3-6 Inch Wide Belt Checkweigher

At SIGMA Equipment, our team is here to help you find the right equipment to match your specific packaging needs. Whether you’re looking for a single machine or a full system, we can guide you to the right 3-6 inch wide belt checkweigher and support your project with shop services that make it easier to upgrade or build a new production line.

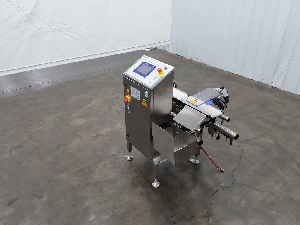

Mettler-Toledo CM6000 C15 Stainless Steel Checkweigher Belt

Used Mettler-Toledo Checkweigher Belt with: Throughput: up to 600 products per minute, depending on size and application Weigh time: 0.05 seconds Conveyor speed: 151.54 feet per minute Infeed...

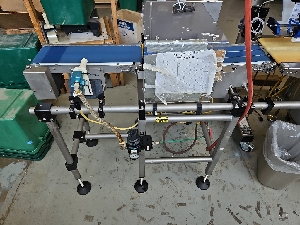

Mettler Toledo C3130 4.75" Wide Belt Checkweigher With Air Blow Reject

Mettler-Toledo Hi-Speed dynamic C-Series checkweighers are a scalable model designed to optimize flexibility on production and packaging lines, helping to ensure manufacturers around the world are...

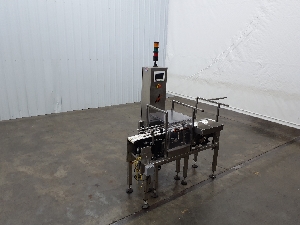

Loma LCW-3000 6" W Check Weigher W/ Air Blow Reject

Used Loma LCW-3000 High Speed Checkweigher with: Capacity: up to 320 packages per minute Maximum weight: 104.16 ounces Minimum weight: 11 ounces Accuracy: ±0.02 ounces Load cell dimensions:...

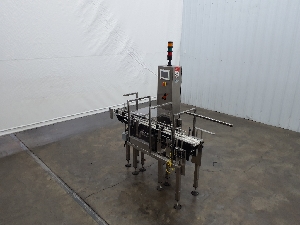

Alpha HP-14 3 Belt Checkweigher 4.5" Wide Belt

Used Alpha HP-14 Checkweigher with: Output: up to 300 container per minute depending on product Maximum weight: up to 8 pounds depending on product Accuracy: +/- .10g with certain...

Alpha HP-14 3 Belt Checkweigher 4.5" Wide Belt

Used Alpha HP-14 Checkweighers 4.5" Wide Belt with: Output: up to 300 container per minute depending on product Maximum weight: up to 8 pounds depending on product Accuracy: +/- .10g with...

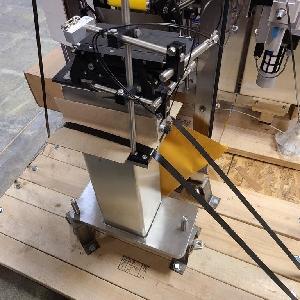

OCS HC-A 3"W x 6"L Checkweigher

Used OCS HC-A 3 Belt Checkweigher with: Speed: up to 600 pieces per minute Dependant on product size and specifications Maximum capacity: 100 grams Weigh belt: Length: 6 inches...

OCS Checkweigher 6" Wide with Domino D620I Coder

Used OCS Checkweigher with: Weighing range: 0-750 grams (200 mg accuracy) Output: up to 250 parts per minute (depending on part) Load cell: type EC-2000 with a maximum dead load of 2500 grams...

Mettler-Toledo XS1 Checkweigher

High-Throughput Weighing of Small Products Last used for: never used Infeed conveyor dimensions: Length: 9.84 inches Width: 3.93 inches Weighing conveyor dimensions: Length...

Thermo Ramsey Icore AutoCheck 9000 Checkweigher

Used Thermo Ramsey Icore AutoCheck 9000 Checkweigher with: Bottle checkweigher Enclosed weighing area allows for more accurate product weighing Timing screw infeed Left to right product flow...

About 3-6 Inch Wide Belt Checkweighers

Checkweighers with a belt width ranging from three inches to six inches are commonly used for small products and product boxes. This type of equipment ensures correct weight of a product for quality control. The product is conveyed over a scale, and if it is too heavy or too light the checkweigher removes the product from the line. Some checkweighers sort the rejected objects into piles. Usually, this can be accomplished with a push-off rejector, arms or a sharp blast of air that redirect the unfit product. Belt checkweighers are designed with different length load cell conveyors. Belt checkweighers are often designed so that the package does not have to stop on the load cell conveyor.

Start Your ProjectHave more to sell? Learn about SIGMA's equipment selling solutions, including valuation, safe removal, warehousing, and targeted marketing to maximize your equipment's resale value.