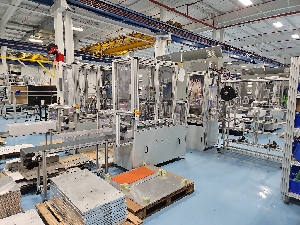

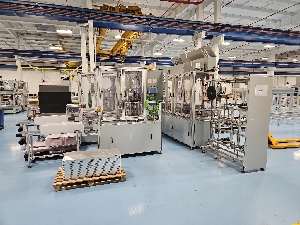

Used Apex 2 Head Filling System Servo Driven Inline Filling Complete Bottling Line

Click image for full size.

Having trouble viewing media for this Apex Filling Systems ?

Click here for full page view of all Equipment Media (49)

Apex Filling Systems Videos

Click here for full page view of all Equipment Media (49)

Equipment Details

| Equipment # | E313354 |

| Item | Apex 2 Head Filling System Servo Driven Inline Filling Complete Bottling Line |

| Category |

Production Line Co-Pack Production Line |

| Manufacturer | Apex Filling Systems |

Equipment Description

Used Apex Filling Line with:

- Production speed: at least 10 bottles per minute, depending on application

- Production batch size: 90 gallons

- Container fill amount: 2 ounce, 8 ounce, 16 ounce, 32 ounce, 64 ounce

- Cap style: flat cap 24-410

- Cap sizes: 38 mm, 48 mm, 70 mm, 89 mm, 120 mm

- Label style: wrap

- Line orientation: left to right

- Line height: 34.5 inches

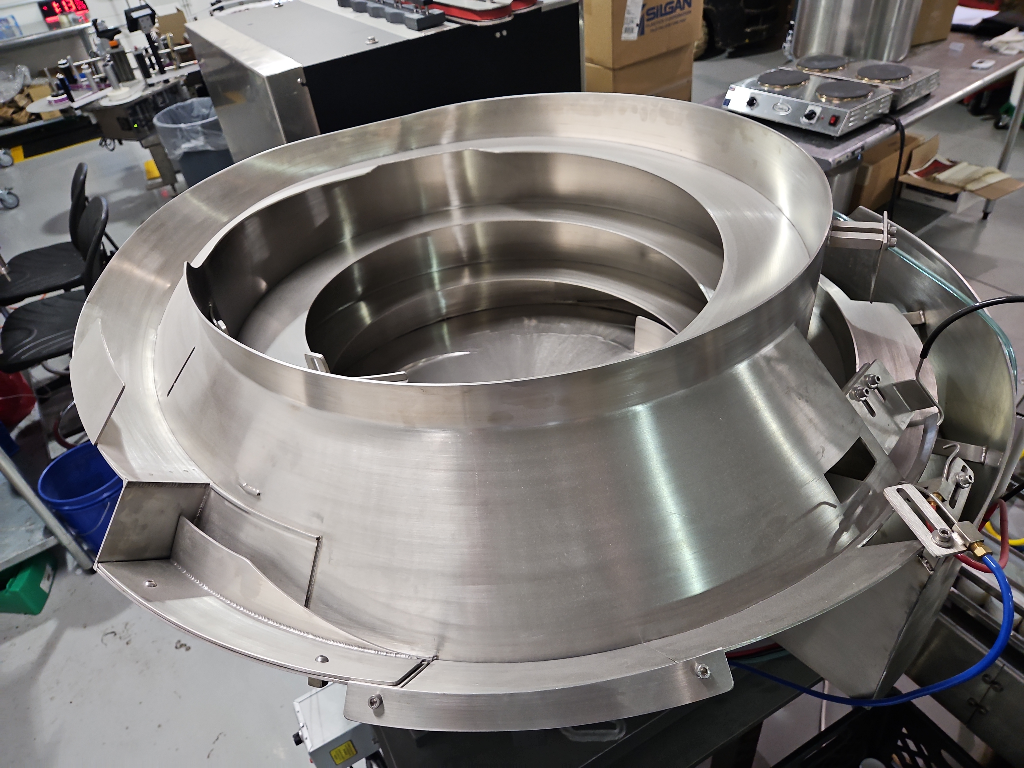

- Apex 40" diameter accumulation table:

- 304 stainless steel disc top

- clockwise and counter clockwise rotation

- Electrical: single phase, 60 hertz, 115 volts

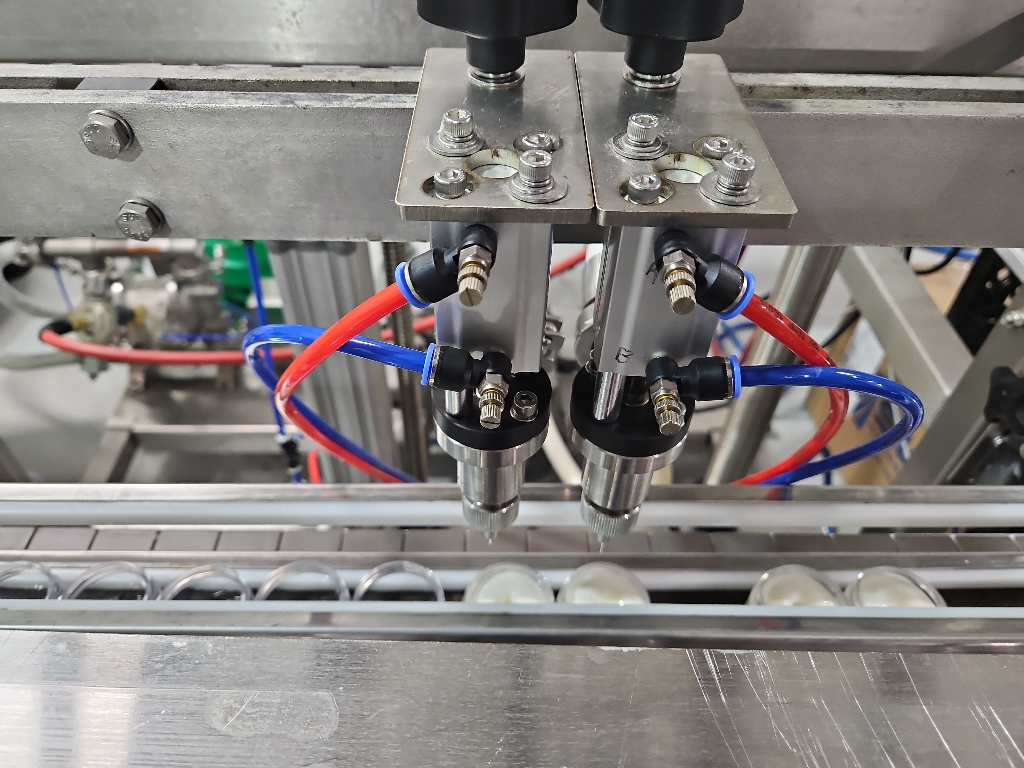

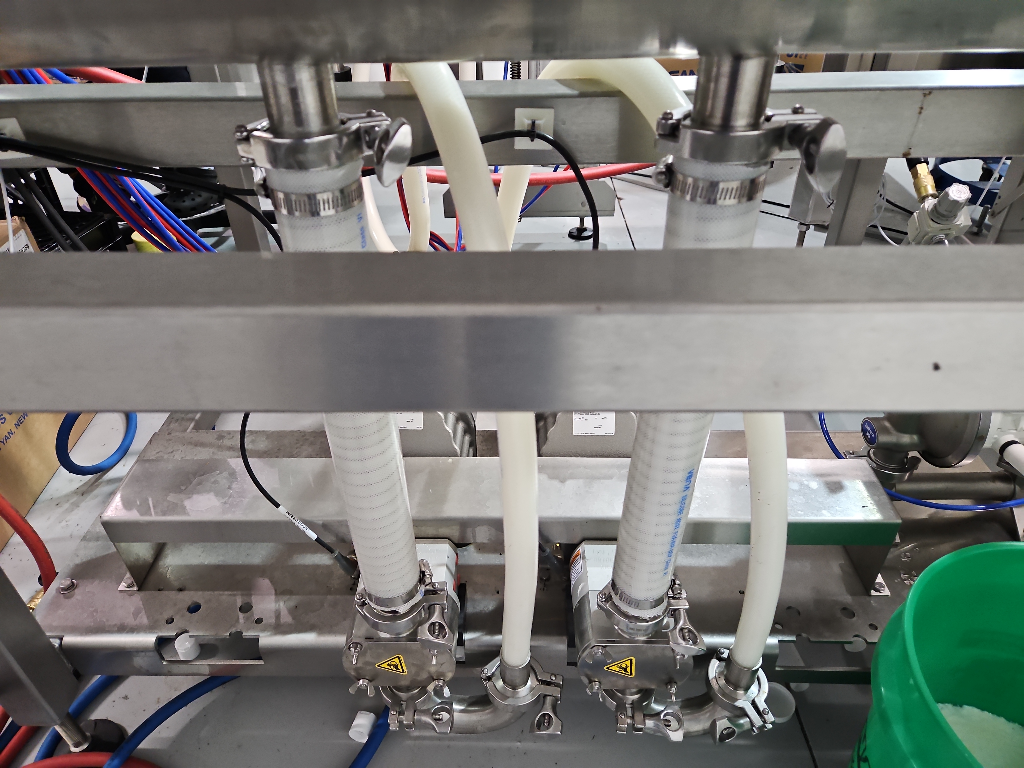

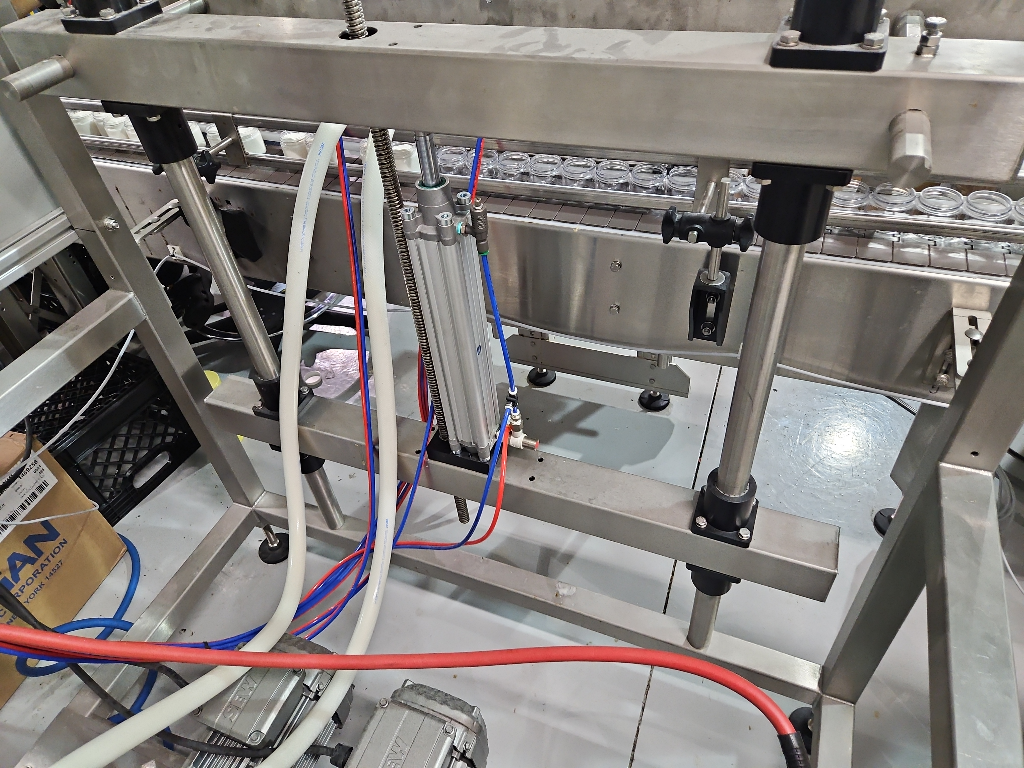

- Apex 2-Head sanitary pump filler:

- 304 stainless steel construction

- Hopper gallons: 35 w/ dual float system for low level indication

- Allen Bradley micrologix 1200 PLC with color touch screen controls

- No-drip filling heads and drip tray

- Controls package with up to 50 recipes

- Sanitary nozzels:

- (2) 0.75 inch ball valve

- (2) 0.75 inch bottom close soleniod valve

- (1) 1.5 inch sanitary grade high pressure product inlet

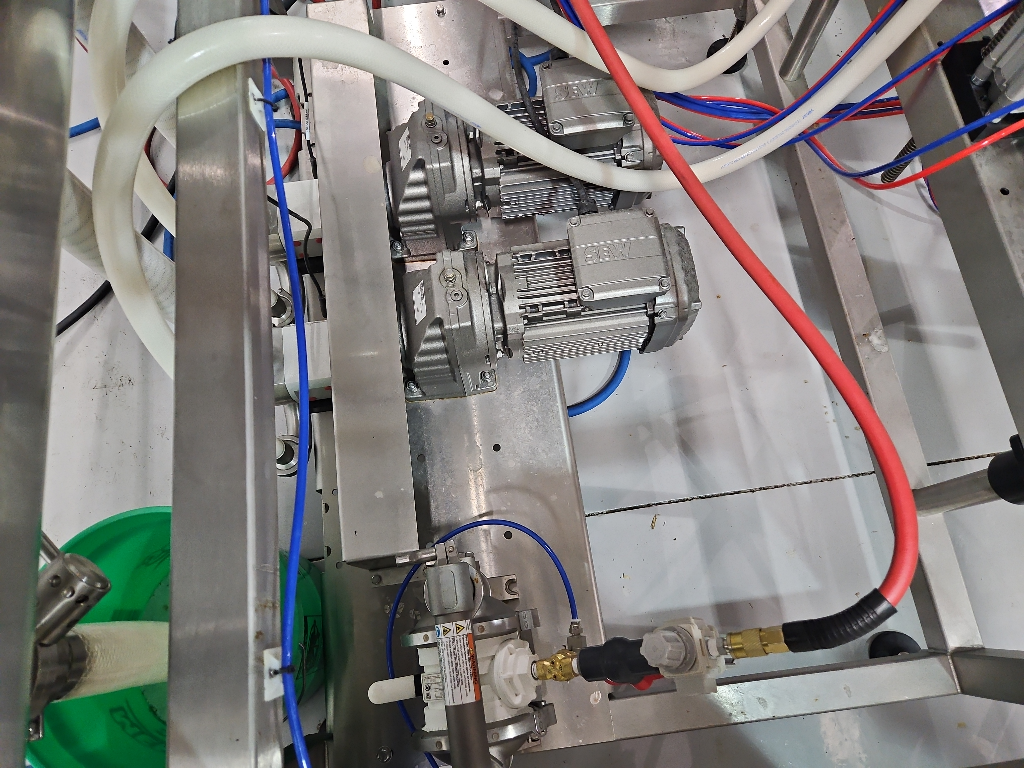

- (2) Uni bloc stainless steel gear pump assembly

- Toolless disassembly and assembly

- No bottle / no fill / bottle counter photo eye

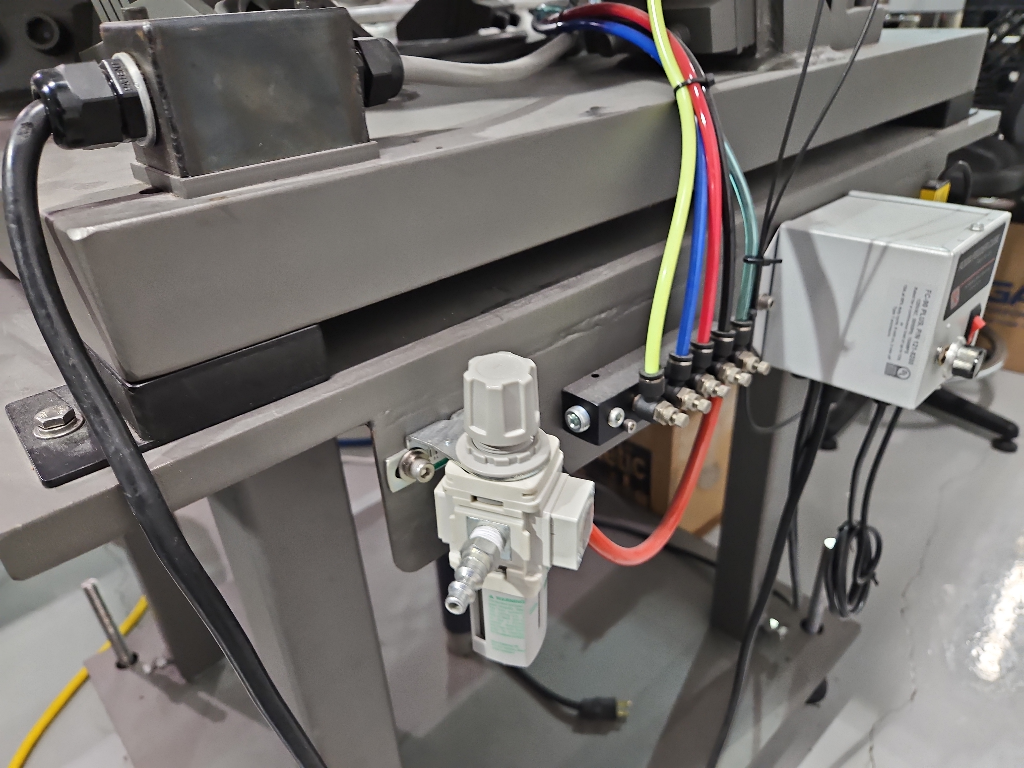

- Air requirements: 5 cfm @ 80 PSI

- Electrical: 3 phase, 60 hertz, 230/460 volts

- Apex 10' long x 4.5 wide variable speed conveyor (filler conveyor):

- Plastic table-top belt

- Motor: 0.5 hp

- Variable speed control

- Guide rails

- Stainless steel construction

- Electrical: single phase, 50-60 hertz, 115 volts

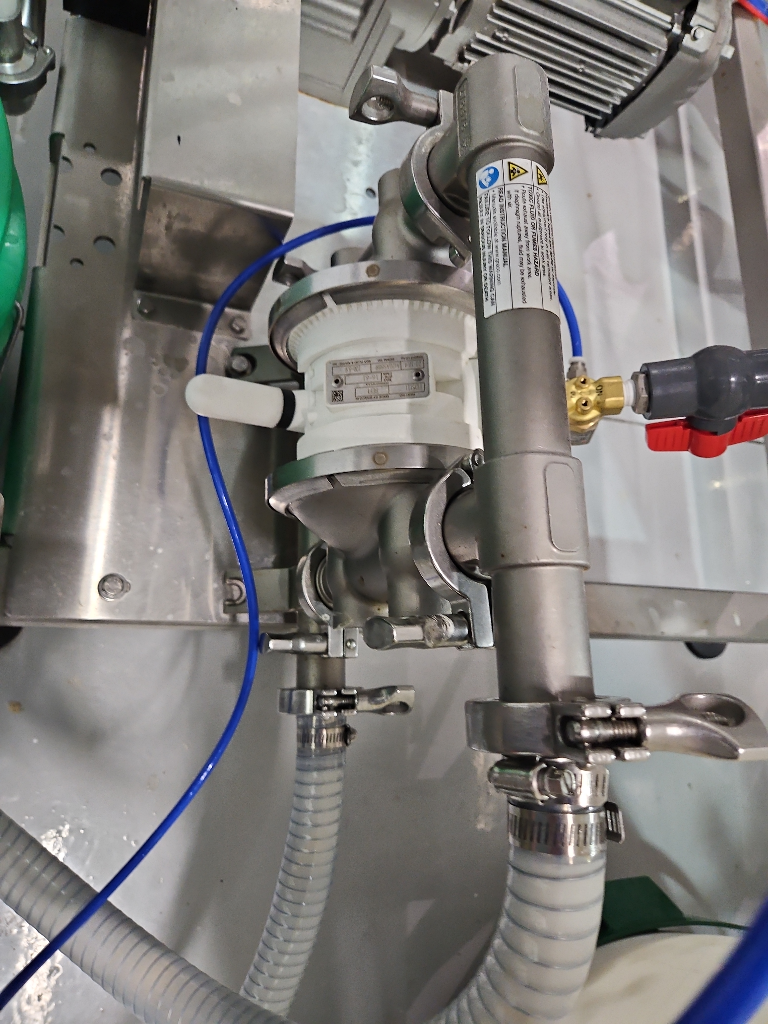

- Sanitary diaphram pump:

- Flow: 16 gallons per minute

- Capable of handling liquids up to 5000 cP

- PTFE seals

- 1" sanitary tri-clamp fittings

- Self priming

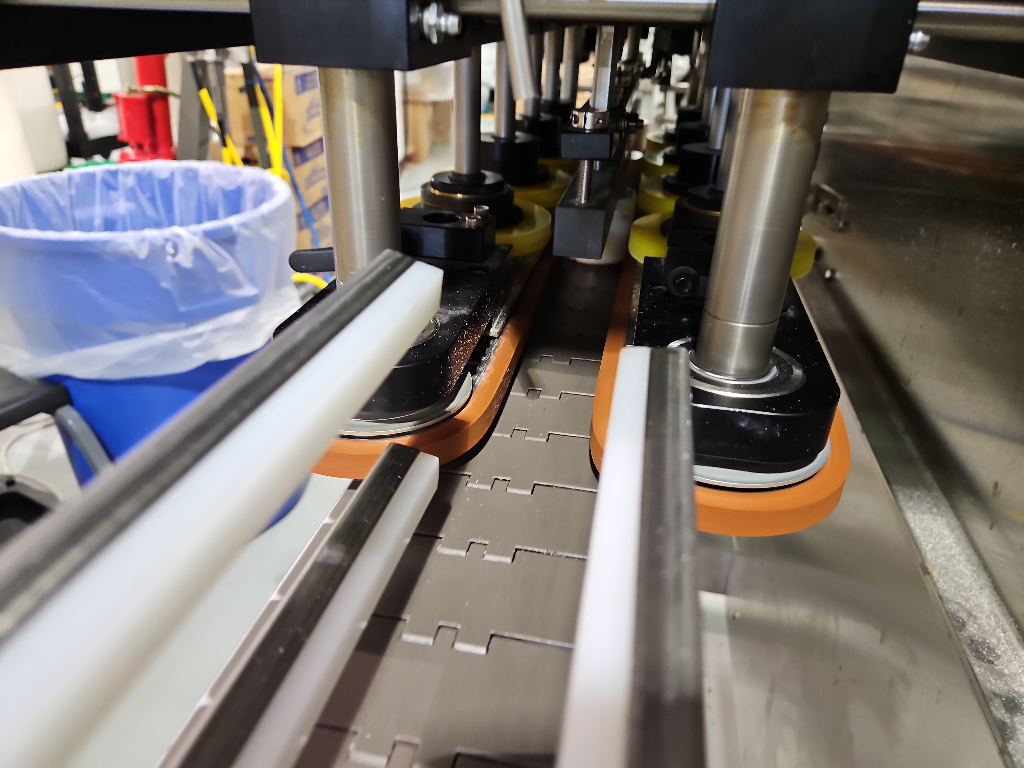

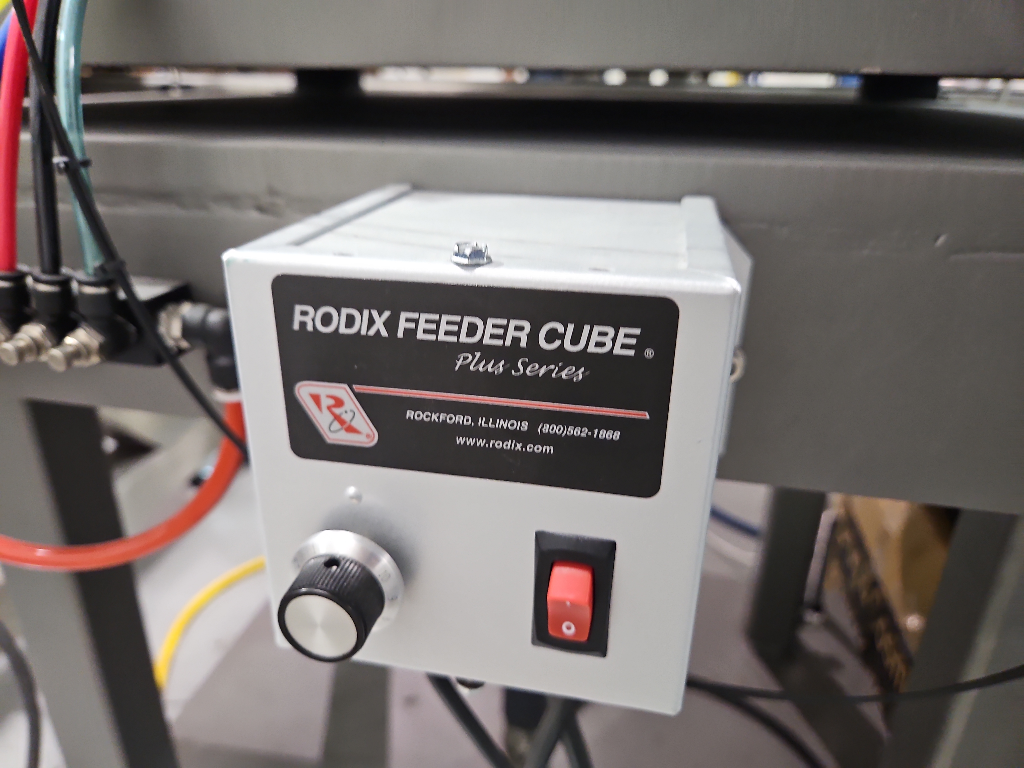

- Apex automatic 8 spindle reversing cap tightener with 30" vibratory capping bowl

- Tooled for cap sizes: 24 mm to 89 mm in diameter

- Alternating vibrating coil and control tube

- Heavy duty bowl cart

- Bottle types: PET, PP, PVC, HDPE, LDPE, and glass

- Stainless steel construction

- Apex 15' long x 4.5" wide plastic table-top conveyor (capper conveyor):

- Motor: 0.5 hp

- Variable speed contol

- Guide rails

- Stainless steel construction

- Electrical: single phase, 50/60 hertz, 115 volts

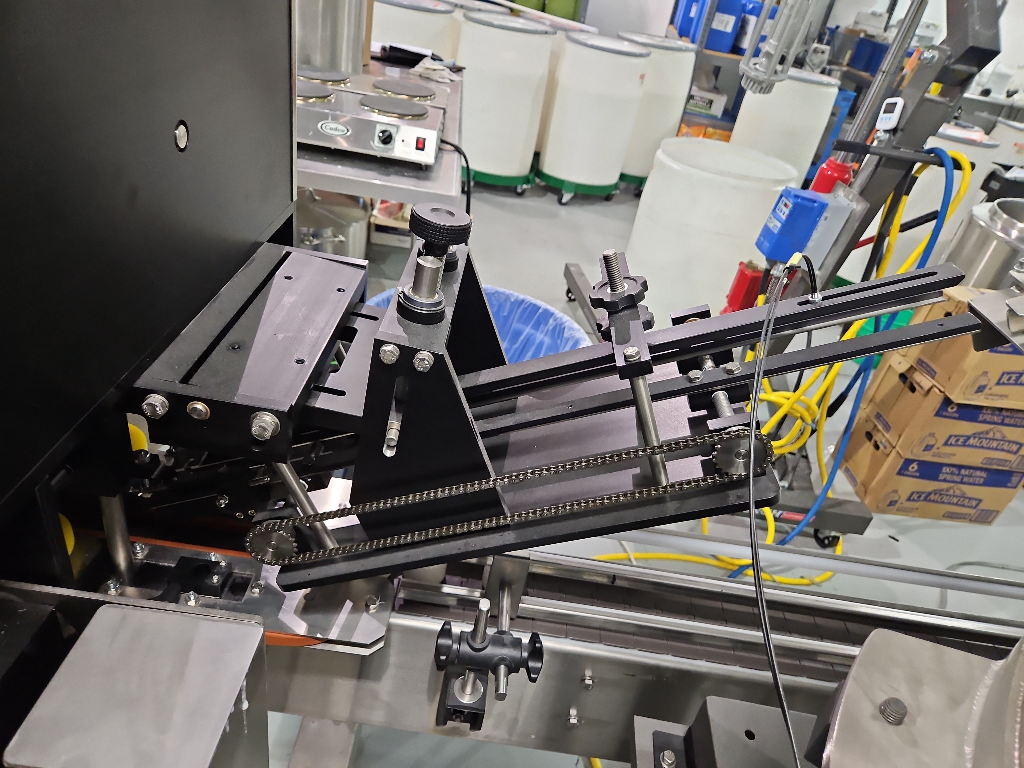

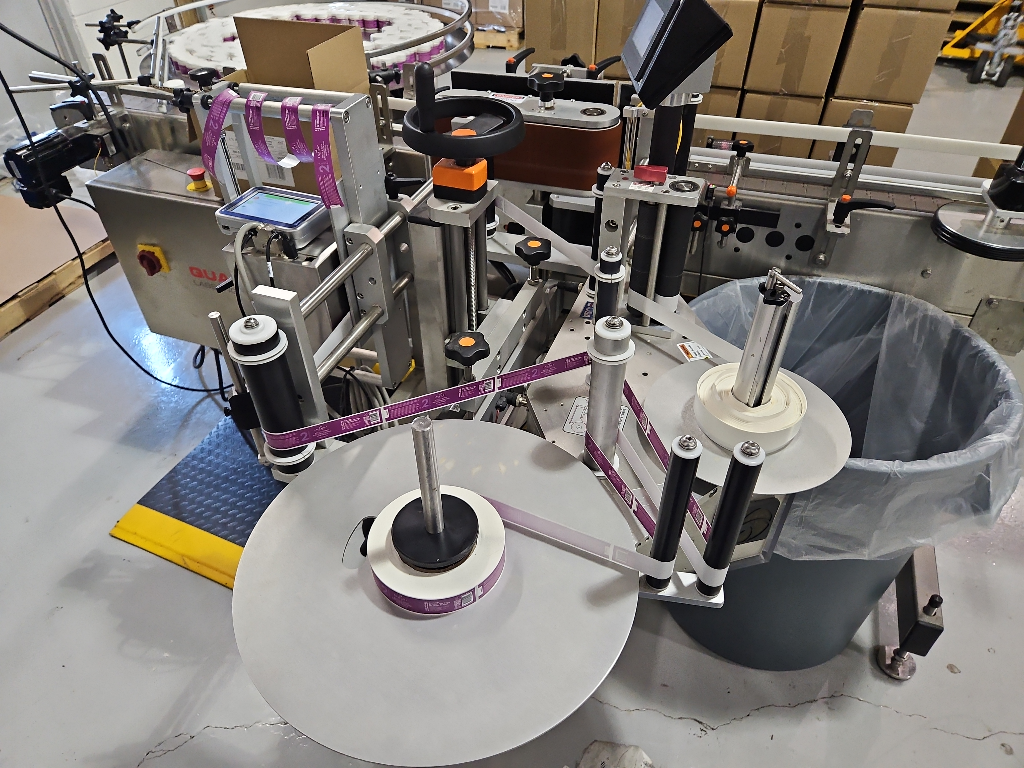

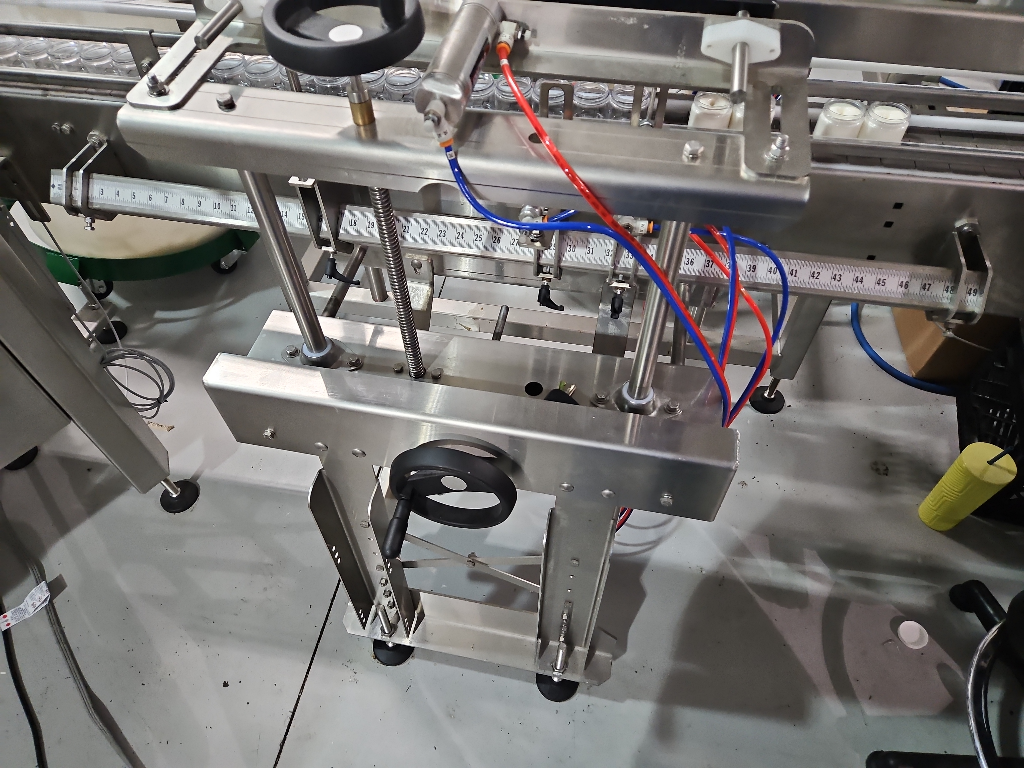

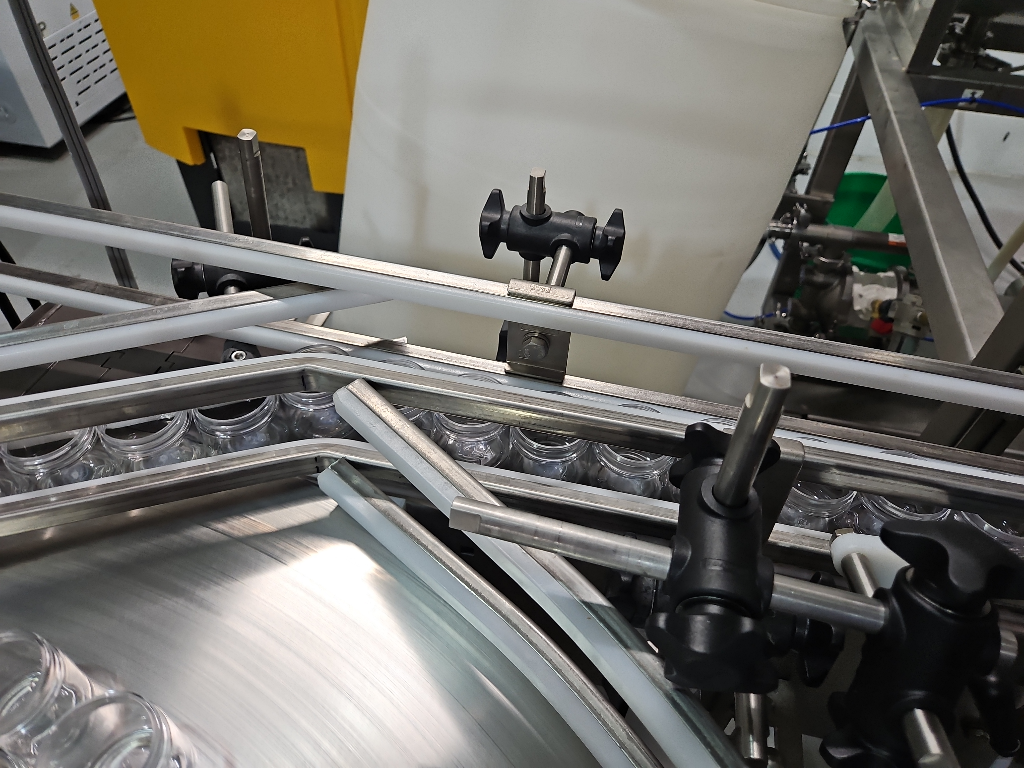

- Quadrel PSA Q105 wrap around labeler:

- Label depensing speed: 1200" per minute

- Web width: 7 inches

- Maximum label width: 6.875 inches

- Label roll unwind capacity: 16 inches

- Wrap station: 4.5 inches wide x 12 inches long

- Conveyor:

- Dimensions: 120 inches long x 4.5 inches wide

- Pacing wheel

- Motor: 1/6 hp

- Stainless steel construction

- 0.5 inch anodized aluminum plate construction

- Label sensor

- Touch screen controls

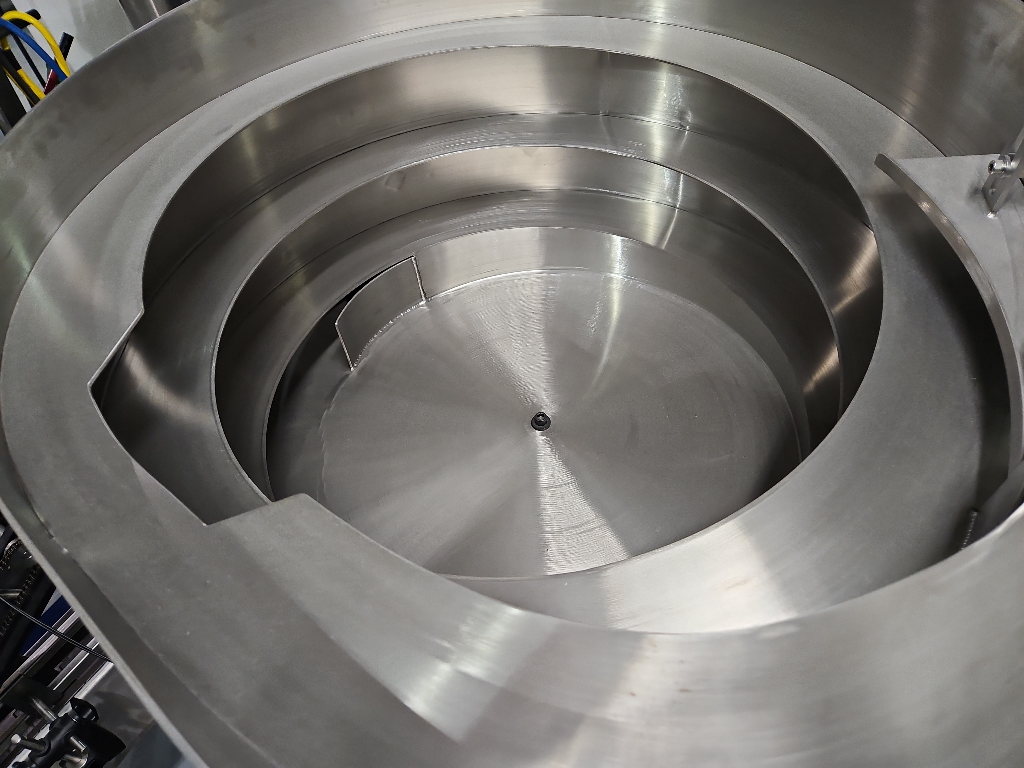

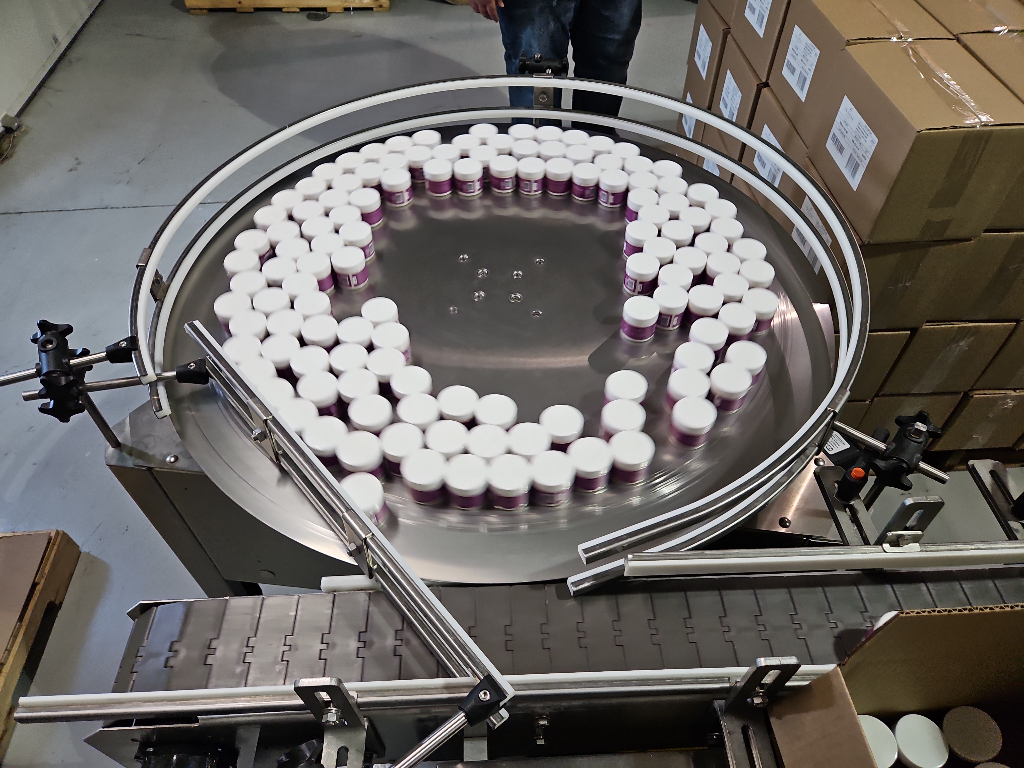

- Apex 40" Diameter Rotary Accumulation table:

- Dimensions:

- Diameter: 40 inches

- Height: 34.5

- Variable speed control

- Counter clockwise and clockwise rotation

- 304 stainless steel disc top

- Guide rails

- Electrical: single phase, 50/ 60 hertz, 115 volts

- Dimensions:

Last application: shampoo, curl cream, conditioner, hair and body butter with a thin to thick viscosity and various bottle shapes and sizes.

Location Details:

To coordinate an inspection of this item, please contact your SIGMA sales team. Call us at (812) 303-8383.Inspection Recommendation

An on-site inspection is the only way to truly evaluate a machine's fit for your needs. An inspection prior to purchase will help avoid unexpected delays and ensure a positive used equipment purchasing experience.

Have questions? Need pricing on this Apex 2 Head Filling System Servo Driven Inline Filling Complete Bottling Line?

Request an email quote or call us at (812) 303-8383 for more information.