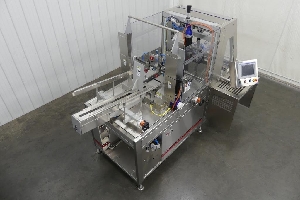

Used Automatic Robotic Pulp Molder for Egg Cartons

Click image for full size.

Having trouble viewing media for this Ecofeutre DBB2?

Click here for full page view of all Equipment Media (66)

Click here for full page view of all Equipment Media (66)

Equipment Details

| Equipment # | C4943 |

| Item | Automatic Robotic Pulp Molder for Egg Cartons |

| Category |

Tray Former Self Locking and Tuck Tab Tray Former |

| Manufacturer |

Ecofeutre Ecofeutre |

| Model | DBB2 |

Try before you buy with a similar item from SIGMA's rental fleet.

Equipment Description

Used Automatic Robotic Pulp Molder for Egg Cartons with:

- Conveyor 10 m length (1 unit) (32.81 feet)

- Pulper (1 unit)

- Low-concentration (1% to 2.5% recycled paper), stainless, pulper

- Capacity 1,585 gallons with a 45 kilowatt engine vertical agitator

- Includes: grinder, pump, pipes, valves, structure, control units and 1 coupling

- Storage Tank (1 unit)

- 5,283 gallons (usable volume 2,642 gallons) stainless steel tank with vertical agitator

- Includes: pump, pipes, valves structure, control units

- White-Water Tank (1 unit)

- 2,642 gallons (usable volume) stainless steel tank

- Includes: pump, pipes, valves structure, control units

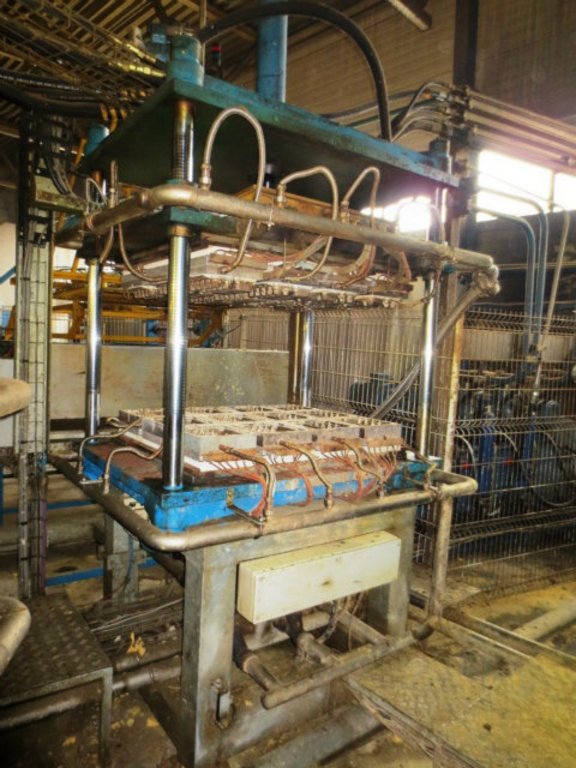

- Forming Station (3 units)

- 237.8 gallons tank with Flanches and Brushless motor mechanism

- Forming platen 1100 x 1100 millimeter (43.31 inches x 43.31 inches)

- 12 plastic forming moulds with bronze frame and stainless steel net

- Moulds designed for the production of 10-egg cartons of sizes 245 x 250 millimeter (9.646 inches x 9.843 inches) ( for 1 unit)

- 9 plastic forming moulds with bronze frame and stainless steel net moulds designed for the production of eggtrays/brets of sizes 290 x 290 millimeter (11.42 inches x 11.42 inches) and 310 x 310 millimeter (12.2 inches x 12.2 inches) (for 1 unit)

- 9 plastic forming moulds with bronze frame and stainless steel net moulds designed for the production of eggtrays/brets of sizes 290 x 290 millimeter (11.42 inches x 11.42 inches) and 310 x 310 millimeter (12.2 inches x 12.2 inches) (for 1 unit, not in working condition)

- Adjustable PLC control of all timers for: water spray, air-blow, vacuum suction

- Frequency control unit for varying motor speeds

- All necessary structures, gears and motors to support and drive the above equipment, platforms, panels and shields for safe and easy operation

- All necessary electrical connections, electrical controls

- 16 kilowatt high pressure water pump, made by Grundfoss

- 1 high pressure cleaning system with stainless steel nozzles

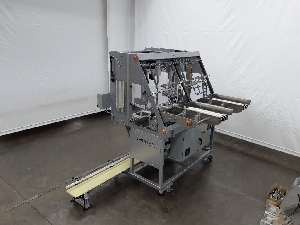

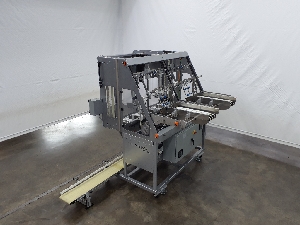

- Robot (3 units)

- 150 kilogram, 6-axes Kuka robot, made in Germany

- Aluminium platen 1100 x 1100 millimeter (43.31 inches x 43.31 inches) (interface between robot and moulds)

- Moulds designed for the production of 10-egg cartons

- Kuka electrical cabinet, including software

- 1 hot-galvanised frame to support the whole system

- Vacuum pipes and valve, compressed-air pipes and valve

- 12 Aluminium transfer moulds

- Vacuum system (1 set)

- 45 kilowatt vacuum pump system made by Samson in Denmark

- 12.5 kilowatt vacuum pump system made by Samson in Denmark

- Stainless steel vacuum tank

- Stainless steel pipes and valves

- Hot Presses (3 sets)

- 3 vertical, 800 millimeter (31.5 inches x 31.5 inches) stroke, 40 t hydraulic presses

- 3 1100 x 1100 millimeter (43.31 inches x 43.31 inches) platens

- 12 male and 12 female aluminium drying moulds

- Moulds designed for the production of 10-egg cartons (for 1 set)

- 9 male and 9 female aluminium drying moulds. Moulds designed for the production of eggtrays/brets (for 2 sets)

- 15 kilowatt hydraulic group

- Stainless steel compressed air and vacuum pipes and valves

- Adjustable PC control of all timers for: air-blow and vacuum suction

- Frequency control unit for varying speeds

- Heat insulation

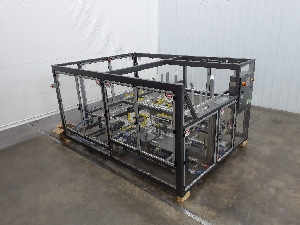

- Stacking Station (3 sets)

- 3 stainless steel stacking stations

- 60.37 kilowatt gear motors with encoder

- Jacks and suctions

- 3 mobile chariots for products unloading

- 3 chairs and frames

- Stainless steel compressed-air and vacuum pipes and valves

- Adjustable PLC control of all timers for: air-blow, vacuum suction

- Frequency control unit for varying speeds

- Electrical Cabinet (3 sets)

- Complete electrical cabinet

- Panel control

- Computer made by Siemens in Germany

- Other equipment

- 50 valves and/or electro-valves

- 4 ultrasound levels

- 95,100 gallons an hour 4 kilowatt pumps

- 3,170 gallons an hour pump for pulp movement in storage tank and level control in forming station

- 3 press position checking systems

- Flexible, joints, miscellaneous screws

- Protection fence

- Heat regulation system

- Vacuum pumps control system

- Technical and Operating Specifications

- Electricity consumption 300 kilowatts per hour

- Paper consumption: 90 kilograms per hour

- Nominal output 2,160 cartons per hour

- Number of operators 2 per shift

Location Details:

LatviaThis machine is located at a client’s facility in Latvia. To coordinate an inspection of this item, please contact your SIGMA sales team.

Call us at (812) 303-8383.Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this Automatic Robotic Pulp Molder for Egg Cartons?

Request an email quote or call us at (812) 303-8383 for more information.