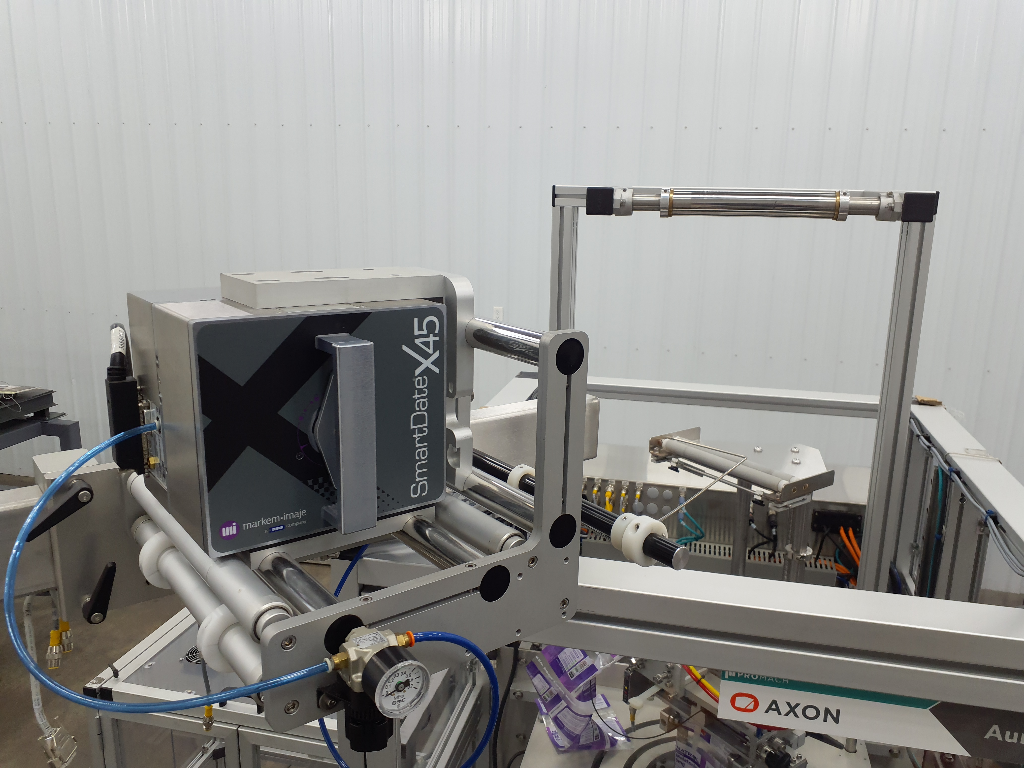

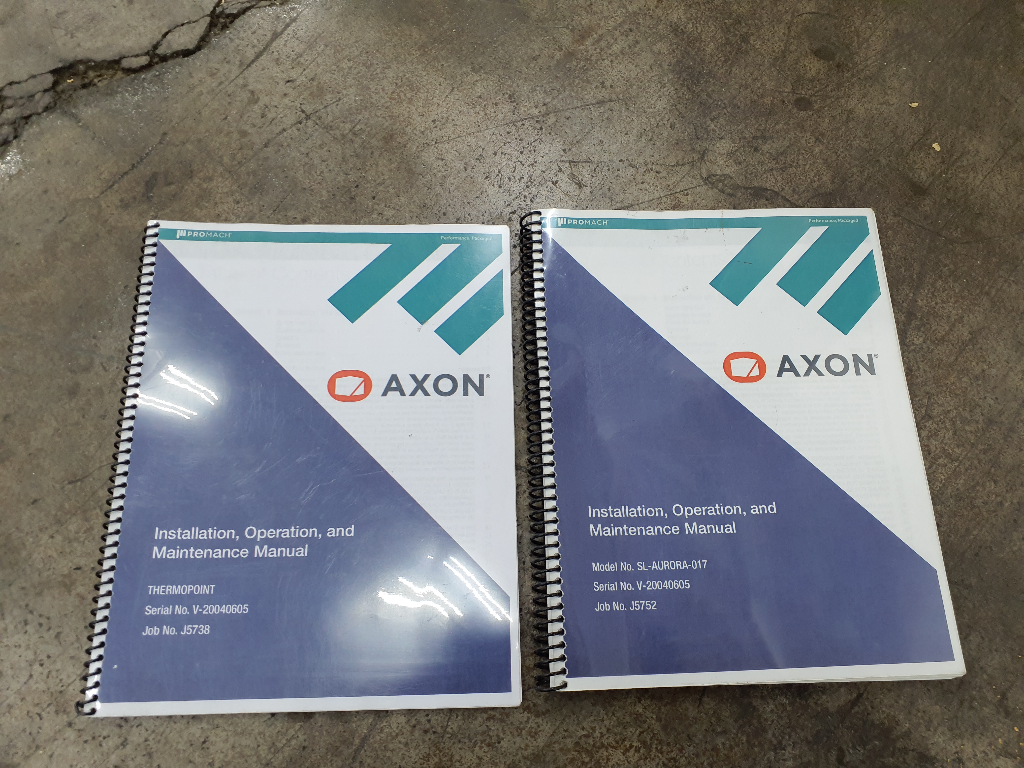

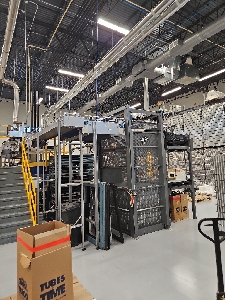

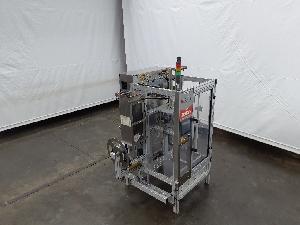

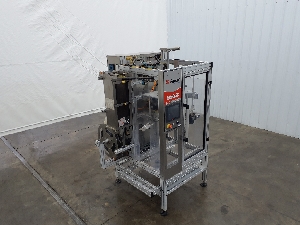

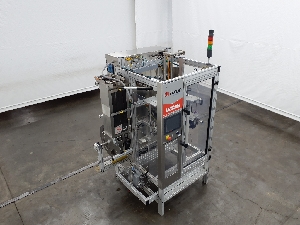

Used Axon Aurora Shrink Sleeve Applicator Up To 400 Containers Per Minute With Steam Tunnel And Boiler

Description

Aurora multi-pack, shrink sleeve label, and tamper band applicators are the mid-speed models in Axon's complete line of shrink systems. Aurora applicators provide dependable, steady-state production speeds up to 400 containers or multi-packs per minute. These units are mandrel style machines that use servo motion control to deliver consistent, repeatable performance. Container changeovers are tool-less and require less than ten minutes depending on product sizes and shapes. Aurora applicators feature PackML programming and user interfaces which simplify machine operation, maintenance, and line integration. Like virtually every Axon shrink sleeve applicator, Aurora offers the flexibility to perform five important shrink applications: Multi-packs and twin packs, Tamper evident bands, Partial body sleeves, Full body sleeves, and Full body over-the-cap sleeves

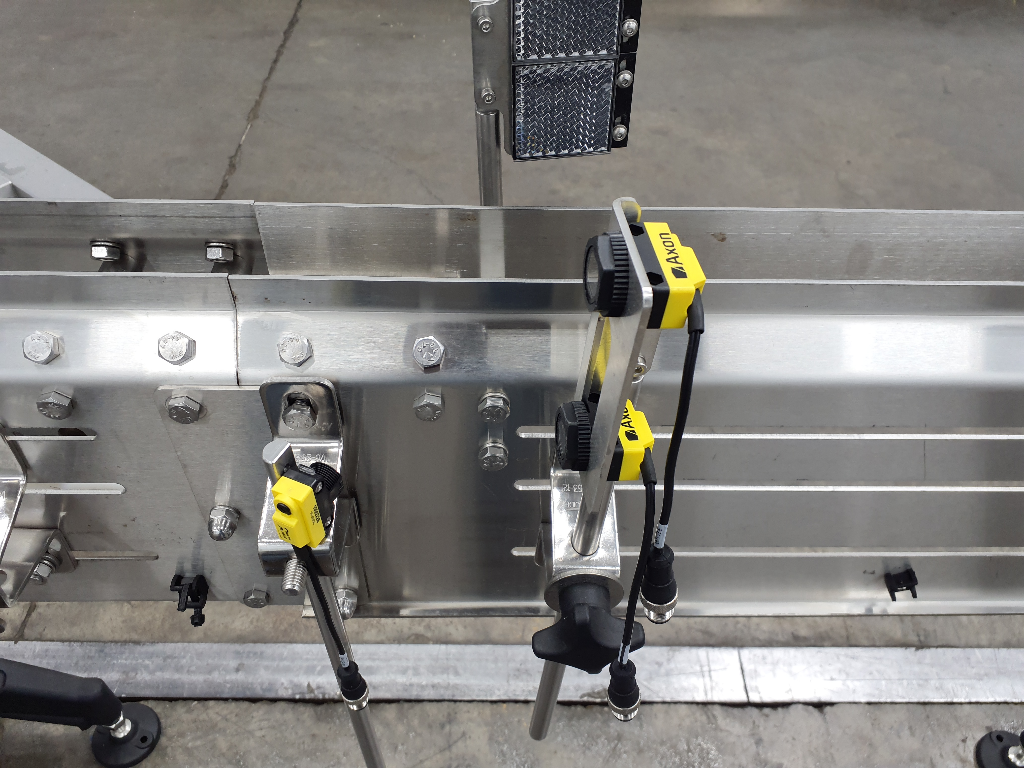

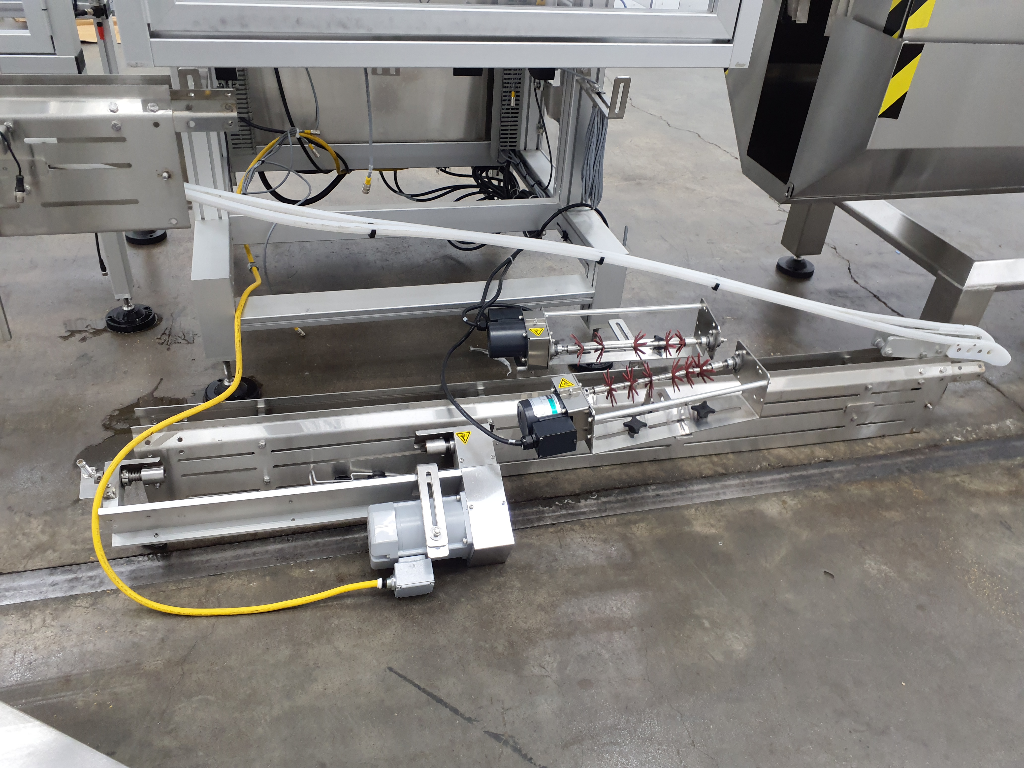

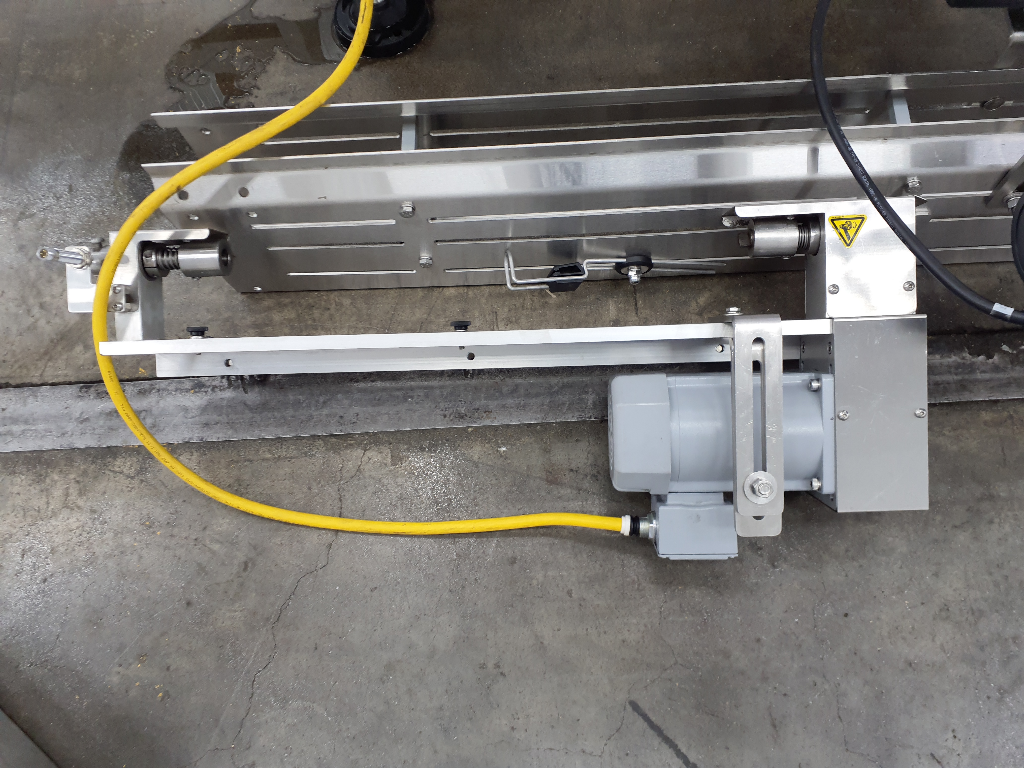

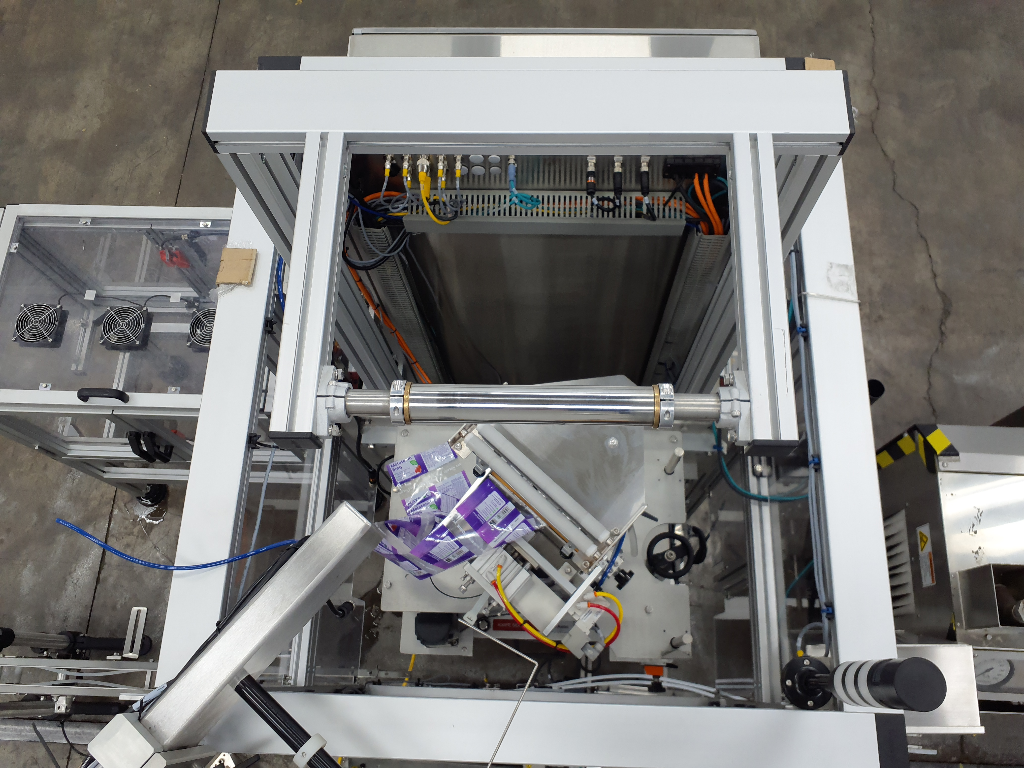

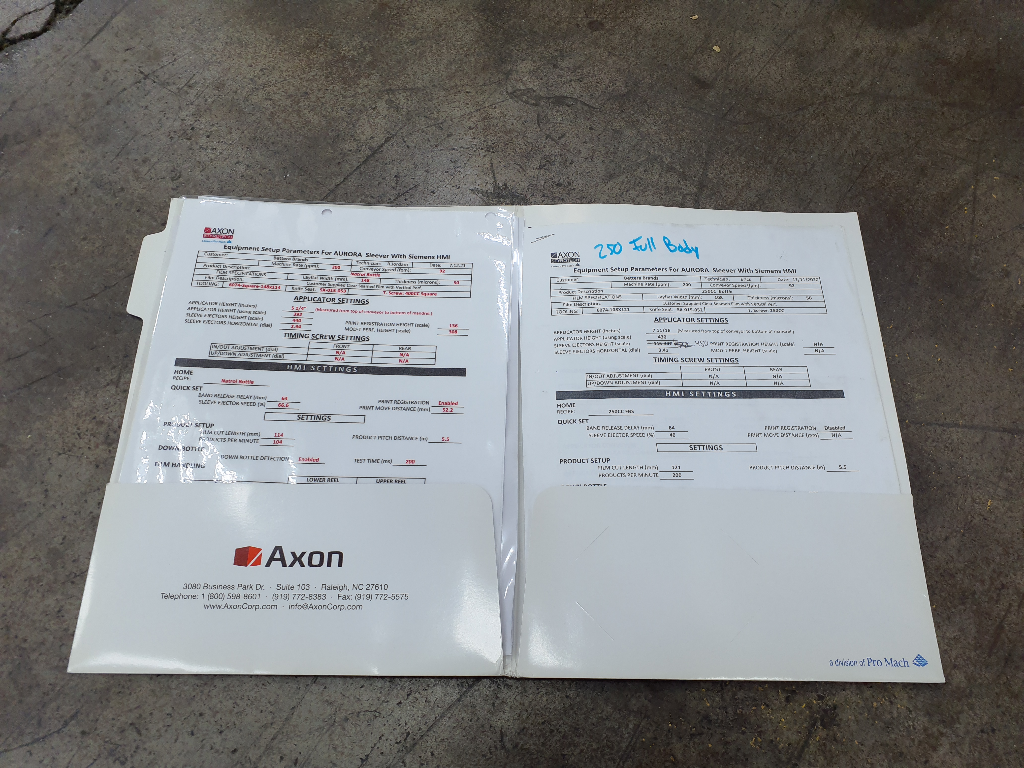

- Axon Aurora Sleever:

- Output: up to 400 containers or multipacks per minute, depending on application

- Container/multipack diameter: 30-125mm

- Lay flat range: 50-200mm

- Applied film materials: PVC, PETG, OPS, PLA

- Film Thickness: 40-70 microns

- Shrink applications:

- Multi-packs and twin packs

- Tamper evident bands

- Partial body sleeves

- Full body sleeves

- Full body over-the-cap sleeves

- Print registration

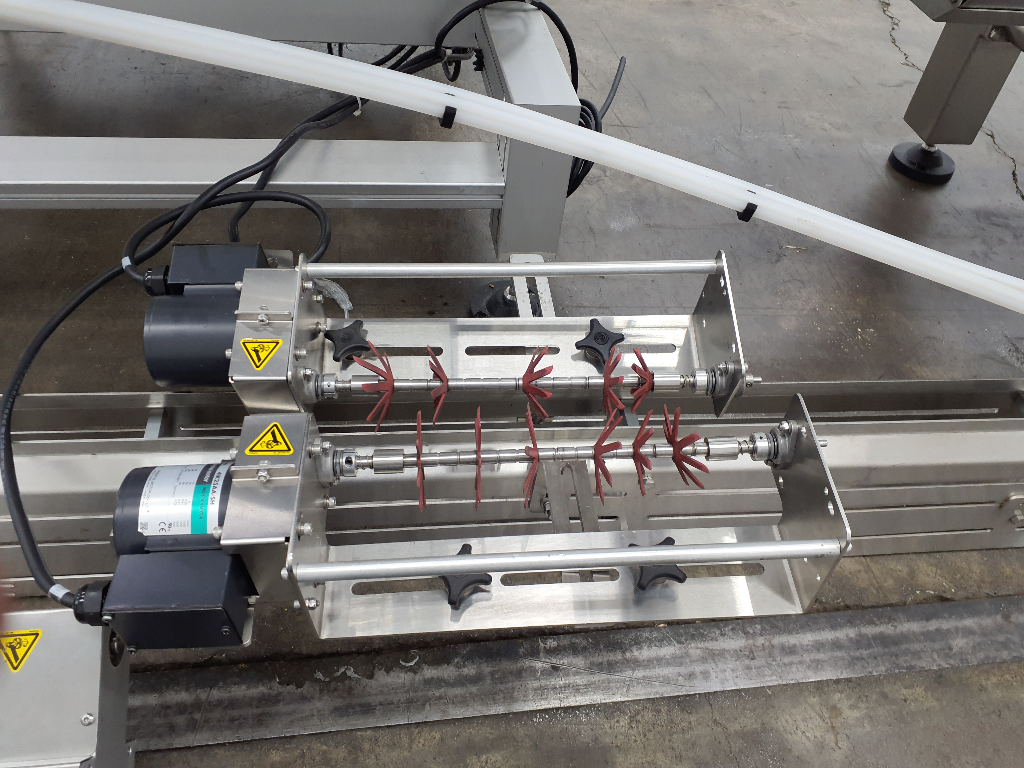

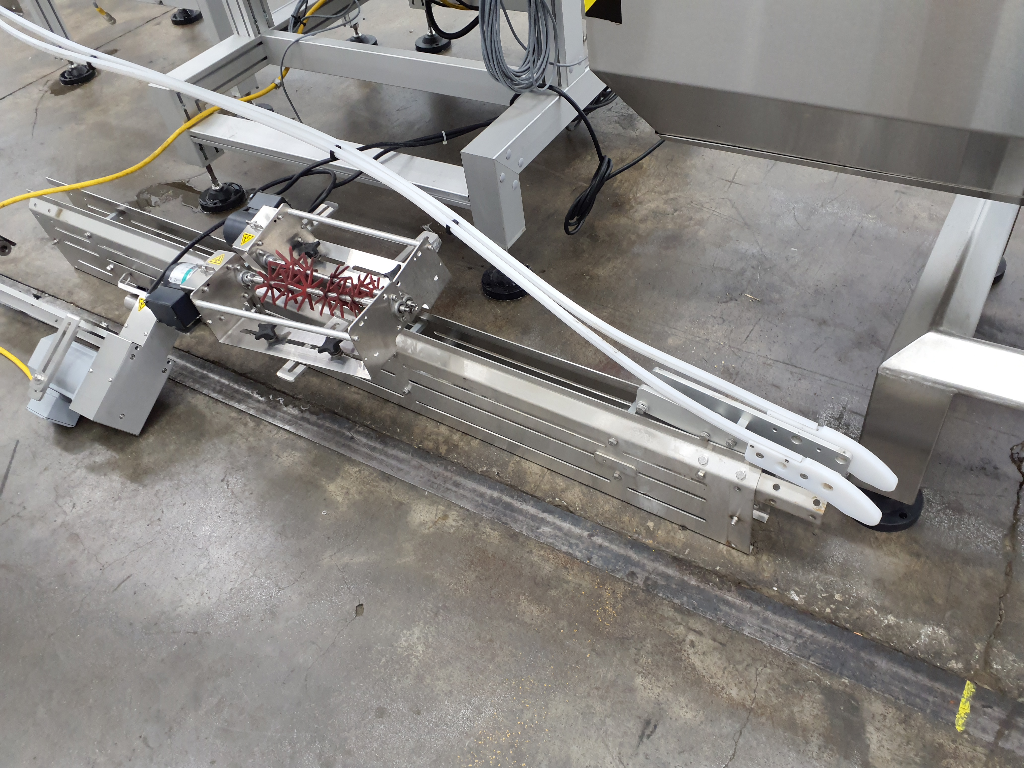

- Auto reversing cutter assembly

- Dual edge blades

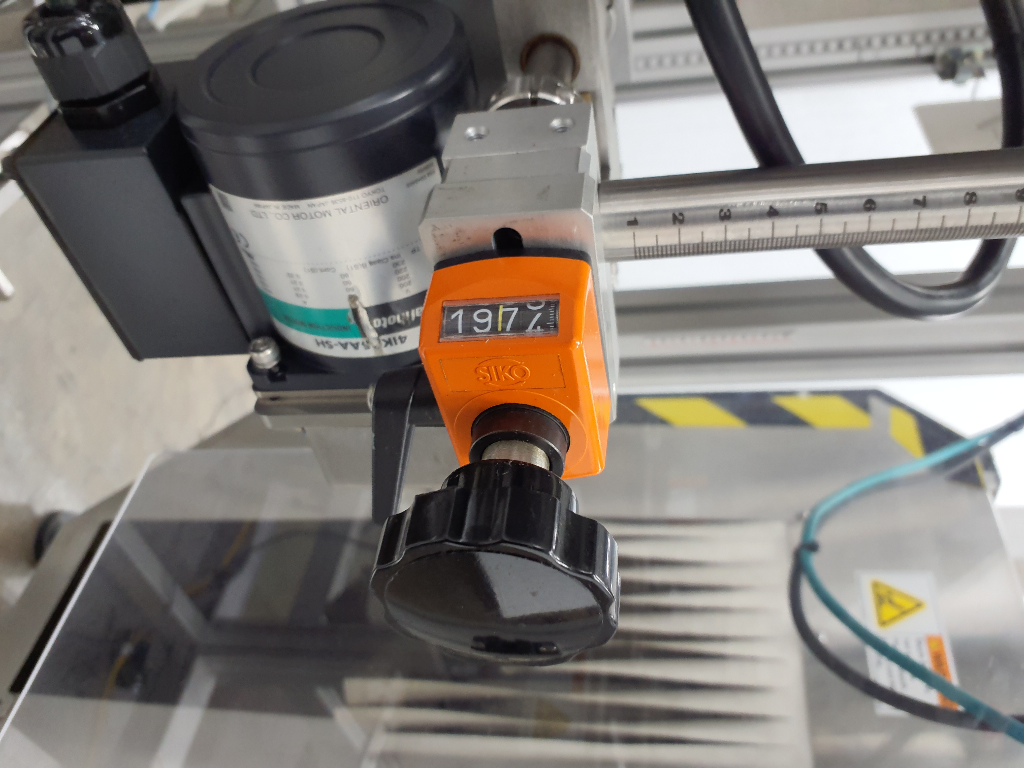

- Electronic height adjustment

- Pivoting head: up to 90° for non-round containers

- Sleeve handling fingers

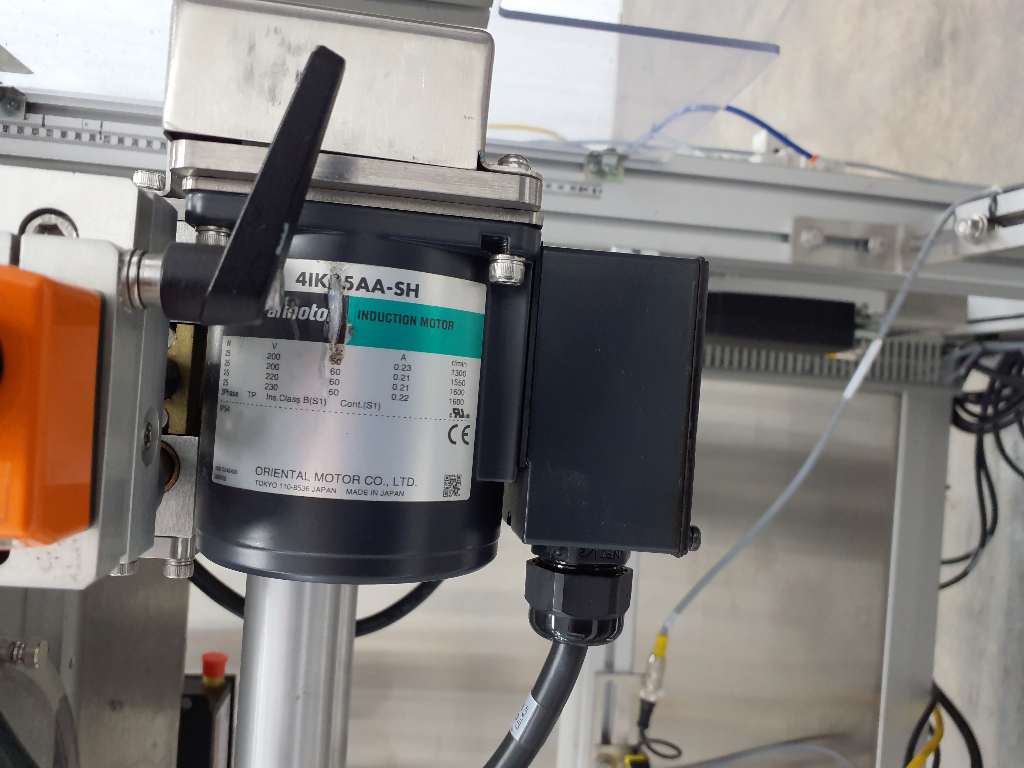

- Servo controlled

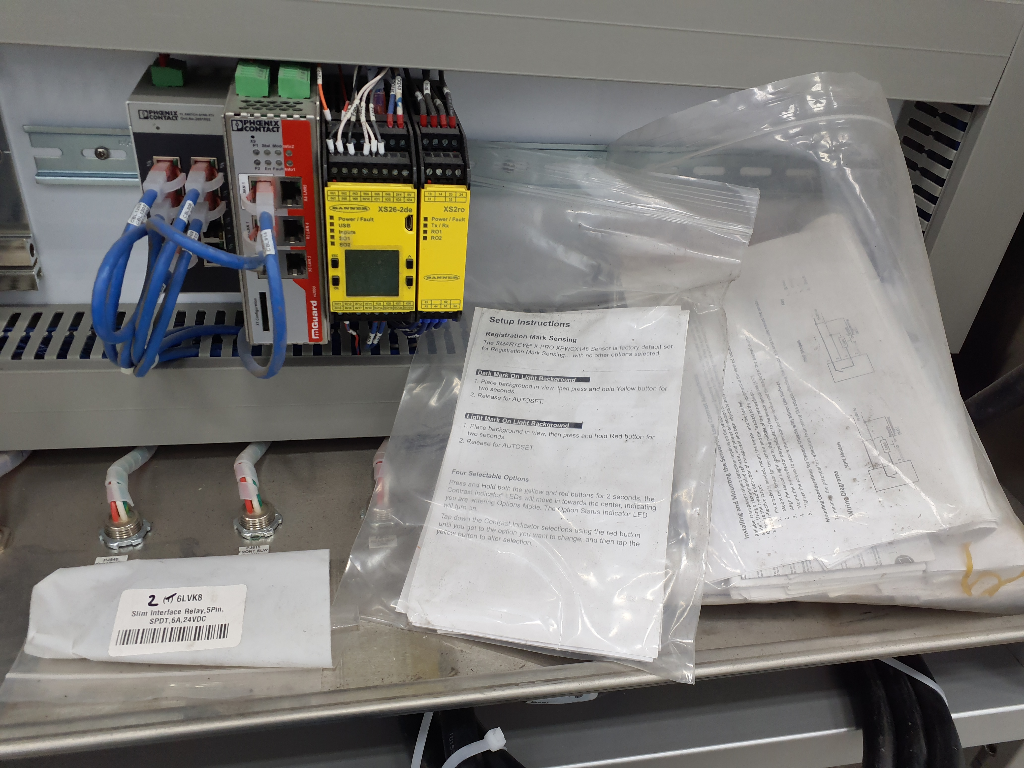

- Touch screen controls

- PackML programming

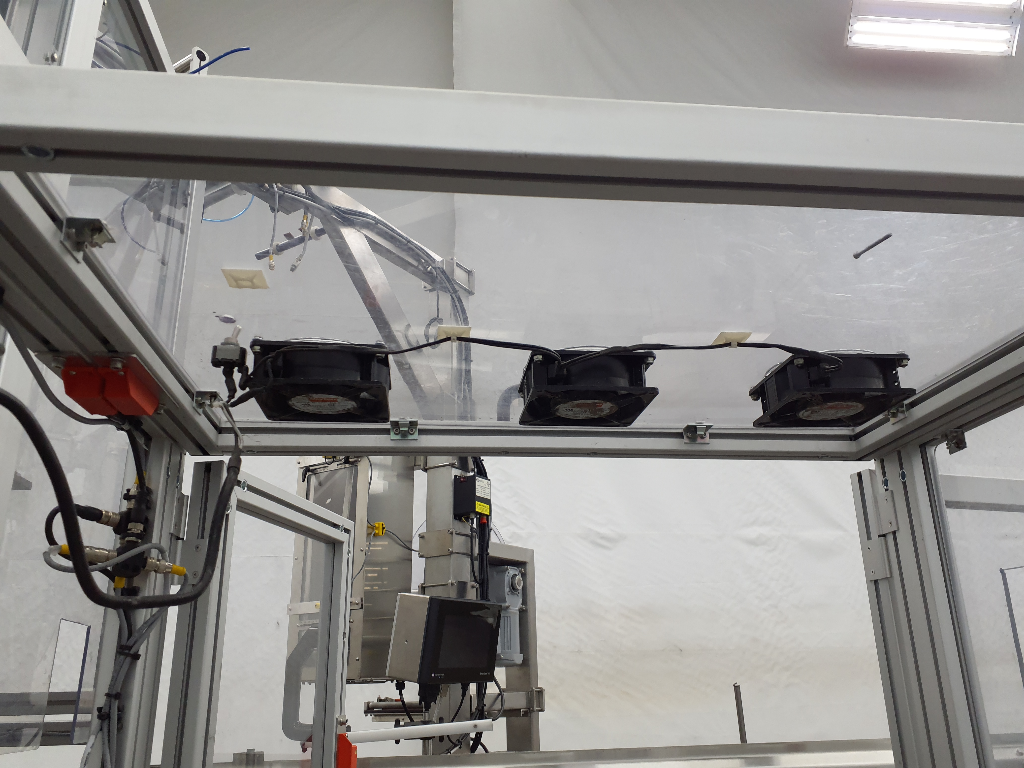

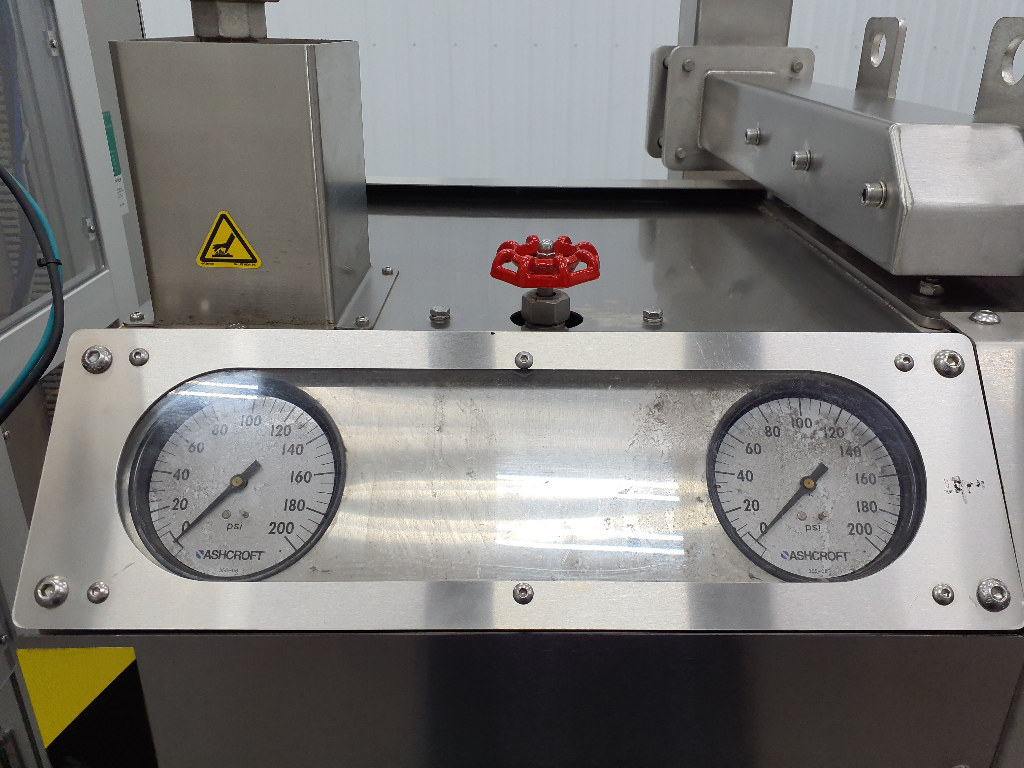

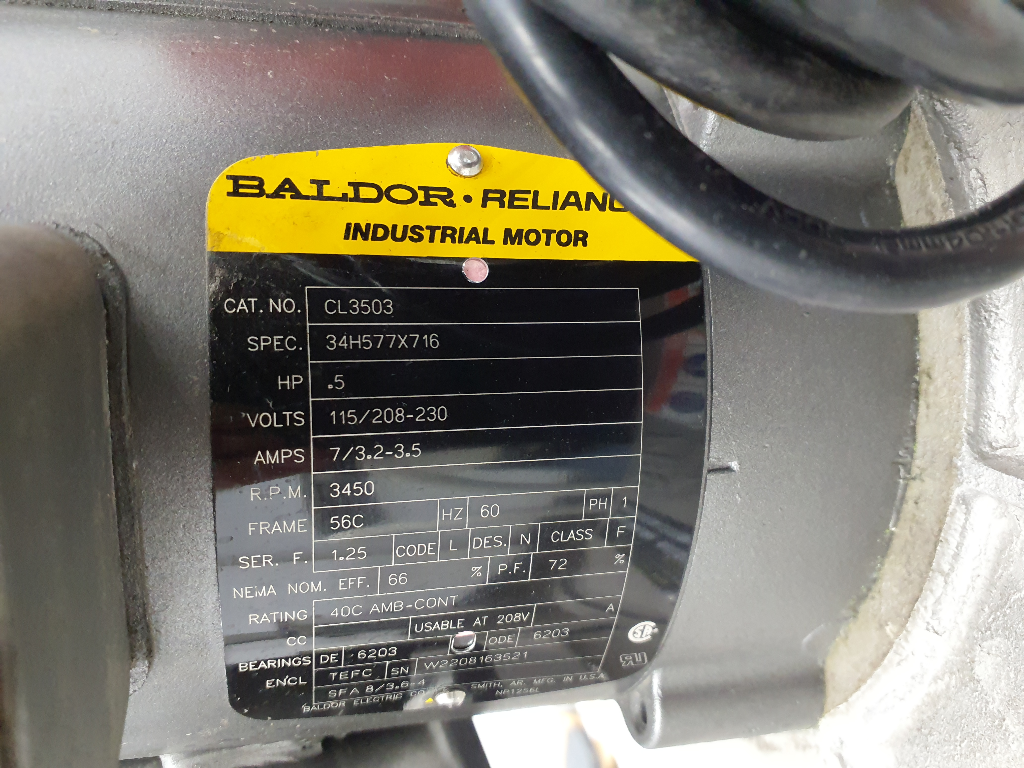

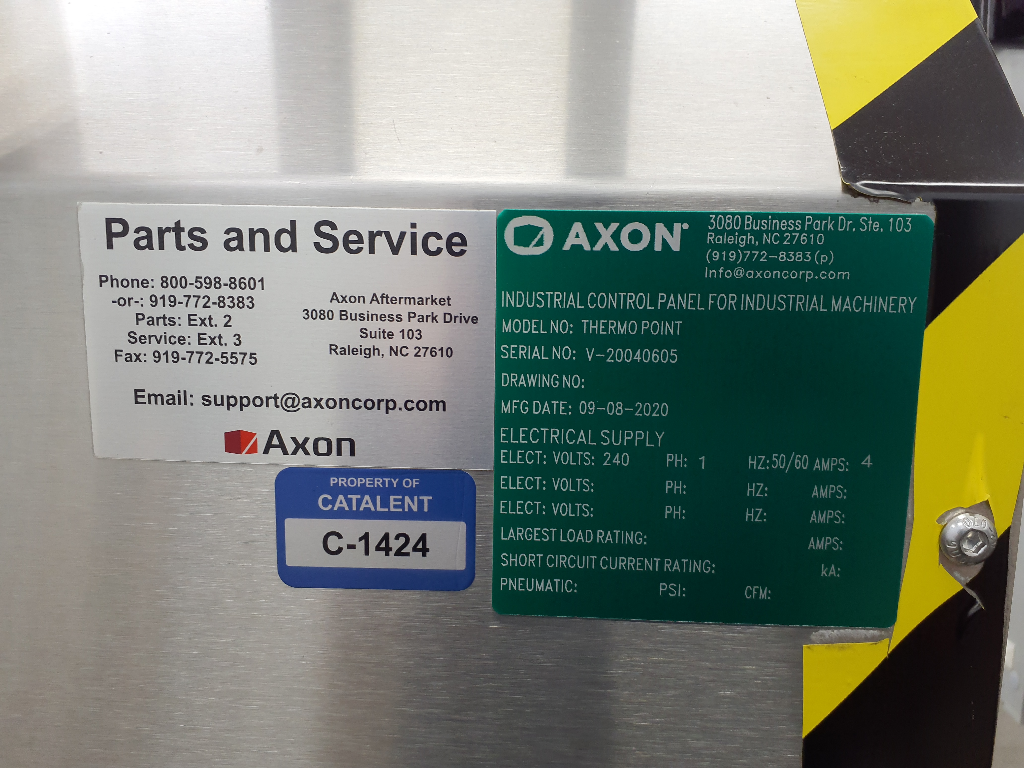

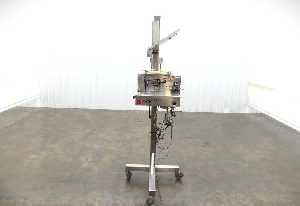

- Axon Thermopoint Steam Tunnel:

- Steam medium

- Three zone flexibility

- Capability to independently set steam rates, heights, and angles for each zone

- Over the conveyor style

- Tunnel dimensions:

- Width: 6 inches

- Height: 15 inches

- Minimum steam input: 80 PSI

- Maximum steam consumption: 200 pounds (30 gallons) per hour

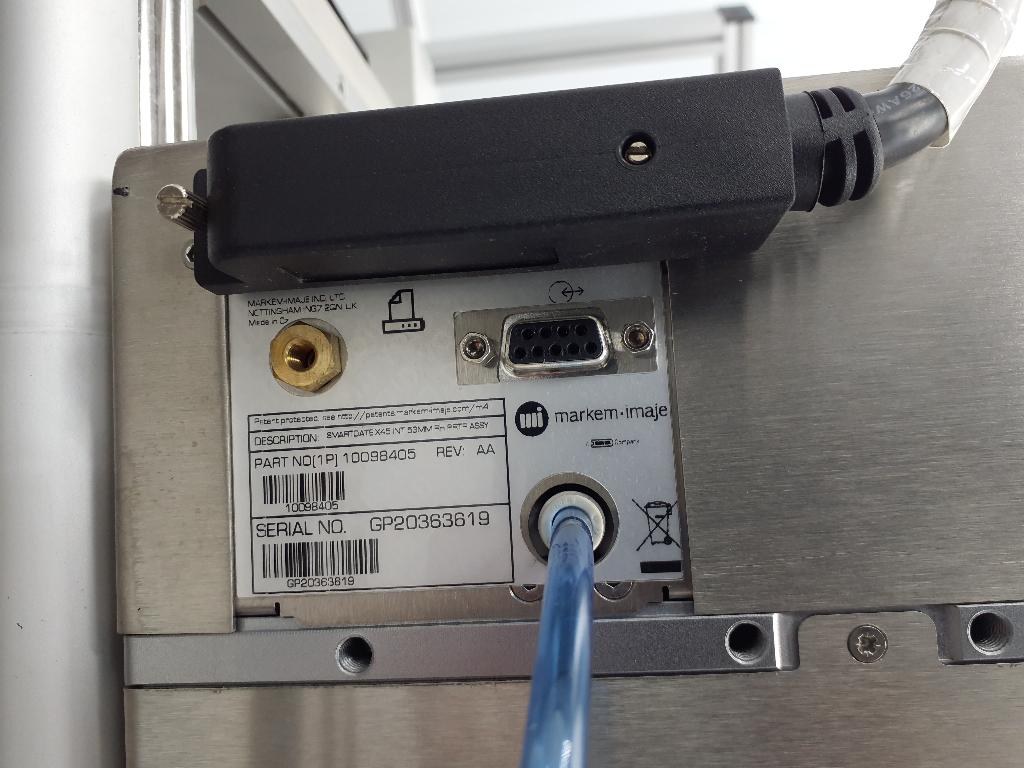

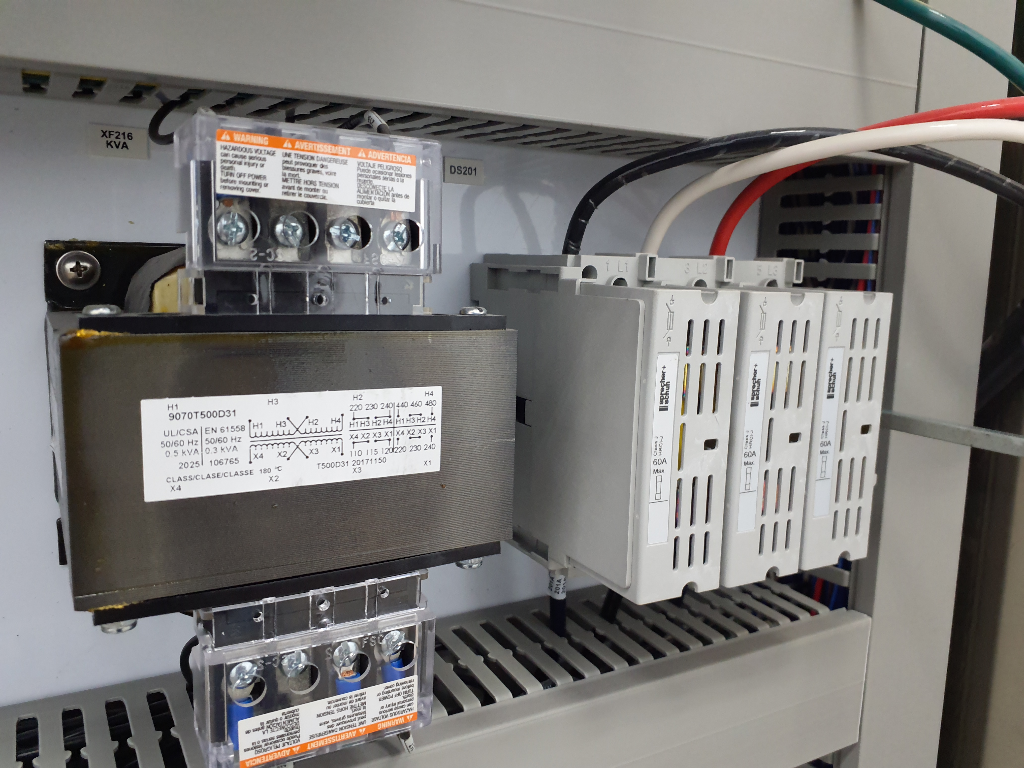

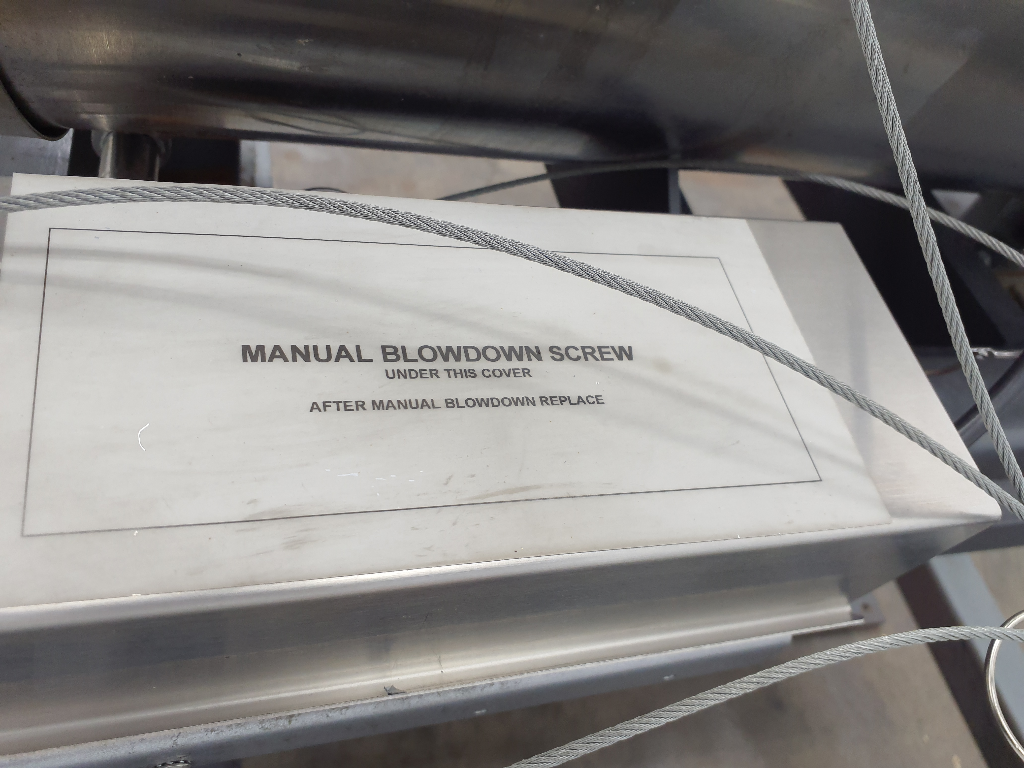

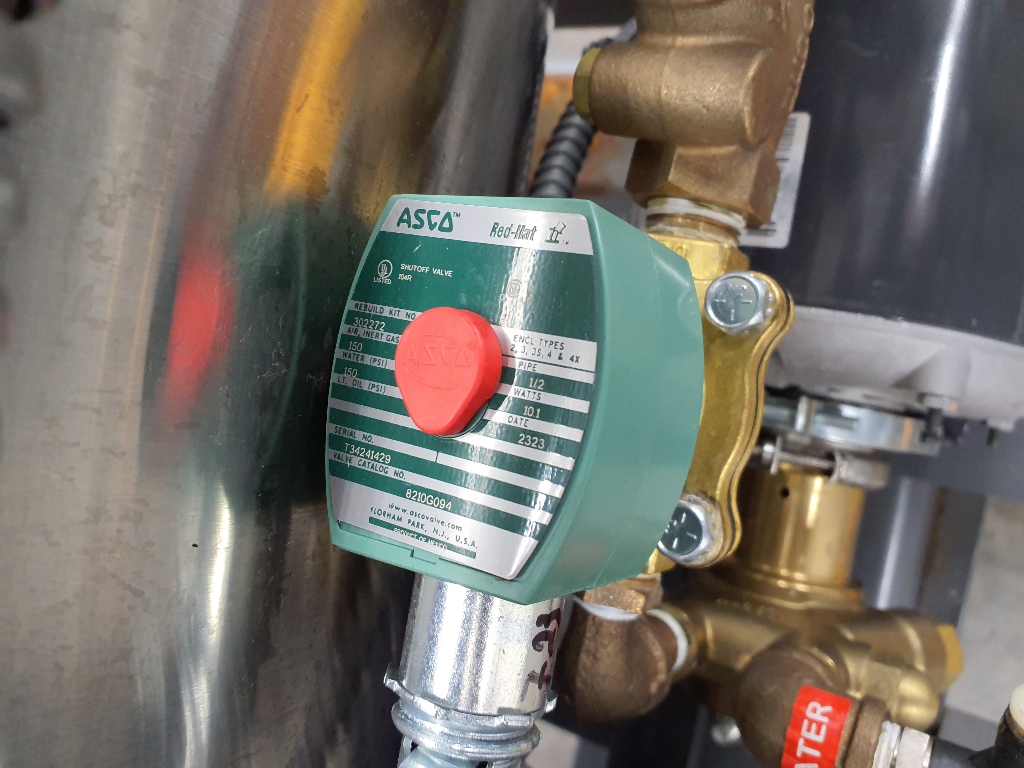

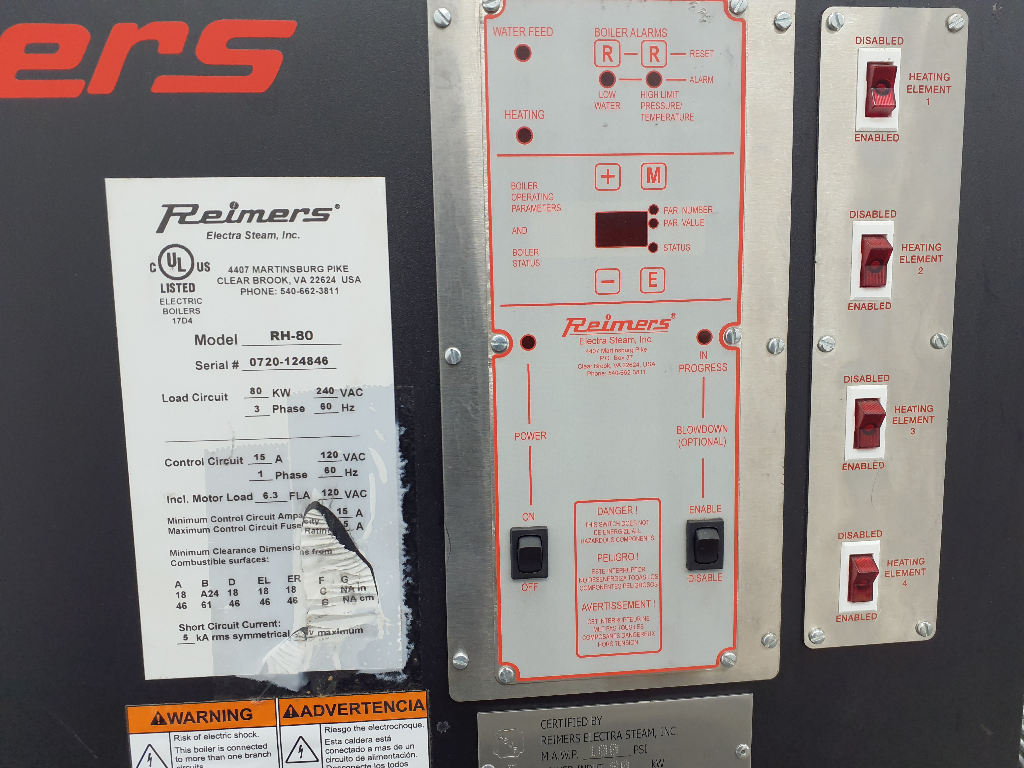

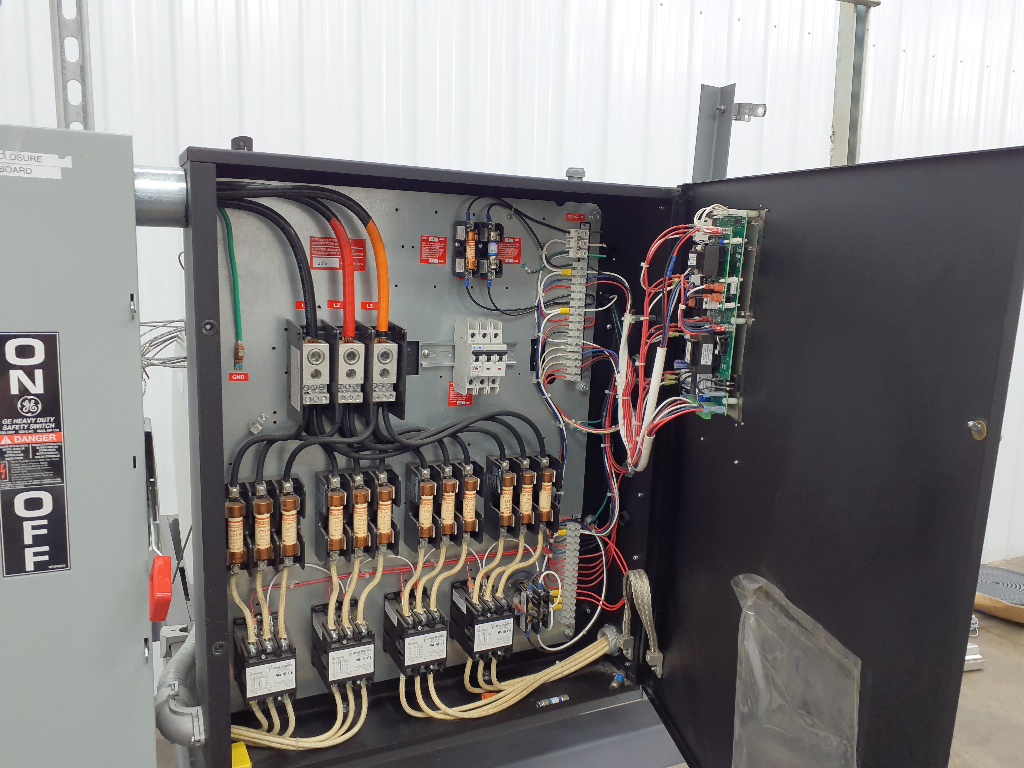

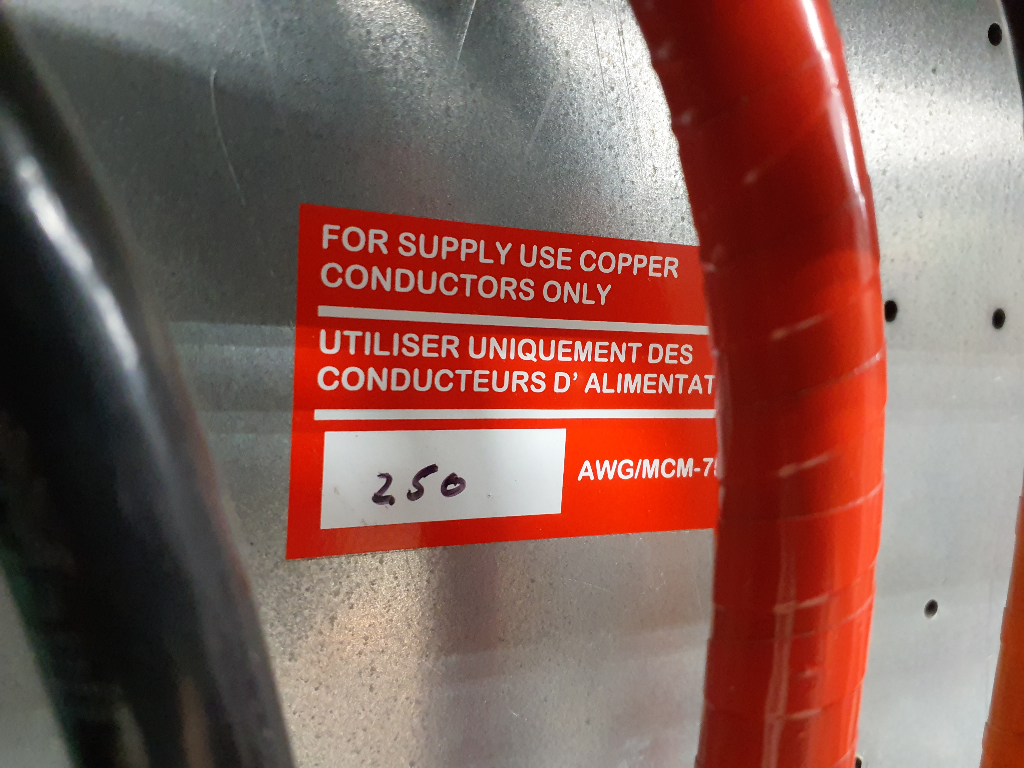

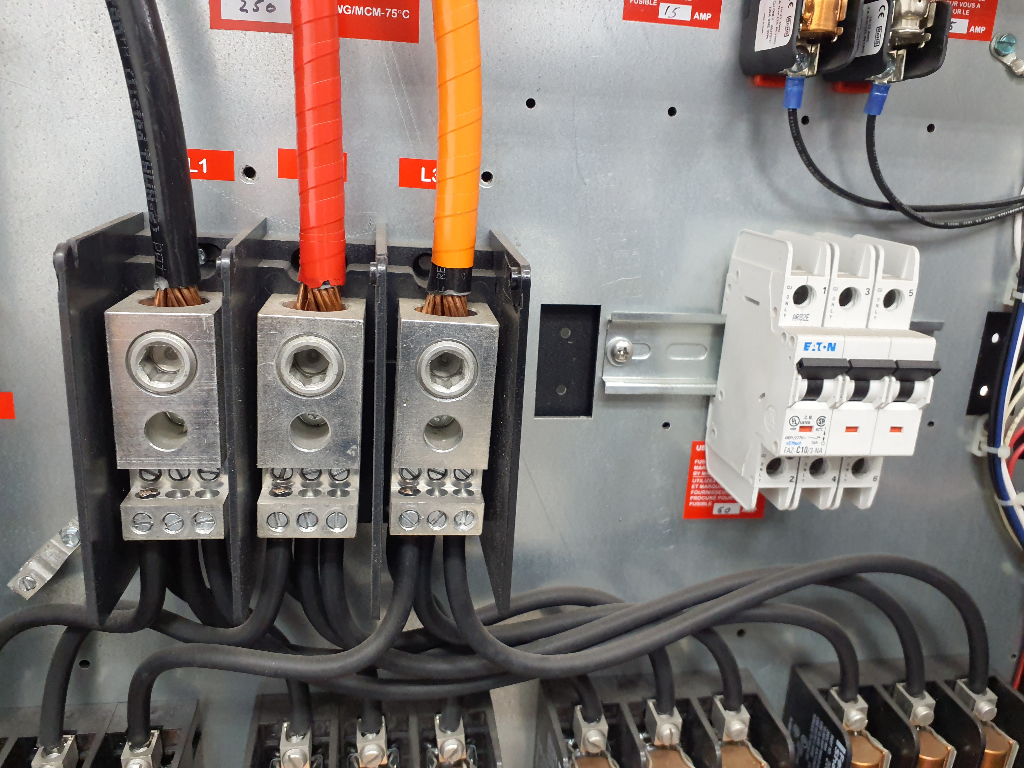

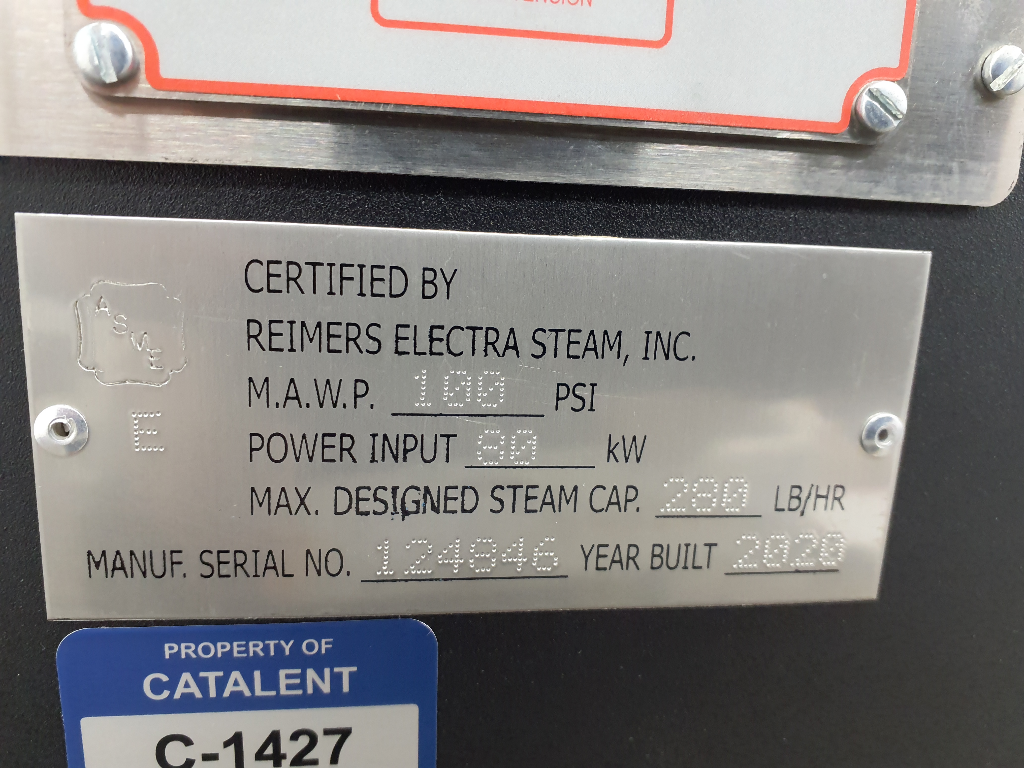

- Reimers RH-80 Steam Boiler:

- Automatic splicer

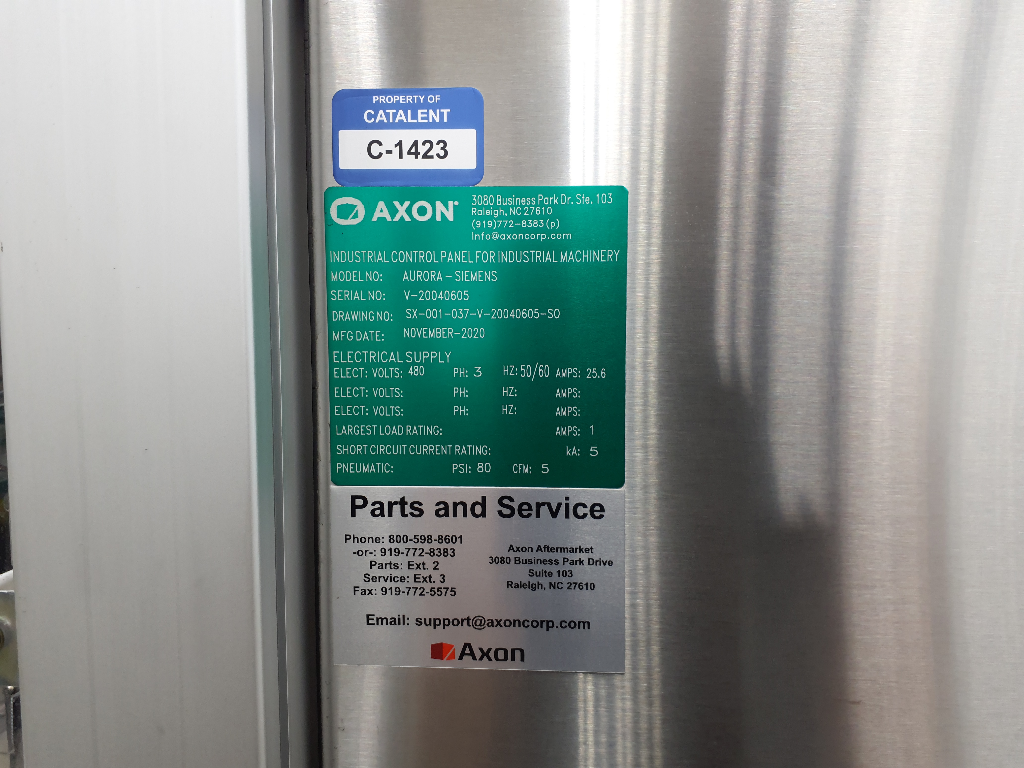

- Siemens touchscreen control panel

- Electrical:

- Volts: 480

- Frequency: 60 Hz

- Phase 3

- Stainless steel frame

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.