Description

Complete CVC Bottling Line:

- CVC 1266-W bottle unscrambler:

- designed to automatically feed bottles from a bin and place them upright onto a conveyor

- No change-parts required

- Output: up to 200 bottles per minute depending on the application

- Bottle dimensions:

- Height: 1.75-7.75 inches ( 45-200 mm)

- Diameter: 1.25-4.75 inches (30-120 mm)

- Neck opening: 1-3.33 inches (25-85 mm)

- Hopper capacity: 14 cubic feet

- Low level hopper sensor

- Bottle backlog sensor at outfeed

- Touchscreen controls

- Electrical:

- Volts: 220

- Frequency: 60 Hz

- Phase 1

- Air requirements: 85 psi

- 304 stainless steel construction

- CVC 1103-U desiccant inserter:

- Output: up to 200 bottles per minute depending on the application

- 1 to 5 Pouch Insertions per bottle

- Applicable pouch sizes:

- Length: 33-73mm

- Width: 17-30mm

- Thickness: 3-10mm

- Touchscreen controls

- Electrical:

- Volts: 220

- Frequency: 60 Hz

- Phase 1

- Air requirements: 87 psi

- CVC ICU80 tablet and capsule counter:

- Capacity:

- 100 count (80 BPM per unit)

- <60 count (100 BPM per unit)

- 1000 count (16 BPM per unit)

- Round or oval shaped tablets and capsules

- Product width:

- Length: 3mm-30mm

- Width/diameter: 3mm-20mm

- Hopper capacity: 30 liters

- Bottle dimensions:

- Height: 1.6-7.8 inches (40mm-200mm)

- Diameter: 1.25-4.25 inches( 30mm-110mm)

- Dust extraction

- Broken tablet detection

- Capacity:

- CVC 1117 SER/U cotton inserter:

- Output: up to 120 bottles per minute depending on the application

- Bottle dimensions:

- Height: 2-8.5 inches (51-216mm)

- Diameter: 1.25-4.25 inches (32mm-108mm)

- Neck opening: 1-2 inches (25-51mm)

- Cotton length: 70-150mm

- Lock Insight HD metal detector:

- CVC 1205 inline capper with hopper elevator:

- 8 spindle capper

- Output: up to 120 bottles per minute depending on the application

- Cap type: plastic screw and CRC

- Cap dimensions:

- Height: 13-19mm

- Diameter: 25-108mm

- Bottle dimensions:

- Height: 2-8.5 inches (51-216mm)

- Diameter: 1.25-4.5 inches (32mm–114mm)

- 9.1 cubic foot integrated cap hopper elevator

- Touchscreen controls with 10 memory function

- Enercon M2000 (Superseal Touch 500 / 700) induction sealer:

- 28-89 mm CT and CRC caps

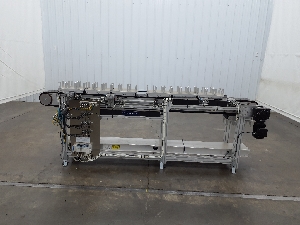

- Bi-directional accumulation table:

- Length: 5 feet

- Width: 2.5 feet

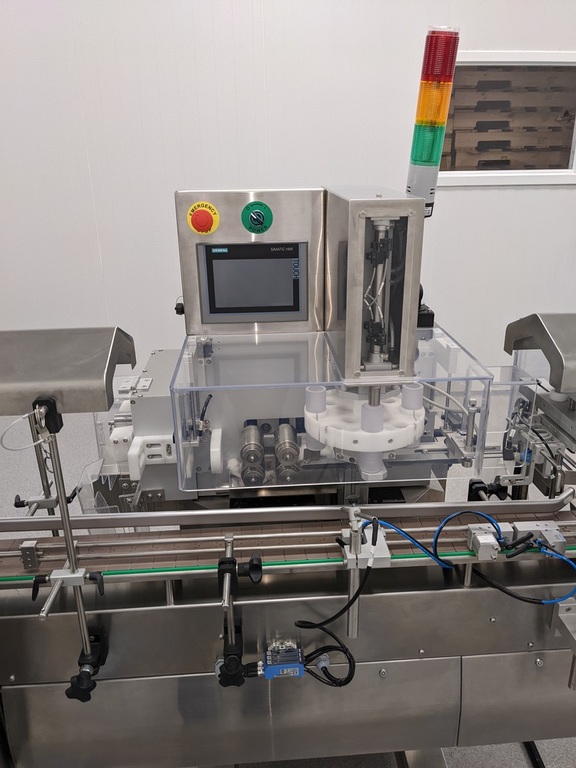

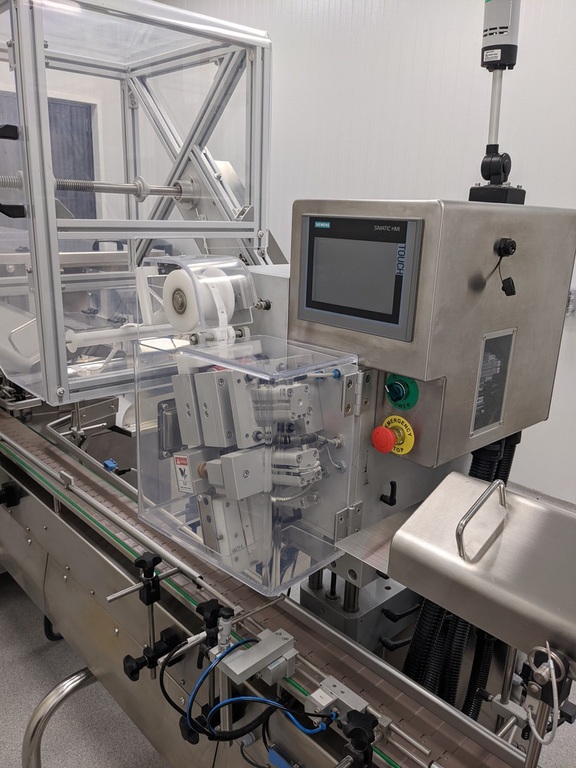

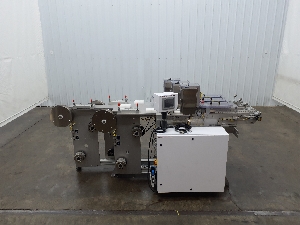

- CVC 302 high speed wrap labeler:

- Output: up to 250 bottles per minute depending on the application

- Label dimensions (dependent upon label head):

- Width: 10-178mm

- Length: 13-305mm

- Touchscreen hmi

- VideoJet DataFlex 6320 Thermal Transfer Printer

- Axon EZ-150 SL shrink sleeve applicator:

- Output: up to 150 bottles per minute depending on the application

- Film lay flat range: 50-200mm

- Container diameter: 20-125mm

- Film Thickness: 1.5-3 mil

- Axon Thermopoint 2.0 steam shrink tunnel:

- Maximum container size:

- Width: 7 inches

- Height: 15 inches

- Maximum container size:

- Bottom Printing Systems With CMI Twin Belt Transport

- Rotary Accumulation table

- Videojet 1220 Inkjet Printer

- Custom stainless steel conveyors

- Conveyors hooding/dust protection

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.