#E320757

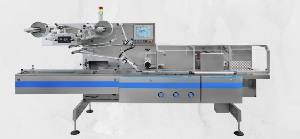

New Viking Masek Pack 900RT Flow Wrapper In Stock

The Viking Masek Pack 900RT Flow Wrapper is built to meet the demands of high-efficiency packaging with precision and versatility. Designed for continuous production lines, this machine excels in wrapping a wide range of products—from food items to non-food goods—with exceptional speed and reliability. Its robust construction and interface make it easy to operate and maintain, while its customizable settings ensure optimal performance for various product sizes and shapes. The Pack 900RT guarantees consistent, high-quality seals and reliable throughput, making it the perfect solution for businesses seeking maximum efficiency and flexibility in their packaging operations.

Main Technical Characteristics

• Product flow from left to right, looking from the operator’s point of view. (Inverted right to left execution,

available upon request).

• Ergonomic design and easy accessibility, in accordance with the international standards of hygiene and

security for a quick and easy cleaning of the machine, and in compliance with the CE safety regulations.

• Machine frame composed by a main body of electro-welded carbon steel plate assembled with a vertical

main plate, on which the machine groups are fixed on cantilever, that easy and minimize the stopping times

for both the cleaning and preventive maintenance operations.

• Electrical cabinet integrated within the machine frame, in accordance with the in-force CE regulations of

electromagnetic compatibility and low tension.

• Hinged doors with safety interlocks in the rear side of the frame, to access to both the main driving groups

and the electrical cabinet.

• Transparent safety guard with security switch which stops the machine in case of opening, and covers all

moving parts, from the forming box up to the outfeed belt.

• All parts in contact with the product are made of stainless steel and /or food grade plastics.

• All mechanical components manufactured by Viking Masek are laser coded, for a quick and easy spare

identification.

• Main movements carried out through motors directly coupled to motion groups. This eliminates the needs

of intermediate transmissions and minimize maintenance operations, as well as decrease the machine

noise level.

• The Pack 900 is controlled by means of 5 independent motors: