Description

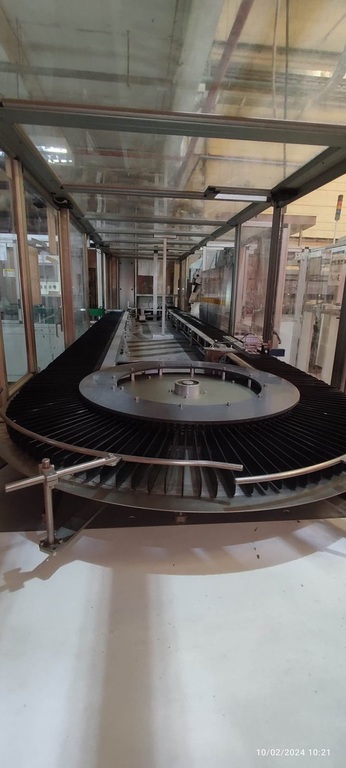

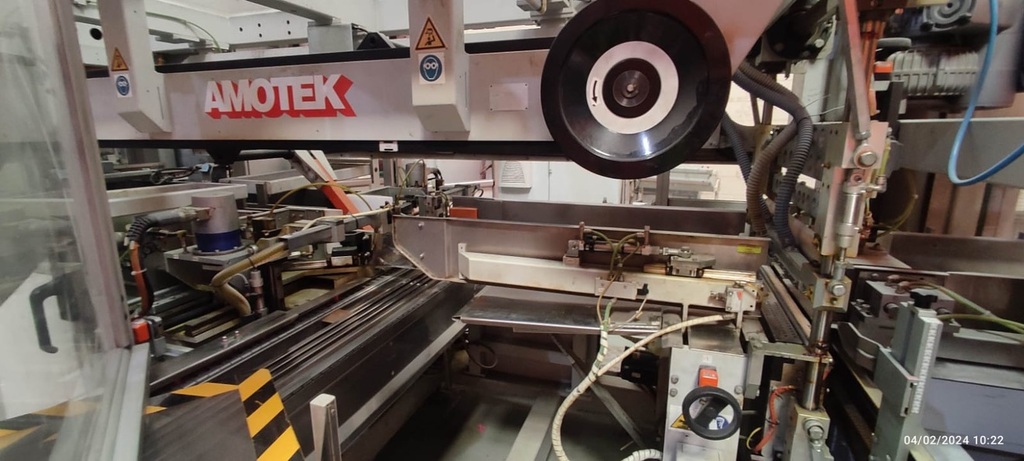

The single products arriving flat laying from the main production machine, are twisted by 90 degrees by a flat belts system so to be positioned on an edge position. The products are then led inside the paddles chain without any stop w here they are counted. As soon as the complete products arrive at the discharge area, the pusher is transferring it to feeding area of the bagging machine. The bagging machine receives the products on the loading area from the horizontal stacker and moves them towards the feeding station by means of bars. Products are timed with the pusher which, after the compression, transfers them to the

bagging area. The polyethylene bag is opened by suction cups while the spreader plates, moving

into the bags, keep it open. The pusher introduces first the compressed products inside the bag and then transfers the obtained package to the sealing station. While the bag is kept locked, its bottom is gussetted and sealed. The waste is removed from the package and then sucked; the final bag is

automatically ejected from the machine.

Used Amotek MOD IS 81 Bagging Stacker Line with:

- Speed: up to 50 packages per minute, depending on product features and bag configuration

- Free inlet product dimensions:

- Length: 140 to 180 (millimeters)

- Width: 100 to 150 (millimeters)

- Thickness: 8 to 35 (millimeters)

- Outlet multipack dimensions:

- Length: 100 to 500 (millimeters)

- Width: 140 to 560 (millimeters)

- Height: 100 to 150 (millimeters)

- Speed at stacker input:

- Minimum: 200 products per minute

- Maximum: 600 products per minute

- Speed at stacker output: up to 55 ejections per minute

- Number of products per row: up to 50 products

- Change over time: 25 to 30 (minutes)

- Pre-made bags wicket driven by servo motor

- Electrical requirements: 400 volts, 50 hertz, 3 phase

Last set up for bi-folded baby diapers.

Let Us Handle Shipping

Let SIGMA’s experienced Logistics Team coordinate the safe delivery of your equipment—on time, fully insured, and professionally secured for transport.

- Ideal for purchases shipping from SIGMA Equipment or brokered within the U.S. or Canada

- Packaging verified for stability and protection

- Volume-partial or dedicated carrier options arranged for direct delivery

- Equipment securely strapped and insured for its full value

- End-to-end coordination for a worry-free experience

Use Your Own Carrier

Prefer to manage your own logistics? We’ll make it easy by providing all the pickup details your carrier needs.

- We supply shipment specs so your team can coordinate pickup

- Customer must provide a Bill of Lading (BOL) before truck arrival

- Responsibility transfers to customer upon equipment loading

We strongly discourage using LTL or Common Carriers for industrial equipment. These carriers often leave shipments unsecured and transfer them between terminals, increasing the risk of damage. Without added insurance, your shipment is unlikely to be covered for loss or damage.

All used equipment is sold "AS IS, WHERE IS, WITH ALL FAULTS". Specifications are approximate and intended as a guide only. Equipment may require inspection, modifications, or additional safety features before use.

- Payment: Full payment required before shipment; all sales are final.

- Delivery: Dates are estimates; SIGMA is not liable for delays or lost revenue due to delivery timing.

- Buyer Responsibility: Crating, rigging, installation, insurance, and compliance with all regulations are the buyer’s responsibility.

- Damage in Transit: Must be claimed directly with the carrier.

- Warranties: No expressed or implied warranties unless specified in writing.

- Indemnification: Buyer assumes all responsibility for safe installation, operation, and regulatory compliance of the equipment.

This is a summary only. Full terms apply to every sale. Please review our complete Terms & Conditions for Used Equipment before purchase.