Description

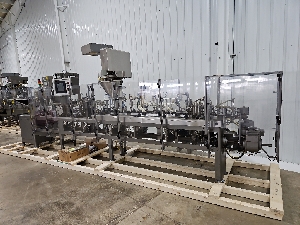

Used Circle Packaging Horizontal Form Fill and Seal with:

- Four sided pouch form fill and seal horizontal wrapper

- Last running moist towelette single serve pouch

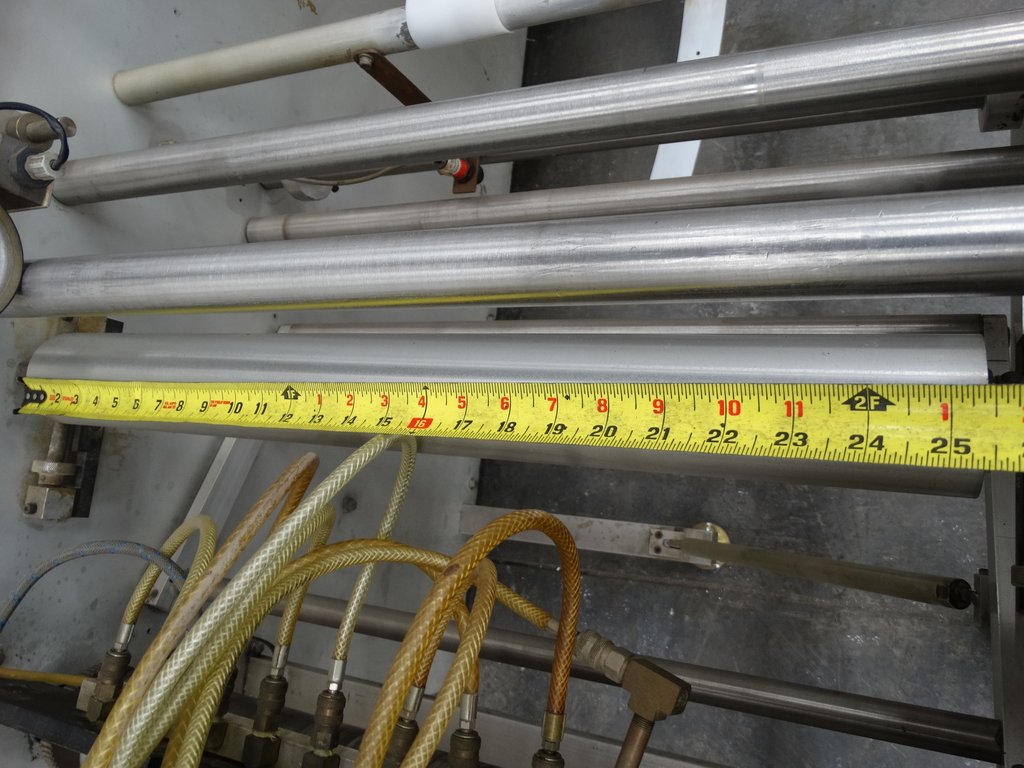

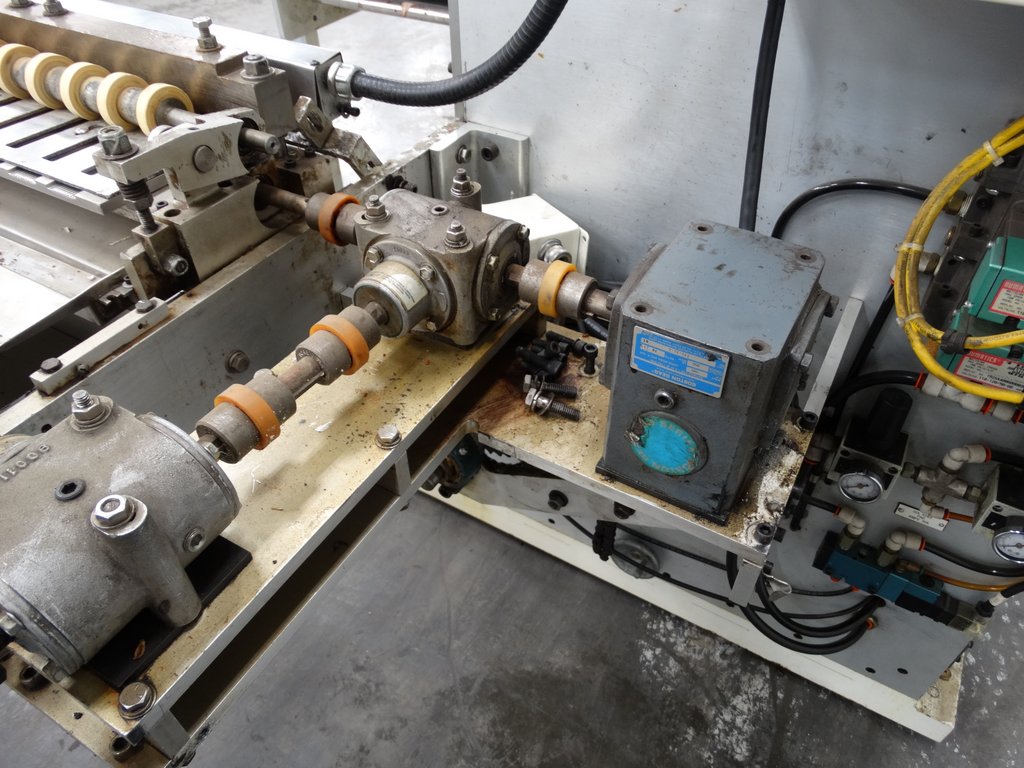

- Fiber towel is unrolled and cut into strips, then folded, dosed in solution(dosing system not included), then cut into final segments and then wrapped with top and bottom film. Wrapped product then travels through a series of two side sealers and a pull wheel.

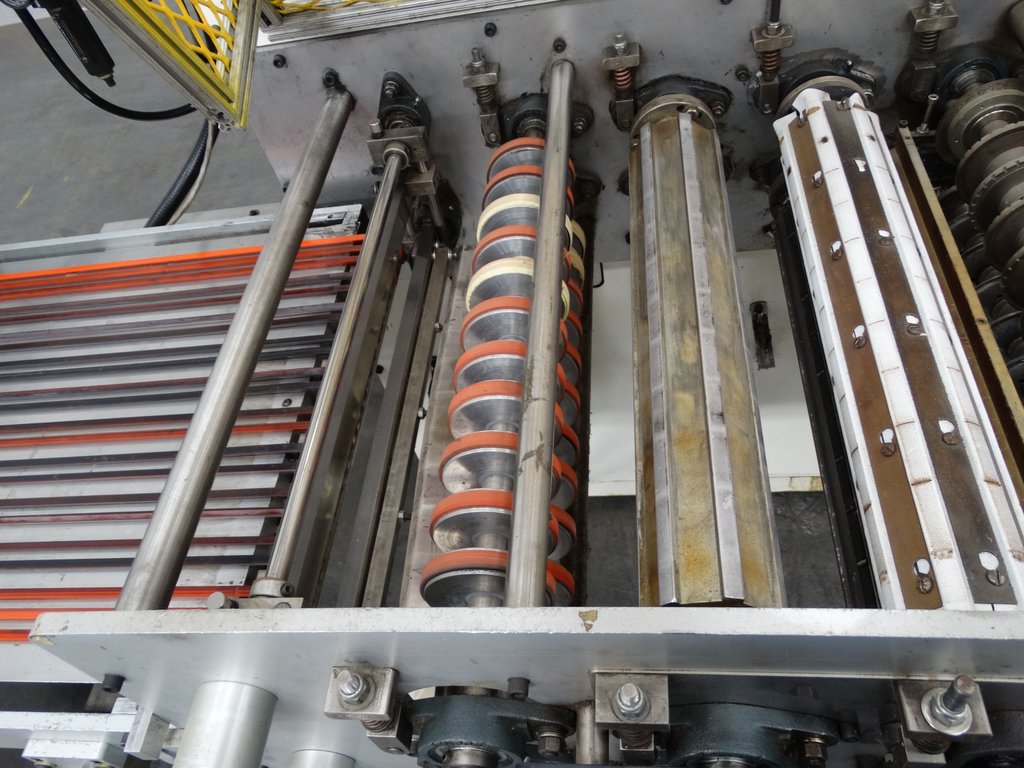

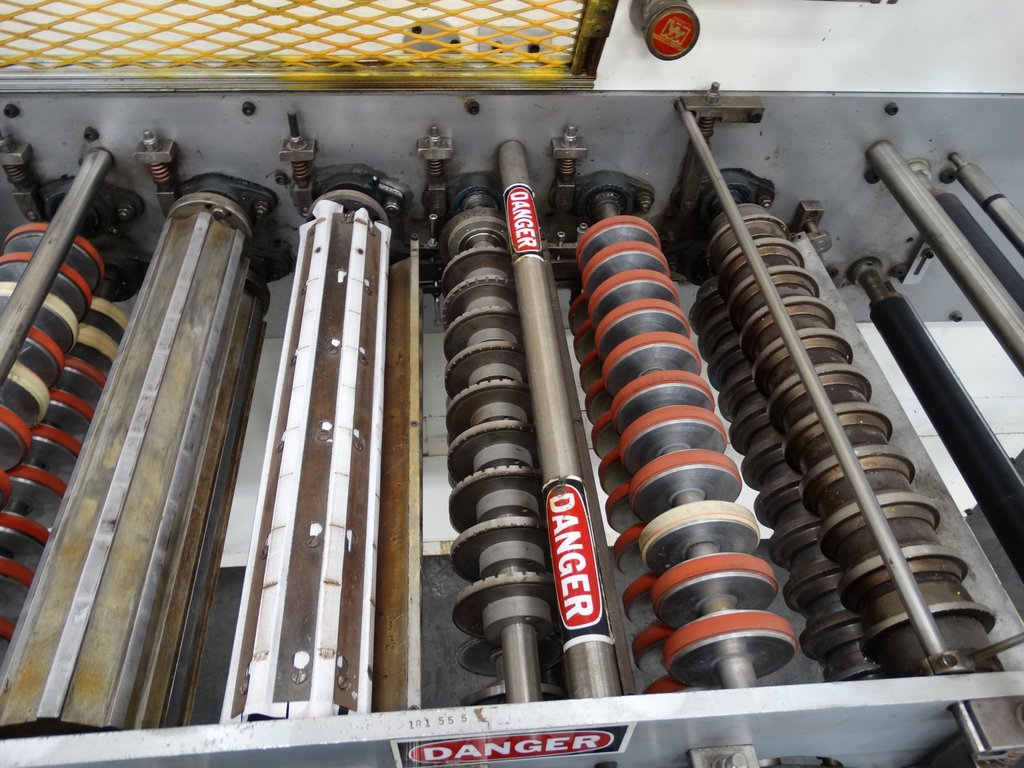

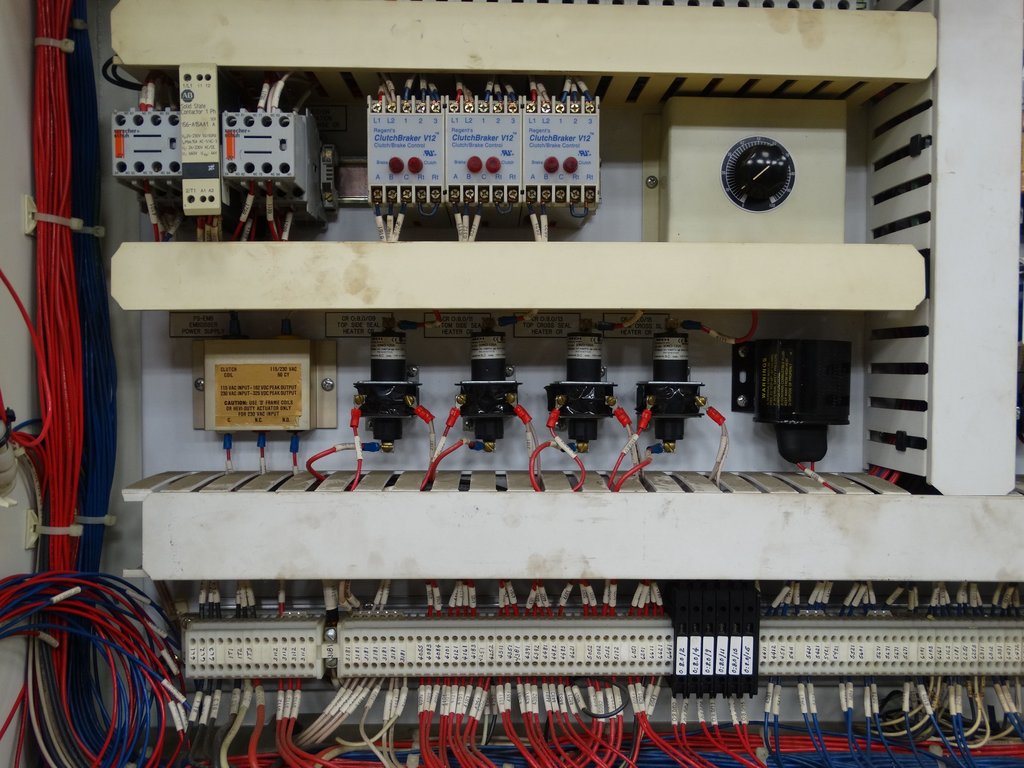

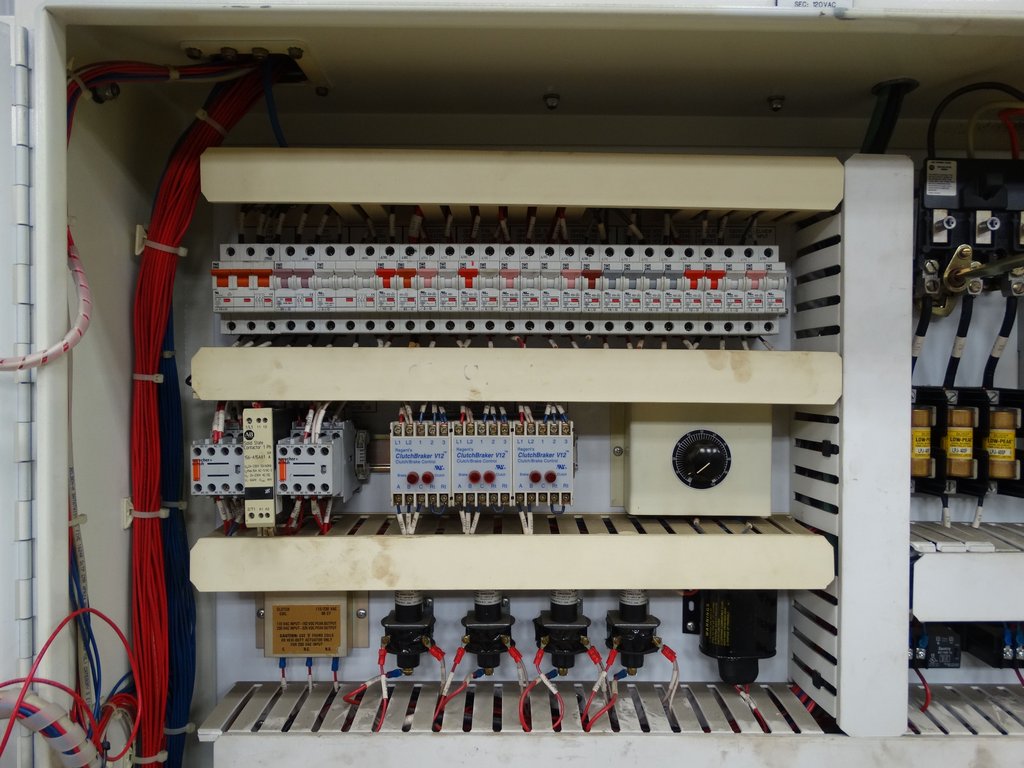

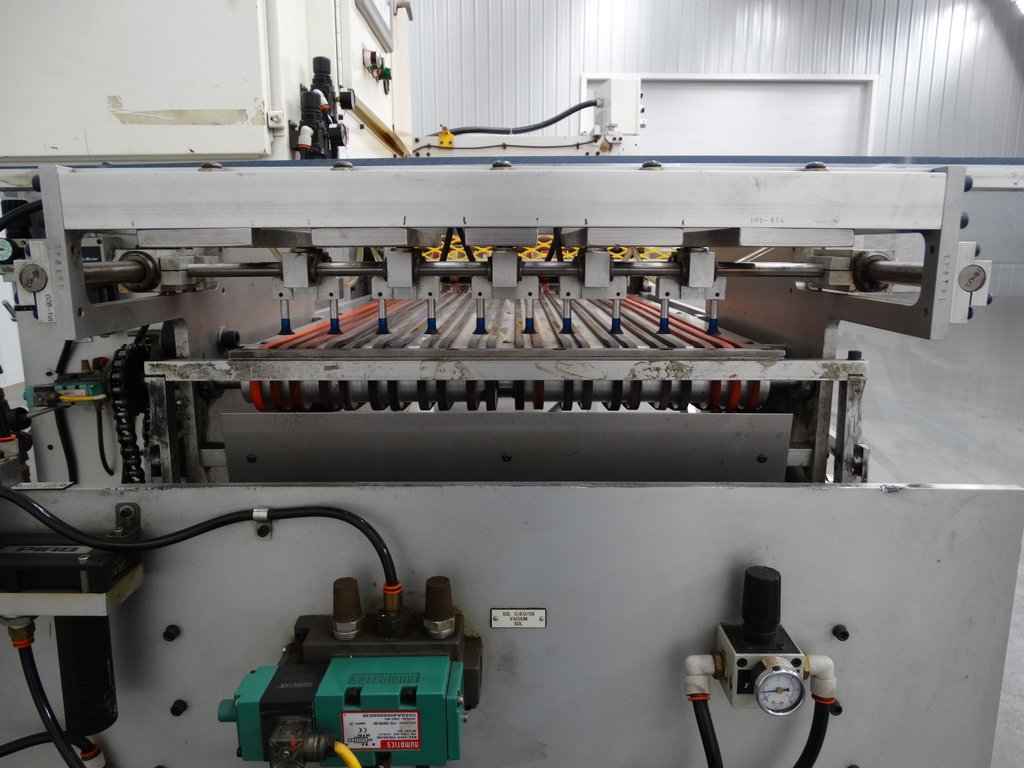

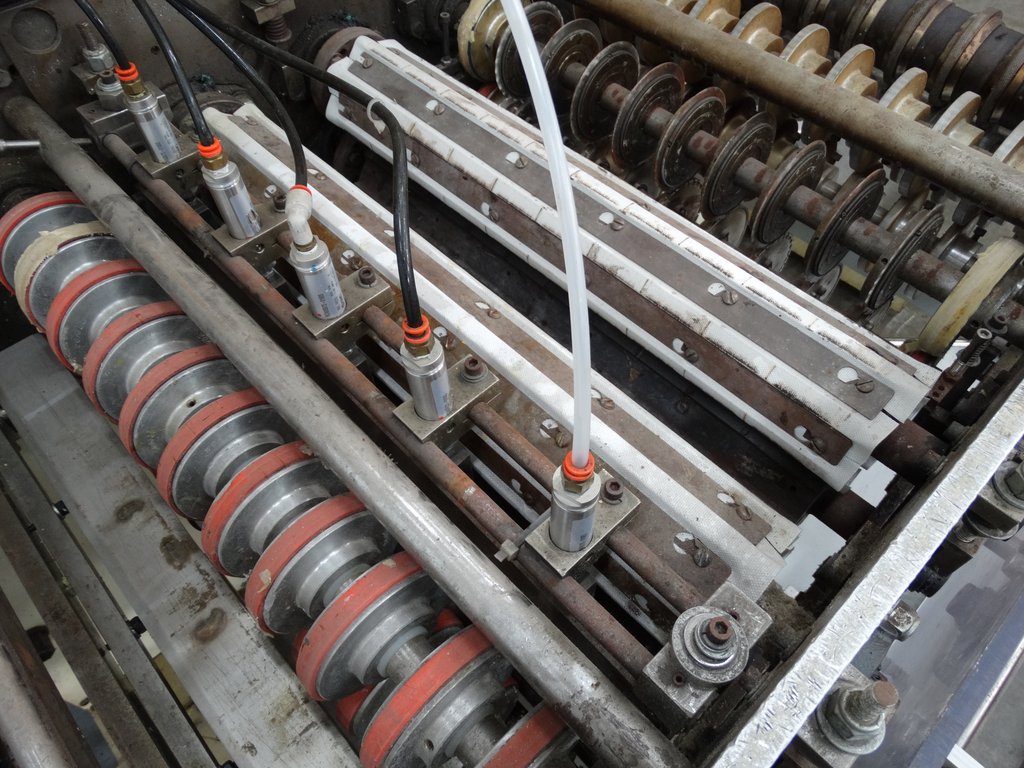

- Side sealers apply constant pressure with controlled heat. The first sealer applies a minimal amount of heat as to be sure not to scorch the wrap. The second sealer applies more heat to ensure the seal is made.

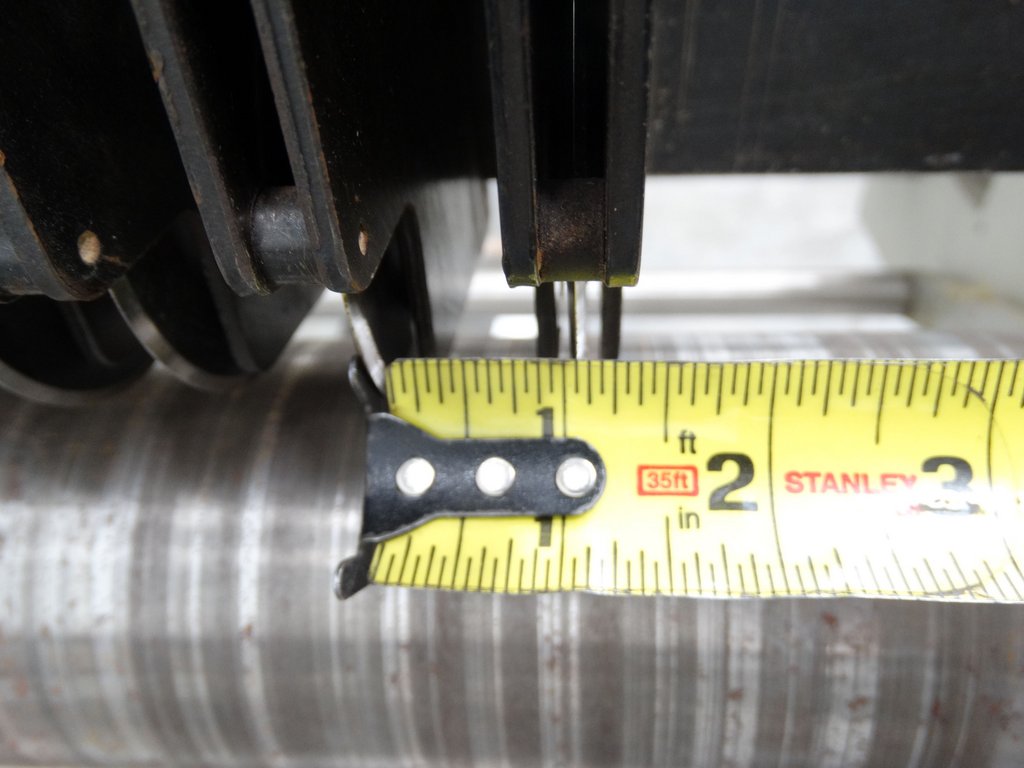

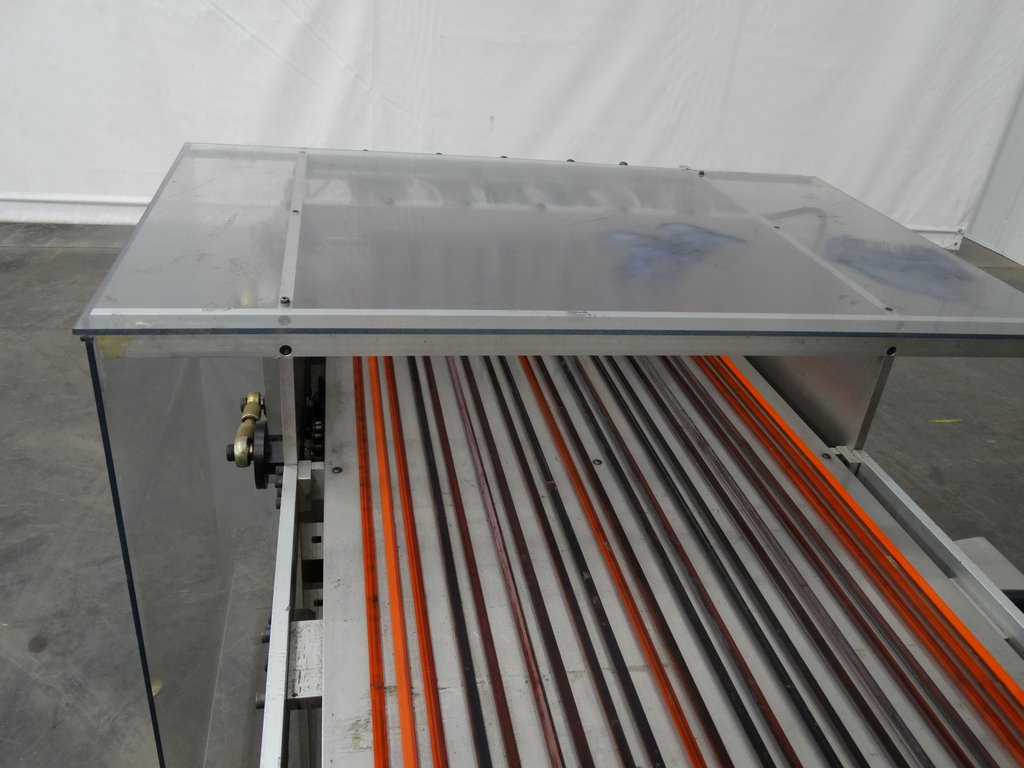

- Pull wheels are used to pull and align film through the machine, while cooling and strengthening the side seals

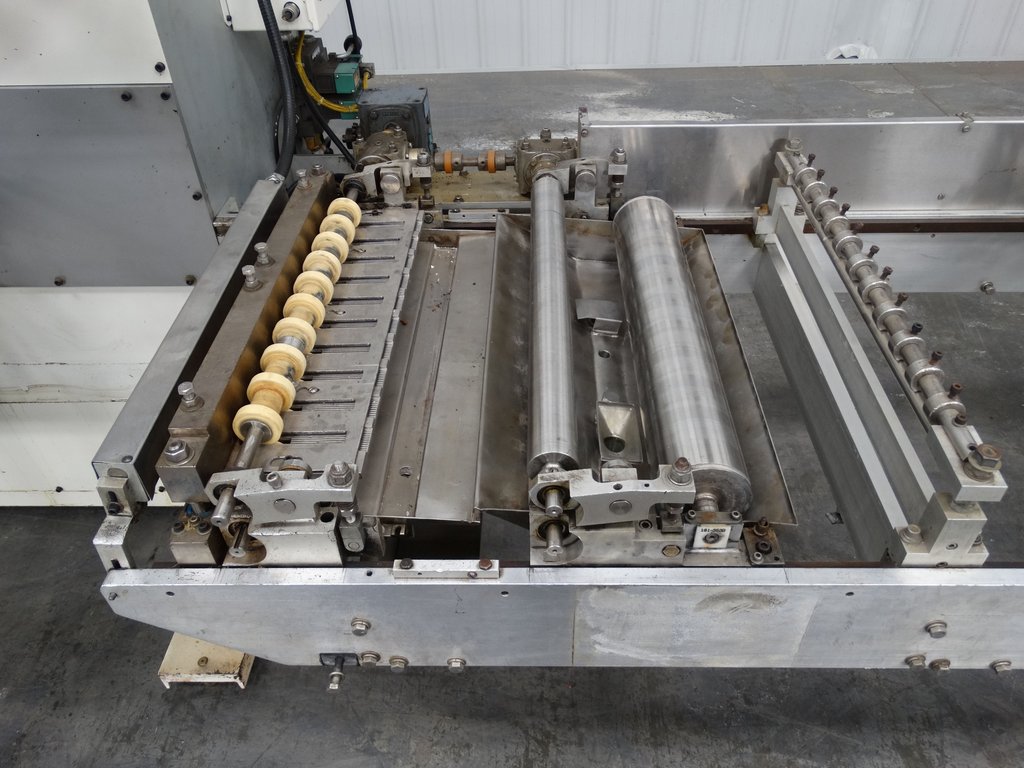

- The package then travels through a cross sealer which seals the remaining two sides. Once the four sides of the package have been sealed, the packages are then separated lengthwise by a slitter which cuts along the seal. The packages then travel through another pull wheel and through the cut-off knife which separates the packages in the cross direction.

- Horizontal orientation pouch machine

- Continuous motion

- Compatible film types:

- Cold seal

- Tyvek

- Laminates

- Metalized

- Poly-coated paper

- Polypropylene

- Previously used for packaging moist towelettes

- Output: approximately up to 1,200 packages per minute

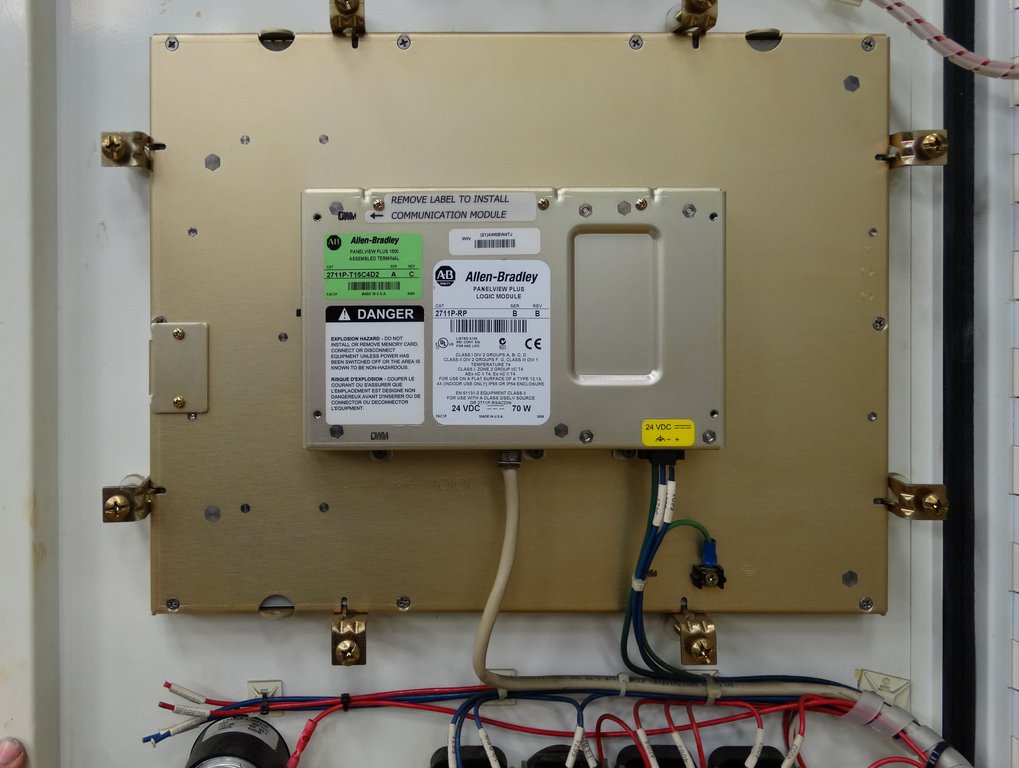

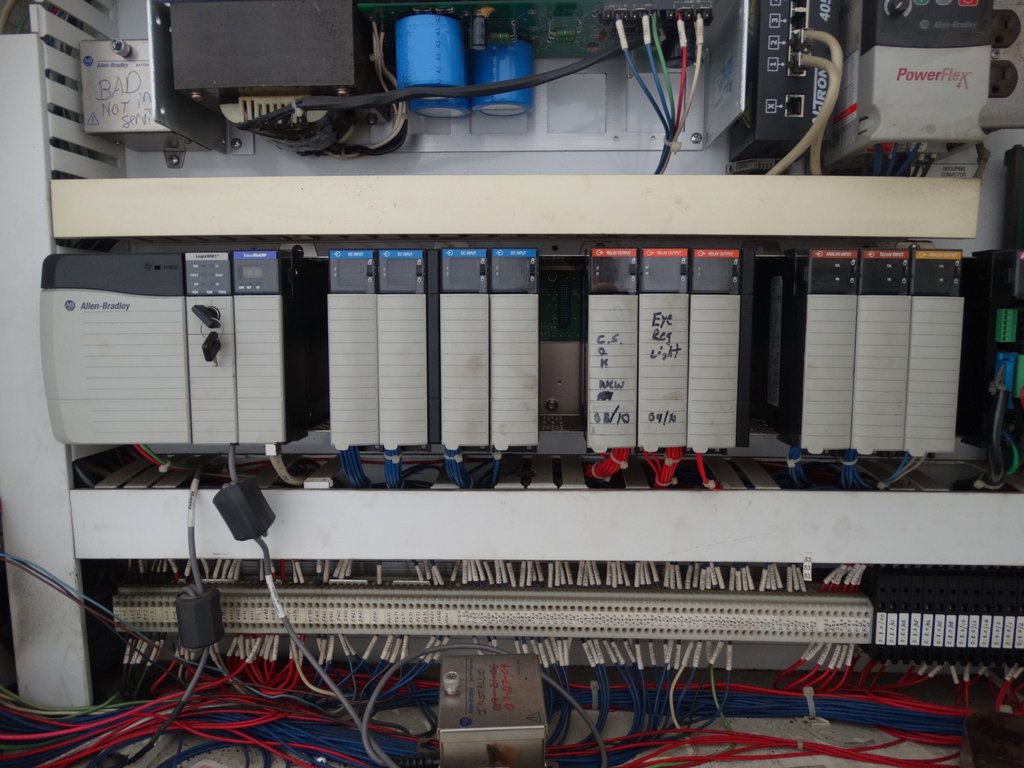

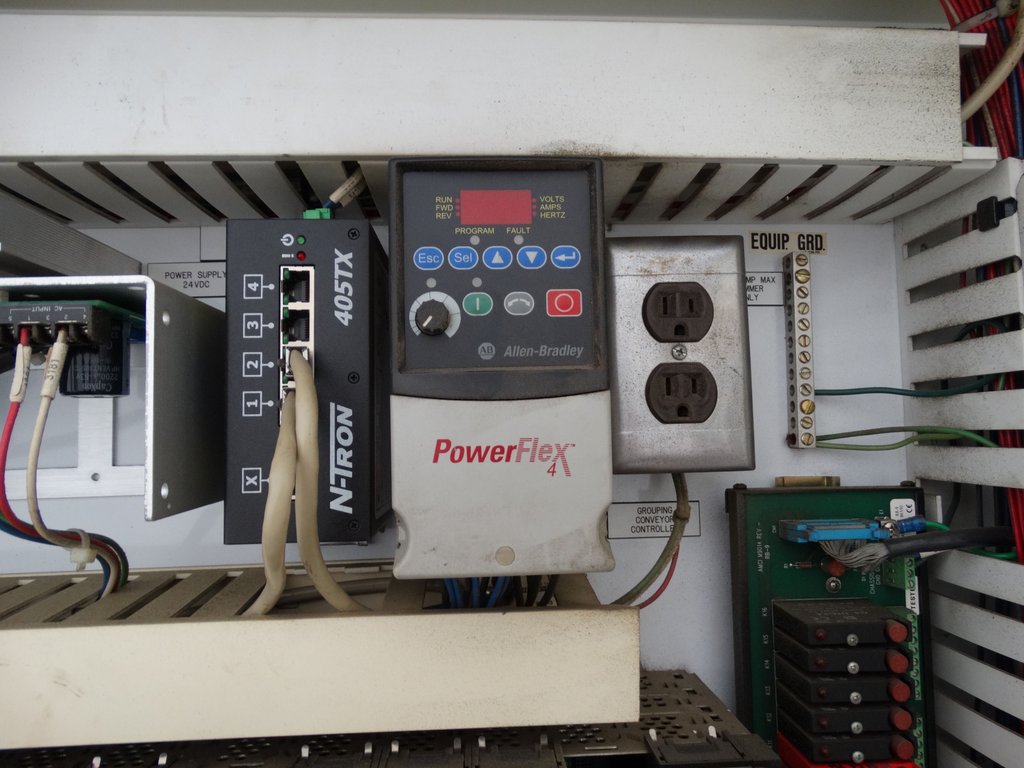

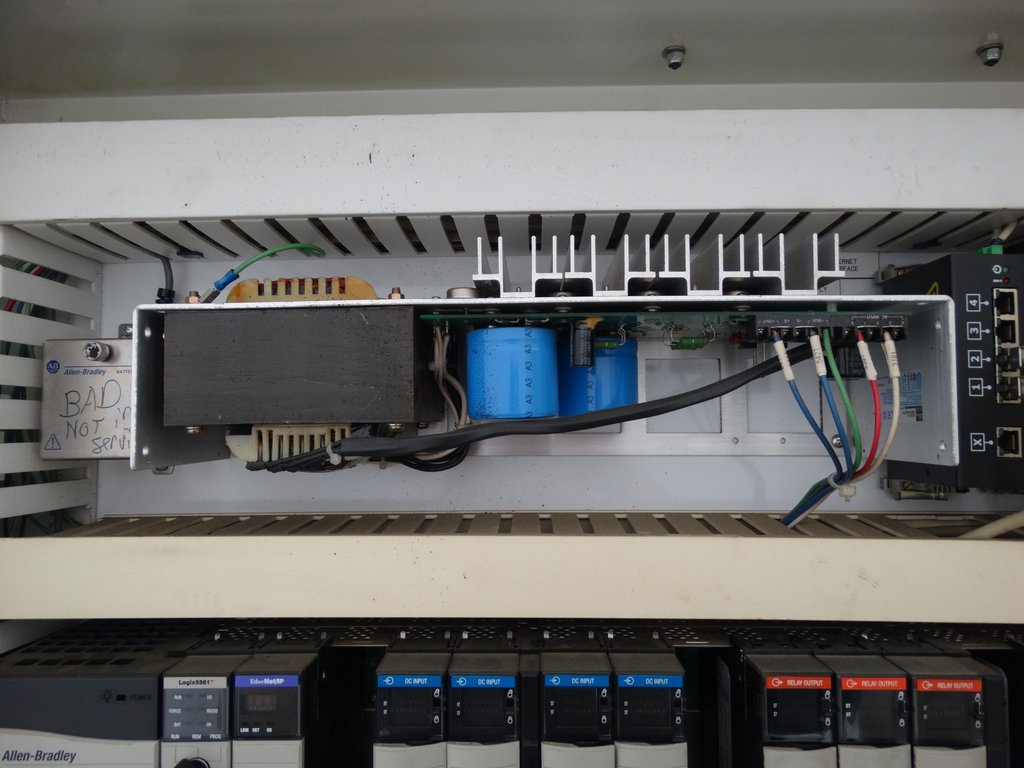

- Allen-Bradley touchscreen HMI for machine human interface

- Stainless steel contact parts

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.