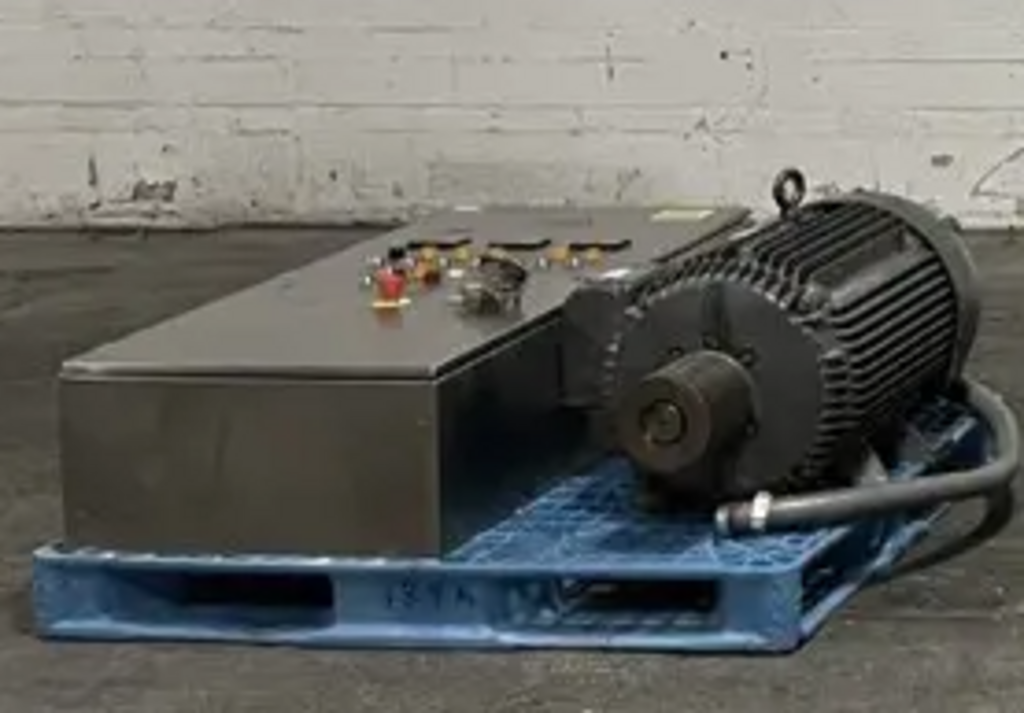

- Hydralic bowl lift

- Electrical:

- Volts: 460

- Frequency: 60 Hz

- Phase 3

- Stainless steel construction

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.