Search Terms: "filling machine"

Blister Sealer ×3 Used Items

Page 1 of 1

The two primary components of a blister pack are the cavity and the backing. The cavity is typically made from either plastic or aluminum. The backing is typically made from paperboard, paper, plastic or aluminium. The product is secured within the blister cavity, which is sealed against the backing. Blister packaging provides a secure way to package products while often allowing the consumer to visually examine the product through transparent plastic.

Search Within Blister Sealer

Alloyd 14S-1216 14 Station Blister Sealing Machine

Used Alloyd 14S-1216 14 Station Blister Sealing Machine with: Blisters and cards are automatically dispensed from a magazine Load stations: 14 platens on the machine and enough room for 2-4 people Platen...

Atlas Vac Machine Auto Belt Inline Blister Sealer

Used Atlas Vac Machine Auto Belt Inline Blister Sealer with: Inline sealer Adjustable seal time Emergency E stop button Current plate size: 14 inches long x 13.5 inches wide

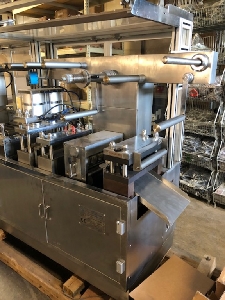

LTPM China Co. DPP 250 Blister Packaging Machine

Used LTPM China Co. DPP 250 Blister Packaging Machine with: Production output rate: 600 to 2100 sheets per hour One (1) load station Blanking frequency: 15 to 50 times per minute Platen...

Showing 1-3 of 3 Items