Used Complete Water Bottling Line From Blow Molding To Stretch Wrapping Up To 46,000 Bottles Per Hour

Click here for full page view of all Equipment Media (36)

Equipment Details

| Equipment # | E312949 |

| Item | Complete Water Bottling Line From Blow Molding To Stretch Wrapping Up To 46,000 Bottles Per Hour |

| Category |

Production Line Beverage Production Line |

| Manufacturer | |

| Model | unknown |

Equipment Description

Complete bottling line for 16.9 fluid ounce PET bottles With 26.7mm plastic screw caps. This line is is still in operation and includes everything from the blow moolder to the stretch wrapper. Running 46,000 bottle per hour in 18, 24, 30, and 40 count unsupported print registered packs. Was originally designed for 72,000 bottles per hour, original second blow molder was removed, dropping the speed to 46,000.

- Tanner Preform dumper

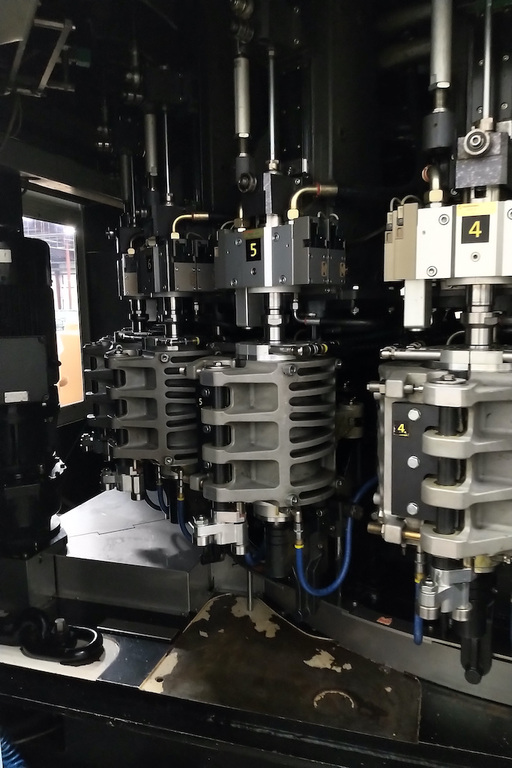

- Krones Contiform S24, 24 cavity blow molder:

- 24 linear heated blow zones

- Up to 3 liter container sizes

- Maximum mechanical output: 48,000 bottles per hour

- High pressure air compressor

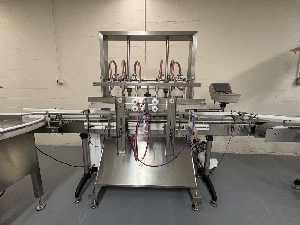

- Lanfranchi L3-SR-21-27 high speed bottle unscrambler:

- Smooth conveyance of bottle to leave no marks

- Output: up to 72,000 bottles per hour depending on application

- Krones AirCo air conveyance system

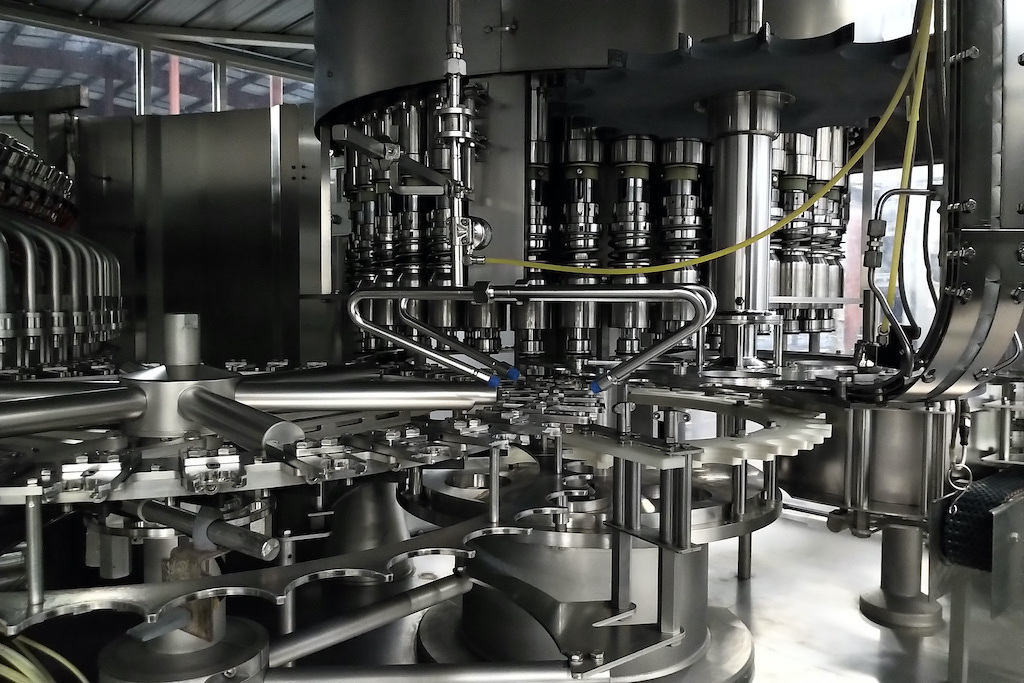

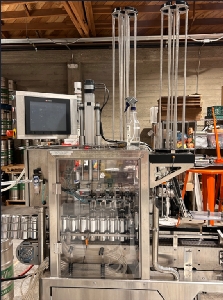

- Krones VODM-PET 104 valve bottle filler, 39 head capper:

- Deisgned for non carbonated beverages in PET containers

- Non-carbonated mineral water, juice, coffee and tea beverages, energy drinks, or milk (change parts may be required for certain fills)

- Output: up to 72,000 bottles per hour depending on application

- 104 valve volumetic flow metering filling stations

- Minimum conductivity of 40 μs/cm required

- 36 head chuck capper

- Neck handling of bottle

- Deisgned for non carbonated beverages in PET containers

- Sidel Aidlin CF2024 cap hopper/feeder

- Sonic air knife system:

- 2 knives approximately 24 inches long

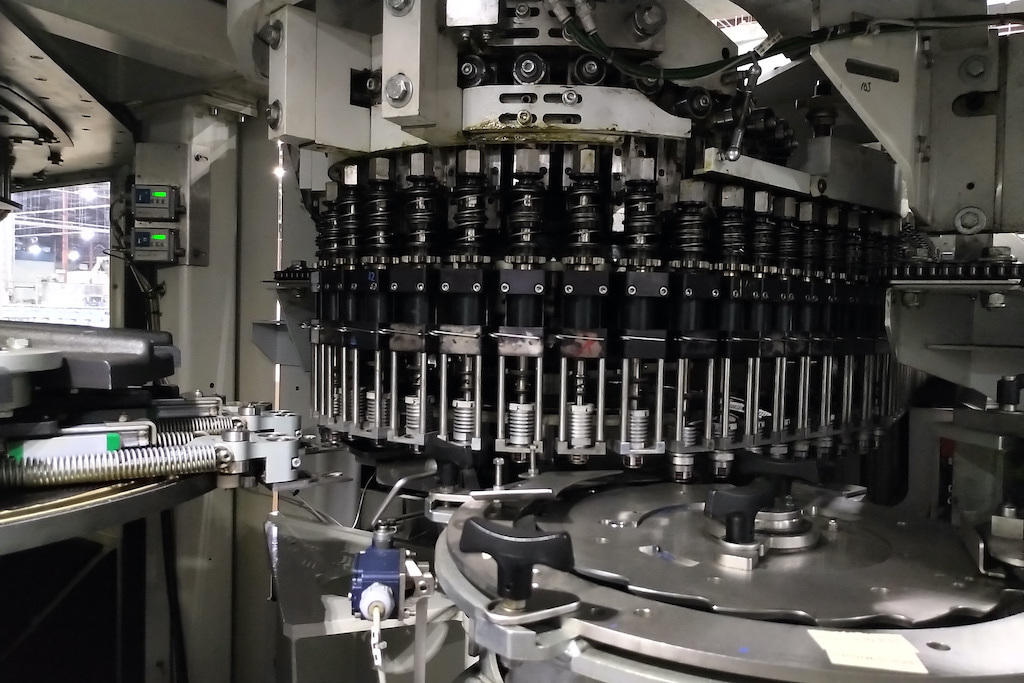

- Krones Canimatic 36 station hot melt pre-cut wrap around rotary labeler:

- 36 station rotary labeler

- Output: up to 72,000 bottles per hour depending on application

- Pre-cut labels (cut and stack)

- Hot melt glue

- Krones Checkmat inspection system:

- Fill level inspection

- Cap position inspection

- Tamper evident ring inspection

- Output: up to 72,000 containers per hour

- Videojet 3320-IP54 laser coder:

- 30-Watt CO2 laser

- Marking speed: up to 1,300 characters per second depending on application

- Line speed: up to 49 feet per second depending on application

- Marking field: moving products: 1.7 to 7.0 inches high

- Marking Formats:

- Standard industrial fonts (Type 1 Windows® TrueType®)

- Machine readable codes (OCR, 2D-matrix, etc.)

- Bar codes: BC25, BC251, BC39, BC128, EAN128, EAN13, UPC_A, RSS14,

- RSS14 Truncated, RSS14 Stacked, RSS14 Stacked Omnidirectional, RSS Limited, RSS Expanded, etc.

- Graphics, logos, symbols, etc.

- Linear, circular, angular, reverse, rotate

- Sequential and batch numbering

- Automatic date, time, shift coding, real-time clock function

- Fumex air control fume extraction system

- Stainless bi-directional plastic mat top accumulation table

- Douglas M75 bundler with Contour heat tunnel:

- Output: up to 75 cycles per minute, depending on application

- Print registered

- Unsupported product

- Bullseye style shrink

- Pack counts: 18, 24, 30, and 40

- Contour heat tunnel

- Descon full bottle stainless conveyor

- Ryson spiral case elevator

- Overhead case conveying system leading to the palletizer

- PAI 5250 high level infeed case palletizer:

- Can handle a wide range of case sizes including unsupported shrink shrink wrap cases

- Output:

- Unsupported shrinkwrap cases: up to 60 cases per minute depending on application

- Non unsupported shrinkwrap cases: up to 130 cases per minute, depending on application

- Soft Case Turning System

- Pattern Forming Area

- Low Pressure Layer Placement

- Forklift Type Pallet Dispenser

- Slip sheet inserter

- Case meetering belt

- Line divider

- Pin style case turner

- Compression system

- Touch screen controls

- Catwalk platform

- Full pallet powered roller conveyor system to palletizer

- Wulftec WCRT-200 fully automatic high speed rotary arm stretch wrapping system:

- Output: up to 100 loads per hour depending on application

- Load weight: up to 5000 pounds

- Maximum load size:

- Length: 48 inches

- Width: 48 inches

- Height: 80 inches

- Touch screen controls

- 20 inch wide film width

- Up to 300 percent stretch

- Automatic film clamping, cutting, and alignment

- Infeed and discharge conveyors

- SAP full pallet labeling system

- Electrical:

- Volts: 460

- Frequency: 60 Hz

- Phase 3

- Stainless steel contact parts

Unit is sold as is where is, not including rigging and shipping

To run at its full capacity, a second blow molder would need to be purchased

Location Details:

To coordinate an inspection of this item, please contact your SIGMA sales team. Call us at (812) 303-8383.Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this Complete Water Bottling Line From Blow Molding To Stretch Wrapping Up To 46,000 Bottles Per Hour?

Request an email quote or call us at (812) 303-8383 for more information.