Description

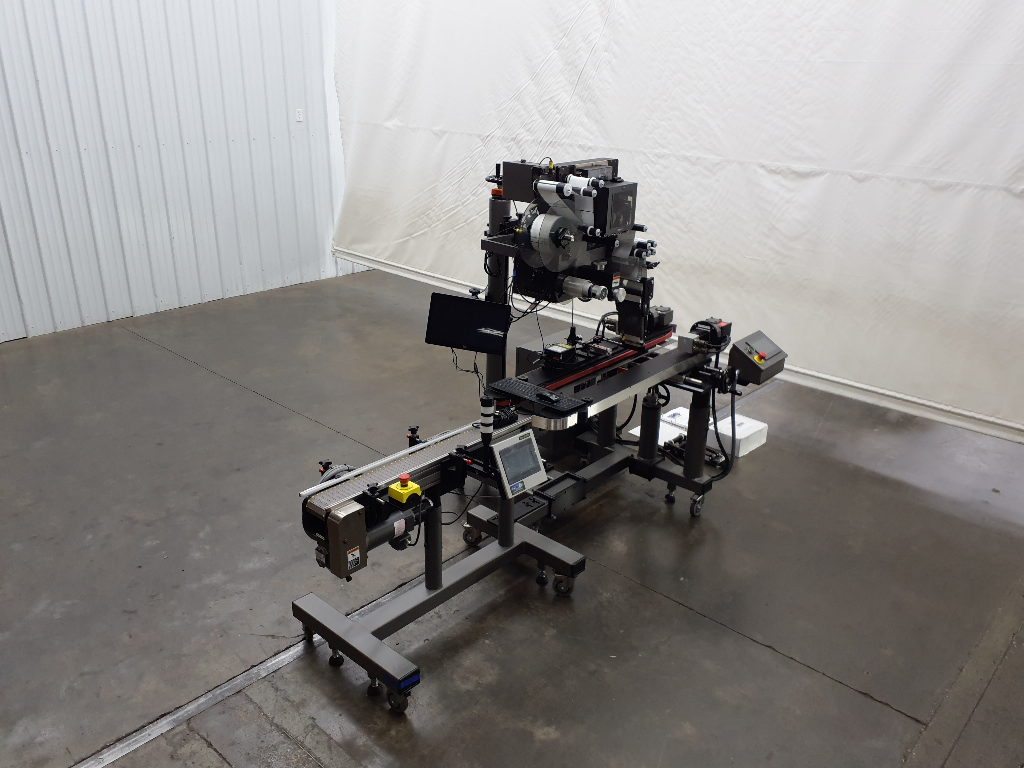

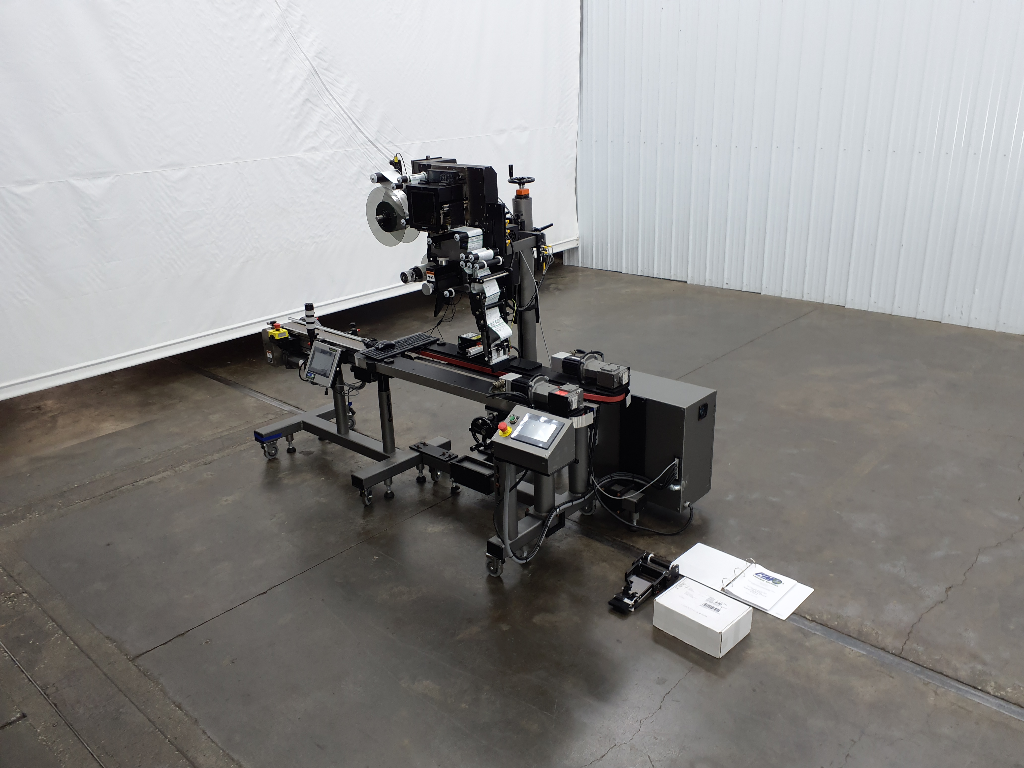

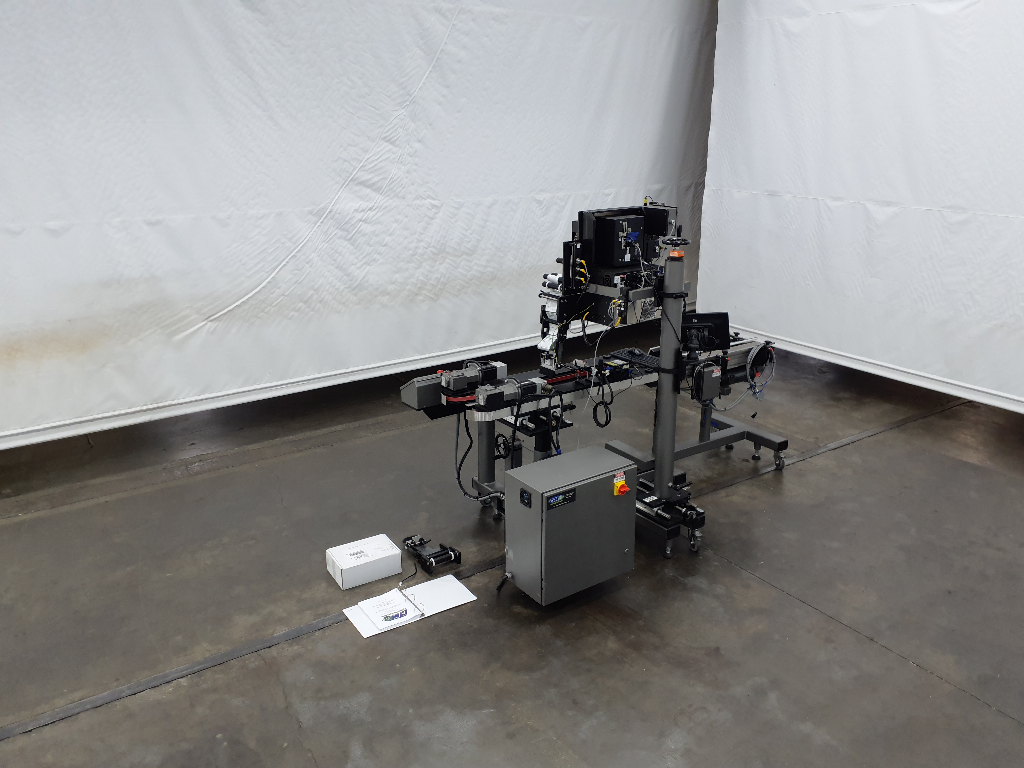

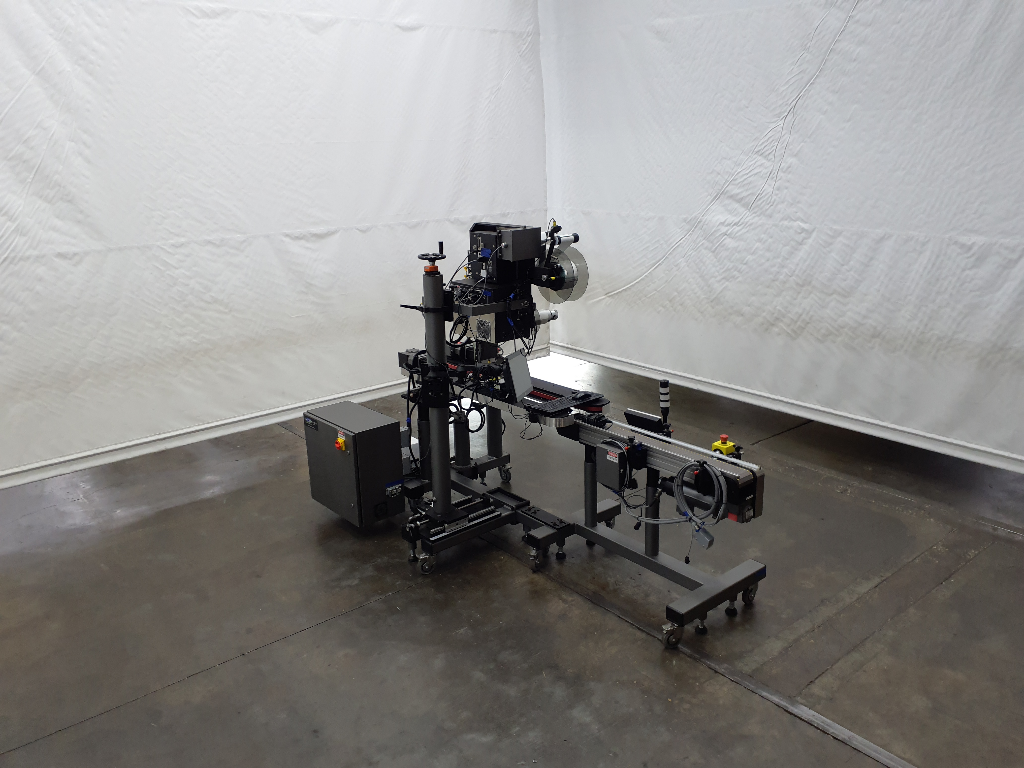

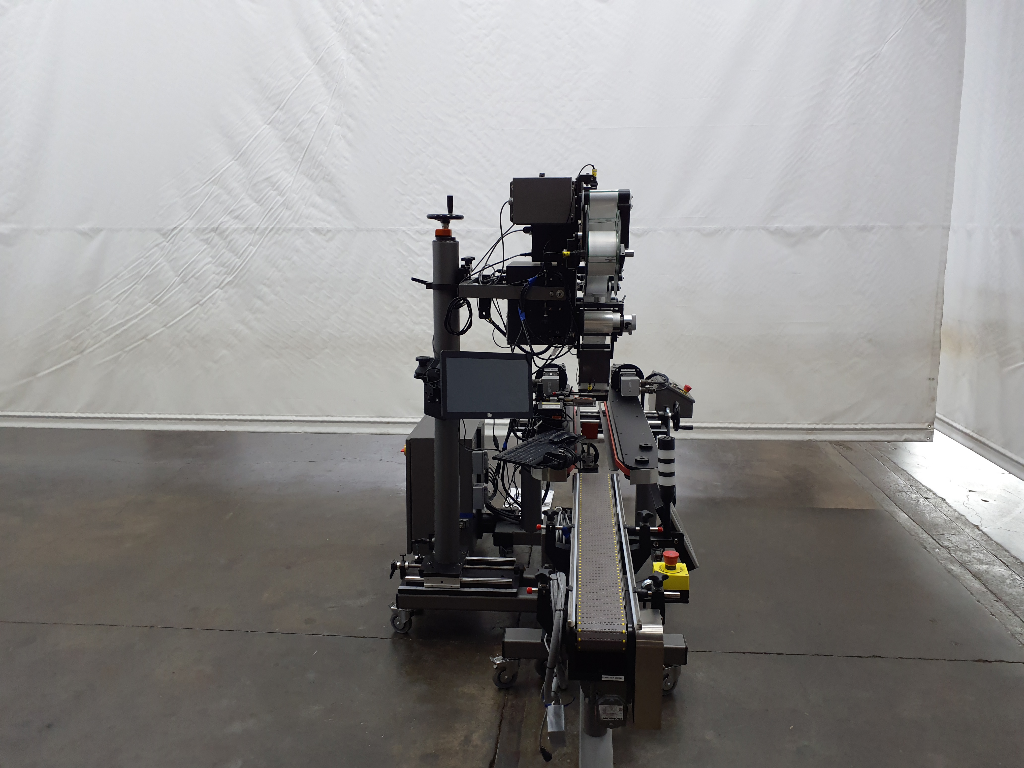

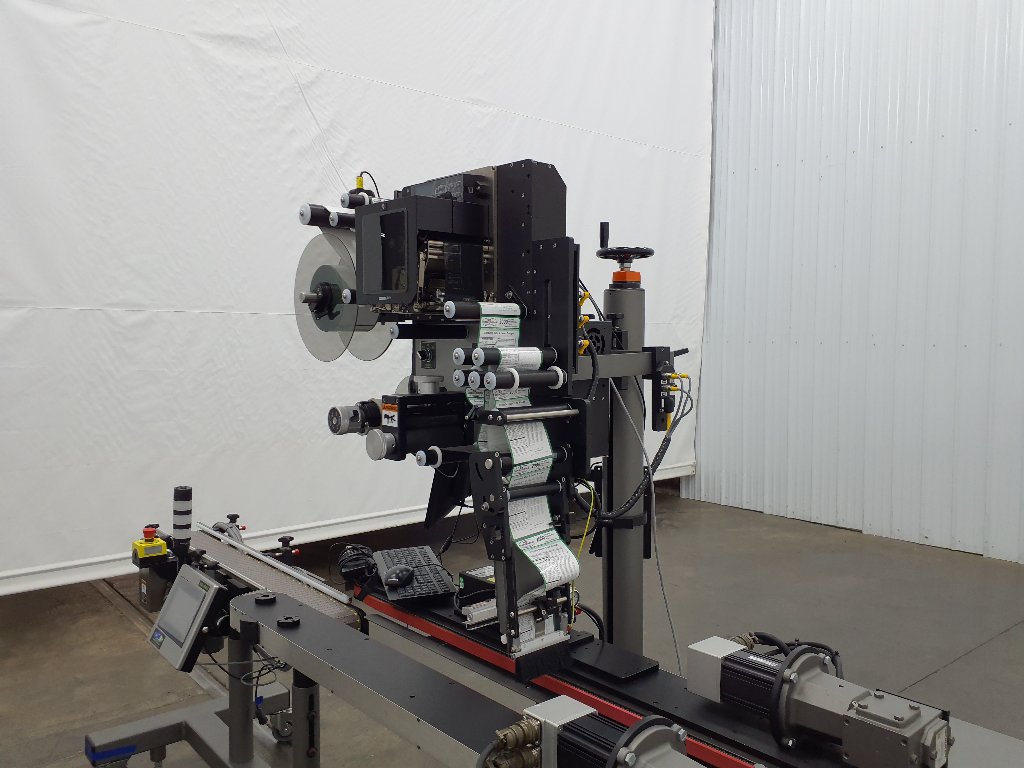

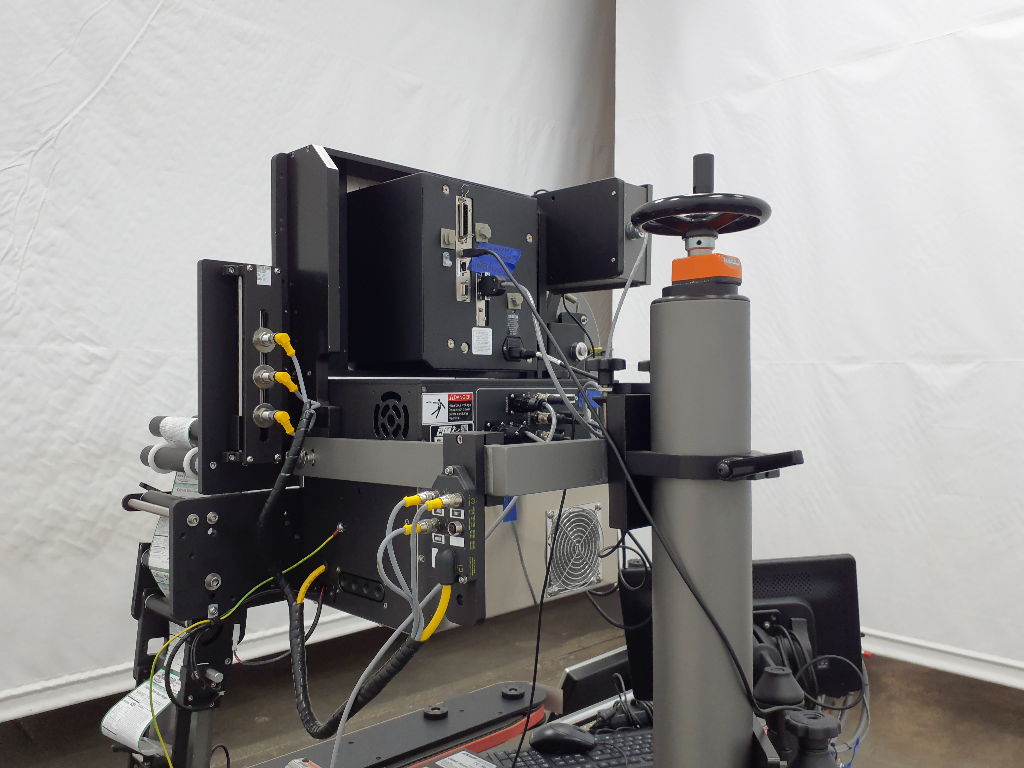

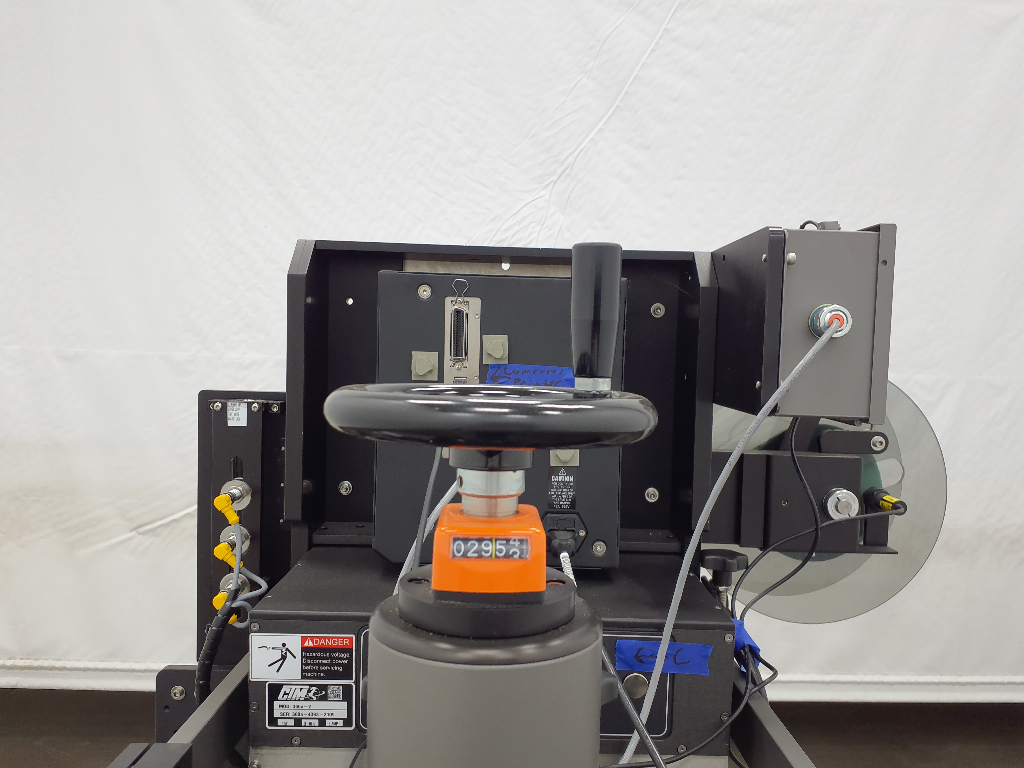

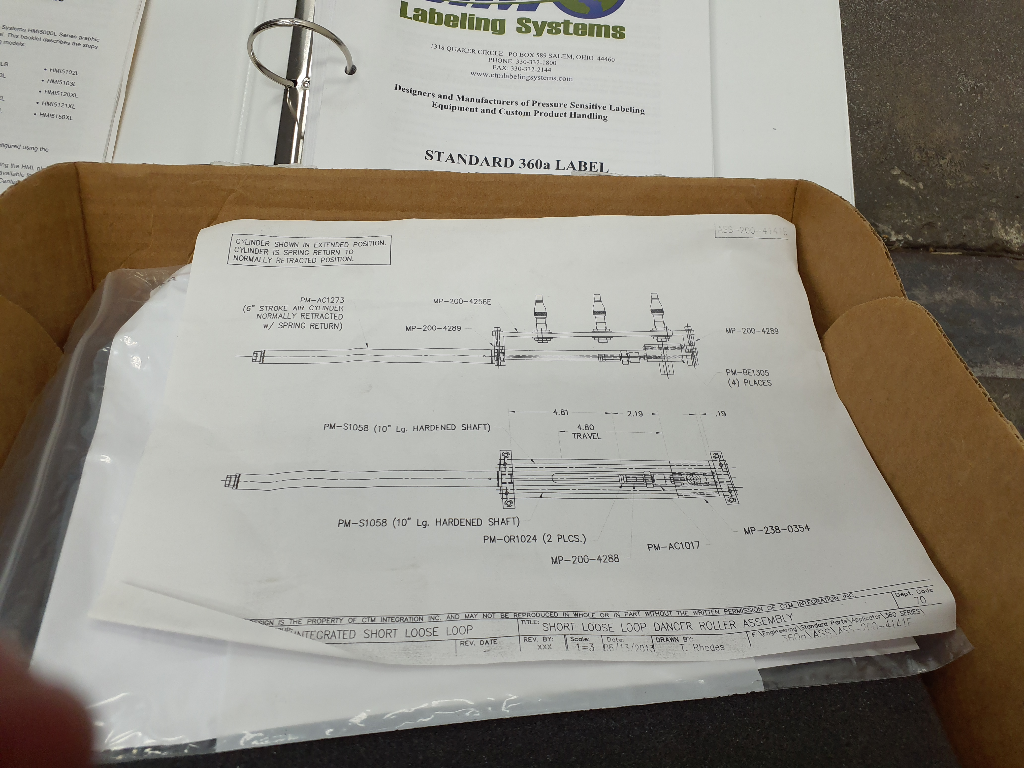

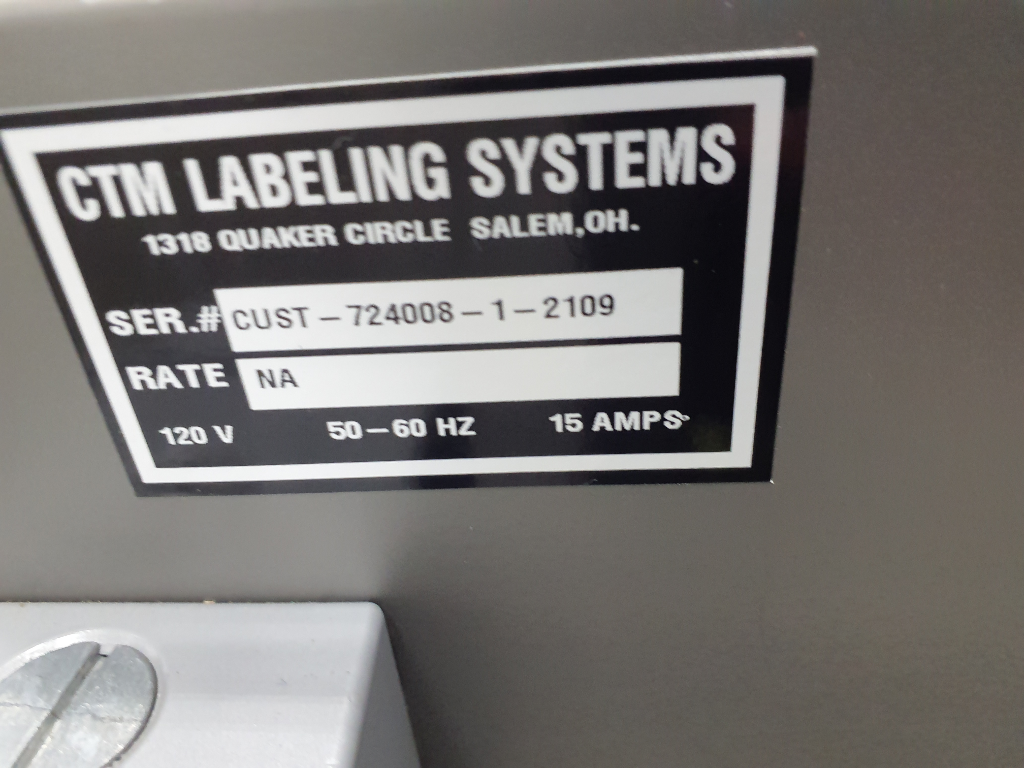

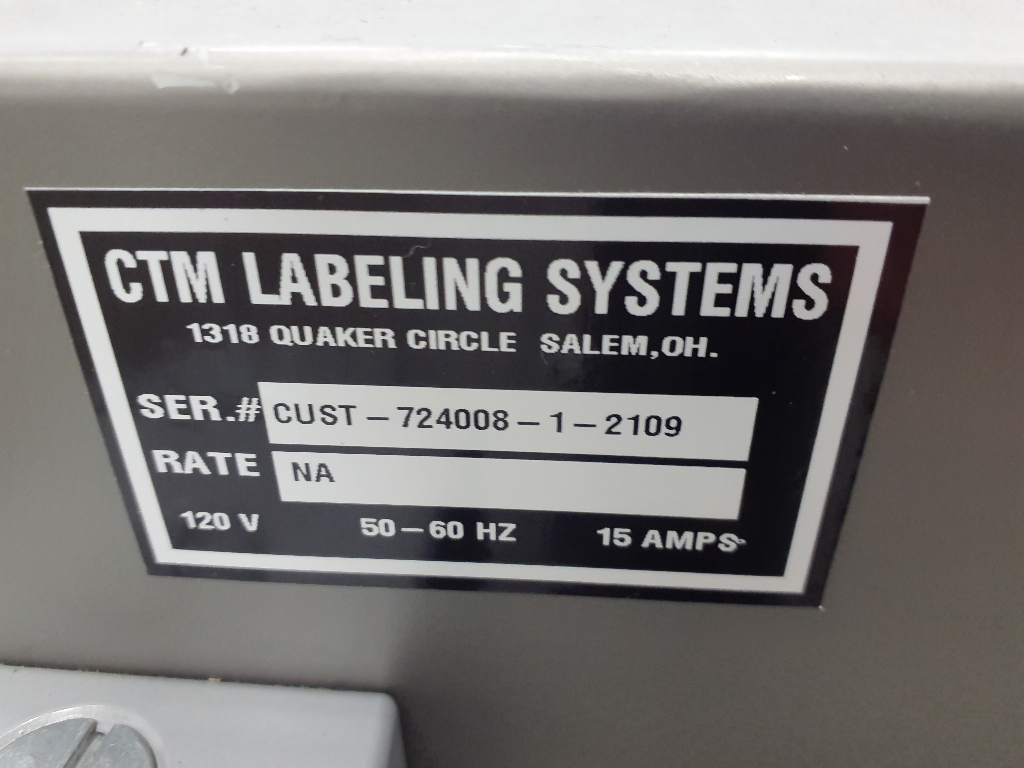

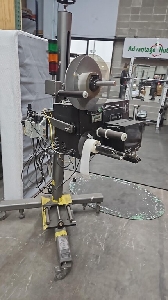

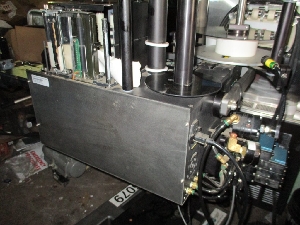

Used CTM 360a-2 Print And Apply Top And Clamshell Labeler With Zebra ZE500 Printer:

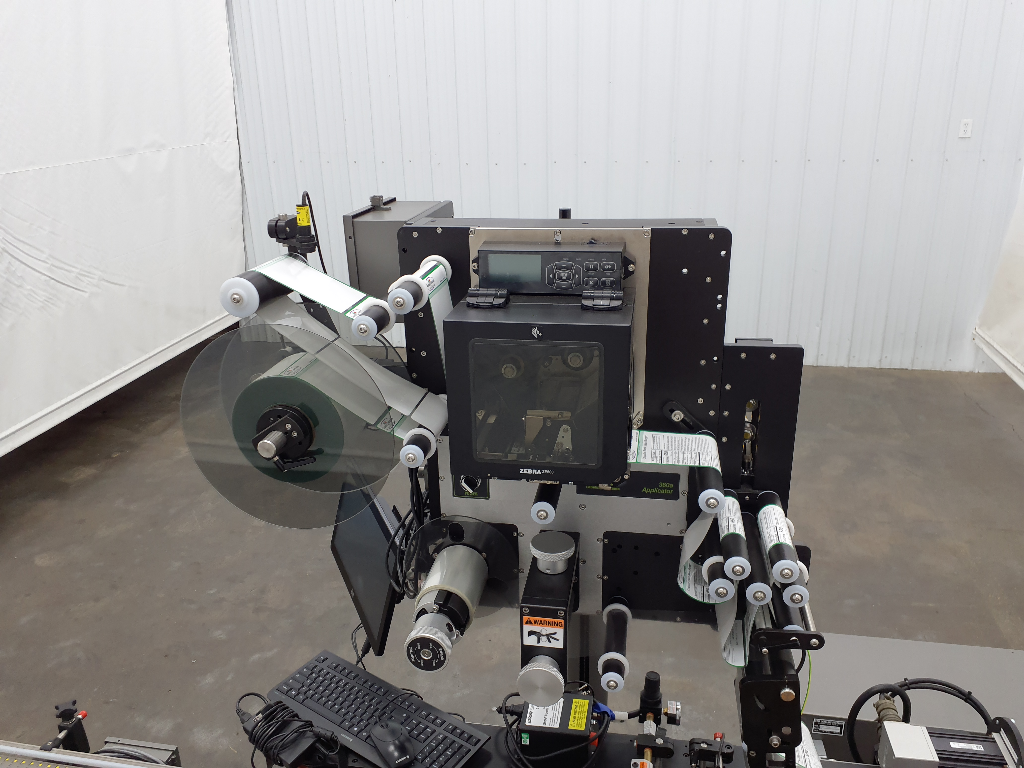

The 360a High Speed Label Applicator comes with a unique and specially designed stepper drive that is capable of dispensing labels at speeds of 2100 inches/minute.

With the built-in dual microprocessor on board, this label applicator is capable of variable speeds depending on workload. The 360a high speed label applicator is programmable from 1500 inches per minute to 2100 inches per minute, with oversize unwind and rewind.

This applicator has also been programmed with speed profiling ability to determine accurate label application speed.

- Production speed: 30 parts per minute or 1500 inches per minute, depending on application

- Web width: 5 inches

- Diameter label unwind: 12 inches

- Machine capability to +/- 1/32 inch at the peel edge, applied tolerance is customer, product and label dependent

- Zebra Model ZE500 print engine

- Print speed: 10 inches a second

- 300 dpi resolution

- Print width: 4.1 inches

- Media width: 4.5 inches

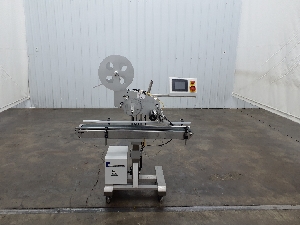

- 1000 series modular mounting base

- Base construction of 3” x 4” welded carbon steel tubing

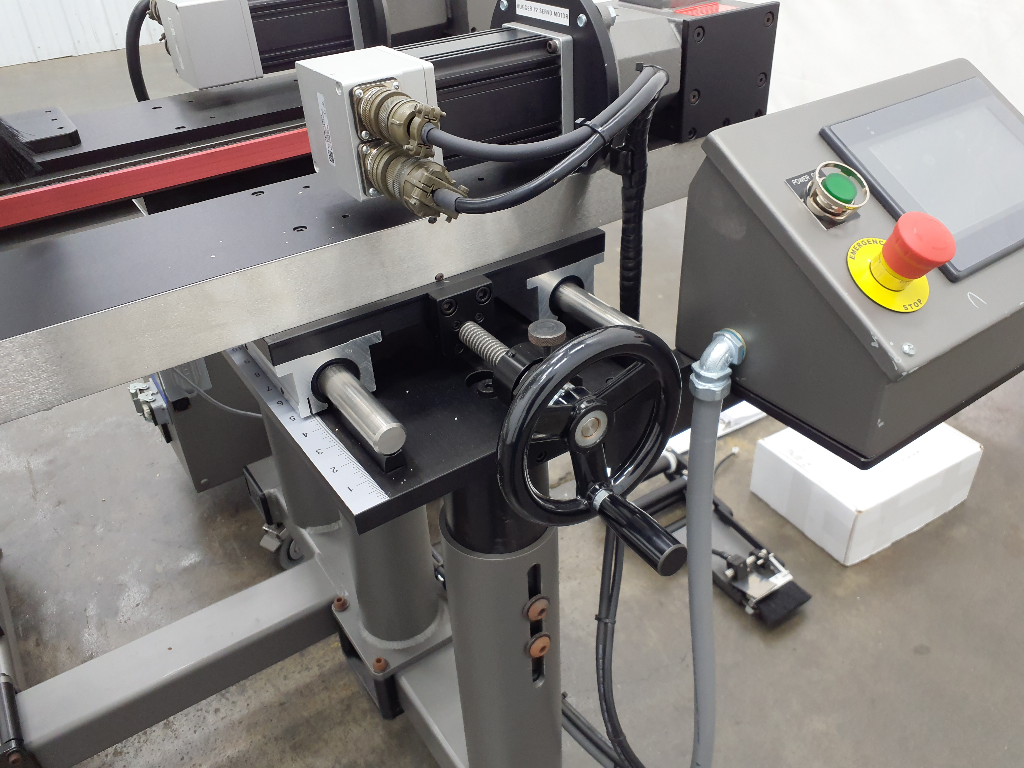

- Standard 54” vertical upright mounted on a single (Y-axis) traverse assembly with standard handwheel

- MT1000 series Low profile mattop infeed conveyor

- Dimensions: 48 length x 7.5 width

- Adjustable infeed height: 30-36 inches

- Variable speed DC drive: up to 90 feet per minute

- Baldor motor: 0.33 hp

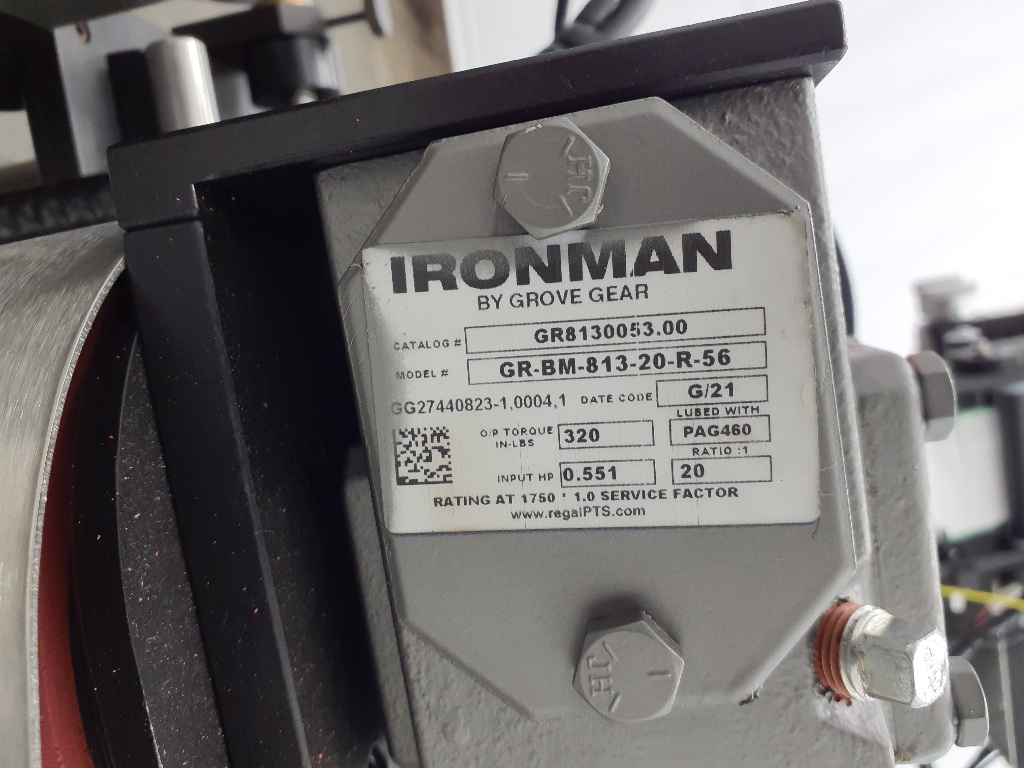

- Lesson gear box

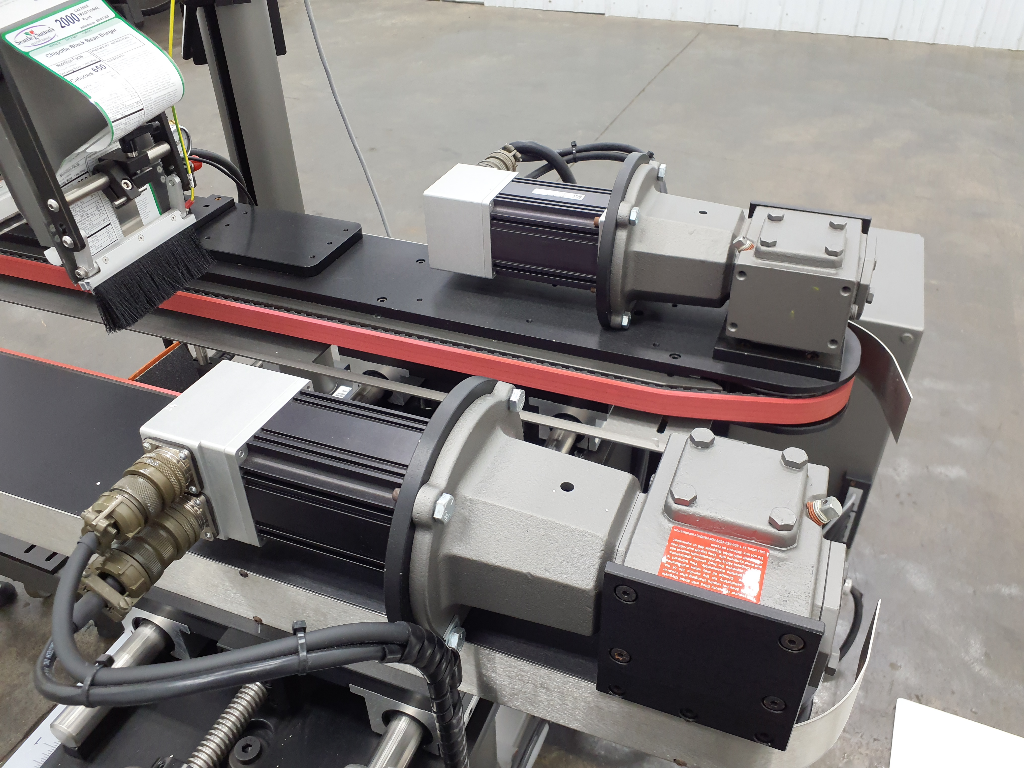

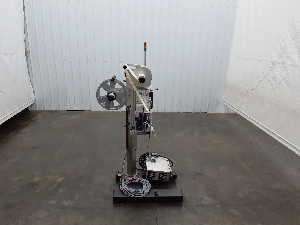

- Hugger transfer belt

- Dimensions: 60 length x 1 thickness (inches)

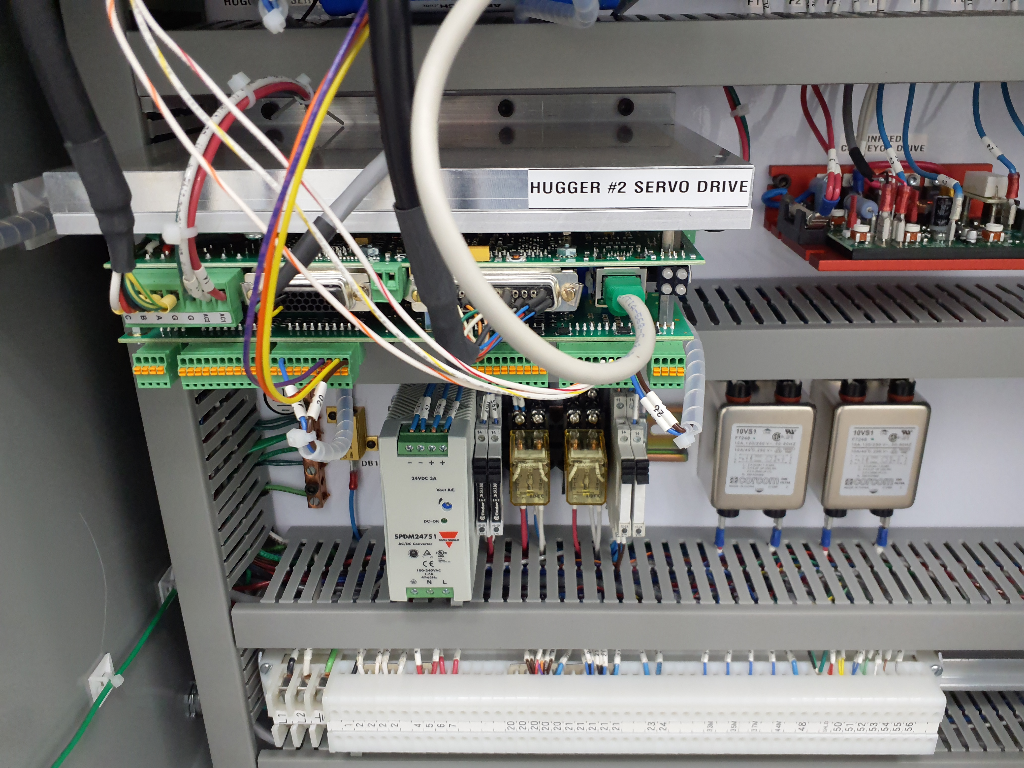

- Variable speed dual servo drive motors: up to 90 feet per minute

- Overall dimensions: 120 length x 60 width x 76 height (inches)

- Dancer arm tension control and standard rewind mandrel

- Integrated in loose loop fashion to CTM 360a label applicator with SATO thermal transfer print engine

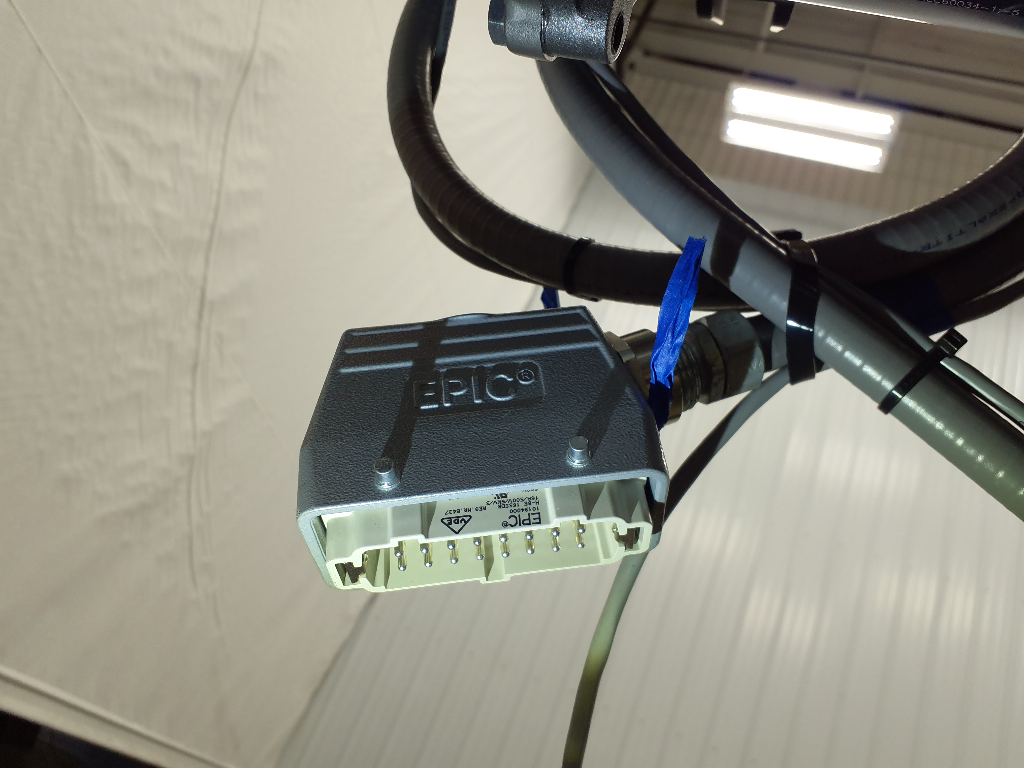

- Mounted to infeed conveyor motor for hugger belt drive, with cable assembly to single 360a labeler

- Low label detection

- End of web detection

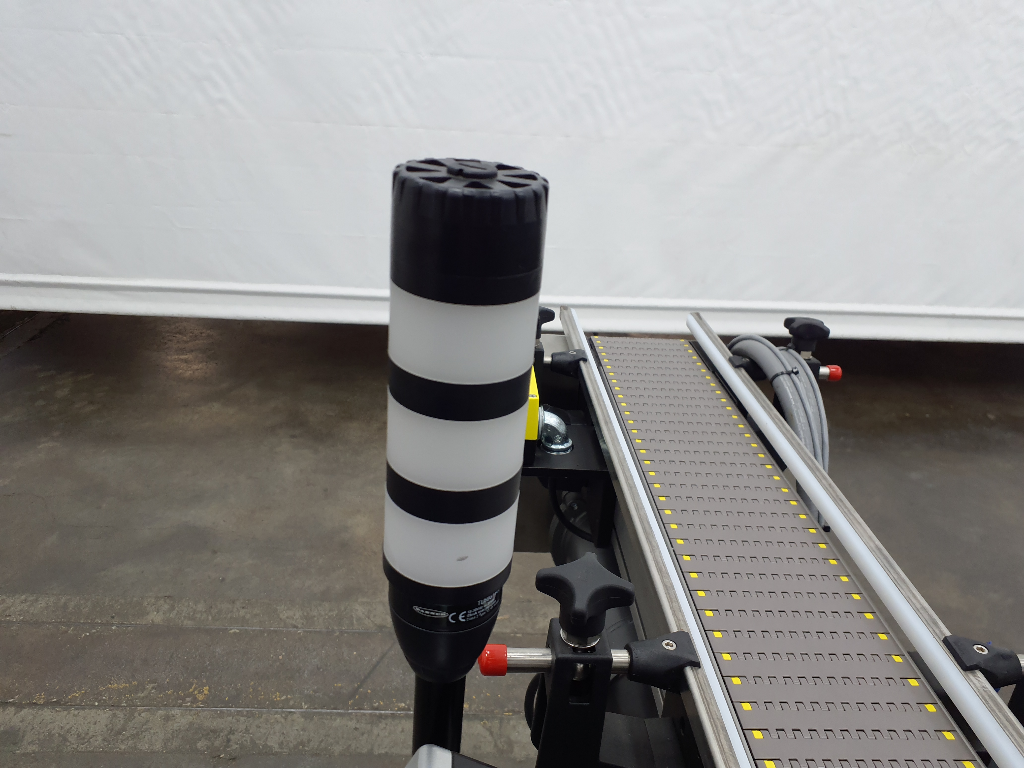

- 3-light alarms stack assembly

- Collapsible rewind mandrel

- Air requirements

- 60-90 psi

- up to 4 CFM

- Electrical requirements: single phase, 50/60 hertz, 108-132 volts

Last application: multiple sizes of trays - filled and sealed - 6.5" wide x 8.5" Feed x 1.2" to 3.5" height - 5 ounce - 22 ounce. Label size: 3.25" wide x 10.5" feed. – 2 Panel Wrap – Wind direction will need to be such that the nutritional information to dispense first (leading) and prime information will trail. Paper Material with Paper Liner.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.